Yintoni umbhobho wentsimbi osele ufakwe i-galvanized?

Njengoko sonke besisazi, iityhubhu zentsimbi ezifakwe ngesinyithi ezishushuluhlobo lombhobho wentsimbi owenziweyo kwaye ugqunywe nge-galvanized emva. Ngoko ke ikwabizwa ngokuba ziityhubhu zentsimbi ezigqunywe nge-galvanized emva kwe-galvanized.

Kutheni umbhobho wentsimbi egalelweyo okanye ityhubhu yentsimbi egalelweyo iyeyona ndlela idumileyo yokwenziwa kweetyhubhu zentsimbi egalelweyo? Isizathu kukuba izixhobo ezifunekayo ekwenzeni azibizi kakhulu kwaye inkqubo inokwandiswa kakhulu. Ngokungafaniyo neepayipi zentsimbi ezigalelweyo ezishushu, amaphepha entsimbi agalelweyo afuna ixesha elifutshane lokucubungula, nto leyo ebangela umaleko we-iron-zinc alloy obhityileyo kunye nomaleko we-zinc ococekileyo otyebileyo.

Nangona kunjalo, ekubeni ubushushu obuveliswa ngexesha lokuweldaimibhobho yentsimbi eyenziwe nge-galvanizedXa isusa i-zinc coating kumphezulu wentsimbi, intsimbi eveziweyo kufuneka ivalwe kwakhona kusetyenziswa inkqubo yokutshiza ngobushushu be-zinc. Oku kuthetha ukuba ii-welds eludongeni lwangaphakathi lombhobho aziyi kugalelwa. Iipropati ze-anode ezizincamayo ze-zinc ziqinisekisa ukuba ii-welds zangaphakathi eziveziweyo aziyi kubeka emngciphekweni ukuxhathisa ukugqwala kwemveliso okanye ubomi bayo benkonzo.

Ukufaka i-galvanizing ngaphambi kokusebenzisa i-galvanizing kuqala kuquka ukufaka amaphepha entsimbi kwi-zinc enyibilikisiweyo ukuze igqunywe. Emva koko, amaphepha ayanqunyulwa ngokobukhulu aze aphinde aguqulwe. Ngexesha lenkqubo yokufakela i-galvanizing ngaphambi kokusebenzisa i-galvanizing, ubukhulu obuthile be-zinc coating bufakwa kwi-sheet yonke. Umzekelo, intsimbi ye-Z275 egqunywe ngaphambi kokusebenzisa i-galvanizing ine-zinc coating ye-275 grams nge-square meter.

Xa ithelekiswa nentsimbi egqunywe nge-hot-dip, intsimbi egqunywe nge-pre-galvanized inikezela ngenzuzo enkulu kwinkangeleko yayo egqwesileyo. Ukongeza, idla ngokuba nexabiso eliphantsi. Izinto ezigqunywe nge-pre-galvanized zisetyenziswa kakhulu kwiimveliso ezahlukeneyo, kubandakanya ii-conduits, ii-flanges, kunye neetshaneli eziveziweyo.

Yintoni umahluko phakathi kwe-pre-intsimbi egalelwe ngesinyithiimibhobhokunye nentsimbi egayiweyoimibhobho?

Ukufakwa kwe-galvanization eshushu kubandakanya ukuntywilisela yonke intsimbi okanye isakhiwo sesinyithi kwi-zinc vet enyibilikisiweyo, nto leyo ebangela ukuba kubekho uqweqwe oluqhubekayo phezu komphezulu. Ukufakwa kwe-galvanization ngaphambi kokusetyenziswa kwenziwa kwinqanaba lokuqala, ngaphambi kokuba amaphepha anqunyulwe abe bukhulu kunye neziqwenga, ukuze imiphetho esikiweyo ingagqunywa.

Iqela leTianjin Yuantai Derunivelisa imibhobho yentsimbi egalelwe kwangaphambili ngokuhambelana ngokupheleleyo nemigangatho yamazwe ngamazwe efana ne-ASTM, i-JIS, i-BS, i-DIN, i-EN, kunye ne-GB. Iintlobo zecandelo ezikhoyo ziquka i-round, square, rectangular, oval, kunye nezinye iimilo ezikhethekileyo ezenzelwe wena ukuhlangabezana neemfuno ezahlukeneyo zesakhiwo nezemizi-mveliso.

Iityhubhu ezingxande ezifakwe i-galvanized ziyindlela eqhelekileyo kushishino lwesakhelo socingo, kwaye zisetyenziswa ngabakhi, abakhi bezakhiwo kunye neenjineli. Abayili bezakhiwo kunye nabayili bezakhiwo basebenzise ucingo lwentsimbi ukuyila iindawo ezahlukeneyo zokuhlala, imigangatho yokukhanyisa kunye nemifanekiso eqingqiweyo yokuhombisa yeendawo ezitratweni, iipaki, iindawo zokumisa iibhasi kunye neebhasi ezilula, iindawo zokuthenga, iivenkile ezinkulu, amabala emidlalo, izakhiwo zeeofisi, iindawo zokupaka kunye nezinye izibonelelo. Iipali zocingo zentsimbi ziyilwe ngononophelo ngemigca ecocekileyo, ukuqina kwesakhiwo kunye nokulula kokufakelwa. Ezi cingo zifumaneka ngobude nobubanzi obahlukeneyo kwiimeko ezahlukeneyo.

Intoni'yiUkusetyenziswa kombhobho wentsimbi osele ufakwe i-galvanizeds?

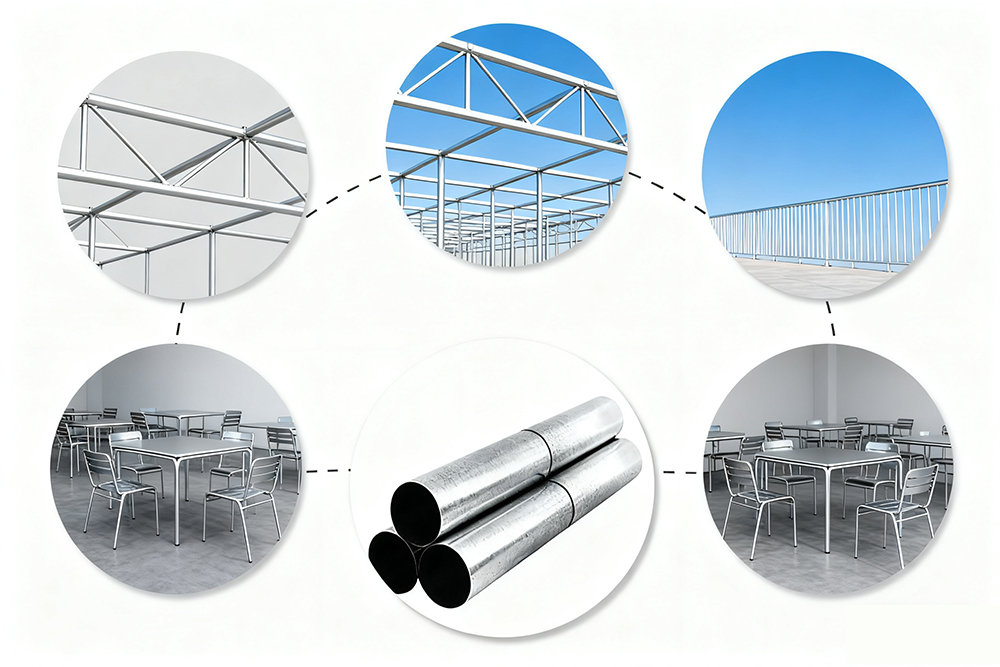

Iipayipi zentsimbi ezifakwe i-galvanized zisetyenziswa kwiindawo ezininzi, ezifana nesakhiwo sentsimbi, isakhiwo sokwakha, ireyili yokukhusela, ifenitshala yesinyithi njl. Iimveliso zethu zithunyelwa kumazwe amalunga nama-45 kwihlabathi liphela, kwaye sifumene udumo olukhulu kubathengi bethu ngomgangatho nenkonzo esiyinikezelayo.

Ixesha leposi: Novemba-07-2025