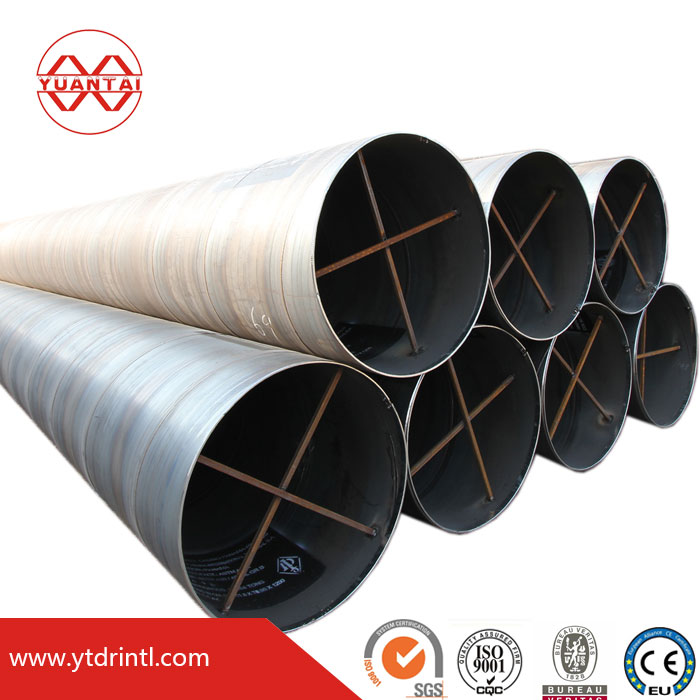

Spiral steel pipe is mainly used in water supply engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, urban construction, for liquid transportation: water supply, drainage, oil transportation. For gas transportation: coal gas, steam, liquefied petroleum gas, natural gas. For structural use: piling pipe, bridge, dock, road, building structure pipe, etc.

Welcome everyone to cantact Yuantai Derun,E-mail:sales@ytdrgg.com, and Real time connection inspection plant or factory visit!

Spiral pipe, also known as spiral steel pipe or spiral welded pipe, is a common type of pipe and is widely used in various fields. The following is a detailed introduction to spiral pipe:

| roduct Name | Spiral welded steel pipe |

| Standard | API 5L psl1/psl2, ISO9000, DIN2240, ASTM A500, A501, A53 EN10219/EN10210, JIS G3466, GB/T6728,GB/T3094,GB/T3091,GB/T9711 |

| Sizes | 219mm to 2032mm |

| Thickness | 4mm to 30mm |

| NDT Test | UT, RT, hydrostatic, |

| Beveled Edges | 30DEG,(-0, +5) |

| Length | 3M-max.24meters,or as required |

| Surface treatment | Black painted/galvanizing etc. |

| Hot Expanded Ends | Available |

| Packing | Loosed PCS/nylon rope(for the coating pipes) |

| Transportation | by 20/40FT containers or by bulk vessels as per conditon |

| Pile shoe | OEM/ODM(for piling) |

| Third party inspection | SGS/BV/JIS/ISO/API/GB/BC1/EPD&PHD |

| Payment Term | TT, LC |

| Application | water/fluid transportation, piling, structural supports, dredging etc. |

2. Types and characteristics

Spiral pipes can be divided into many types according to different welding methods and materials:

1. Single-sided welded spiral pipe: only welded on one side, suitable for general fluid transportation and structural pipes.

2. Double-sided welded spiral pipe: welded on both sides, with higher strength and sealing, suitable for high-pressure fluid transportation and structural engineering and other fields.

3. Ordinary spiral steel pipe: It is the most common type of spiral steel pipe, with simple manufacturing process and low cost, suitable for general demand occasions.

4. Welded spiral steel pipe: It has good welding performance and strength, and is widely used in high-pressure fluid transportation, structural engineering, pile foundation support and other fields.

5. Double-sided submerged arc spiral steel pipe: It is a high-end product with good corrosion resistance and pressure resistance. It is mainly used in important engineering projects, offshore platform construction and other high-demand environments.

6. Corrosion-resistant spiral steel pipe: Made of special anti-corrosion materials, it is suitable for chemical industry, marine engineering, sewage treatment and other fields with high corrosion resistance requirements.

7. Low-temperature spiral steel pipe: It is mainly used for transportation in low-temperature environments, with good low-temperature toughness and cold resistance, and is widely used in liquefied natural gas, liquid nitrogen transportation and other fields

3. Performance and Use

Spiral pipes have high strength and corrosion resistance, can withstand high pressure and high temperature, and are therefore widely used in various fields:

1. Petroleum and natural gas industry: used for long-distance transportation of petroleum and natural gas, as well as gathering and transportation pipelines of oil fields and gas fields.

2. Energy and power: used for cooling water systems, steam and flue gas emission systems of thermal power plants, etc.

3. Civil engineering: Spiral steel pipes are often used in foundation pit support, bank protection engineering, geological exploration and other fields, with good compressive resistance and stability.

4. Infrastructure engineering: Spiral steel pipes can be used in infrastructure construction such as urban drainage systems, sewage treatment plants, and water supply projects.

5. Pressure vessels: Spiral pipes are often used to manufacture pressure vessels, such as boilers, reactors, etc., which can withstand high temperature and high pressure working environments.

6. Boiler construction: Spiral pipes can be used to manufacture the heating surface and shell of boilers, which can ensure the normal operation of boilers under high temperature and high pressure environments.

7. Construction: Spiral pipes are also widely used in the construction field, such as drainage pipes for high-rise buildings, underground water conservancy and municipal sewage pipes.

8. Transportation: Spiral pipes are also widely used in transportation construction such as roads, railways, bridges, etc., and can be used as drainage pipes for bridges, tunnels, subways, underground passages, etc.

4. Quality inspection

The quality inspection of spiral pipes is an important link to ensure their performance and use. Common quality inspection methods include:

1. Appearance inspection: Observe the surface defects and dimensional deviations of the weld by naked eye or with the help of standard templates, gauges, magnifying glasses and other tools.

2. Physical inspection: Use physical phenomena for measurement or inspection, such as non-destructive testing, to check the internal defects of materials or workpieces.

3. Strength inspection: Conduct water pressure test or air pressure test to check the density of welds of containers and pipes working under pressure.

4. Density inspection: Used to find non-dense defects in welds, such as penetrating cracks, pores, slag inclusions, incomplete penetration and loose tissue.

We will conduct product testing before each shipment. Yuantai Derun has a nationally certified laboratory to ensure the quality of each batch of goods.

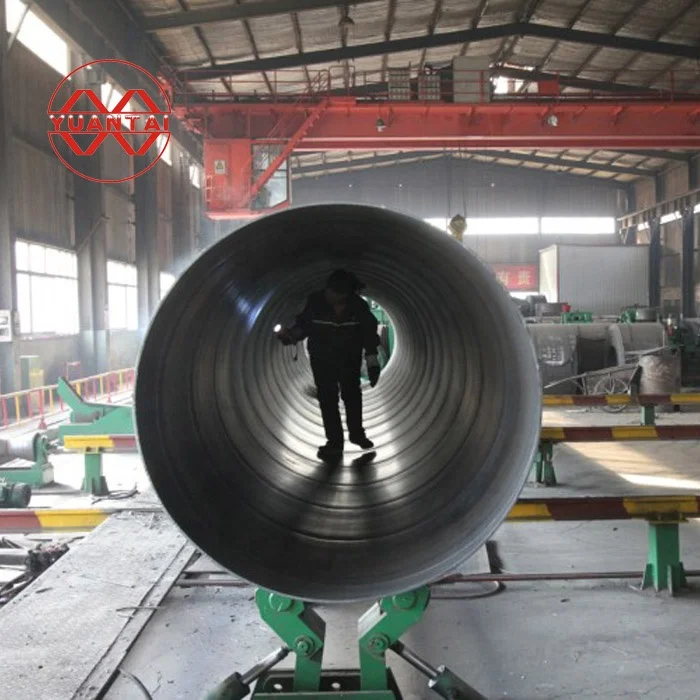

Productive Process

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821

Send your message to us:

-

Reasonable price for China 75X75 Carbon Steel and Iron Rectangular / Square Metal Ms Steel Tube f...

-

Wholesale customization Large diameter medium thick wall SHS steel pipe square hollow section

-

Yuantaiderun Square Hollow Section Astm A36 Square Pipe Factories

-

Manufacturing of hollow tube ERW galvanized pipe

-

Welded Structure Pipe 200×200 square hollow section pipe

-

High Performance Welded Steel Pipe Oil Line Spiral Welded Pipe ASTM A252 Carbon Steel Pipes Large...