Txog cov khoom

Peb tuaj yeem xa cov lus qhia tsis tu ncua rau koj nrog LCL kev pabcuam.

Cov roj pleev xim tiv thaiv xeb,

pleev xim rau xim,

ral3000 pleev xim,

galvanized,

3LPE, 3PP

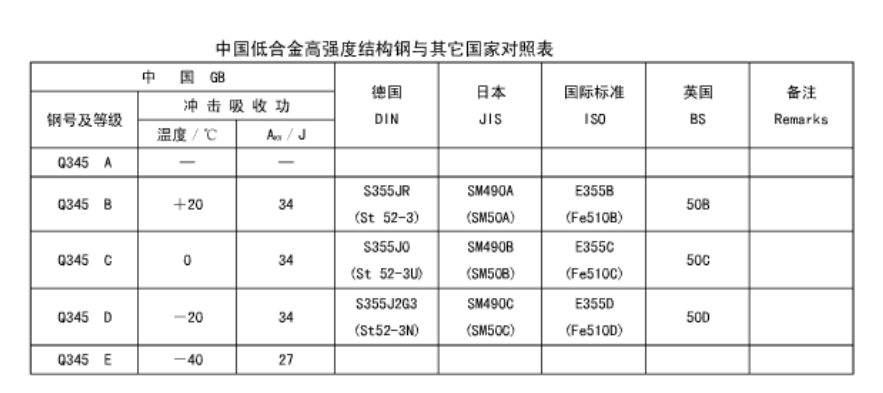

Q195 = S195 / A53 Qib A

Q235 = S235 / A53 Qib B / A500 Qib A / STK400 / SS400 / ST42.2

Q345 = S355JR / A500 Qib B Qib C

Q235 Al tua = EN39 S235GT

L245 = Api 5L / ASTM A106 Qib B

Cov yeeb nkab dub yog cov yeeb nkab hlau yooj yim uas tsis muaj cov txheej tiv thaiv. Cov yeeb nkab dub siv rau ntau yam kev siv hauv tsev. Nws yog ib qho uas pom cov yeeb nkab dub siv rau koj cov kav roj av thiab cov kav dej txau dej. Vim tias cov yeeb nkab dub tsis muaj txheej tiv thaiv, nws yuav xeb tau yooj yim hauv cov chaw ntub dej lossis noo noo. Yuav kom tiv thaiv cov yeeb nkab kom tsis txhob xeb lossis xeb sab nraud, koj yuav tsum muab ib txheej tiv thaiv rau sab nraud ntawm cov yeeb nkab. Txoj kev yooj yim tshaj plaws yog pleev xim rau nws.

YOG. Peb muaj kev koom tes zoo nrog SINOSURE

RHS sawv cev rau Rectangular Hollow Section, uas yog cov yeeb nkab hlau plaub fab.

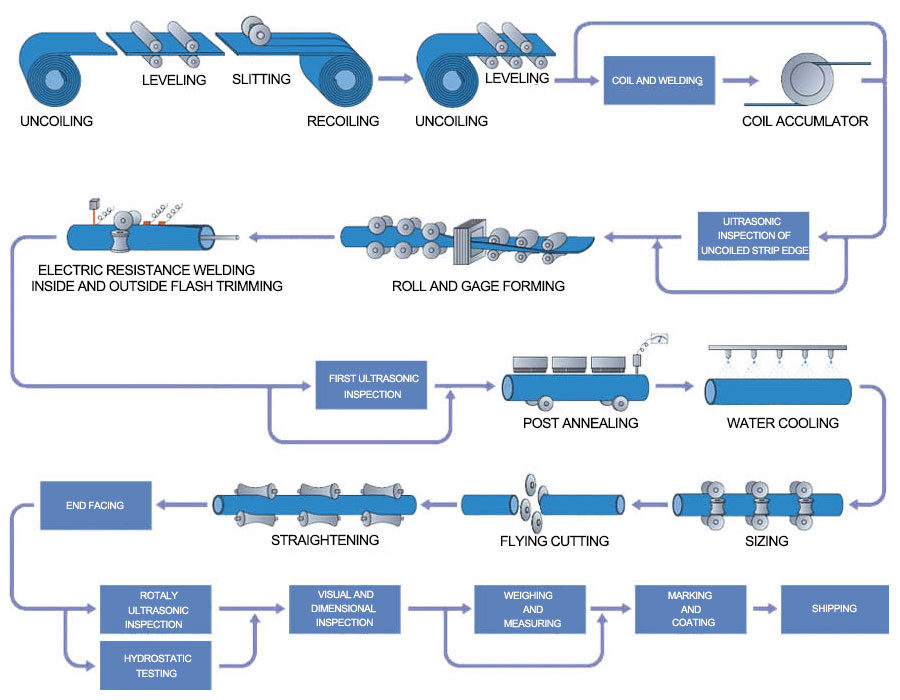

Peb kuj muaj cov yeeb nkab steel square hollow section, raws li tus qauv: ASTM A500, EN10219, JIS G3466, GB/T6728 txias tsim square thiab rectangular steel yeeb nkab.

ERW yeeb nkab hlau, SSAW yeeb nkab hlau, LSAW yeeb nkab hlau, galvanized yeeb nkab hlau, stainless hlau yeeb nkab, casing thiab tubing yeeb nkab, luj tshib, reducer, tee, cap, coupling, flange, weldolet, Seamless yeeb nkab hlau

TT, L/C (Rau qhov kev txiav txim loj, 30-90 hnub tuaj yeem lees txais).

Cov kav hlau galvanized muab faib ua cov kav hlau galvanized txias thiab cov kav hlau galvanized kub. Cov kav hlau galvanized feem ntau yog siv rau dej, roj, roj thiab lwm yam kav dej siab. Lawv kuj siv rau hauv kev lag luam kerosene, tshwj xeeb tshaj yog cov kav dej roj hauv cov teb roj hauv hiav txwv, cov cua txias, cov kav dej pauv thee thiab cov kav dej choj, cov kav dej txhawb nqa hauv kuv lub qhov dej, thiab lwm yam.

Cov kav hlau galvanized muab faib ua cov kav hlau galvanized txias thiab cov kav hlau galvanized kub. Cov kav hlau galvanized feem ntau yog siv rau dej, roj, roj thiab lwm yam kav dej siab. Lawv kuj siv rau hauv kev lag luam kerosene, tshwj xeeb tshaj yog cov kav dej roj hauv cov teb roj hauv hiav txwv, cov cua txias, cov kav dej pauv thee thiab cov kav dej choj, cov kav dej txhawb nqa hauv kuv lub qhov dej, thiab lwm yam.

Lawv hais tias cov yeeb nkab hlau galvanized yog siv rau roj thiab cua sov. Ua ib lub yeeb nkab dej, yuav pom me ntsis xeb tom qab ob peb xyoos. Nws tsis yog tsuas yog ua rau cov khoom siv huv xwb, tab sis kuj tseem muaj cov kab mob loj hlob ntawm phab ntsa sab hauv ntawm cov yeeb nkab. Xeb ua rau muaj cov hlau ntau hauv lub cev dej thiab ua rau tib neeg muaj kev phom sij.

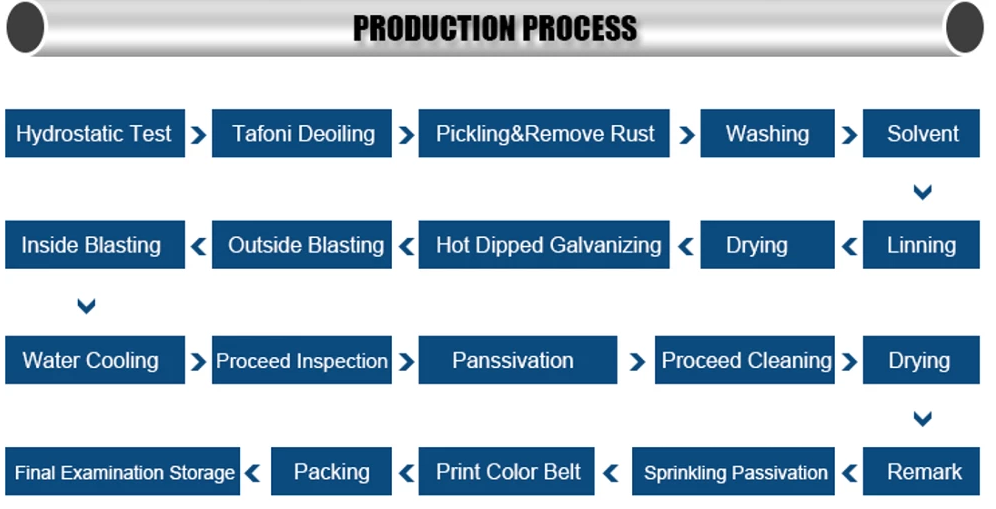

Kev kub dip galvanizing yog kev muab cov yeeb nkab hlau rau hauv cov kua qaub rau kev ntxuav, thiab npaj cov kua dej nrog ammonium chloride aqueous solution lossis zinc chloride thiab zinc chloride, thiab nchuav rau hauv qhov zawj. Cov txheej txheem kub dip galvanized yog sib xws, nrog kev nplaum zoo thiab lub neej ntev. Lub matrix ntawm cov yeeb nkab hlau kub-dip galvanized yog cov tshuaj electroplating uas muaj zog thiab yaj, yog li cov tshuaj lom neeg ua rau muaj kev teeb tsa me me thiab tiv taus corrosion. Cov txheej alloy yog sib xyaw nrog cov txheej zinc ntshiab thiab cov yeeb nkab hlau, yog li nws muaj kev tiv taus corrosion zoo.

Cov yeeb nkab galvanized txias yog electro galvanized, thiab muaj qhov sib txawv loj ntawm kev tiv thaiv corrosion thiab cov yeeb nkab galvanized kub-dip. Yuav kom ntseeg tau tias qhov zoo, feem ntau cov chaw tsim khoom tswj hwm galvanizing tsis siv electro galvanizing (txias plating). Cov lag luam me me tsis raws cai yuav siv electro galvanizing vim tias tus nqi pheej yig. Cov txheej galvanized ntawm cov yeeb nkab hlau galvanized txias-dip yog ib txheej. Cov txheej zinc yog stacked ywj pheej nrog cov yeeb nkab hlau matrix. Cov txheej zinc yog nyias, uas tsuas yog txuas nrog cov yeeb nkab hlau thiab yooj yim poob tawm. Yog li ntawd, nws qhov kev tiv thaiv corrosion tsis zoo. Yog li ntawd, rau qee cov yeeb nkab faus ncaj qha, cov yeeb nkab hlau galvanized tsim los ntawm cov chaw tsim khoom ib txwm tseem siv.

Yuav ua li cas tshem tawm cov yeeb nkab galvanized hlau xeb?

Ua ntej, siv cov tshuaj yaj rau sab nraud ntawm cov hlau kom tshem tawm cov organic teeb meem. Xeb kuj tseem tuaj yeem tshem tawm los ntawm kev sib xyaw tom qab txhuam kom tiv thaiv xeb, ntxuav lossis hlau, xeb, vuam slag, thiab lwm yam. Galvanizing yog muab faib ua thermoelectric txheej thiab txias txheej. Thermoelectric txheej tsis yooj yim rau xeb thiab txias txheej yooj yim rau xeb.

Cov yeeb nkab dej tua hluav taws tam sim no feem ntau siv cov yeeb nkab galvanized, thiab txheej sab nraud ntawm cov yeeb nkab galvanized raug siv rau ib txheej xim. Nws tuaj yeem pom tias cov yeeb nkab hluav taws yog galvanized tiag tiag. Hauv cov qauv hlau, kev tsim kho vuam muaj nws txoj kev koom tes. Yog li ntawd, kev siv cov yeeb nkab hlau galvanized ntau zaus tuaj yeem tiv thaiv qhov tshwm sim ntawm cov xwm txheej xeb ntev.

1. OD 219mm thiab hauv qab no Hauv cov pob khoom hexagonal seaworthy ntim los ntawm cov hlau strips, Nrog ob lub nylon slings rau txhua pob khoom

2. saum OD 219mm hauv qhov ntau lossis raws li kev xav ntawm tus kheej

3. 25 tons/thawv thiab 5 tons/loj rau kev txiav txim sim;

4. Rau 20 "thawv qhov ntev tshaj plaws yog 5.8m;

5. Rau 40 "thawv qhov ntev tshaj plaws yog 11.8m.

YOG PEB MUAJ

YUANTAIDERUN Hom TOP 500 Tuam Tshoj

Cov hlau sib xyaw ua ke suav tias yog hlau sib xyaw thaum manganese ntau dua 1.65%, silicon ntau dua 0.5%, tooj liab ntau dua 0.6%, lossis lwm yam khoom sib xyaw tsawg kawg nkaus xws li chromium, nickel, molybdenum, lossis tungsten muaj nyob. Muaj ntau yam khoom sib txawv rau cov hlau los ntawm kev hloov cov ntsiab lus no hauv daim ntawv qhia.

Ib txoj kev ua kom cov hlau stainless zoo dua los ntawm kev txo cov pa roj carbon

Tus nqi ntawm cov pa roj carbon hauv cov hlau tsis xeb yuav tsum qis dua li cov hlau carbon lossis cov hlau alloy qis dua (piv txwv li, cov hlau uas muaj cov ntsiab lus alloying qis dua 5%). Thaum cov cub hluav taws xob arc (EAF) yog cov txheej txheem ib txwm siv los yaj thiab ua kom cov hlau tsis xeb zoo, AOD yog qhov ntxiv pheej yig, vim tias lub sijhawm ua haujlwm luv dua thiab qhov kub qis dua li hauv EAF steelmaking. Tsis tas li ntawd, kev siv AOD rau kev ua kom cov hlau tsis xeb zoo ua rau muaj EAF rau kev yaj.

Cov hlau uas yaj lawm, tsis tau ua kom zoo lawm raug xa mus los ntawm EAF mus rau hauv ib lub thawv sib cais. Ib qho sib xyaw ntawm argon thiab oxygen raug tshuab los ntawm hauv qab ntawm lub thawv hla cov hlau uas yaj lawm. Cov tshuaj ntxuav raug ntxiv rau hauv lub thawv nrog rau cov pa roj no kom tshem tawm cov khoom tsis huv, thaum cov pa oxygen sib xyaw nrog cov pa roj carbon hauv cov hlau uas tsis tau ua kom zoo lawm kom txo cov pa roj carbon. Qhov muaj argon ua rau cov pa roj carbon sib txuas zoo dua thiab yog li ntawd ua rau cov pa roj carbon raug tshem tawm yooj yim dua.

Kev xeb ntawm cov hlau qauv yog ib qho txheej txheem electrochemical uas xav tau tib lub sijhawm ntawm cov dej noo thiab oxygen. Yog tsis muaj ob qho tib si, xeb tsis tshwm sim. Yeej, cov hlau hauv cov hlau yog oxidized los tsim xeb, uas nyob kwv yees li 6 npaug ntawm qhov ntim ntawm cov khoom siv thawj zaug siv hauv cov txheej txheem. Cov txheej txheem xeb dav dav tau piav qhia ntawm no. Ib yam li kev xeb dav dav, muaj ntau hom kev xeb hauv zos uas kuj tuaj yeem tshwm sim; bimetallic xeb, pitting xeb thiab crevice xeb. Txawm li cas los xij, cov no feem ntau tsis tseem ceeb rau cov hlau qauv. Tus nqi uas cov txheej txheem xeb nce mus ntxiv nyob ntawm ntau yam uas cuam tshuam nrog 'micro-climate' tam sim ntawd nyob ib puag ncig cov qauv, feem ntau yog lub sijhawm ntawm kev ntub dej thiab qib pa phem hauv huab cua. Vim muaj kev hloov pauv hauv cov huab cua ib puag ncig, cov ntaub ntawv xeb tsis tuaj yeem dav dav. Txawm li cas los xij, cov ib puag ncig tuaj yeem faib ua pawg dav dav, thiab cov hlau ntsuas xeb ntsuas sib xws muab cov cim qhia txog qhov yuav muaj feem xeb. Cov ntaub ntawv ntxiv tuaj yeem pom hauv BS EN ISO 12944-2 thiab BS EN ISO 9223

Pleev ximSHS (square hollow sections)thiab RHS (cov seem hollow rectangular) yog cov seem hlau hollow uas muaj zog heev uas tau pleev xim rau thaum lub sijhawm khaws cia thiab tuav.

Cov duab tshwm sim rau Kub dip galvanized square steel yeeb nkab

Nyob rau lub sijhawm ntev, kev raug tshuaj tas mus li, qhov kub siab tshaj plaws uas pom zoo rau cov hlau kub-dip galvanized yog 200 ° C (392 ° F), raws li American Galvanizers Association. Kev siv cov hlau galvanized ntawm qhov kub siab dua qhov no yuav ua rau cov zinc tev tawm ntawm cov txheej hlau intermetallic.

Nws txhais tau tias lub voos xwmfab hollow uas yog luv luv li SHS

Nws txhais tau tias lub voj voog hollow seem, uas yog luv luv li SHS.

Txog kev xa khoom

Feem ntau nws yog 3-5 hnub yog tias cov khoom muaj nyob hauv Tshuag. lossis nyob ib ncig ntawm 25 hnub yog tias cov khoom tsis muaj nyob hauv Tshuag thiab nws yog raws li qhov yuav tsum tau ua.

Mus rau South Africa: 45 hnub

Mus rau Middle East: 30 hnub

Mus rau South America: 60 hnub

Mus rau North America: 30 hnub

Mus rau Russia: 7 hnub

Mus rau Tebchaws Europe: 45 hnub

Mus rau Kaus Lim Qab Teb: 5 hnub

Mus rau Nyiv Pooj: 5 hnub

Mus rau Nyab Laj: 15 hnub

Mus rau Thaib teb: 15 hnub

Mus rau Is Nrias teb: 30 hnub

Mus rau Indonesia: 15 hnub

Mus rau Singapore: 10 hnub

Txog kev pabcuam

YUANTAIDERUN ZOO ZOO ZOO NQI ZOO SERVCE.

Peb muaj ib lub chaw kuaj mob tshaj lij,

Thiab cov neeg ua haujlwm kuaj xyuas kev tshaj lij.

Kev Thov Kom Zoo/Ntau: Tus Neeg Yuav Khoom muaj cai ua ob qho tib si kev thov kom zoo thiab ntau npaum li cas ua ntawv tawm tsam tus Neeg Muag Khoom hauv 90 hnub tom qab tuaj txog ntawm chaw nres nkoj ntawm qhov chaw mus.

EN210 EN219 BC1 API UL ISO FPC CE EPD PHD JIS3466 GB

A: 1. Peb khaws cov khoom zoo thiab cov nqi sib tw kom ntseeg tau tias peb cov neeg siv khoom tau txais txiaj ntsig.

2. Peb hwm txhua tus neeg siv khoom ua peb tus phooj ywg thiab peb ua lag luam thiab ua phooj ywg nrog lawv, txawm lawv tuaj qhov twg los xij.

Yog, koj tuaj yeem tau txais cov qauv muaj nyob rau hauv peb cov Tshuag. Dawb rau cov qauv tiag tiag, tab sis cov neeg siv khoom yuav tsum tau them tus nqi thauj khoom.

Cov peev xwm siv hlau hauv cov tsev thiab cov khoom siv hauv paus tsis muaj kev txwv. Cov ntawv thov feem ntau yog teev hauv qab no. Rau cov tsev Cov ntu ntawm cov qauv: cov no muab lub thav duab ruaj khov, tawv rau lub tsev thiab ua rau 25% ntawm cov hlau siv hauv cov tsev. Cov pas nrig txhawb nqa: cov no ntxiv lub zog tensile thiab kev tawv rau cov pob zeb thiab ua rau 44% ntawm cov hlau siv hauv cov tsev. Hlau siv vim nws khi zoo rau cov pob zeb, muaj cov coefficient thermal expansion zoo sib xws thiab muaj zog thiab pheej yig dua. Cov pob zeb txhawb nqa kuj tseem siv los muab cov hauv paus tob thiab hauv qab nthab thiab tam sim no yog cov khoom siv hauv tsev tseem ceeb hauv ntiaj teb. Cov khoom ntawv: 31% yog nyob rau hauv cov khoom ntawv xws li ru tsev, purlins, phab ntsa sab hauv, qab nthab, cladding, thiab cov vaj huam sib luag rwb thaiv tsev rau phab ntsa sab nraud. Cov hlau tsis yog cov qauv: hlau kuj pom muaj nyob rau hauv ntau daim ntawv thov tsis yog cov qauv hauv cov tsev, xws li cov khoom siv cua sov thiab txias thiab cov kav dej sab hauv. Cov khoom siv sab hauv thiab cov khoom siv xws li cov ntsia hlau, txee thiab ntaiv kuj yog ua los ntawm hlau. Rau cov kev tsim kho vaj tseKev thauj mus los hauv network: hlau yog qhov yuav tsum tau rau cov choj, qhov av, txoj kev tsheb ciav hlau thiab hauv kev tsim cov tsev xws li chaw nres tsheb roj, chaw nres tsheb ciav hlau, chaw nres nkoj thiab tshav dav hlau. Kwv yees li 60% ntawm cov hlau siv hauv daim ntawv thov no yog ua cov hlau txuas thiab qhov seem yog cov ntu, phaj thiab txoj kev tsheb ciav hlau. Cov khoom siv (roj, dej, fais fab): ntau tshaj 50% ntawm cov hlau siv rau daim ntawv thov no yog nyob rau hauv cov kav dej hauv av los faib dej mus rau thiab los ntawm cov tsev nyob, thiab faib roj. Tus so yog feem ntau yog cov hlau txuas rau cov chaw fais fab thiab cov tsev twj.