YuanTai DeRun – Ígwè Galvanized A Mịrị Ọkụ

Ọkpọkọ galvanized na-amịkọrọ ọkụ, iji melite iguzogide nchara nke paịpụ ígwè, a na-eji galvanized eme paịpụ ígwè n'ozuzu. A na-ekewa paịpụ ígwè galvanized n'ime galvanizing ọkụ na electro-galvanizing. Galvanizing ọkụ na-etinye nwere akwa galvanized dị arọ, electro-galvanizing nwere ọnụ ala dị ala, elu ya adịghịkwa mma nke ukwuu.

A na-ekewa paịpụ ígwè e ji ígwè rụọ n'ime paịpụ galvanized nke a na-etinye n'ime oyi na paịpụ galvanized nke a na-etinye n'ime ọkụ.

A ga-eme ka ígwè gbazere agbaze megharịa ya na matrix ígwè iji mepụta oyi akwa alloy, ka matrix na mkpuchi ahụ wee jikọta. Galvanizing ọkụ-mikpu bụ ịchacha ọkpọkọ ígwè ahụ mbụ. Iji wepụ iron oxide n'elu paịpụ ígwè ahụ, mgbe a pịchara ya, a na-ehicha ya na mmiri ammonium chloride ma ọ bụ zinc chloride ma ọ bụ mmiri a gwakọtara agwakọta nke ammonium chloride na zinc chloride, wee ziga ya na tankị mkpuchi ọkụ-mikpu. Galvanizing ọkụ-mikpu nwere uru nke mkpuchi otu, nrapado siri ike, na ndụ ogologo oge ọrụ. Matrix ọkpọkọ ígwè ahụ na-enweta mmeghachi omume anụ ahụ na kemịkalụ dị mgbagwoju anya na ngwọta mkpuchi agbaze iji mepụta oyi akwa zinc-iron alloy na-eguzogide nchara nke nwere usoro siri ike. A na-ejikọta oyi akwa alloy ahụ na oyi akwa zinc dị ọcha na matrix ọkpọkọ ígwè. Ya mere, ọ nwere ike iguzogide nchara siri ike.

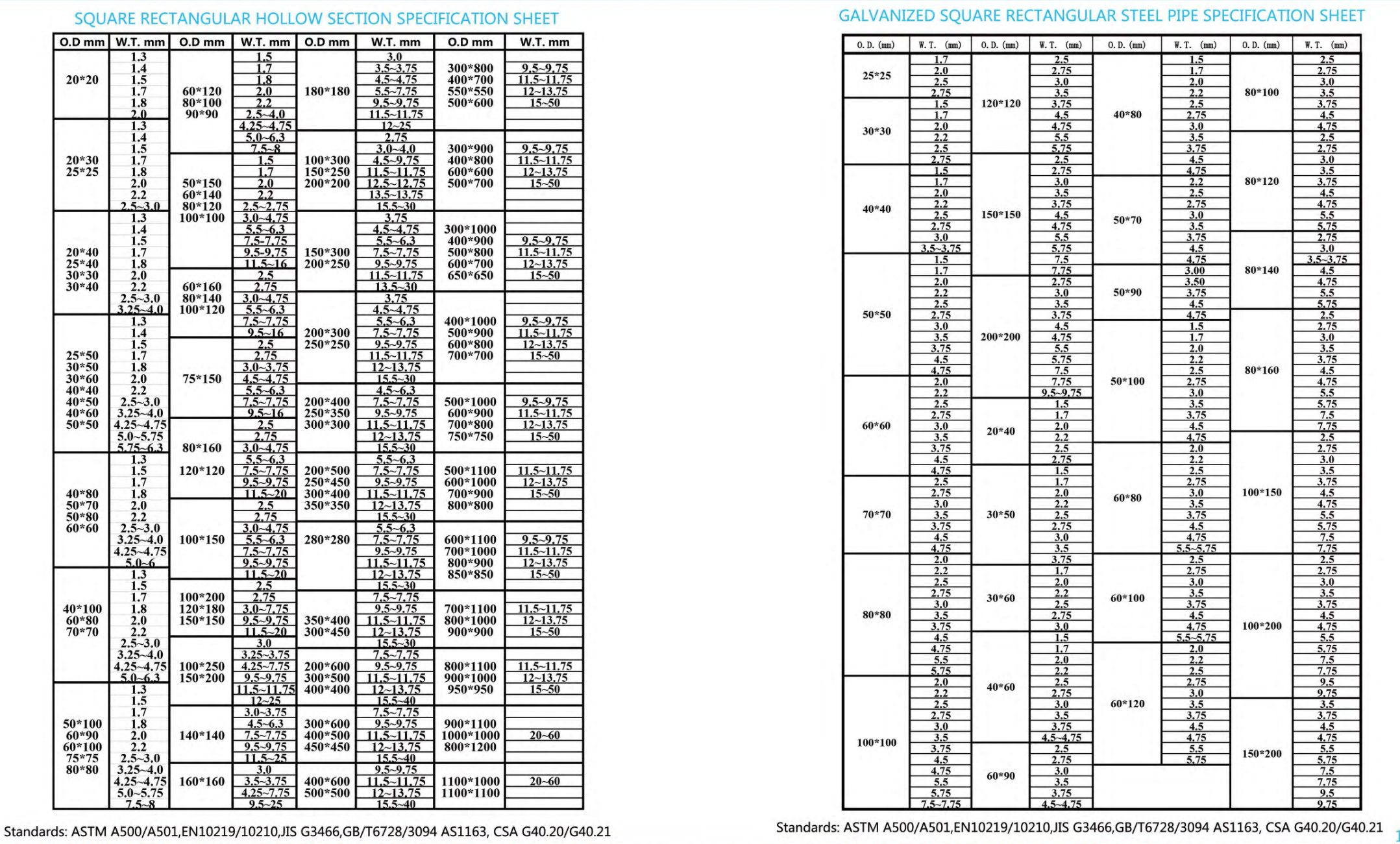

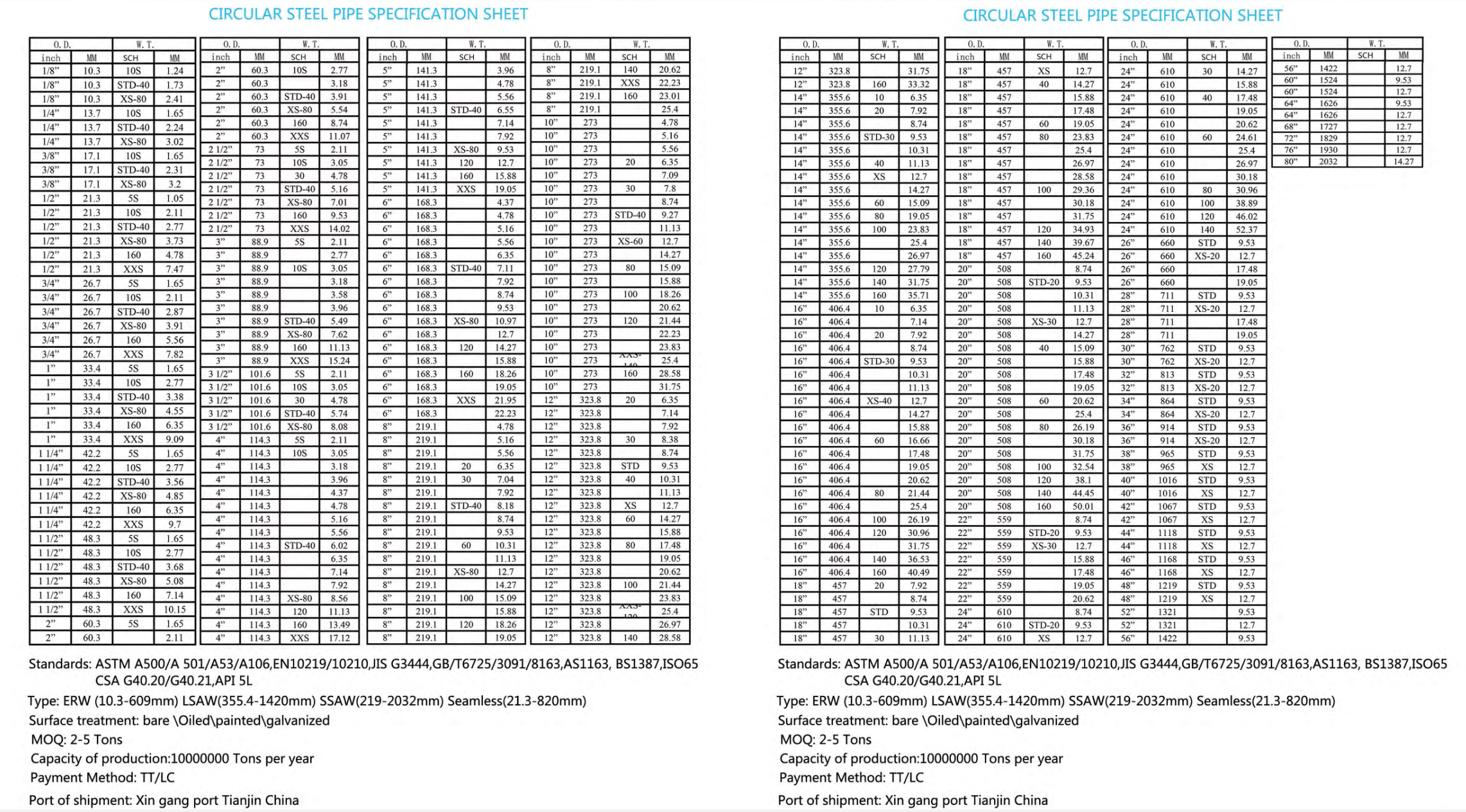

A na-ejikarị ọkpọkọ ígwè e ji ígwè rụọ ọkụ eme ihe n'ọtụtụ ebe n'ihe gbasara owuwu na injinia, ọkwa ihe ha na-emetụtakwa ịdị mma na ndụ ọrụ nke ngwaahịa ahụ ozugbo. Ịhọrọ ọkwa ihe kwesịrị ekwesị dị oke mkpa maka nchekwa na ntụkwasị obi nke ọrụ ahụ. Ihe ndị a ga-egosi ọkwa ihe na njirimara nke ọkpọkọ ígwè e ji ígwè rụọ ọkụ eme ihe iji nyere gị aka ịghọta ma zụta ngwaahịa kwesịrị ekwesị.

1. Nhazi ọkwa ihe eji eme ihe:

Oge ozi: Julaị-21-2025