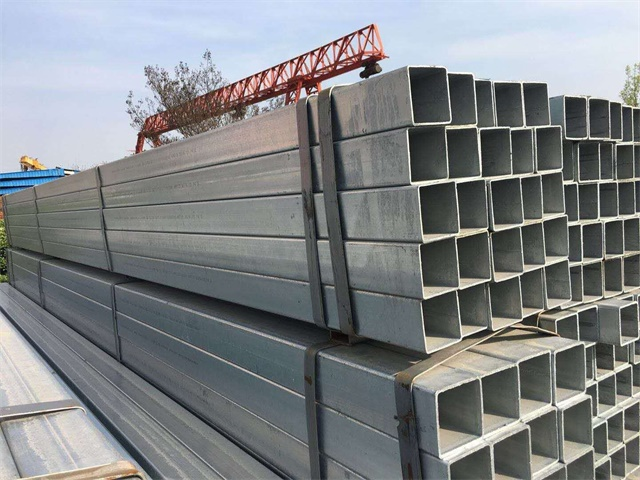

Kev Tiv Thaiv Xeb rau Yuantai Derun Square Tubes

Tianjin Yuantai Derun cov kav dej plaub fab feem ntau siv cov galvanizing kub rau kev tiv thaiv xeb. Cov txheej zinc cais cov kav dej hauv paus ntawm huab cua, tiv thaiv xeb. Cov txheej zinc nws tus kheej tsim cov zaj duab xis tiv thaiv, txhim kho kev tiv thaiv xeb. Txhawm rau txhim kho kev tiv thaiv xeb ntxiv, cov chaw puas tsuaj ntawm cov txheej galvanized tuaj yeem rov siv dua nrog cov xim tiv thaiv xeb. Xwb, kev ntsuas xws li kev ua kom zoo dua cov xwm txheej khaws cia, tswj cov khoom thauj, thiab kev ua kom cov txheej txheem vuam siv tau los txuas lub neej kev pabcuam. Kev tshuaj xyuas ntxaws ntxaws raws li nram no:

1. Cov Ntsiab Cai Tiv Thaiv Xeb ntawm Kev Kub-Dip Galvanizing

Tianjin Yuantai Derun square tubes siv kub-dip galvanizing, uas tso ib txheej zinc rau ntawm qhov chaw ntawm lub raj hlau. Cov txheej zinc no ua lub luag haujlwm tseem ceeb hauv kev tiv thaiv xeb thiab xeb:

Kev Cais Huab Cua: Cov txheej zinc npog qhov chaw ntawm lub raj hlau, cais nws tawm ntawm huab cua thiab tiv thaiv kev sib cuag ncaj qha nrog huab cua, uas tuaj yeem ua rau xeb.

Kev Tsim Zaj Duab Tiv Thaiv: Zinc muaj zog heev thiab tsim cov zaj duab tiv thaiv zinc carbonate nyias, ntom ntom hauv huab cua ntawm chav tsev kub, tiv thaiv cov txheej zinc ntxiv los ntawm kev oxidation ntxiv.

II. Cov Lus Qhia Txog Kev Txhim Kho Kev Tiv Thaiv Xeb

Txawm hais tias cov kav dej kub-dip galvanized square twb muaj kev tiv thaiv xeb zoo, cov kev ntsuas hauv qab no tuaj yeem ua tau rau qee qhov xwm txheej kom txhim kho lawv txoj kev tiv thaiv xeb ntxiv:

Rov siv xim tiv thaiv xeb: Thaum cov xim galvanized puas lawm (piv txwv li, vim yog vuam lossis hlawv cov xim ntawm cov pob qij txha), cov kav dej plaub fab raug cua thiab poob qhov kev tiv thaiv ntawm cov xim galvanized. Hauv qhov no, rov siv xim tiv thaiv xeb rau cov kav dej plaub fab thiab plaub fab tuaj yeem ua rau lawv tiv taus xeb zoo dua.

Kev Txhim Kho Cov Xwm Txheej Cia Khoom: Thaum lub sijhawm khaws cia, xaiv qhov chaw tsim nyog kom deb ntawm cov pa phem thiab hmoov av; khaws lub tsev rau khoom kom qhuav thiab qhov av noo qis dua 70%; khaws cov khoom siv thiab cov chaw khaws khoom kom huv si; muab cov khoom sib sau ua ke thiab npog kom zoo, tsa hauv qab ntawm pawg kom muaj cua nkag tau zoo; thiab tswj kom cov txheej tiv thaiv thiab cov khoom ntim khoom ruaj khov.

III. Kev Tiv Thaiv Xeb Thaum Siv

Thaum siv Tianjin Yuantai Derun square tubes, cov ntsiab lus hauv qab no yuav tsum tau ua kom ntev lawv lub neej kev pabcuam:

To taub qhov muaj peev xwm thauj khoom: Tsis txhob muab cov raj plaub fab thauj khoom ntau dhau. Kev thauj khoom ntau dhau yuav ua rau puas tsuaj lossis hloov pauv, ua rau lawv lub neej ua haujlwm luv dua.

Kev Ua Haujlwm Vuam Txheem: Tsis txhob ua kev vuam tsis raws cai rau ntawm cov raj plaub fab. Kev vuam tuaj yeem ua rau lub raj puas tsuaj, cuam tshuam rau nws lub zog thiab lub neej ntev. Yog tias tsim nyog vuam, nrhiav kev pab los ntawm cov kws tshaj lij.

Kev Tshuaj Xyuas thiab Kev Txij Nkawm Tsis Tu Ncua: Tshuaj xyuas thiab tswj cov raj plaub fab tsis tu ncua kom pom thiab daws cov teeb meem xws li xeb.

Lub sijhawm tshaj tawm: Lub Yim Hli-27-2025