De réir Chaighdeán API SPEC 5CT1988 den chéad eagrán de chuid Institiúid Peitriliam Mheiriceá, is féidir grád cruach phíobáin chásála ola API 5CT a roinnt ina dheich gcineál, lena n-áirítear H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 agus Q-125. Soláthraímid an phíobán cásála & Feadánra Cásála API 5CT K55 in éineacht le snáithe agus cúpláil, nó cuirimid ár dtáirge ar fáil de réir na bhfoirmeacha seo a leanas le haghaidh rogha.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Sonraíochtaí Feadánra Cásála API 5CT K55

| Sonraíochtaí Feadánra Cásála API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Caighdeáin | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Raon Fad | 3-12M nó de réir riachtanas an chliaint | |

| Grád Cruach (Gráid Chásála, Gráid Feadánra) | Gr.A, Gr.B, Gr.C, X42, X52, X60, X65, X70 | |

| Cineál Snáithe Scriú | Foirceann snáithithe neamh-trína chéile (NUE), foirceann snáithithe seachtrach trína chéile (EUE) | |

| Speisialtachtaí |

| |

| Críochnú Deiridh | Foircinn Sheachtracha Suaithe (EUE), Comhpháirteach Sruthlaithe, PH6 (agus naisc choibhéiseacha), Comhpháirteach Comhtháite (IJ) | |

Riachtanas Teanntachta & Cruas Feadánra Cásála API 5CT K55

| Grúpa | Grád | Cineál | Síneadh iomlán faoi ualach % | Neart toradh MPa | Neart teanntachta íosmhéid MPa | Cruas uasmhéid. | Tiús balla sonraithe mm | Athrú cruas incheadaithe b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| nóim. | uasmhéid | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 go 19.04 19.05 go 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 go 19.04 19.05 go 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 go 19.04 19.05 go 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | C125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 go 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aI gcás díospóide, úsáidfear tástáil chruas saotharlainne Rockwell C mar mhodh moltóra. bNíl aon teorainneacha cruas sonraithe, ach tá an t-athrú uasta srianta de réir 7.8 agus 7.9 de Shonraíocht API 5CT. | ||||||||||

Toisí Feadánra Cásála K55

| Méideanna Cásála Píopaí, Méideanna Cásála Réimse Ola & Méideanna Drift Cásála | |

|---|---|

| Trastomhas Seachtrach (Méideanna Píopa Cásála) | 4 1/2"-20", (114.3-508mm) |

| Méideanna Cásála Caighdeánacha | 4 1/2"-20", (114.3-508mm) |

| Cineál Snáithe | Cásáil snáithe taca, Cásáil snáithe fada cruinn, Cásáil snáithe gearr cruinn |

| Feidhm | Is féidir leis an bpíopa feadánra a chosaint. |

Feadán Ola do Thionscail Peitriliam agus Gáis Nádúrtha

| Ainm na bPíopaí | Sonraíocht | Grád Cruach | Caighdeánach | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Píopa Cásála Peitriliam | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80P110. | Sonraíocht API 5CT (8) |

| Feadánra Peitriliam | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Sonraíocht API 5CT (8) |

| Cúpláil | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Sonraíocht API 5CT (8) |

Gnéithe Feadánra Cásála API 5CT K55

- Cuirtear Feadánra Cásála API 5CT K55 ar fáil le raon faid saor ó 8m go 13m bunaithe ar an norm SY/T6194-96. Mar sin féin, tá sé ar fáil freisin nach lú ná 6m ar fhad agus níor cheart go mbeadh a chainníocht níos mó ná 20%.

- Ní cheadaítear do dhífhoirmíochtaí a luaitear thuas teacht ar dhromchla seachtrach cúplála Feadánra Cásála API 5CT K55.

- Ní ghlactar le haon dífhoirmiú amhail líne gruaige, scaradh, roic, scoilt nó screamh ar dhromchlaí istigh agus seachtracha an táirge. Ba chóir na lochtanna seo go léir a bhaint go hiomlán agus ní mór don doimhneacht bhainte a bheith níos mó ná 12.5% de thiús ainmniúil an bhalla.

- Ba chóir go mbeadh dromchla snáithe an chúplála agus Feadánra Cásála API 5CT K55 réidh gan aon bhorradh, cuimilt ná lochtanna eile a d’fhéadfadh tionchar diúltach a imirt ar an neart agus ar an nasc dlúth.

Tá sé tábhachtach d'oibreoirí ola agus gáis a gclúdaigh tobair táirgthe a chosaint ar chreimeadh le cosaint chatóideach agus is chun ola agus gáis a aistriú a fheidhmíonn Feadánra Réimse Ola API 5CT go príomha.

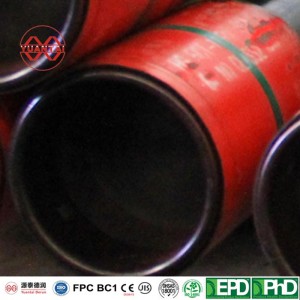

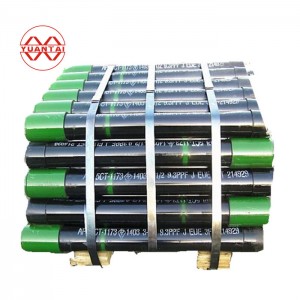

Cód Dath Cruach Feadánra Cásála API 5CT Grád K55

| Ainm | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Cásáil | banda glas geal | dhá bhanda glasa geala | banda dearg geal | banda geal dearg + banda glas | banda dearg + banda donn | banda bán geal |

| Cúpláil | cúpláil ghlas iomlán + banda bán | cúpláil ghlas iomlán | cúpláil dhearg iomlán | cúpláil dhearg iomlán + banda glas | cúpláil dhearg iomlán + banda donn | cúpláil bán iomlán |

Sonraíochtaí feadánra cásála ISO/API/API 5CT K55

| Códa | Dia Seachtrach | Meáchan ainmniúil (le snáithe agus cúpláil) b,c | Tiús Balla | Cineál próiseála deiridh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Punt/troigh | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Píopa Casála API 5CT Codea | Trastomhas seachtrach píopa cásála API 5CT | Píopa cásála API 5CT Meáchan ainmniúil (le snáithe agus cúpláil) b,c | Tiús bhalla píopa cásála API 5CT | Píopa cásála API 5CT Cineál próiseála deiridh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Punt/troigh | K55 | C95 | 1, C | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Snáithe gearr bhabhta, L-Snáithe fada bhabhta, B-Snáithe taca | ||||||||||||

| a. Úsáidtear an cód le haghaidh tagairt ordaithe. | ||||||||||||

| b. Ní thaispeántar meáchan ainmniúil an chásála snáithithe agus cúpláilte (colún 2) ach mar thagairt. | ||||||||||||

| c. Tá cruach cróimiam mhartensíteach (L80 9Cr agus 13Cr) difriúil ó chruach carbóin ó thaobh dlúis de. Ní luach cruinn é an meáchan a thaispeántar de chruach cróimiam mhartensíteach. Is féidir an fachtóir ceartúcháin maise 0.989 a úsáid. | ||||||||||||

| d. Ba chóir cásáil ghrád cruach C90, T95 agus Q125 a sholáthar de réir na sonraíochta, an mheáchain agus thiús an bhalla atá liostaithe sa tábla nó san ordú thuas. | ||||||||||||

Comhdhéanamh Ceimiceach API 5CT K55

| Grúpa | Grád | Cineál | C | Mn | Mo | Cr | Ní uasmhéid. | Uasmhéid Cu. | Uasmhéid P. | Uasmhéid S. | Si uasmhéid. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| nóim. | uasmhéid | nóim. | uasmhéid | nóim. | uasmhéid | nóim. | uasmhéid | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 lá | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | C125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Féadfar cion carbóin L80 a mhéadú suas le 0.50% ar a mhéad má dhéantar an táirge a mhúchadh le hola. b Níl aon lamháltas íosta ag baint le hábhar moluibdín Grád C90 Cineál 1 má tá tiús an bhalla níos lú ná 17.78 mm. Féadfar cion carbóin R95 a mhéadú suas le 0.55% ar a mhéad má dhéantar an táirge a mhúchadh le hola. Féadfar cion moluibdín T95 Cineál 1 a laghdú go 0.15% ar a laghad má tá tiús an bhalla níos lú ná 17.78 mm. e I gcás EW Grád P110, is é 0.020% uasmhéid an cion fosfair agus 0.010% uasmhéid an cion sulfair. NL = gan teorainn. Ba cheart na heilimintí a thaispeántar a thuairisciú in anailís táirge. | |||||||||||||||

Airíonna Meicniúla API 5CT k55 Gr.

| Caighdeán Cásála API 5CT | Cineál | Neart Teanntachta Cásála API 5CT MPa | Neart Toradh Cásála API 5CT MPa | Cruas Cásála API 5CT Uasmhéid. |

|---|---|---|---|---|

| Sonraíochtaí API 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Cuireann an chuideachta tábhacht mhór le cáilíocht na dtáirgí, infheistíonn sí go mór i dtrealamh agus i ngairmithe chun cinn a thabhairt isteach, agus déanann sí a dícheall chun freastal ar riachtanais na gcustaiméirí sa bhaile agus thar lear.

Is féidir an t-ábhar a roinnt go garbh i: comhdhéanamh ceimiceach, neart toraidh, neart teanntachta, maoin tionchair, srl.

Ag an am céanna, is féidir leis an gcuideachta braiteadh lochtanna agus annealing ar líne agus próisis chóireála teasa eile a dhéanamh de réir riachtanais an chustaiméara.

https://www.ytdrintl.com/

Ríomhphost:sales@ytdrgg.com

Grúpa Déantúsaíochta Feadán Cruach Tianjin YuantaiDerun Co., Ltd.an bhfuil monarcha píopaí cruach deimhnithe agEN/ASTM/ JISag speisialú i dtáirgeadh agus in onnmhairiú gach cineál píopa dronuilleogach cearnach, píopa ghalbhánuithe, píopa táthaithe ERW, píopa bíseach, píopa táthaithe stua tumtha, píopa uaim dhíreach, píopa gan uaim, corna cruach brataithe le dath, corna cruach ghalbhánuithe agus táirgí cruach eile. Le hiompar áisiúil, tá sé 190 ciliméadar ar shiúl ó Aerfort Idirnáisiúnta Caipitil Béising agus 80 ciliméadar ar shiúl ó Tianjin Xingang.

Whatsapp: +8613682051821