Factory wholesale Spiral welded steel pipe for Nicaragua Manufacturers Detail:

Product detail pictures:

Related Product Guide:

Find The Attractive Stainless Steel

What is the difference between Pipe and Tube?

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Factory wholesale Spiral welded steel pipe for Nicaragua Manufacturers, The product will supply to all over the world, such as: kazakhstan, Bahrain, Sri Lanka, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, make sure you do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821

Send your message to us:

-

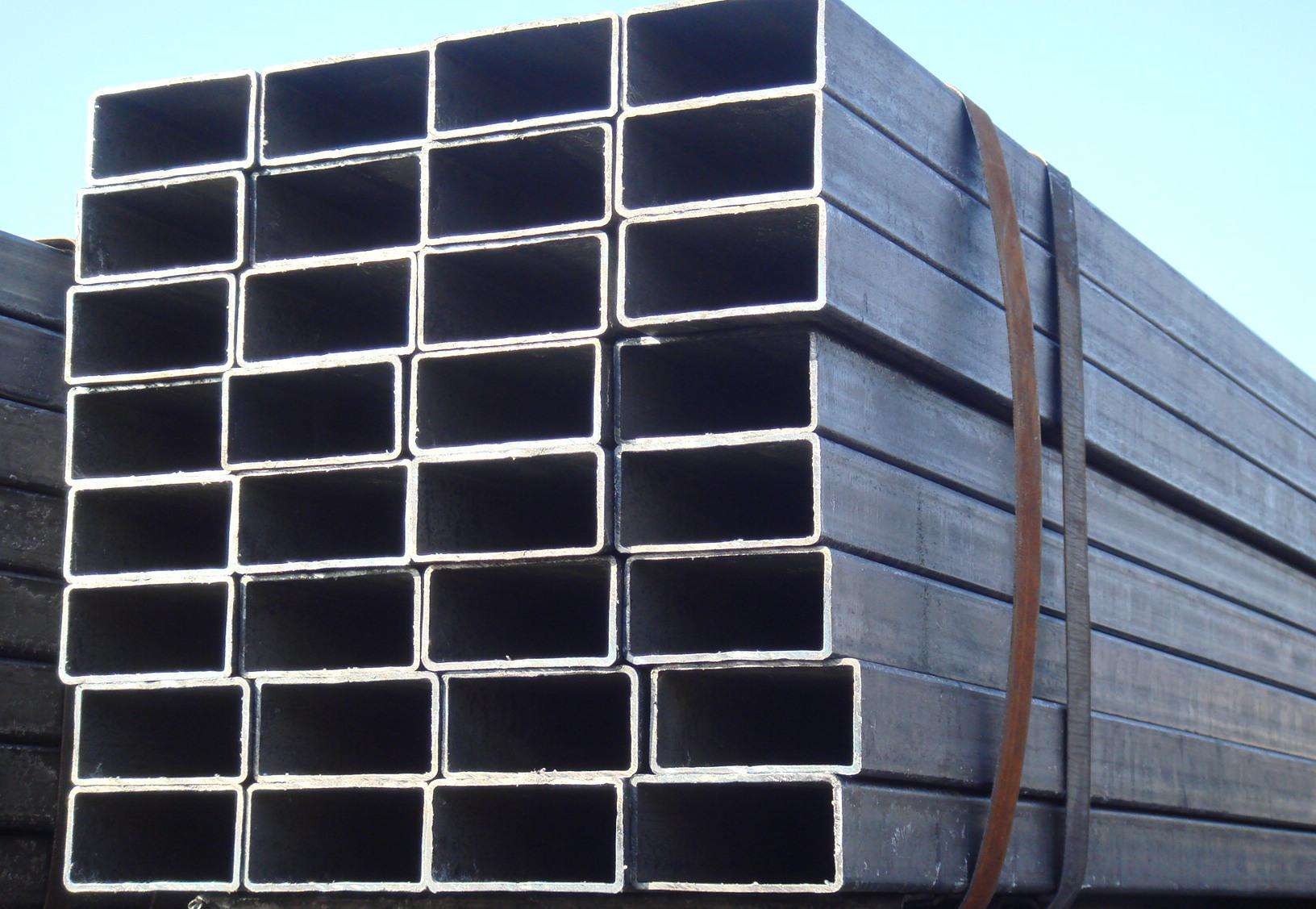

Hot-selling attractive price rectangular tube for Colombia Factory

-

China Professional Supplier API 5CT SMLS casing K55-N80 for Swiss Factories

-

China Manufacturer for rectangular pipe for Ireland Factory

-

Chinese Professional Strip steel to Argentina Importers

-

Cheapest Price Strip steel for Romania Factory

-

8 Years Manufacturer rectangular tube for Moldova Importers