Pipila ka mga pulong gikan sa Yuantai Derun Steel Group

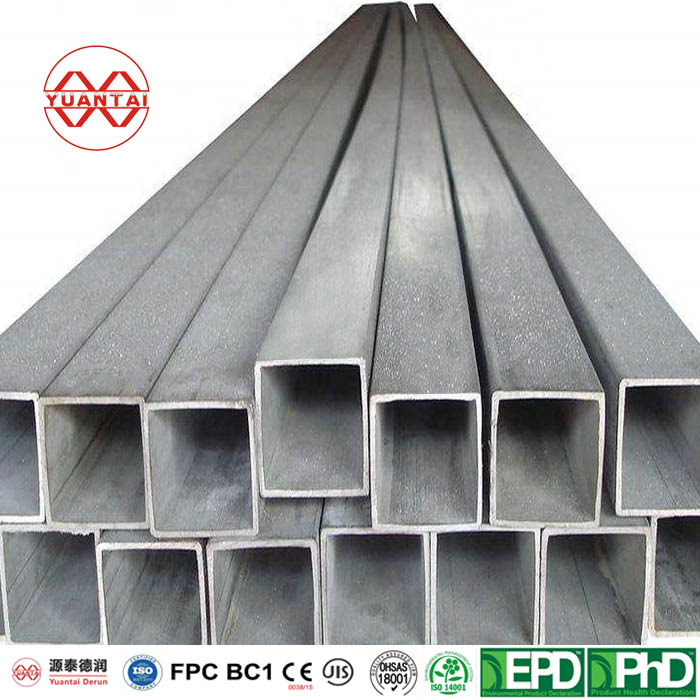

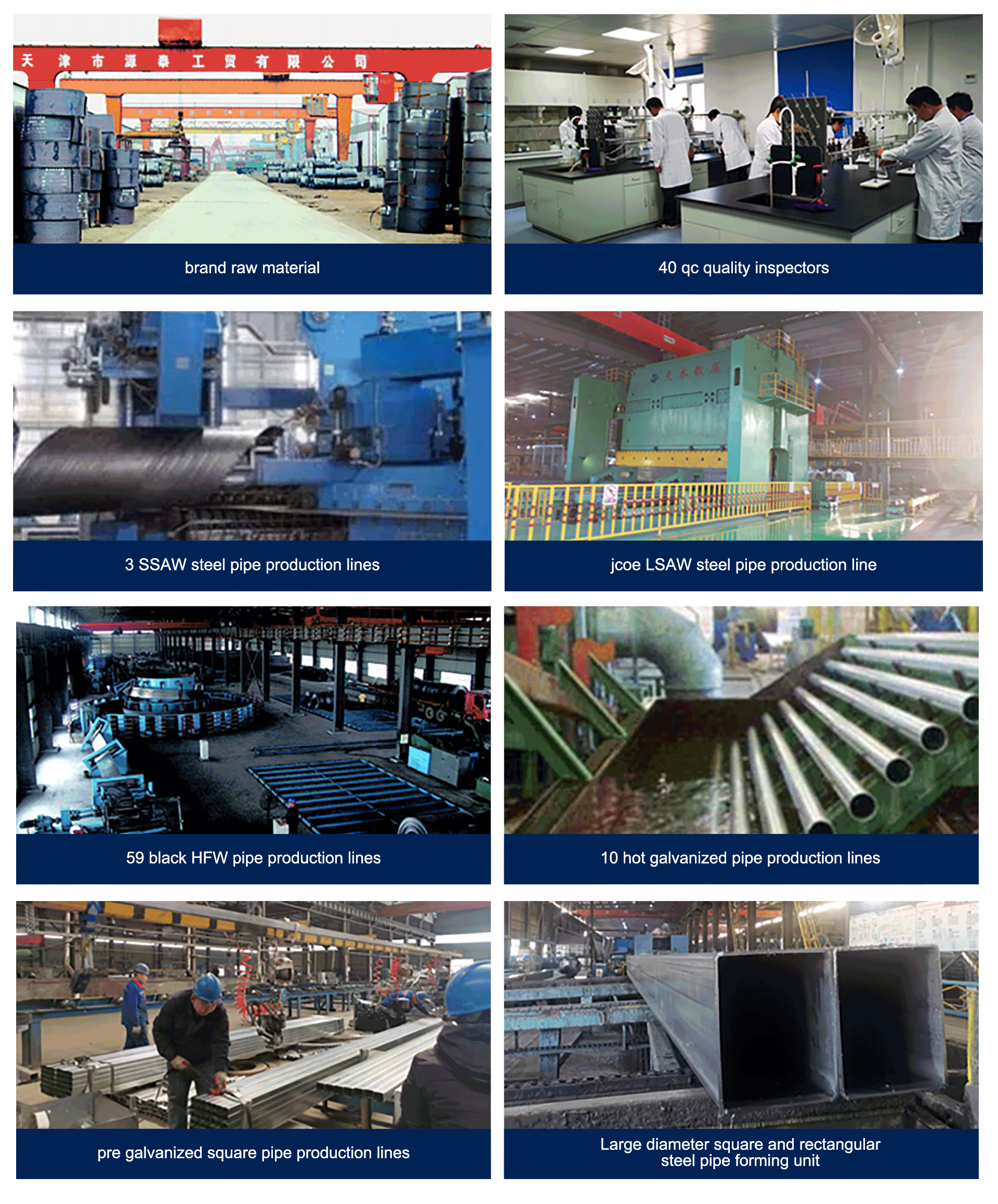

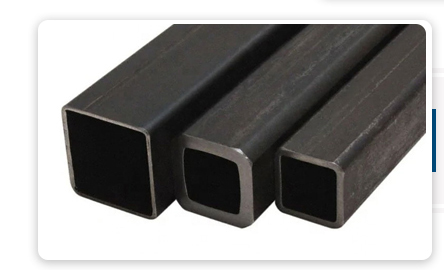

Uban sa usa ka tinuig nga output sa 10 ka milyon nga tonelada, Yuantai Derun mao ang kinadak-ang manufacturer sa ERW square tubo, rectangular tubo, hollow tubo, galvanized tubo, tul-id submerged arc welded steel tubo ug spiral welded tubo sa China.Ang tinuig nga halin miabot ug 15 bilyon dolyares.Ang Yuantai Derun adunay 59 ka itomERW pipelinya sa produksiyon, 10galvanized nga tubomga linya sa produksiyon ug 3 spiral welded pipe production lines.Square pipe 10 * 10 * 0.5mm ngadto sa 1000 * 1000 * 60MM,rectangular steel pipe10 * 15 * 0.5mm to 800 * 1100 * 60MM, straight seam welded steel pipe φ 355.6-2000mm, spiral pipe Φ 219-2032mm, seamless pipe φ 21.3-820mm。 Yuantai Derun can produce square rectangular pipes conforming to ASTM A500, JIS g3466, en10219, din2240 and as1163. Yuantai Derun has the largest square tube inventory in China, which can meet the direct purchase needs of customers. Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Pagtino sa square ug rectangular hollow sections

| OD(MM) | GIBAG-O(MM) | OD(MM) | GIBAG-O(MM) | OD(MM) | GIBAG-O(MM) | OD(MM) | GIBAG-O(MM) |

| 20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

| 1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

| 1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

| 1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

| 1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

| 2.0 | 2.5-4.0 | 11.5-11.75 | |||||

| 20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | ||||

| 1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |||

| 1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

| 1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

| 1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

| 2.2 | 2.20 | 13.5-13.75 | |||||

| 2.5-3.0 | 2.5-2.75 | 15.5-30 | |||||

| 20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | ||

| 1.4 | 5.5-6.3 | 4.5-4.75 | |||||

| 1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

| 2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

| 2.2 | 2.75 | 13.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |||

| 3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |||||

| 25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

| 1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

| 1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

| 1.8 | 3.0-3.75 | 12-13.75 | |||||

| 2.0 | 4.5-4.75 | 15.5-30 | |||||

| 2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |||

| 2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

| 4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

| 5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

| 5.75-6.3 | 3.0-4.75 | 15.5-30 | |||||

| 40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 750*750 | ||

| 1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

| 2.2 | 2.75 | 15.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |||

| 3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

| 4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

| 1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | ||||

| 1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |||

| 1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

| 2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | ||||

| 3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |||

| 4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

| 1.5 | 12.25 | 15.5-40 | |||||

| 1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 400*400 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | ||

| 1.8 | 4.5-6.3 | 9.5-9.75 | |||||

| 2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

| 2.2 | 9.5-9.75 | 12-13.75 | |||||

| 2.5-3.0 | 11.5-25 | 15.5-40 | |||||

| 3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | ||

| 4.25-4.75 | 3.5-3.75 | 11.5-11.75 | 20-60 | ||||

| 5.0-5.75 | 4.25-7.75 | 12-13.75 | |||||

| 7.5-8 | 9.5-25 | 15.5-40 |

01 DERECT DEAL

Espesyalista kami sa

paghimo og puthaw sulod sa daghang katuigan

- 02 KUMPLETO

- MGA ESPISPIKASYON

OD:10*10-1000*1000MM 10*15-800*1100MM

Gibag-on: 0.5-60mm

Gitas-on: 1-24M

3 ANG SERTIPIKASYON MAO

KUMPLETO

makahimo og steel pipe nga mga produkto sa kalibutan

stardard, sama sa European standard, American standard,

Japanese standard, Astralian standard, natinal standard

ug uban pa.

04 DAKO NGA IMBENTARYO

Kasagaran nga mga detalye perennial imbentaryo sa

200000 ka tonelada

A: Kami pabrika.

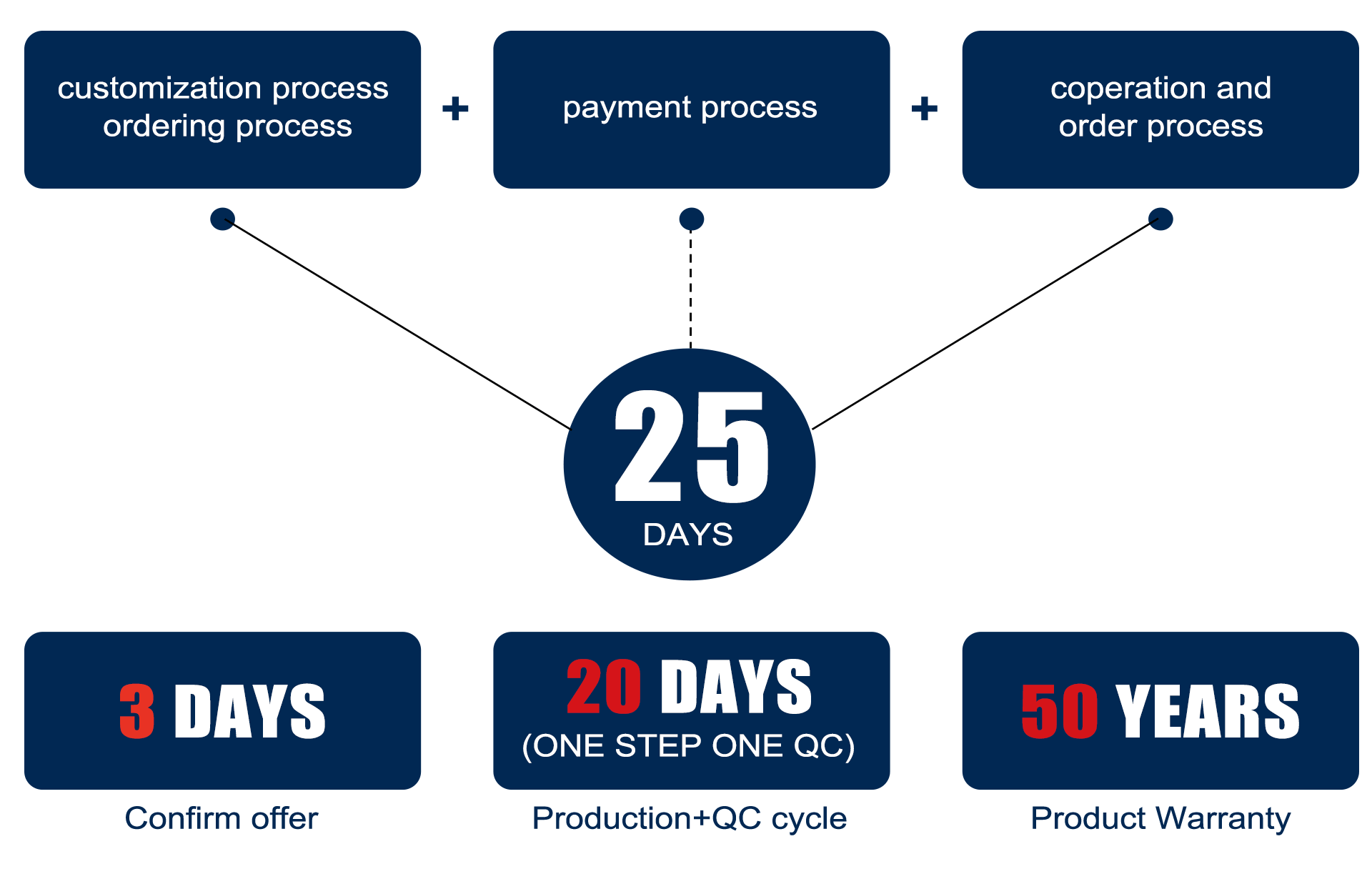

A: Kasagaran kini 5-10 ka adlaw kung ang mga butang naa sa stock.o kini 30 ka adlaw kung ang mga butang wala sa stock, kini sumala sa gidaghanon.

A: Oo, mahimo namong itanyag ang sample nga libre nga bayad sa gasto sa kargamento nga gibayad sa kustomer.

A: Pagbayad <= 1000USD, 100% nga abante.Pagbayad> = 1000USD 30% T/T sa abante, balanse sa wala pa shippment.If kamo adunay lain nga pangutana, pls mobati nga gawasnon sa pagkontak kanamo sama sa ubos

Gihatagan ug dakong importansya sa kompanya ang kalidad sa mga produkto, namuhunan pag-ayo sa pagpaila sa mga advanced nga kagamitan ug mga propesyonal, ug gihimo ang tanan aron matubag ang mga panginahanglanon sa mga kostumer sa balay ug sa gawas sa nasud.

Ang sulud mahimong halos bahinon sa: kemikal nga komposisyon, kusog sa ani, kusog nga tensile, kabtangan sa epekto, ug uban pa.

Sa parehas nga oras, mahimo usab nga himuon sa kompanya ang on-line nga flaw detection ug annealing ug uban pang mga proseso sa pagtambal sa kainit sumala sa mga kinahanglanon sa kostumer.

https://www.ytdrintl.com/

E-mail:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.usa ka pabrika sa steel pipe nga gi-sertipikado niEN/ASTM/ JISnag-espesyalisar sa produksyon ug pag-eksport sa tanang matang sa square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil ug uban pang steel products.With sayon nga transportasyon, kini mao ang 190 ka kilometro ang gilay-on gikan sa Beijing Capital International Airport ug 80 ka kilometro gikan sa Tianjin Xingang.

Whatsapp: + 8613682051821