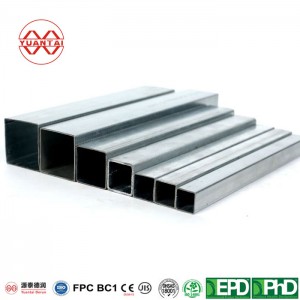

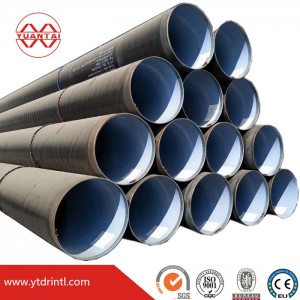

With an annual output of 5 million tons, Yuantai Derun is the largest square and rectangular pipe manufacturer, besides,in terms of hollow section profiles,It has three national group standards, which is the only manufacturer in China with this standard,The main products produced are,hollow section pipe(round&rectangular&square), galvanized pipe, spiral welded pipe, LSAW pipe,right angle tube,trapezoidal tube and other Isotropic tube,Seamless pipe,Stainless steel pipe,Oil casing,OTCG pipes,GI coil and PPGI coil, and so on.

|

Product Name |

Hot galvanized pipe |

|

Size |

OD: 10.3mm-609mm Wall Thickness: 0.5-60mm Length: 3-12m or according to clients` requirements. |

|

Steel material |

GrA, Gr B, GrC, SS330, S275J0H; S355JR ; S355J0H; S355J2H.SS400,S235JR,S235JO,S235J2,S420,S460 |

|

Standard |

EN10219, EN10210, GB/T6728, GB/T3094, GB/T3091,JIS G3466 |

|

Usage |

Used For Structure, Accessorize And Construction |

|

Ends |

1) Plain 2) Beveled 3) Thread |

|

End protector |

1) Plastic pipe cap 2) Iron protector |

|

Surface Treatment |

Galvanized |

|

Technique |

ERW LSAW |

|

Type |

Welded |

|

Section Shape |

Round |

|

Inspection |

With Hydraulic Testing, Eddy Current , Infrared Test |

|

Package |

1) Bundle, 2) In Bulk 3) Bags 4) Clients' Requirements |

|

Delivery |

1) Container 2) Bulk carrier |

|

Port of Shipment |

Xingang, China |

|

Payment |

L/C T/T

|

PRODUCT SHOW:

Annual sales reached $15 billion. Yuantai Derun has 59 black ERW pipe production lines, 10 galvanized pipe production lines and 3 spiral welded pipe production lines. Square pipe 20 * 20 * 1mm to 500 * 500 * 40MM, rectangular steel pipe 20 * 30 * 1.2mm to 400 * 600 * 40MM, spiral pipe Ø 219-1420mm can be made of steel grades from Q (s) 195 to Q (s) 345B / Gr.A-Gr.D. Yuantai Derun can produce square rectangular tubes according to ASTM A500,ASTM A501,JIS G3466, EN10219, DIN2240 and AS1163. Yuantai Derun has the largest square rectangular tube inventory in China, which can meet the direct purchasing demand of customers. Welcome everyone to cantact Yuantai Derun,E-mail:sales@ytdrgg.com, and Real time connection inspection plant or factory visit!

FACTORY WORKSHOP SHOW

| square and rectangular hollow section Unit: mm |

|||||

| Non-standard size | standard size | thickness | non-standard size | standard size | thickness |

| 1.0 | 1.5 | ||||

| 1.2 | 1.7 | ||||

| 1.3 | 40*135 | 50*150 | 2.0 | ||

| 19*19 | 20*20 | 1.4 | 50*140 | 60*140 | 2.2 |

| 1.5 | 60*130 | 80*120 | 2.5~5.0 | ||

| 153 | 1.7 | 75*125 | 100*100 | 5.25~6.0 | |

| 2.0 | 6.5~9.75 | ||||

| 1.0 | 395 | 11.5~16 | |||

| 1.2 | 50*160 | 2.5 | |||

| 1.3 | 60*150 | 60*160 | 2.75 | ||

| 25*25 | 1.4 | 60*180 | 80*140 | 3.0~4.0 | |

| 1.5 | 65*180 | 80*160 | 4.25~4.75 | ||

| 153 | 20*30 | 1.7 | 70*150 | 100*150 | 5.25~6.0 |

| 1.8 | 90*150 | 120*120 | 6.5~7.75 | ||

| 2.0 | 90*160 | 110*110 | 9.5~9.75 | ||

| 2.2 | 100*120 | 120*180 | 10.5~11.75 | ||

| 2.5~3.0 | 100*125 | 125*125 | 12.5~15.75 | ||

| 1.0 | 100*140 | 470 | 16~~30 | ||

| 20*40 | 1.2 | 60*170 | 75*150 | 2.5 | |

| 20*50 | 1.3 | 70*16070*200 | 100*200 | 2.75 | |

| 25*40 | 1.4 | 80*150 | 140*140 | 3.0~5.75 | |

| 32*32 | 1.5 | 80*180 | 150*150 | 7.5~9.75 | |

| 30*30 | 1.7 | 127*127 | 130*130 | 10.5~11.75 | |

| 35*35 | 1.8 | 570 | 12.5~15 | ||

| 30*40 | 2.0 | 60*200 | 100*250 | 2.5 | |

| 2.2 | 60*220 | 160*160 | 2.75~3.25 | ||

| 2.5~3.0 | 80*200 | 180*180 | 3.5~5.0 | ||

| 232 | 3.5~3.75 | 80*220 | 140*180 | 5.25~7.75 | |

| 1.2 | 100*180 | 150*170 | 9.5~11.75 | ||

| 1.3 | 120*160 | 150*180 | 12.5~15.75 | ||

| 1.4 | 120*200 | 150*200 | 16~~30 | ||

| 20*60 | 25*50 | 1.5 | 100*350 | 2.75 | |

| 20*80 | 30*50 | 1.7 | 125*250 | 3.0~3.25 | |

| 25*65 | 30*60 | 1.8 | 130*250 | 100*300 | 3.5~9.75 |

| 30*70 | 40*40 | 2.0 | 135*135 | 150*250 | 11.5~11.75 |

| 35*60 | 40*50 | 2.2 | 140*240 | 200*200 | 12.5~14.75 |

| 38*38 | 40*60 | 2.5~4.0 | 150*220 | 200*250 | 15.5~15.75 |

| 45*45 | 50*50 | 4.25~5.0 | 225*225 | 770 | 16~~30 |

| 5.25~5.75 | 100*400 | 150*300 | 3.5~4.0 | ||

| 153 | 5.75~6.0 | 130*300 | 200*300 | 4.5~7.75 | |

| 1.3 | 150*350 | 250*250 | 9.5~11.75 | ||

| 1.4 | 200*280 | 180*300 | 12.5~14.75 | ||

| 30*100 | 40*80 | 1.5 | 220*220 | 1010 | 15.5~17.75 |

| 40*70 | 40*100 | 1.7 | 200*350 | 200*400 | 4.75~11.75 |

| 40*90 | 50*70 | 1.8 | 250*350 | 250*300 | 12.5~14.75 |

| 50*60 | 50*80 | 2.0 | 300*300 | 15.5~17.75 | |

| 50*75 | 60*60 | 2.2 | 200*500 | 4.75~11.75 | |

| 50*90 | 60*80 | 2.5~4.0 | 300*320 | 250*450 | 12.5~14.75 |

| 55*55 | 70*70 | 4.25~5.0 | 300*350 | 300*400 | 15.5~17.75 |

| 65*65 | 5.25~5.75 | 350*350 | 18~~30 | ||

| 232 | 5.75~6.0 | 200*450 | 200*600 | 4.5~5.75 | |

| 1.3 | 250*400 | 280*280 | 6.5~11.75 | ||

| 40*120 | 50*100 | 1.5 | 250*500 | 300*500 | 12.5~14.75 |

| 40*140 | 60*90 | 1.7 | 300*450 | 350*400 | 15.5~17.75 |

| 50*110 | 60*100 | 1.8 | 400*400 | 18~~30 | |

| 50*120 | 60*120 | 2.0 | 300*650 | 300*600 | 4.5~7.75 |

| 50*125 | 75*75 | 2.2 | 400*500 | 9.5~9.75 | |

| 70*100 | 80*80 | 2.5~4.0 | 300*700 | 400*600 | 11.5~13.75 |

| 85*85 | 80*100 | 4.25~5.0 | 450*450 | 14.5~15.75 | |

| 90*90 | 5.25~5.75 | 320*320 | 500*500 | 16.5~17.75 | |

| 312 | 7.5~9.75 | 18~~30 | |||

| 1300*1300 | 70~80 | ||||

| The length, width and thickness of other specifications can be customized | |||||

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821

Send your message to us:

-

China Yuantaiderun Black Hollow Section Spiral Steel Tube Manufacturer

-

Large Diameter Spiral Welded SSAW Black Carbon Steel Pipe

-

Yuantaiderun Hollow Section carbon steel tube Spiral Pipe

-

Yuantai Square Rectangular Steel Pipe mild steel hollow section

-

wholesale erw black round steel welded pipe Manufacturer

-

Yuantaiderun Square Hollow Section Astm A36 Square Pipe Factories