H beam, also known as universal columns or I-beams, are fundamental structural components in modern construction and engineering. Their cross-section resembles the letter ‘H’ or ‘I’. This unique shape delivers an exceptional strength-to-weight ratio, which makes them indispensable for carrying heavy loads.

This comprehensive guide will explore the world of standard European H beams. We will delve into the specifications, applications, and key differences of the primary profiles: HEA, HEB, and HEM sections.

What Are H Beams?

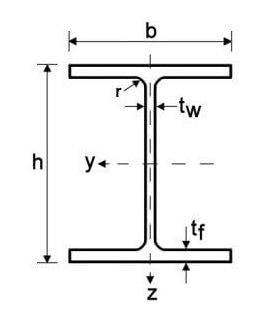

Manufacturers roll H beams into structural steel members with a cross-section that resembles the letter “H.” They consist of two parallel flanges connected by a vertical web. This design efficiently distributes load and resists bending forces in multiple directions. The hot-rolling process manufactures Carbon Steel H beam, yielding consistent profiles with excellent mechanical properties.

Key Advantages of H Beam Structures

High Load-Bearing Capacity: The H-shape distributes steel efficiently, positioning most material far from its center. This maximizes key strength properties (moment of inertia and section modulus), enabling it to support heavy loads.

Versatility: Suitable for columns, beams, purlins, and various composite structures.

Cost-Effectiveness: Reduced material usage for achieved strength leads to economic designs

Ease of Fabrication: Simple to weld, bolt, and modify for specific project requirements.

Proven Reliability: Standardized dimensions and predictable performance under stress

Deep Dive: European Standard H Beams – HEA, HEB, HEM

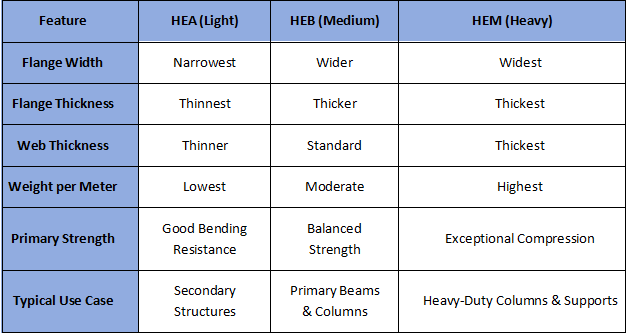

European standard H beams are categorized primarily by their dimensional proportions and weight per meter. The most common series are:

HEA Beams (Light Series)

HEA beams are characterized by relatively narrower and thinner flanges compared to their height. They are often referred to as “light series” or “IPE-like” light h-beams but with wider flanges.

Typical Applications: Secondary structural elements, purlins, lighter columns, and applications where moderate loads are expected.

Key Feature: More economical in weight for given height, favoring bending resistance about the major axis.

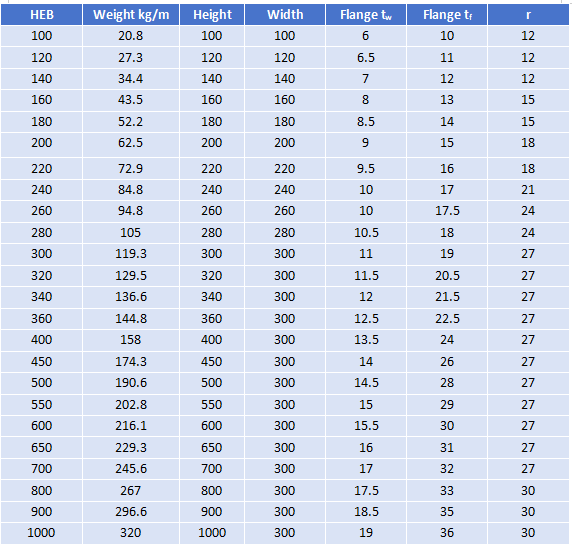

HEB Beams (Medium/Standard Series)

HEB beams represent the standard or medium series-medium h-beam, featuring wider and thicker flanges than HEA sections of the same nominal height.

Typical Applications: Primary load-bearing columns and beams in buildings, industrial frames, and bridges. This is the most commonly used series for general construction.

Key Feature: Excellent all-round performance, offering strong resistance to both bending and compression, making them ideal for columns.

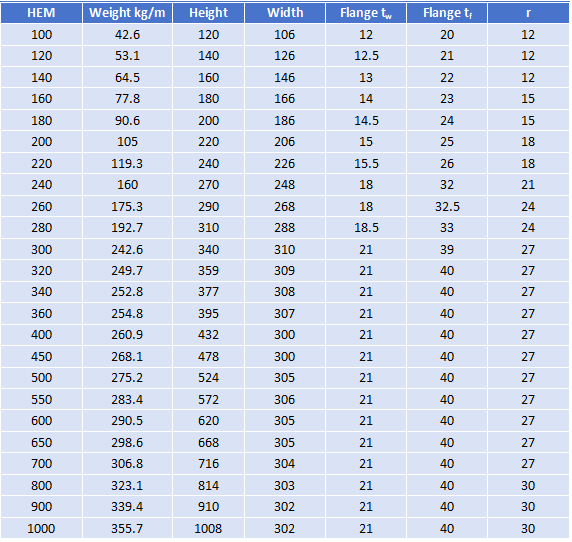

HEM Beams (Heavy Series)

HEM beams are the heavy and robust members of the family.HEM Beams are heavy h-beams and high load h-beam. They have the widest and thickest flanges among the three, with a web thickness also significantly increased.

Typical Applications: Heavy-duty columns in multi-story buildings, foundational support for heavy machinery, civil engineering projects (like piers), and any structure subjected to extremely high loads.

Key Feature: Superior axial load capacity and stiffness. Their substantial flange width also provides great stability against buckling.

Critical Considerations for Selection

Choosing between HEA, HEB, and HEM beams requires careful engineering evaluation. Key factors include:

Load Type and Magnitude: Axial (compressive) loads favor HEB or HEM sections, while pure bending scenarios might utilize HEA or HEB.

Span Length: Longer spans often require deeper sections for adequate bending resistance.

Stability Requirements: Resistance to buckling (both local and global) is enhanced by thicker flanges and webs found in HEB and HEM sections.

Connection Details: Flange width and thickness impact welding and bolting connections.

Architectural Constraints: Available space may limit the depth or width of the section.

Cost and Material Optimization: The goal is to meet all safety and performance criteria with the most economical section, minimizing total steel weight.

Common Applications in Industry

Building Framing: Skeleton of commercial, industrial, and residential high-rises.

Bridge Construction: Girders and supporting substructures.

Industrial Mezzanines and Platforms: Support frames for elevated floors.

Heavy Machinery Bases: Stable foundations for presses, turbines, and large equipment.

Warehouse Racking Systems: Upright frames for high-density storage.

Truck and Trailer Chassis: Main longitudinal frame members.

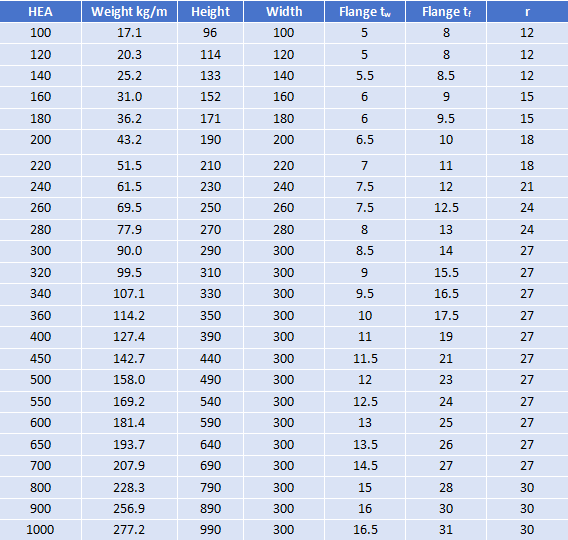

HEA,HEB,HEM Chart

Conclusion

Understanding the nuanced differences between HEA, HEB, and HEM beam sections is crucial for efficient and safe structural design and steel structure material. HEA beams offer a lightweight solution for secondary elements. HEB beams serve as the versatile workhorse for most primary structural applications. HEM beams provide the necessary robustness for the most demanding heavy-load scenarios.

Always consult relevant design codes and work with qualified structural engineers to select the appropriate H beam profile for your specific project. The right choice ensures structural integrity, material efficiency, and project success.

Post time: Jan-06-2026