1. Táirgí ardchaighdeáin - Feadánra agus Cúpláil Cásála API 5CT

2. Seachadadh tapa.

3. Seirbhísí OEM.

4. Seirbhísí foirfe tar éis díola.

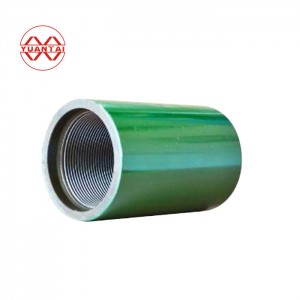

Cúpláil Feadánra agus Cásála API 5CT

| Méid agus Sonraíochtaí le haghaidh Feadánra API 5CT agus Cúplála Cásála | ||||

| Tuairiscí agus Méid | Cineál Snáithe | OD* L | Meáchan | |

| (mm) | (kg) | |||

| Cúpláil Feadánra | 2-3/8" | NUE | 73.02*107.95 | 1.28 |

| 2-3/8" | EUE | 77.80*123.82 | 1.55 | |

| 2-7/8" | NUE | 88.90*130.18 | 2.34 | |

| 2-7/8" | EUE | 93.17*133.35 | 2.4 | |

| 3-1/2" | NUE | 107.95*142.88 | 3.71 | |

| 3-1/2" | EUE | 114.30*146.05 | 4.1 | |

| 4" | NUE | 120.65*146.05 | 4.35 | |

| 4" | EUE | 127.00*152.40 | 4.82 | |

| 4-1/2" | NUE | 132.08*155.58 | 4.89 | |

| 4-1/2" | EUE | 141.30*158.75 | 6.05 | |

| Cúpláil Cásála | 4-1/2" | STC | 127.00*158.75 | 5.23 |

| 4-1/2" | LTC | 127.00*177.80 | 4.15 | |

| 4-1/2" | BTC | 127.00*225.42 | 4.55 | |

| 5" | STC | 141.30*165.10 | 4.66 | |

| 5" | LTC | 141.30*196.85 | 5.75 | |

| 5" | BTC | 141.30*231.78 | 5.85 | |

| 5-1/2" | STC | 153.67*171.45 | 5.23 | |

| 5-1/2" | LTC | 153.67*203.20 | 6.42 | |

| 5-1/2" | BTC | 153.67*234.95 | 6.36 | |

| 6-5/8" | STC | 187.71*184.15 | 9.12 | |

| 6-5/8" | LTC | 187.71*222.25 | 11.34 | |

| 6-5/8" | BTC | 187.71*244.48 | 11.01 | |

| 7" | STC | 194.46*184.15 | 8.39 | |

| 7" | LTC | 194.46*228.60 | 10.83 | |

| 7" | BTC | 194.46*254.00 | 10.54 | |

| 7-5/8" | STC | 215.90*190.50 | 12.3 | |

| 7-5/8" | LTC | 215.90*234.95 | 15.63 | |

| 7-5/8" | BTC | 215.90*263.52 | 15.82 | |

| 8-5/8" | STC | 244.48*196.85 | 16.23 | |

| 8-5/8" | LTC | 244.48*254.00 | 21.67 | |

| 8-5/8" | BTC | 244.48*269.88 | 20.86 | |

| 9-5/8" | STC | 269.88*196.85 | 18.03 | |

| 9-5/8" | LTC | 269.88*266.70 | 25.45 | |

| 9-5/8" | BTC | 269.88*269.88 | 23.16 | |

| 10-3/4" | STC | 298.45*203.20 | 20.78 | |

| 10-3/4" | BTC | 298.45*269.88 | 25.74 | |

| 11-3/4" | STC | 323.85*203.20 | 22.64 | |

| 11-3/4" | BTC | 323.85*269.88 | 28.03 | |

| 13-3/8" | STC | 365.12*203.20 | 25.66 | |

| 13-3/8" | BTC | 365.12*269.88 | 31.77 | |

Nótaí:

Grád: J55, K55, N80Q, N801, L80, P110.

De réir mar is gá do chliaint.

1. Táirgí ardchaighdeáin - Feadánra agus Cúpláil Cásála API 5CT

2. Seachadadh tapa.

3. Seirbhísí OEM.

4. Seirbhísí foirfe tar éis díola.

SEÓ OIBRÍ MONARCHA

SEÓ CEARDLANN MONARCHA

CUR I LÁTHAIR Ó FHOIREANN CUSTAIMÉIRÍ

Níl mná níos lú ná fir.

Tá buaiteoir aonair i gcatagóir bainte amach ag buanseasmhacht leanúnach

Is féidir le ham gach rud a athrú, ach ní fhéadfaidh am gach rud a athrú, mar shampla, an croí tosaigh

Daoine Yuantai ag troid i bpoist éagsúla

SEACHADADH AGUS LÓISTÍOCHT

Cuireann an chuideachta tábhacht mhór le cáilíocht na dtáirgí, infheistíonn sí go mór i dtrealamh agus i ngairmithe chun cinn a thabhairt isteach, agus déanann sí a dícheall chun freastal ar riachtanais na gcustaiméirí sa bhaile agus thar lear.

Is féidir an t-ábhar a roinnt go garbh i: comhdhéanamh ceimiceach, neart toraidh, neart teanntachta, maoin tionchair, srl.

Ag an am céanna, is féidir leis an gcuideachta braiteadh lochtanna agus annealing ar líne agus próisis chóireála teasa eile a dhéanamh de réir riachtanais an chustaiméara.

https://www.ytdrintl.com/

Ríomhphost:sales@ytdrgg.com

Grúpa Déantúsaíochta Feadán Cruach Tianjin YuantaiDerun Co., Ltd.an bhfuil monarcha píopaí cruach deimhnithe agEN/ASTM/ JISag speisialú i dtáirgeadh agus in onnmhairiú gach cineál píopa dronuilleogach cearnach, píopa ghalbhánuithe, píopa táthaithe ERW, píopa bíseach, píopa táthaithe stua tumtha, píopa uaim dhíreach, píopa gan uaim, corna cruach brataithe le dath, corna cruach ghalbhánuithe agus táirgí cruach eile. Le hiompar áisiúil, tá sé 190 ciliméadar ar shiúl ó Aerfort Idirnáisiúnta Caipitil Béising agus 80 ciliméadar ar shiúl ó Tianjin Xingang.

Whatsapp: +8613682051821

Seol do theachtaireacht chugainn:

-

Píopa Cruach Carbóin Gan uaim API 5L ASTM A53 ASTM A106

-

Monaróirí Píopaí Cruach Gan uaim Grád STBA20-STBA26

-

Píopaí Cruach Táthaithe Dubha Monarcha Síneach monaróir píopa líne

-

Píopa Líne Cruach Smls Api 5L X42/X46/X60/X70 Líne Píopa

-

Píopa cruach cruinn API 5L feadán ola alt log ciorclach

-

Píopa Cásála API 5CT SMLS K55-N80