When you walk onto a construction site or into a local steel fabrication shop, you’ll notice that while there are hundreds of possible steel profiles, a handful of Rectangular Hollow Section (RHS) sizes do the heavy lifting. These aren’t just random dimensions; they are the “sweet spots” of engineering—offering the best balance of weight, price, and strength.

If you’re planning a build or sourcing materials, here is a look at the RHS sizes you’ll actually encounter and how they play out in the real world.

The “Everyday” Sizes: 80×40mm and 100×50mm

If there were a “default” setting for steel frames, this would be it. In many parts of the world, 80×40 and 100×50 are the first things a supplier pulls off the rack because they handle the vast majority of light-to-medium structural tasks.

The 80×40mm in action: Think about the last time you saw a modern metal fence, a park gate, or the internal racking in a delivery van. This size is popular because it’s easy to handle—a single fabricator can move a 6-meter length without needing a crane, making it perfect for residential gates, light trailers, and mezzanine handrails.

The 100×50mm shift: When you move up to 100×50, you’re usually talking about “load-bearing” in a commercial sense. You’ll find these as purlins in small warehouses or the primary frame for solar panel arrays. Because it’s exactly twice as deep as it is wide, it’s incredibly predictable for engineers to calculate how much it will deflect under a heavy snow or wind load.

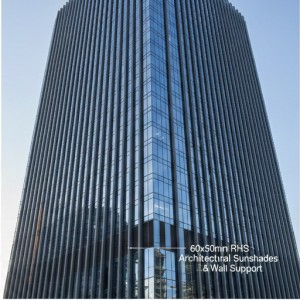

The Specialized Giants: 200×500mm and 60×500m

Once you get into te 500mm depth range, you aren’t just building a frame; you’re building a landmark. These sizes are typically “project-ordered” rather than kept as dusty stockThe 200×500mm (The Heavy Lifter): This is a beast of a section. You’ll see these in logistics hubs or massive industrial plants. Because of its huge internal volume, it’s often used as a “composite column.” Builders will stand it up, pour high-strength concrete down the middle, and suddenly you have a column that can support a multi-story warehouse while remaining relatively slim compared to a massive concrete pillar.

The 60×500mm (The Architect’s Choice): This is a fascinating, skinny profile. It looks like a giant steel fin. You’ll see this on the exterior of high-end office buildings or airport terminals. It’s used for “curtain walling.” The 500mm depth is there to stop the glass wall from blowing in during a storm, but the 60mm width is so thin that it doesn’t block the view for the people inside. It’s the perfect marriage of “tough” and “transparent.”

The “Details” Steel: Small-Size RHS (e.g., 40×20mm)

Not everything needs to hold up a roof. Sometimes you just need a clean, straight edge that won’t warp like timber.

Where it fits: This is the territory of furniture designers and shopfitters. If you see a “minimalist” desk frame in a tech office or a clothing rack in a high-street store, it’s likely 40×20mm RHS. It’s thin walled pipe(1.6mm to 2.0mm), meaning it’s easy to weld with a standard MIG welder and takes a powder-coated finish beautifully.

Why “Closed” Sections Win

A common question is: Why use a rectangular tube (RHS) instead of a standard I-beam or a C-channel?

The answer usually comes down to Torsion (Twisting). If you take a C-channel and put a heavy weight on one side, it wants to twist like a noodle. An RHS is a closed loop; it hates twisting. This makes it much safer for “unbalanced” structures, like a cantilevered balcony or a signpost sticking out from a building. Plus, there are no “lips” or “pockets” for water and bird droppings to collect in, which significantly slows down rust.

A Note on the “Paperwork” (Grades and Standards)

While the size matters, the “DNA” of the steel matters just as much. You’ll usually hear two main terms:

S235 vs. S355: Think of S235 as “standard” and S355 as “high-test.” If you’re building a simple backyard shed, S235 is fine. If you’re building a bridge or something that will be hit by high winds, you go for S355.

Galvanized vs. Black: If the steel is going to be hidden inside a wall, “Black” (oiled) steel is cheaper. If it’s going outside, you want it “Hot-Dip Galvanized.” It’ll look silver and a bit mottled, but it won’t rust for thirty years.

Post time: Jan-22-2026