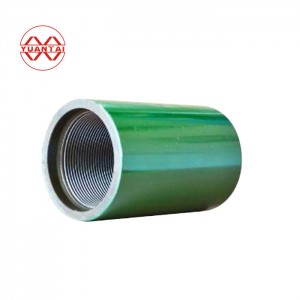

1. Yüksek kaliteli ürünler - API 5CT Boru ve muhafaza bağlantı elemanı

2. Hızlı teslimat.

3. OEM hizmetleri.

4. Kusursuz satış sonrası hizmetler.

API 5CT Boru ve Muhafaza Bağlantı Elemanı

| API 5CT Boru ve Muhafaza Bağlantı Elemanları İçin Boyut ve Özellikler | ||||

| Açıklamalar ve Boyutlar | Diş Tipi | OD* L | Ağırlık | |

| (mm) | (kilogram) | |||

| Boru Bağlantı Elemanı | 2-3/8" | NUE | 73.02*107.95 | 1.28 |

| 2-3/8" | AB | 77.80*123.82 | 1.55 | |

| 2-7/8" | NUE | 88.90*130.18 | 2.34 | |

| 2-7/8" | AB | 93.17*133.35 | 2.4 | |

| 3-1/2" | NUE | 107,95*142,88 | 3.71 | |

| 3-1/2" | AB | 114.30*146.05 | 4.1 | |

| 4" | NUE | 120.65*146.05 | 4.35 | |

| 4" | AB | 127.00*152.40 | 4.82 | |

| 4-1/2" | NUE | 132.08*155.58 | 4.89 | |

| 4-1/2" | AB | 141.30*158.75 | 6.05 | |

| Muhafaza Bağlantısı | 4-1/2" | STC | 127.00*158.75 | 5.23 |

| 4-1/2" | LTC | 127.00*177.80 | 4.15 | |

| 4-1/2" | BTC | 127.00*225.42 | 4.55 | |

| 5" | STC | 141.30*165.10 | 4.66 | |

| 5" | LTC | 141.30*196.85 | 5.75 | |

| 5" | BTC | 141.30*231.78 | 5.85 | |

| 5-1/2" | STC | 153.67*171.45 | 5.23 | |

| 5-1/2" | LTC | 153.67*203.20 | 6.42 | |

| 5-1/2" | BTC | 153.67*234.95 | 6.36 | |

| 6-5/8" | STC | 187.71*184.15 | 9.12 | |

| 6-5/8" | LTC | 187.71*222.25 | 11.34 | |

| 6-5/8" | BTC | 187.71*244.48 | 11.01 | |

| 7" | STC | 194.46*184.15 | 8.39 | |

| 7" | LTC | 194.46*228.60 | 10.83 | |

| 7" | BTC | 194.46*254.00 | 10.54 | |

| 7-5/8" | STC | 215,90*190,50 | 12.3 | |

| 7-5/8" | LTC | 215,90*234,95 | 15.63 | |

| 7-5/8" | BTC | 215.90*263.52 | 15.82 | |

| 8-5/8" | STC | 244.48*196.85 | 16.23 | |

| 8-5/8" | LTC | 244.48*254.00 | 21.67 | |

| 8-5/8" | BTC | 244.48*269.88 | 20.86 | |

| 9-5/8" | STC | 269.88*196.85 | 18.03 | |

| 9-5/8" | LTC | 269.88*266.70 | 25.45 | |

| 9-5/8" | BTC | 269.88*269.88 | 23.16 | |

| 10-3/4" | STC | 298.45*203.20 | 20.78 | |

| 10-3/4" | BTC | 298.45*269.88 | 25.74 | |

| 11-3/4" | STC | 323.85*203.20 | 22.64 | |

| 11-3/4" | BTC | 323.85*269.88 | 28.03 | |

| 13-3/8" | STC | 365.12*203.20 | 25.66 | |

| 13-3/8" | BTC | 365.12*269.88 | 31.77 | |

Notlar:

Sınıf: J55, K55, N80Q, N801, L80, P110.

Müşterilerin ihtiyaçlarına göre.

1. Yüksek kaliteli ürünler - API 5CT Boru ve muhafaza bağlantı elemanı

2. Hızlı teslimat.

3. OEM hizmetleri.

4. Kusursuz satış sonrası hizmetler.

FABRİKA İŞÇİSİ GÖSTERİSİ

FABRİKA ATÖLYESİ GÖSTERİSİ

MÜŞTERİ EKİBİ SUNUMU

Kadınlar erkeklerden aşağı değildir.

Tutarlı azim, bir kategoride tek bir şampiyonun ortaya çıkmasını sağladı.

Zaman her şeyi değiştirebilir, ama zaman her şeyi değiştirmeyebilir de; örneğin, ilk kalp atışı gibi.

Yuantai halkı çeşitli mevzilerde savaşıyor.

TESLİMAT VE LOJİSTİK

Şirket, ürün kalitesine büyük önem vermekte, gelişmiş ekipman ve profesyonellerin istihdamına büyük yatırımlar yapmakta ve yurt içi ve yurt dışındaki müşterilerinin ihtiyaçlarını karşılamak için elinden gelenin en iyisini yapmaktadır.

İçerik kabaca şu başlıklara ayrılabilir: kimyasal bileşim, akma dayanımı, çekme dayanımı, darbe özelliği vb.

Aynı zamanda şirket, müşteri ihtiyaçlarına göre çevrimiçi hata tespiti, tavlama ve diğer ısıl işlem süreçlerini de gerçekleştirebilir.

https://www.ytdrintl.com/

E-posta:sales@ytdrgg.com

Tianjin YuantaiDerun Çelik Boru İmalat Grubu A.Ş.sertifikalı bir çelik boru fabrikasıdır.EN/ASTM/ JISHer türlü kare ve dikdörtgen boru, galvanizli boru, ERW kaynaklı boru, spiral boru, tozaltı kaynaklı boru, düz dikişli boru, dikişsiz boru, renkli kaplamalı çelik rulo, galvanizli çelik rulo ve diğer çelik ürünlerinin üretim ve ihracatında uzmanlaşmıştır. Ulaşım açısından elverişli bir konumda olup, Pekin Başkent Uluslararası Havalimanı'na 190 kilometre ve Tianjin Xingang'a 80 kilometre uzaklıktadır.

WhatsApp:+8613682051821

Mesajınızı bize gönderin:

-

API 5L ASTM A53 ASTM A106 Dikişsiz Karbon Çelik Boru

-

STBA20-STBA26 Kalite Dikişsiz Çelik Boru Üreticileri

-

Siyah Kaynaklı Çelik Borular Çin Fabrikası hat borusu üreticisi

-

Smls Çelik Boru Hattı API 5L X42/X46/X60/X70 Boru Hattı

-

API 5L yağ tüpü, yuvarlak çelik boru, dairesel içi boş kesit.

-

API 5CT SMLS KILIF BORUSU K55-N80