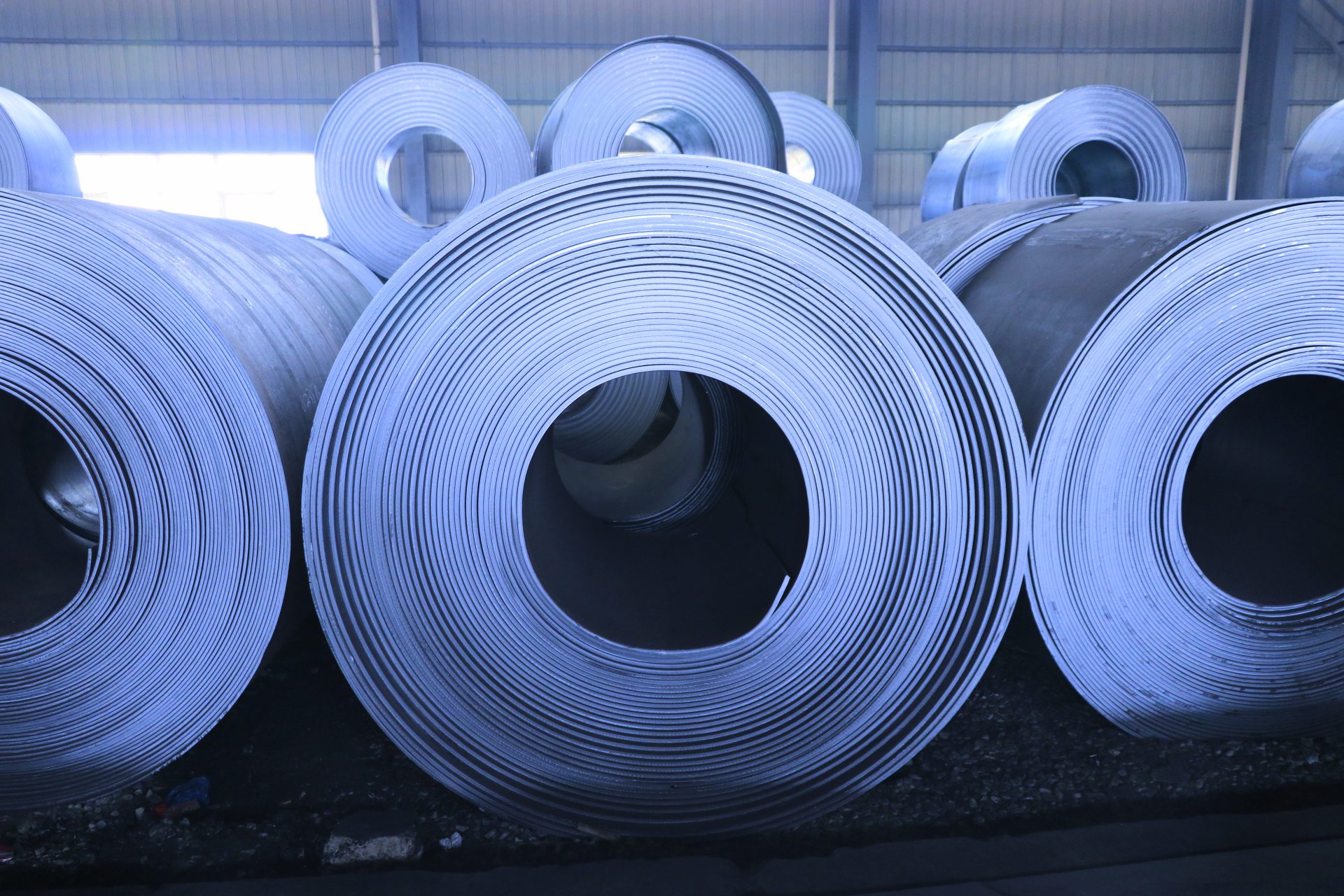

China Wholesale for Stainless Coil to Slovenia Importers Detail:

Product detail pictures:

Related Product Guide:

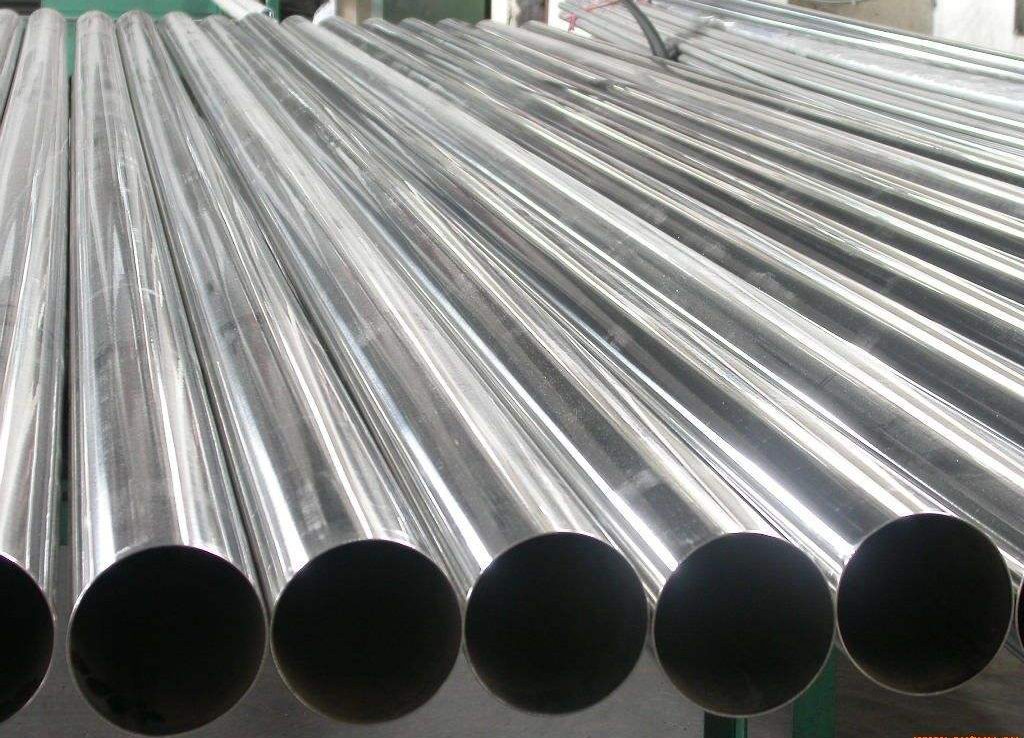

Metal or Plastic Pipes – Which Are Best?

Buying Stainless Steel Coils

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for China Wholesale for Stainless Coil to Slovenia Importers, The product will supply to all over the world, such as: Netherlands, Orlando, Iraq, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821

Send your message to us:

-

Wholesale Dealers of Strip steel for Manchester Factories

-

Wholesale price for Galvanized tube for Slovenia Manufacturer

-

Factory supplied Strip steel for Sierra Leone Manufacturers

-

OEM/ODM Supplier for Stainless steel pipe for Netherlands Importers

-

Best Price for Steel strip for Hongkong Factory

-

Bottom price for Strip Stainless strip to Senegal Factories