EN10219 Muundo wa kemikali, sifa za mitambo, uvumilivu na viwango vya upimaji wa mabomba ya chuma yaliyonyooka

N10219-2006 Bomba la chuma lenye mashimo lenye umbo la baridi la chuma kisichotumia aloi na chuma cha kimuundo chenye nafaka laini (bomba la chuma lenye umbo la LSAW lenye umbo la arc lenye umbo la longitudinal)

Nyenzo kuu S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S420MH, S420MLH, S460MH, S460MLH, S460NH, S460NH, S460NH

1, Maana ya nambari na herufi katika EN10219-2006

S: Chuma cha kimuundo

Nambari baada ya S: zui nguvu ndogo ya mavuno (unene wa ukuta ≤ 16mm)

JR: jaribio la athari kwenye halijoto ya kawaida ≥ 27J

J0: 0 ℃ jaribio la athari ≥ 27J

J2: - 20 ℃ jaribio la athari ≥ 27J

K2: - 20 ℃ jaribio la athari ≥ 40J

N: Kuviringisha kwa kawaida au kwa kawaida (chuma laini, jaribio la athari lazima lifanyike, joto la zui ni chini ya - 20 ℃ ≥ 40J)

M: Uzungushaji unaodhibitiwa na thermo-mechanical (jaribio la athari lazima lifanyike, na halijoto ya zui ni chini ya - 20 ℃ ≥ 40J)

50: - 50 ℃ jaribio la athari ≥ 27J

H: Wasifu tupu

2, Muundo wa kemikali (unene T ≤ 40mm) na sifa za mitambo

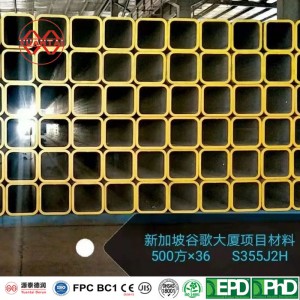

Yuantai Derun inaweza kutoa mabomba ya chuma ya EN10219-2006. Je, ni vifaa gani vya S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NH, S355NLH, S460NH na S460NLH katika EN10219-2006?

S235JRH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S235JRH

Muundo wa kemikali wa S235JRH

Kaboni ≤ 0.17%, silikoni ≤ haihitajiki, manganese ≤ 1.40%, fosforasi ≤ 0.04%, salfa ≤ 0.04%, nitrojeni ≤ 0.009%

Sifa za mitambo za S235JRH

3mm

16mm

Nyenzo ya S275J0H ni nini, na ni nyenzo gani ya kubadilisha, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono wa S275J0H ulionyooka?

Muundo wa kemikali wa S275J0H

Kaboni ≤ 0.20%, silikoni ≤ haihitajiki, manganese ≤ 1.50%, fosforasi ≤ 0.035%, salfa ≤ 0.035%, nitrojeni ≤ 0.009%

Sifa za mitambo za S275J0H

3mm

16mm

S275J2H ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S275J2H

Muundo wa kemikali wa S275J2H

Kaboni ≤ 0.20%, silikoni ≤ haihitajiki, manganese ≤ 1.50%, fosforasi ≤ 0.030%, salfa ≤ 0.030%, nitrojeni ≤ haihitajiki

Sifa za mitambo za S275J2H

3mm

16mm

Nyenzo ya S355J0H ni nini na ni nyenzo gani inayotumika kuibadilisha? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S355J0H

Muundo wa kemikali wa S355J0H

Kaboni ≤ 0.22%, silikoni ≤ 0.55%, manganese ≤ 1.60%, fosforasi ≤ 0.035%, salfa ≤ 0.035%, nitrojeni ≤ 0.009%

Sifa za mitambo za S355J0H

3mm

16mm

S355J2H ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S355J2H

Muundo wa kemikali wa S355J2H

Kaboni ≤ 0.22%, silikoni ≤ 0.55%, manganese ≤ 1.60%, fosforasi ≤ 0.030%, salfa ≤ 0.030%, nitrojeni ≤ haihitajiki

Sifa za mitambo za S355J2H

3mm

16mm

Nyenzo ya S355K2H ni nini, ni nyenzo gani inayotumika badala yake, na ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S355K2H

Muundo wa kemikali wa S355K2H

Kaboni ≤ 0.22%, silikoni ≤ 0.55%, manganese ≤ 1.60%, fosforasi ≤ 0.030%, salfa ≤ 0.030%, nitrojeni ≤ haihitajiki

Sifa za mitambo za S355K2H

3mm

16mm

S275NH ni nyenzo gani? Ni nyenzo gani inayotumika badala yake? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S275NH

Muundo wa kemikali wa S275NH

Kaboni ≤ 0.20%, silikoni ≤ 0.40%, manganese ≤ 0.5-1.40%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.05%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.30%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.015%,

Sifa za mitambo za S275NH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 275MPa, nguvu ya mvutano ≥ 370-510MPa, urefu ≥ 24%

16mm

S275NLH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S275NLH

Muundo wa kemikali wa S275NLH

Kaboni ≤ 0.20%, silikoni ≤ 0.40%, manganese ≤ 0.5-1.40%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.05%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.3%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.015%,

Sifa za mitambo za S275NLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 275MPa, nguvu ya mvutano ≥ 370-510MPa, urefu ≥ 24%

16mm

S355NH ni nyenzo gani? Ni nyenzo gani inayotumika badala yake? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S355NH

Muundo wa kemikali wa S355NH

Kaboni ≤ 0.20%, silikoni ≤ 0.50%, manganese ≤ 0.9-1.65%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.5%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.015%,

Sifa za mitambo za S355NH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 355MPa, nguvu ya mvutano ≥ 470-630MPa, urefu ≥ 22%

16mm

S355NLH ni nyenzo gani, ni nyenzo gani inayotumika kuibadilisha, na ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S355NLH

Muundo wa kemikali wa S355NLH

Kaboni ≤ 0.18%, silikoni ≤ 0.50%, manganese ≤ 0.9-1.65%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.5%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.015%,

Sifa za mitambo za S355NLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 355MPa, nguvu ya mvutano ≥ 470-630MPa, urefu ≥ 22%

16mm

S460NH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, na ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S460NH

Muundo wa kemikali wa S460NH

Kaboni ≤ 0.20%, silikoni ≤ 0.60%, manganese ≤ 1.0-1.70%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.20%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.8%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.025%,

Sifa za mitambo za S460NH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 460MPa, nguvu ya mvutano ≥ 550-720MPa, urefu ≥ 17%

16mm

S460NLH ni nyenzo gani, ni nyenzo gani inayotumika kuibadilisha, na ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S460NLH

Muundo wa kemikali wa S460NLH

Kaboni ≤ 0.20%, silikoni ≤ 0.60%, manganese ≤ 1.0-1.70%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.20%,

Alumini ≥ 0.020%, titani ≤ 0.03%, kromiamu ≤ 0.30%, nikeli ≤ 0.8%, molibdenamu ≤ 0.10%, shaba ≤ 0.35%, nitrojeni ≤ 0.025%,

Sifa za mitambo za S460NLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 460MPa, nguvu ya mvutano ≥ 550-720MPa, urefu ≥ 17%

16mm

S275MH ni nyenzo gani? Ni nyenzo gani inayotumika badala yake? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S275MH

Muundo wa kemikali wa S275MH

Kaboni ≤ 0.13%, silikoni ≤ 0.50%, manganese ≤ 1.50%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.08%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.30%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S275MH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 275MPa, nguvu ya mvutano ≥ 360-510MPa, urefu ≥ 24%

16mm

S275MLH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, na ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S275MLH

Muundo wa kemikali wa S275MLH

Kaboni ≤ 0.13%, silikoni ≤ 0.50%, manganese ≤ 1.50%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.08%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.30%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S275MLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 275MPa, nguvu ya mvutano ≥ 360-510MPa, urefu ≥ 24%

16mm

S355MH ni nyenzo gani? Ni nyenzo gani inayotumika badala yake? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S355MH

Muundo wa kemikali wa S355MH

Kaboni ≤ 0.14%, silikoni ≤ 0.50%, manganese ≤ 1.50%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.10%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S355MH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 355MPa, nguvu ya mvutano ≥ 450-610MPa, urefu ≥ 22%

16mm

S355MLH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S355MLH

Muundo wa kemikali wa S355MLH

Kaboni ≤ 0.14%, silikoni ≤ 0.50%, manganese ≤ 1.50%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.10%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S355MLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 355MPa, nguvu ya mvutano ≥ 450-610MPa, urefu ≥ 22%

16mm

S420MH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S420MH

Muundo wa kemikali wa S420MH

Kaboni ≤ 0.16%, silikoni ≤ 0.50%, manganese ≤ 1.70%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S420MH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 420MPa, nguvu ya mvutano ≥ 500-660MPa, urefu ≥ 19%

16mm

S420MLH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S420MLH

Muundo wa kemikali wa S420MLH

Kaboni ≤ 0.16%, silikoni ≤ 0.50%, manganese ≤ 1.70%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.02%,

Sifa za mitambo za S420MLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 420MPa, nguvu ya mvutano ≥ 500-660MPa, urefu ≥ 19%

16mm

S460MH ni nyenzo gani? Ni nyenzo gani inayotumika badala yake? Ni kampuni gani inayoweza kutengeneza bomba la chuma la mshono ulionyooka la S460MH

Muundo wa kemikali wa S460MH

Kaboni ≤ 0.16%, silikoni ≤ 0.60%, manganese ≤ 1.70%, fosforasi ≤ 0.035%, salfa ≤ 0.030%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.025%,

Sifa za mitambo za S460MH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 460MPa, nguvu ya mvutano ≥ 530-720MPa, urefu ≥ 17%

16mm

S460MLH ni nyenzo gani, ni nyenzo gani inayotumika badala yake, na ni kampuni gani inaweza kutengeneza bomba la chuma la mshono ulionyooka la S460MLH

Muundo wa kemikali wa S460MLH

Kaboni ≤ 0.16%, silikoni ≤ 0.60%, manganese ≤ 1.70%, fosforasi ≤ 0.030%, salfa ≤ 0.025%, niobamu ≤ 0.05%, vanadiamu ≤ 0.12%,

Alumini ≥ 0.020%, titani ≤ 0.05%, nikeli ≤ 0.3%, molibdenamu ≤ 0.20%, nitrojeni ≤ 0.025%,

Sifa za mitambo za S460MLH

Unene wa ukuta ≤ 16mm: nguvu ya mavuno ≥ 460MPa, nguvu ya mvutano ≥ 530-720MPa, urefu ≥ 17%

16mm

3, EN10219-2006 Aina ya uvumilivu wa kawaida

Kipenyo na kupotoka kwa mviringo (kwa bomba la chuma la SAWL LSAW):

Uvumilivu wa kipenyo cha nje ≤± 1%, zui ndogo ± 0.5mm, zui kubwa ± 10mm

Mbinu ya kupima kipenyo cha nje ni mbinu ya mduara, na kipenyo cha nje kilichopimwa = mduara/mduara

Uzito: 2% wakati kipenyo/unene wa nje ≤ 100

Mbinu ya hesabu ya uvumilivu=(kipenyo kikubwa cha nje cha zui - kipenyo kidogo cha nje cha zui)/kipenyo cha kawaida cha nje X100%

Kupotoka kwa unene wa ukuta (kwa bomba la chuma lililounganishwa kwa unene wa SAWL kwa urefu):

Kipenyo cha nje ≥ 406mm, uvumilivu wa unene wa ukuta ≤± 10%, zui kubwa ± 2mm

Kupotoka kwa unyoofu (kwa bomba la chuma lililounganishwa kwa upinde wa SAWL, L ni urefu wa bomba la chuma katika mm):

Kupotoka kwa unyoofu wa urefu kamili ≤ 0.002L

Mkengeuko wa uzito: ± 6% (kwa kila urefu wa kitengo)

Uvumilivu wa urefu wa weld za ndani na nje za bomba la arc lililozama

Unene (T) ≤ 14.2zui Urefu mkubwa wa kulehemu 3.5mm

Unene (T) > 14.2zui Urefu mkubwa wa kulehemu 4.8mm

Uvumilivu wa urefu:

Urefu wowote: 4000-16000mm, safu moja inayoelea 2000mm, 10% ya bidhaa zinazotolewa zinaweza kuwa chini kuliko thamani ndogo ya zui iliyoainishwa katika mpangilio, lakini si chini ya 75% ya thamani ndogo ya zui

Urefu wa takriban: kiwango cha uvumilivu ni 0 hadi + 50mm wakati ≥ 4000mm

Urefu:

Kiwango cha uvumilivu ni 0 hadi 5mm wakati urefu ni chini ya 6000 mm

Kiwango cha uvumilivu ni 0 hadi 15mm wakati urefu ni 6000mm ≤ ≤ 10000mm

Uvumilivu 0 hadi 5mm+1mm/m wakati urefu ni zaidi ya 10000mm

4, Jaribio letu la NDT:

Upimaji wa X-ray na Ultrasound (RT&UT)

Radiografia (RT): Ukaguzi wa bomba la chuma 100%

Ultrasonic (UT): ukaguzi wa bomba la chuma 100%

Shinikizo la maji linapaswa kuwa kulingana na kiwango au kujadiliwa na pande zote mbili

Maneno machache kutoka kwa Kundi la Chuma la Yuantai Derun

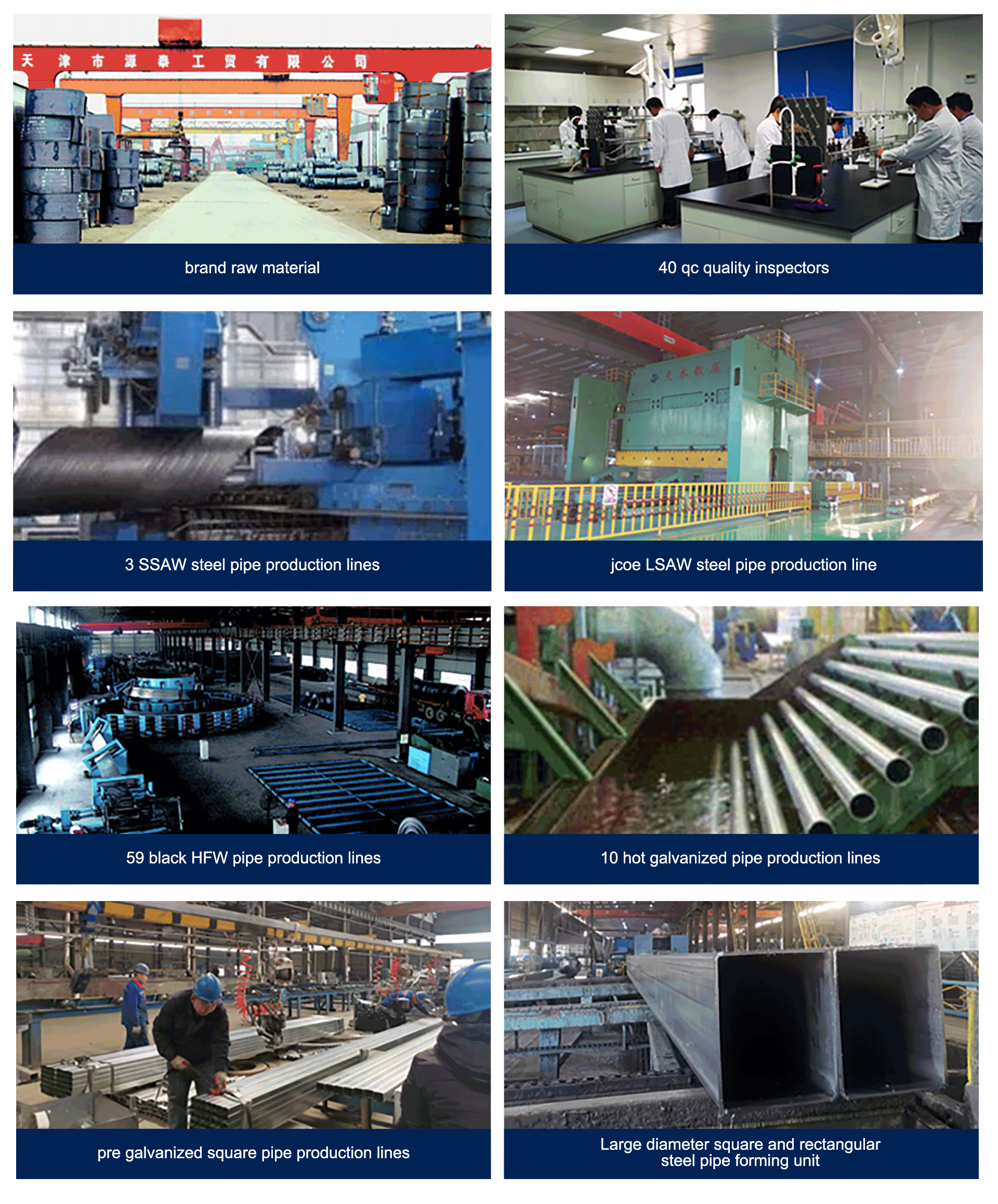

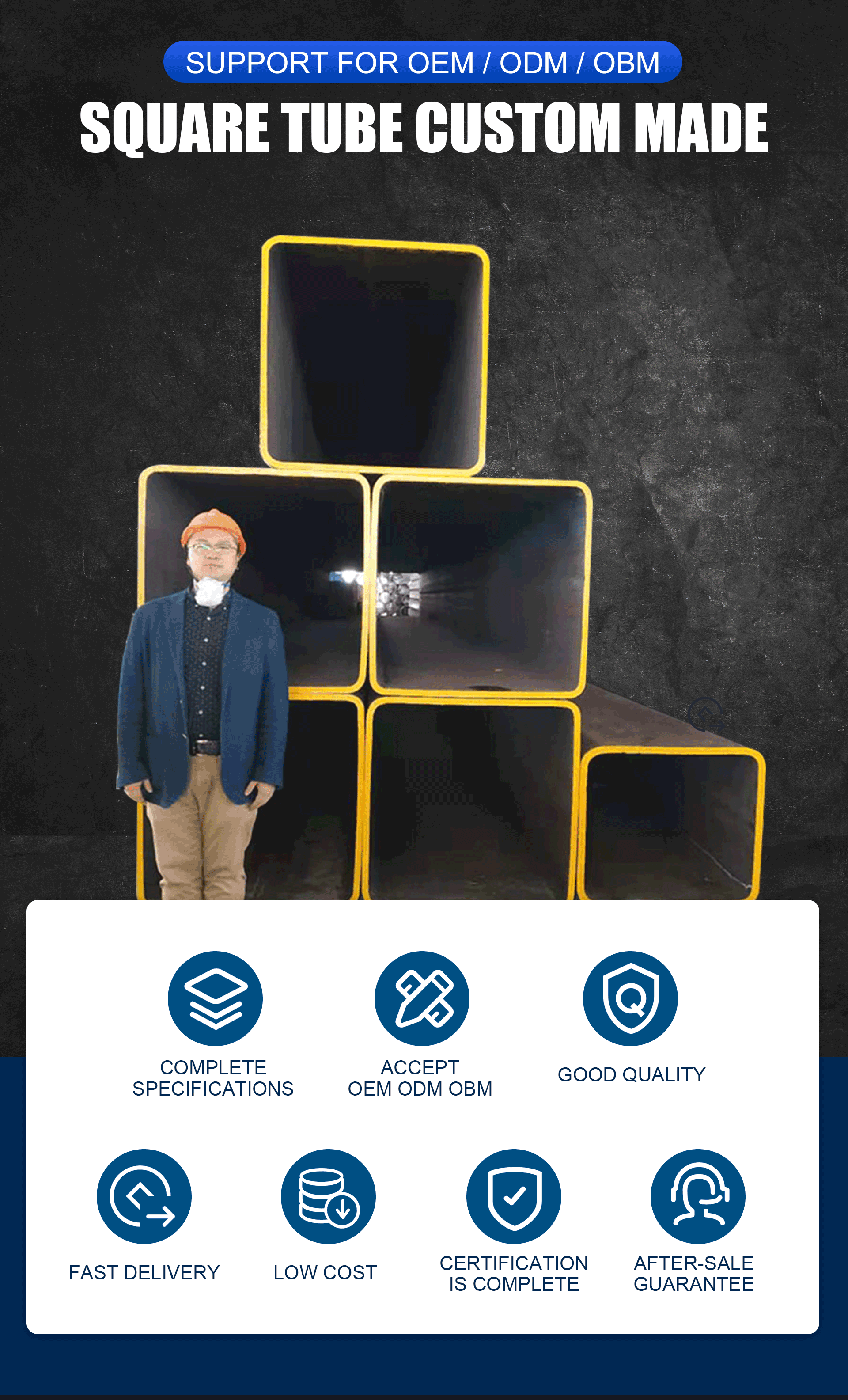

Kwa uzalishaji wa kila mwaka wa tani milioni 10, Yuantai Derun ndiye mtengenezaji mkubwa zaidi wa mabomba ya mraba ya ERW, mabomba ya mstatili, mabomba yenye mashimo, mabomba ya mabati, mabomba ya chuma yaliyounganishwa kwa safu iliyonyooka na mabomba ya spirali yaliyounganishwa nchini China. Mauzo ya kila mwaka yalifikia dola bilioni 15 za Marekani. Yuantai Derun ina mabomba 59 meusi.Bomba la ERWmistari ya uzalishaji, 10bomba la mabatimistari ya uzalishaji na mistari 3 ya uzalishaji wa bomba lenye svetsade ya ond. Bomba la mraba 10 * 10 * 0.5mm hadi 1000 * 1000 * 60MM,bomba la chuma la mstatili10 * 15 * 0.5mm to 800 * 1100 * 60MM, straight seam welded steel pipe φ 355.6-2000mm, spiral pipe Φ 219-2032mm, seamless pipe φ 21.3-820mm。 Yuantai Derun can produce square rectangular pipes conforming to ASTM A500, JIS g3466, en10219, din2240 and as1163. Yuantai Derun has the largest square tube inventory in China, which can meet the direct purchase needs of customers. Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Vipimo vya sehemu zenye mashimo ya mraba na mstatili

| OD(MM) | UNENE(MM) | OD(MM) | UNENE(MM) | OD(MM) | UNENE(MM) | OD(MM) | UNENE(MM) |

| 20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

| 1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

| 1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

| 1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

| 1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

| 2.0 | 2.5-4.0 | 11.5-11.75 | |||||

| 20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | ||||

| 1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |||

| 1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

| 1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

| 1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

| 2.2 | 2.20 | 13.5-13.75 | |||||

| 2.5-3.0 | 2.5-2.75 | 15.5-30 | |||||

| 20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | ||

| 1.4 | 5.5-6.3 | 4.5-4.75 | |||||

| 1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

| 2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

| 2.2 | 2.75 | 13.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |||

| 3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |||||

| 25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

| 1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

| 1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

| 1.8 | 3.0-3.75 | 12-13.75 | |||||

| 2.0 | 4.5-4.75 | 15.5-30 | |||||

| 2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |||

| 2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

| 4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

| 5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

| 5.75-6.3 | 3.0-4.75 | 15.5-30 | |||||

| 40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 750*750 | ||

| 1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

| 2.2 | 2.75 | 15.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |||

| 3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

| 4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

| 1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | ||||

| 1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |||

| 1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

| 2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | ||||

| 3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |||

| 4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

| 1.5 | 12.25 | 15.5-40 | |||||

| 1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 400*400 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | ||

| 1.8 | 4.5-6.3 | 9.5-9.75 | |||||

| 2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

| 2.2 | 9.5-9.75 | 12-13.75 | |||||

| 2.5-3.0 | 11.5-25 | 15.5-40 | |||||

| 3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | ||

| 4.25-4.75 | 3.5-3.75 | 11.5-11.75 | 20-60 | ||||

| 5.0-5.75 | 4.25-7.75 | 12-13.75 | |||||

| 7.5-8 | 9.5-25 | 15.5-40 |

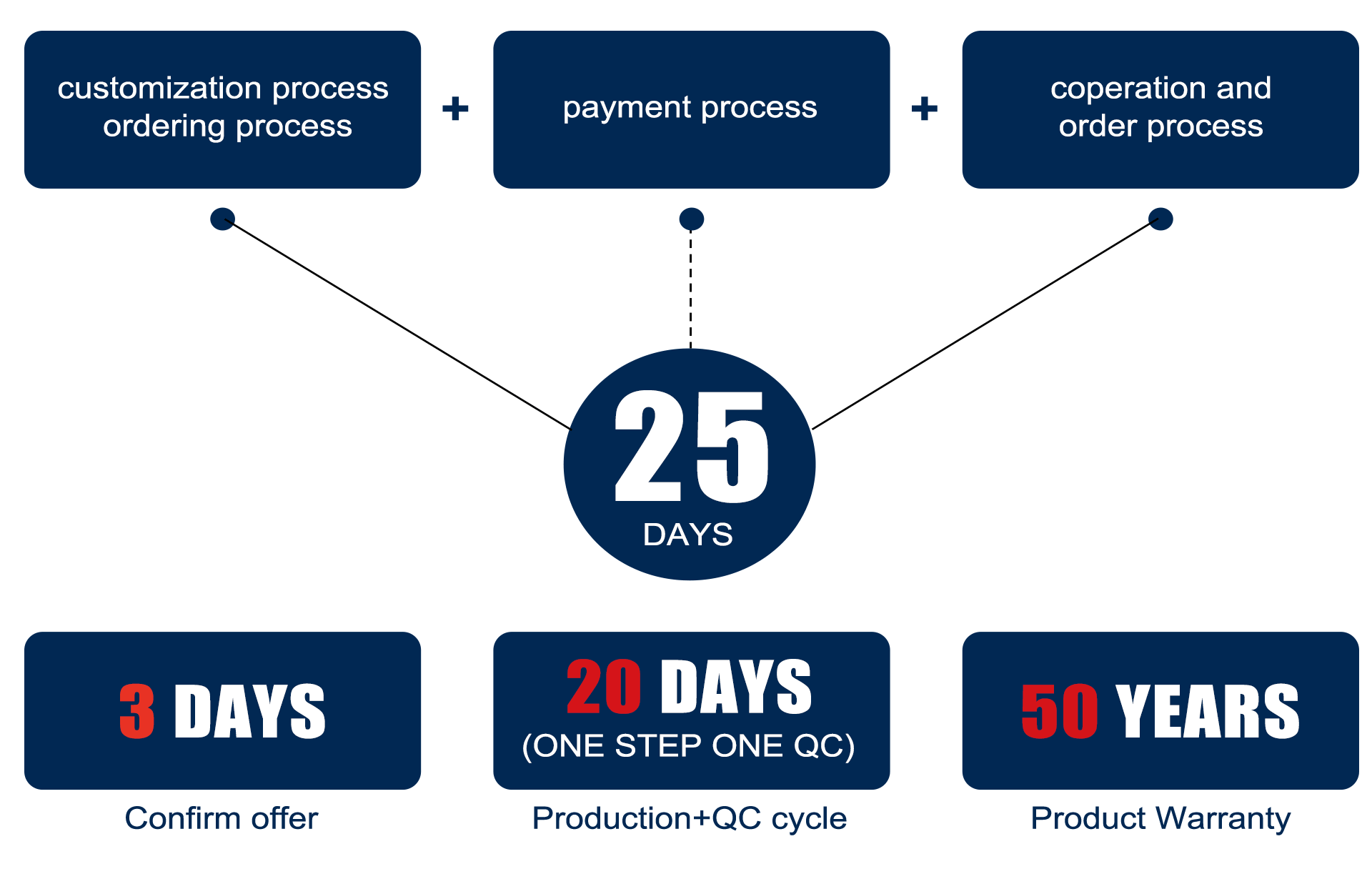

01 OFA HALISI

Tumebobea katika

kutengeneza chuma kwa miaka mingi

- 02 KAMILI

- VIPIMO

OD: 10*10-1000*1000MM 10*15-800*1100MM

Unene: 0.5-60mm

Urefu: 1-24M

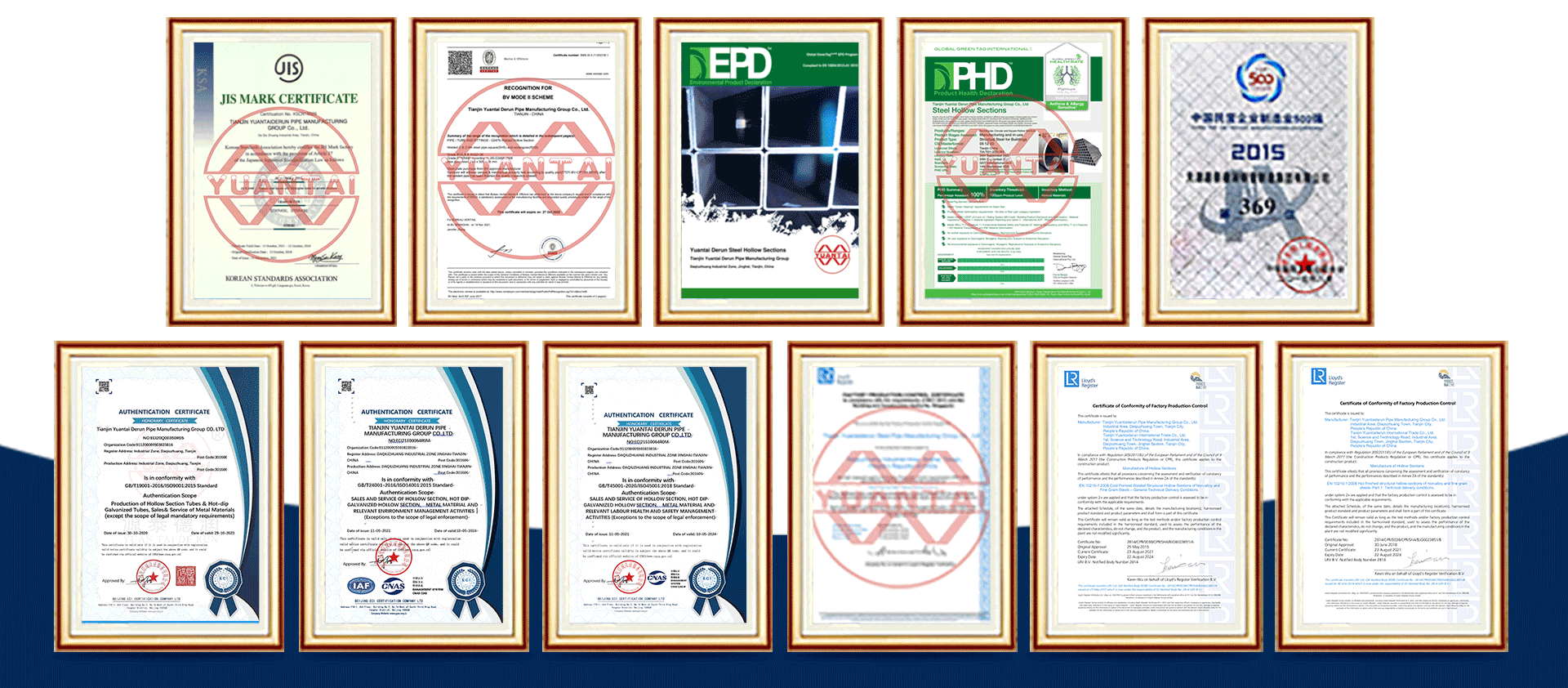

3 UTHIBITISHO NI

KAMILI

inaweza kutoa bidhaa za mabomba ya chuma duniani

nyota, kama vile kiwango cha Ulaya, kiwango cha Marekani,

Kiwango cha Kijapani, kiwango cha Astralia, kiwango cha kuzaliwa

na kadhalika.

04 ORODHA KUBWA

Vipimo vya kawaida vya hesabu ya kudumu ya

Tani 200000

A: Sisi ni kiwanda.

J: Kwa ujumla ni siku 5-10 ikiwa bidhaa zipo. au ni siku 30 ikiwa bidhaa hazipo, ni kulingana na wingi.

J: Ndiyo, tunaweza kutoa sampuli bila malipo kwa gharama ya usafirishaji inayolipwa na mteja.

A: Malipo<=1000USD, 100% mapema. Malipo>=1000USD 30% T/T mapema, salio kabla ya usafirishaji. Ikiwa una swali lingine, tafadhali jisikie huru kuwasiliana nasi kama ilivyo hapo chini.

Kampuni inatilia maanani sana ubora wa bidhaa, inawekeza sana katika kuanzishwa kwa vifaa na wataalamu wa hali ya juu, na inajitolea kikamilifu kukidhi mahitaji ya wateja ndani na nje ya nchi.

Yaliyomo yanaweza kugawanywa katika: muundo wa kemikali, nguvu ya mavuno, nguvu ya mvutano, sifa ya athari, n.k.

Wakati huo huo, kampuni inaweza pia kufanya utambuzi wa dosari mtandaoni na michakato mingine ya matibabu ya joto kulingana na mahitaji ya wateja.

https://www.ytdrintl.com/

Barua pepe:sales@ytdrgg.com

Kikundi cha Utengenezaji wa Mirija ya Chuma cha Tianjin YuantaiDerun Co., Ltd.ni kiwanda cha mabomba ya chuma kilichoidhinishwa naEN/ASTM/ JISmaalumu katika uzalishaji na usafirishaji wa kila aina ya bomba la mraba mstatili, bomba la mabati, bomba la ERW svetsade, bomba la ond, bomba la arc svetsade lililozama ndani ya maji, bomba la mshono ulionyooka, bomba lisilo na mshono, koili ya chuma iliyofunikwa kwa rangi, koili ya chuma iliyotiwa mabati na bidhaa zingine za chuma. Kwa usafiri rahisi, iko kilomita 190 kutoka Uwanja wa Ndege wa Kimataifa wa Beijing Capital na kilomita 80 kutoka Tianjin Xingang.

WhatsApp:+8613682051821

Tutumie ujumbe wako:

-

BEI YA BOMBA LA CHUMA LA MBAO LA UBORA WA JUU

-

Bomba la Chuma Lisilo na Mshono la Api Astm Asme lenye Ubora wa Juu Lenye Iso 9001

-

mtengenezaji wa bomba la chuma la mstatili lenye sehemu yenye mashimo

-

Mirija ya Mstatili 2×3 - Mirija ya Chuma ya Ubora wa Juu | Kikundi cha Mabomba ya Chuma cha Yuantai Derun

-

Sehemu yenye mashimo ya China YuantaiDerun

-

mtengenezaji wa sehemu yenye mashimo ya chuma cha mraba China yuantaiderun