| Пункт | Бясшвовыя сталёвыя трубы | |

| Стандартны | ASTM, DIN, GB/T, JIS, BS, API | |

| Матэрыял | 20 #, 35 #, 45 #, 20G, Q345 (16Mn), 27SiMn, 20A, 40Mn2, 45Mn2, 40MnB, 20MnVB, 20Cr, 30Cr, 35Cr, 40Cr, 45Cr, 50Cr, 38CrSi, 12CrMo 20CrMo, 35CrMo, 42CrMo, 12CrMoV і г.д. | |

| Тэхналогіі | Гарачакатаная | Халоднакатаная |

| Памер | (6-1260)x(0,2-100) | (4-1260)x(0,2-100) |

| Даўжыня трубы | Ад 5,8 м да 12 м, можна наладзіць у адпаведнасці з патрабаваннямі да даўжыні | |

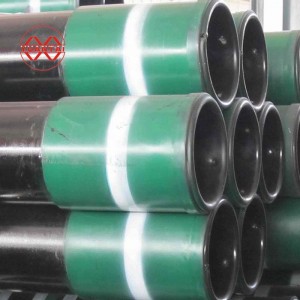

| Паверхня | Чорная фарба, лак, алей, гарачае ацынкаванне, адпал | |

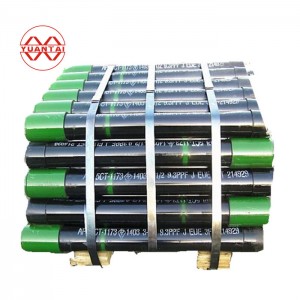

| Канцы труб | Гладкія канцы, скошаныя канцы, разьбовыя, разетка з адтулінамі, з ПВХ-хлопком/муфтай | |

| Захоўшчык канца | 1. Пластыкавыя вечкі (малы знешні дыяметр) 2. Жалезны ахоўнік (вялікі знешні дыяметр) | |

| Прыкладанне | Труба для вадкасці, нафтаправод, газаправод, канструкцыйны трубаправод, труба для катла, труба для механічнай апрацоўкі, гідраўлічная труба і г.д. | |

| Тэст | Аналіз хімічных кампанентаў, механічныя ўласцівасці, тэхнічныя ўласцівасці, знешнія памеры | |

| Прадукцыйнасць | 50 000 тон у месяц | |

| Мінімальны заказ | 5 тон | |

| Заўвага | Спецыяльная канструкцыя даступная ў адпаведнасці з патрабаваннямі | |

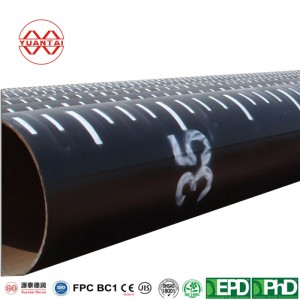

| Назва прадукту | ASTM A795 СТАЛЬНАЯ ТРУБА ДЛЯ ПАЖАРНАГА СПРЫНКЕРА | |

| Памер | OD | 1" - 88" |

| Таўшчыня сценкі | 2-70 мм | |

| Даўжыня | 2-40 м або па індывідуальнай замове | |

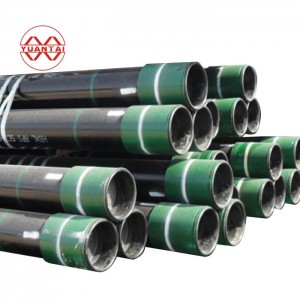

| Сталь Матэрыял | API 5L GR.B, X42, X46, X56, X65, X70 ASTM A53 КЛАС A, КЛАС B | |

| Стандартны | API 5L, API 5CT, ASTM A53, ASTM A252, EN10217, EN10219, DIN, JIS, BS | |

| Заканчваецца | Звычайныя канцы, скошаныя канцы або з ахоўнымі каўпачкамі. | |

| Паверхня | Эпаксіднае пакрыццё для злучэння, эпаксідная смала каменнавугальнай смалы, 3PE, FBE, лакавае пакрыццё, бітумнае пакрыццё, пакрыццё чорным алеем і г.д. | |

| Праверка трэціх асоб | SGS, BV | |

| Інспекцыя | Аналіз хімічных кампанентаў, механічныя ўласцівасці (максімальная мяжа трываласці на расцяжэнне, мяжа цякучасці, падаўжэнне), тэхнічныя Уласцівасці (выпрабаванне на сплюшчванне, выпрабаванне на выгіб, выпрабаванне на ўдар, выпрабаванне на ўдар), кантроль знешніх памераў, гідрастатычнае выпрабаванне, рэнтгенаўскае выпрабаванне Сертыфікат выпрабаванняў млына: EN 10204/3.1B | |

| Вытворчая магутнасць | 1500 тон у месяц | |

| Мінімальны заказ | 5 тон на памер | |

| Цэнавы тэрмін | EXW завод, FOB, C&F і CIF | |

| Тэрмін аплаты | T/T, L/C, West Union, Money Gram і г.д. | |

| Экспартаваць у | Канада, Аўстралія, Францыя, Іспанія, Аман, Ірак, Сінгапур, В'етнам і г.д. | |

| Дастаўка | Грузавое судна або кантэйнер | |

| ІНДЭКСЫ АНТЫКАРАЗІЙНАГА СЛОЮ | ||

| Пункт | Індэксы | |

| Трываласць на адрыў (Н/см) (20℃±10℃)/(50℃±5℃) | ≥70 ≥35 | ≥100 (кагезійнае разбурэнне) ≥70 (кагезійнае разбурэнне) |

| Катоднае раз'яднанне (65℃, 48 гадзін)/(мм) | ≤15 | ≤6 |

| Катоднае раз'яднанне (найвышэйшая тэмпература, 30 дзён)/(мм) | ≤25 | ≤15 |

| Ударная глейкасць (Дж/мм) | ≥8 | / |

| Супрацьлеглы выгін (-20℃, 2,5°) | Няма расколін | / |

| Шчыльнасць (г/м3) | 0,920~0,950 | |

| MFR (190℃, 2,16 кг)/(г/10 хв) | ≥0,7 | |

| Тэмпература размякчэння па Віка (℃) | ≥90 | |

| Тэмпература далікатнасці (℃) | ≤-50 | |

| Час індукцыі акіслення (OIT) (200℃)/(мін) | ≥10 | |

| Утрыманне вільгаці (%) | ≤0,1 | |

| Трываласць на расцяжэнне (МПа) | ≥17 | |

| Падаўжэнне пры разрыве (%) | ||

ШОУ ФАБРЫЧНЫХ РАБОТНІКАЎ

ВЫСТАВА ФАБРЫЧНАЙ МАЙСТЭРНІ

ПРЭЗЕНТАЦЫЯ КАМАНДЫ КЛІЕНТА

Жанчыны нічым не саступаюць мужчынам.

Паслядоўная настойлівасць дасягнула адзінага чэмпіёна ў катэгорыі

Час можа змяніць усё, але час можа не змяніць усё, напрыклад, пачатковае сэрца

Юаньтайцы змагаюцца на розных пастах

ДАСТАЎКА І ЛАГІСТЫКА

Кампанія надае вялікае значэнне якасці прадукцыі, укладвае значныя сродкі ва ўкараненне перадавога абсталявання і спецыялістаў, а таксама робіць усё магчымае, каб задаволіць патрэбы кліентаў як у краіне, так і за мяжой.

Змест можна ўмоўна падзяліць на: хімічны склад, мяжу цякучасці, трываласць на расцяжэнне, ударатрывалыя ўласцівасці і г.д.

Адначасова кампанія можа выконваць анлайн-дэфектаскапію, адпал і іншыя працэсы тэрмічнай апрацоўкі ў адпаведнасці з патрэбамі кліента.

https://www.ytdrintl.com/

Электронная пошта:sales@ytdrgg.com

ТАА «Група па вытворчасці сталёвых труб «Юаньтайдэрун» у Цяньцзініз'яўляецца заводам сталёвых труб, сертыфікаванымEN/ASTM/ JISспецыялізуецца на вытворчасці і экспарце ўсіх відаў квадратных прастакутных труб, ацынкаваных труб, зварных труб ERW, спіральных труб, зварных труб пад флюсам, прамых швоў, бясшвовых труб, сталёвых рулонаў з каляровым пакрыццём, ацынкаваных сталёвых рулонаў і іншых сталёвых вырабаў. Дзякуючы зручнаму транспарту, кампанія знаходзіцца ў 190 кіламетрах ад Пекінскага сталічнага міжнароднага аэрапорта і ў 80 кіламетрах ад Цяньцзіня Сінгана.

WhatsApp: +8613682051821