Why Material Choice Matters

Material selection is a critical factor in ensuring structural safety. It not only determines the immediate strength of a component but also has a profound impact on its durability and long-term performance. Even when two U Channels share the same dimensions, their actual behavior under load can vary significantly. This variation is primarily influenced by the steel grade used and the quality of the surface finish.

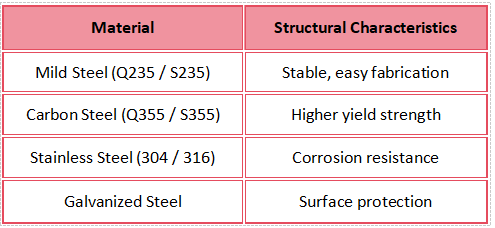

Common Materials Used for U Channel Steel

Mild steel is commonly used in general construction due to its ease of fabrication and adequate strength for standard structural applications. In contrast, carbon steel is preferred for systems subjected to higher loads, offering greater strength and durability to withstand more demanding structural requirements

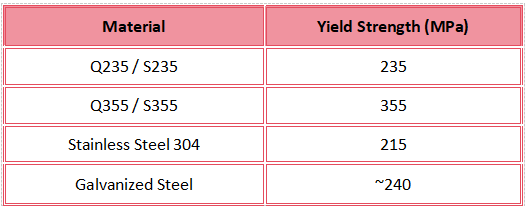

Yield strength is a key factor in determining the allowable stress of a structural component. Design codes and engineering standards provide clear guidelines on how these values should be applied, ensuring that structures remain safe and reliable under expected loads.

Let’s see the Example: Q235 vs Q355 U Channel

Although U Channels made from Q235 and Q355 may share the same dimensions, their load-bearing capacities differ significantly. Q355 has a higher allowable stress, which often enables the use of smaller sections to carry the same load. This demonstrates how material selection directly impacts structural efficiency and performance.

Corrosion Considerations

Structures exposed to outdoor conditions face moisture, temperature changes, and other environmental factors. In such cases, galvanized or stainless steel provides superior durability and corrosion resistance. For indoor, dry environments, standard carbon steel is often sufficient. Choosing the appropriate material not only enhances structural longevity but also minimizes maintenance requirements.

Post time: Dec-18-2025