Introduction

When we look at the modern world—from the skylines of our mega-cities to the invisible energy networks powering our homes—there is a silent hero holding the weight of progress: the large-diameter steel pipe.

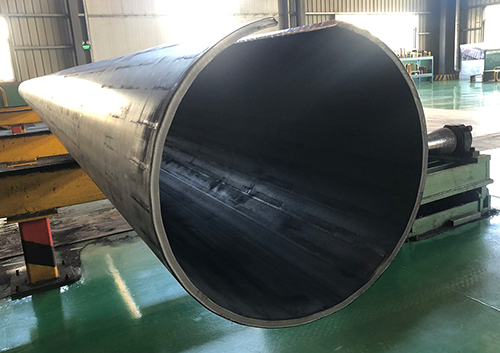

However, in the world of heavy engineering, not all pipes are created equal. When a project moves from “standard” to “extreme”—involving massive pressures, corrosive deep-sea environments, or critical structural loads—the industry moves away from generic options. Instead, the gold standard becomes LSAW (Longitudinal Submerged Arc Welded) pipes, specifically those forged through the sophisticated JCOE process.

But what actually distinguishes a JCOE pipe from a common spiral tube? And how does a flat steel plate transform into a high-pressure vessel capable of surviving on the ocean floor for fifty years? This guide explores the engineering logic, the manufacturing rigor, and the market standards that define this essential steel technology.

Decoding the Industry Terminology

To appreciate why these pipes command a premium, we first have to clear up the jargon found on technical data sheets.

Understanding LSAW LSAW pipe refers to the welding method. Unlike spiral-welded pipes (SSAW), which are formed like a cardboard paper towel roll with a winding seam, LSAW pipes feature a single, straight weld running the entire length.

The Engineering Edge: A straight seam is significantly shorter than a spiral one. In the world of quality control, a shorter seam means a smaller “statistical footprint” for potential defects. This is why LSAW is the non-negotiable choice for high-stakes natural gas transmission.

Defining JCOE It is a common mistake to think JCOE is a product; it is actually a mechanical choreography. The acronym represents the physical transformation the steel undergoes:

J: The initial crimping of the plate edges.

C: Bending the first half of the plate.

O: Closing the circle.

E: The critical “Expansion” phase that finalizes the pipe’s integrity.

The Manufacturing Journey: From Plate to Precision

The production of an LSAW pipe is a masterclass in heavy metalworking. It’s a violent yet precise process that turns raw plate into a high-performance instrument.

1. Edge Preparation

Everything starts with a heavy-duty steel plate. Before any bending happens, the edges are milled to exact angles. This ensures that when the two sides eventually meet, the “V-groove” is perfect for deep-penetration welding.

2. The J-C-O Forming Sequence

This is where the heavy hydraulics come in. A massive press applies thousands of tons of pressure in stages:

J-Forming: The press curl one side of the plate up, creating a “J” profile.

C-Forming: The plate is flipped or shifted, and the other side is curled to mirror the first, resulting in an open “C.”

O-Forming: The center is pressed down, bringing the two edges together to form a closed “O.”

3. Submerged Arc Welding (SAW)

With the seam closed, the pipe enters the welding station. The “Submerged” part of the name refers to the layer of granular flux that buries the arc. This isn’t just for safety; it isolates the molten metal from atmospheric oxygen, preventing brittle welds. Most high-spec pipes are welded twice—once from the inside and once from the outside—to ensure a 100% bond.

4. The “E” – Mechanical Expansion (The Game Changer)

This is the most misunderstood step. After welding, a pipe isn’t perfectly round, and it’s full of internal “stress” from being bent. A mechanical expander is inserted into the pipe and forced outward. This cold-expands the steel by about 1%, forcing it into a perfect circle and, crucially, relieving the internal stresses. This is why JCOE pipes have far better dimensional tolerances than their competitors.

Technical Specs & Procurement Standards

For engineers and procurement officers, the “spec sheet” is the bible. JCOE technology is built for the “big stuff,” and the numbers reflect that.

| Feature | Standard Capability |

| Outer Diameter | 16″ (406mm) to 56″ (1422mm) |

| Wall Thickness | 6mm up to 40mm+ (Customizable for heavy piling) |

| Common Grades | API 5L (X42 through X80), ASTM A252, EN 10219 |

Survival Coatings: The Pipe’s “Skin”

Since these assets are often buried or submerged for decades, the coating is as important as the steel.

3PE/3PP: The industry standard for corrosion resistance. 3PP (Polypropylene) is preferred for high-temperature contents.

CWC (Concrete Weight Coating): Specifically for subsea lines. The concrete doesn’t just protect; it adds the weight necessary to keep the pipe from floating off the seabed.

Internal Flow Coating: A slick epoxy layer that reduces friction, essentially making the pipe “faster” for oil and gas transit.

High-Stakes Applications

Where do you find LSAW? Usually, in places where a leak or a collapse would be a catastrophe.

1.High-Pressure Energy Arteries: When moving volatile gas at pressures exceeding 10 MPa, the reliability of a single longitudinal seam is mandatory.

2.Structural Foundations: Because of their thick walls, JCOE pipes are the first choice for bridge pilings and Offshore Wind Monopiles, where they must withstand the constant rhythmic battering of ocean waves.

3.Critical Water Mains: Major cities use LSAW for their primary water “highways” to ensure the risk of urban flooding from a burst pipe is kept to an absolute minimum.

Looking Ahead: The Hydrogen Frontier

The industry is currently pivoting toward Hydrogen-ready pipelines. Hydrogen molecules are tiny and can cause “embrittlement” in standard steel. Modern LSAW mills are already experimenting with new metallurgy and specialized internal coatings to prepare for the green energy transition. Furthermore, the introduction of AI-driven Automatic Ultrasonic Testing (AUT) is making human error in weld inspection a thing of the past.

Final Thoughts

The JCOE-manufactured LSAW pipe is the “heavy artillery” of the infrastructure world. It marries raw physical strength with geometric precision. While the initial investment is higher than that of spiral pipes, the long-term ROI is found in its reliability. In an era where we need infrastructure to last 50+ years under increasingly harsh environmental conditions, JCOE remains the engineer’s most trusted choice.

Post time: Jan-23-2026