With an annual output of 5 million tons, Yuantai Derun is the largest ERW square pipe, rectangular pipe, hollow pipe, galvanized pipe and spiral welded pipe manufacturer in China. Annual sales reached $15 billion. Yuantai Derun has 59 black ERW pipe production lines, 10 galvanized pipe production lines and 3 spiral welded pipe production lines. Square pipe 20 * 20 * 1mm to 500 * 500 * 40MM, rectangular steel pipe 20 * 30 * 1.2mm to 400 * 600 * 40MM, spiral pipe Ø 219-1420mm can be made of steel grades from Q (s) 195 to Q (s) 345B / gr.a-gr.d. Yuantai Derun can produce square rectangular tubes according to ASTM A500, JIS g3466, en10219, din2240 and as1163. Yuantai Derun has the largest square rectangular tube inventory in China, which can meet the direct purchasing demand of customers. Welcome everyone to cantact Yuantai Derun,E-mail:sales@ytdrgg.com, and Real time connection inspection plant or factory visit!

|

Product Name |

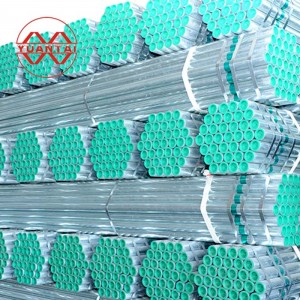

Hot galvanized pipe |

|

Size |

OD: 10.3mm-609mm Wall Thickness: 0.5-60mm Length: 3-12m or according to clients` requirements. |

|

Steel material |

GrA, Gr B, GrC, SS330, S275J0H; S355JR ; S355J0H; S355J2H.SS400,S235JR,S235JO,S235J2,S420,S460 |

|

Standard |

EN10219, EN10210, GB/T6728, GB/T3094, GB/T3091,JIS G3466 |

|

Usage |

Used For Structure, Accessorize And Construction |

|

Ends |

1) Plain 2) Beveled 3) Thread |

|

End protector |

1) Plastic pipe cap 2) Iron protector |

|

Surface Treatment |

Galvanized |

|

Technique |

ERW LSAW |

|

Type |

Welded |

|

Section Shape |

Round |

|

Inspection |

With Hydraulic Testing, Eddy Current , Infrared Test |

|

Package |

1) Bundle, 2) In Bulk 3) Bags 4) Clients' Requirements |

|

Delivery |

1) Container 2) Bulk carrier |

|

Port of Shipment |

Xingang, China |

|

Payment |

L/C T/T |

Who we are?

China's largest square tube manufacturing enterprises,China's top 500 manufacturing companies,The annual production capacity reaches 5 million tons.There are 2,000 employees

What do we do?

Square tube, galvanized square tube, spiral welded tube, double-sided submerged arc welded tube, hot rolled strip.Committed to providing excellent products and services for steel pipe users.

How to order?

Commissioner will quote according to your use specifications, and then you are satisfied with the price and quality of the intention to pay in advance, and then we begin to schedule production, product qualified after inspection, packing, balance, receive.

Why choose YuantaiDerun?

1. We have European standard, American standard, Japanese standard and other full series of product certification, from raw materials to finished products through 219 to test procedures, neither let a unqualified steel pipe into the market, excellent quality, won the market praise.

2. Preferential price, because it is factory direct sales, we will sell to you with the thinnest profit, to achieve high quality and low price products

3. Strong supply capacity and production capacity, annual output of more than 5 million tons, no matter how much your demand, guarantee the delivery time

4. More than 20 years of manufacturing experience and cooperation experience in major projects all over the world, give your order double insurance

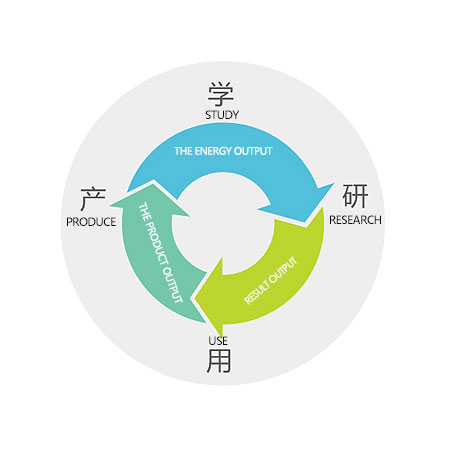

PRODUCE& LEARN&RESEARCH&USE

Tianjin YuantaiDerun group, founded in 2002, since its founding has been insist to do steel tube of the rectangular tube structure, since so many years, our party rectangular tubes from small furniture, use the door window, slowly do engineering machinery, equipment manufacturing, the main framework, up to now we developing the steel structure building, especially in recent years, pushing the prefabricated steel structure residential building,In the whole steel structure system, there are more applications for this industry to open a new market space.Then we launched in 2018 established the torque tube industry development and cooperation innovation alliance, behind we also invited by tianjin capital, Beijing university of architecture and so on some of the colleges and universities, and some scientific research institutions, together to come in to the platform and make the industry chain, to do the production, study and research, with a joint, from two aspects of the standardization and intelligent manufacturing,Bring something new to the industry

PATENT

TOP ENTERPRISE

EMPLOYEES

SERVICE FREQUENCY

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821