Malunga nemveliso

Singakuthumela iinkcukacha eziqhelekileyo kuwe ngenkonzo ye-LCL.

Umzobo weoyile ochasene nokugqwala,

ukupeyinta ngevanishi,

ipeyintiwe yi-ral3000,

i-galvanized,

3LPE, 3PP

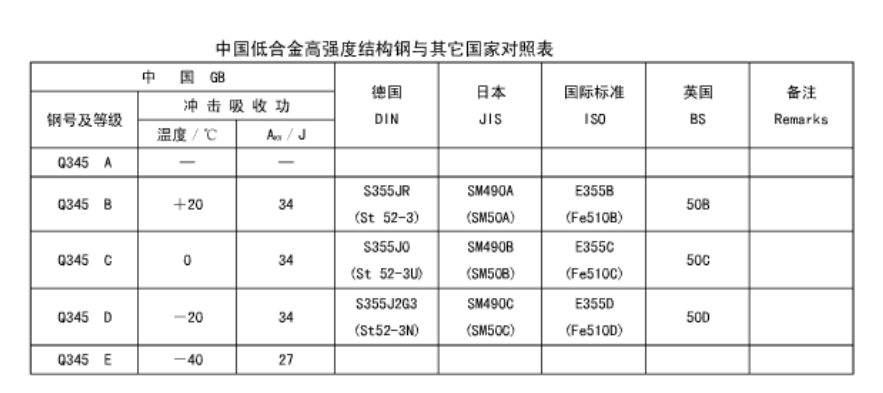

Q195 = S195 / A53 Ibanga A

Q235 = S235 / A53 Ibanga B / A500 Ibanga A / STK400 / SS400 / ST42.2

Q345 = S355JR / A500 Ibanga B Ibanga C

Q235 Al wabulawa = EN39 S235GT

L245 = Api 5L / ASTM A106 Ibanga B

Umbhobho omnyama ngumbhobho wentsimbi nje ongenanto ngaphandle kwengubo yokukhusela. Umbhobho omnyama usetyenziselwa iintlobo ngeentlobo zezicelo ekhayeni. Kuqhelekile ukubona umbhobho omnyama usetyenziselwa umgca wakho wegesi yendalo kunye nemigca yenkqubo yokutshiza. Ekubeni umbhobho omnyama ungenangubo yokukhusela, unokugqwala ngokulula kwiindawo ezimanzi okanye ezifumileyo. Ukuze umbhobho ungagqwali okanye ubole ngaphandle, kufuneka unike umaleko wokukhusela ngaphandle kombhobho. Eyona ndlela ilula kukuyipeyinta.

EWE. Sinentsebenziswano eqinileyo ne-SINOSURE

I-RHS imele iCandelo eliyiRectangular Hollow, oko kukuthi umbhobho wentsimbi oyirectangular.

Sikwanayo nombhobho wentsimbi onesikwere esingenanto, ngokwemigangatho: ASTM A500, EN10219, JIS G3466, GB/T6728 umbhobho wentsimbi obandayo noxande.

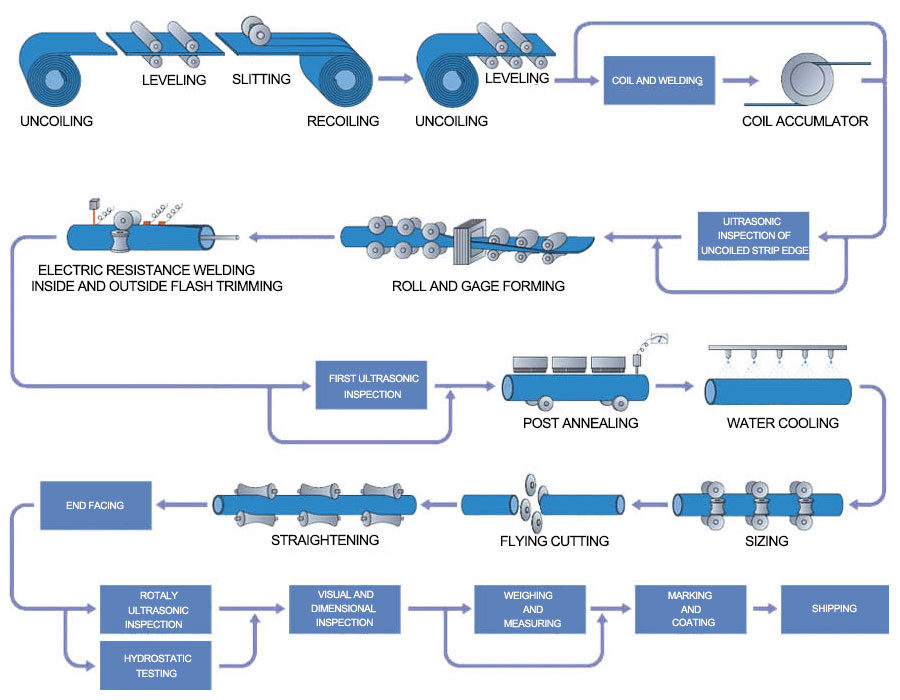

Umbhobho wentsimbi we-ERW, umbhobho wentsimbi we-SSAW, umbhobho wentsimbi we-LSAW, umbhobho wentsimbi ogqunyiweyo, umbhobho wentsimbi engatyiwayo, umbhobho we-casing kunye ne-tubing, i-elbow, i-reducer, i-tee, i-cap, i-coupling, i-flange, i-weldolet, umbhobho wentsimbi ongenamthungo

TT, L/C (Kwi-odolo enkulu, iintsuku ezingama-30-90 zingamkeleka).

Iipayipi zentsimbi ezigayiweyo zahlulwe zaba ziipayipi zentsimbi ezigayiweyo ezibandayo kunye neepayipi zentsimbi ezigayiweyo ezishushu. Iipayipi ezigayiweyo zihlala zisetyenziselwa amanzi, igesi, ioyile kunye neminye imibhobho eqhelekileyo yoxinzelelo oluphezulu. Zikwasetyenziswa kushishino lwe-kerosene, ngakumbi imibhobho yentsimi yeoyile kwiindawo zeoyile ezikude nolwandle, kwiindawo ezipholileyo, kwiipayipi zokutshintshiselana ngomphunga wamalahle kunye neepayipu zebhulorho, iipayipi zokuxhasa imigodi, njl.njl.

Iipayipi zentsimbi ezigayiweyo zahlulwe zaba ziipayipi zentsimbi ezigayiweyo ezibandayo kunye neepayipi zentsimbi ezigayiweyo ezishushu. Iipayipi ezigayiweyo zihlala zisetyenziselwa amanzi, igesi, ioyile kunye neminye imibhobho eqhelekileyo yoxinzelelo oluphezulu. Zikwasetyenziswa kushishino lwe-kerosene, ngakumbi imibhobho yentsimi yeoyile kwiindawo zeoyile ezikude nolwandle, kwiindawo ezipholileyo, kwiipayipi zokutshintshiselana ngomphunga wamalahle kunye neepayipu zebhulorho, iipayipi zokuxhasa imigodi, njl.njl.

Kuthiwa umbhobho wentsimbi egalelweyo usetyenziselwa igesi kunye nokufudumeza. Njengombhobho wamanzi, inani elincinci lomhlwa liya kufunyanwa emva kweminyaka embalwa. Ayingcolisi nje kuphela izinto zokucoca, kodwa neebhaktheriya ziyakhula eludongeni lwangaphakathi lombhobho. Umhlwa ubangela umxholo ophezulu wesinyithi emzimbeni wamanzi kwaye ubeka impilo yabantu emngciphekweni.

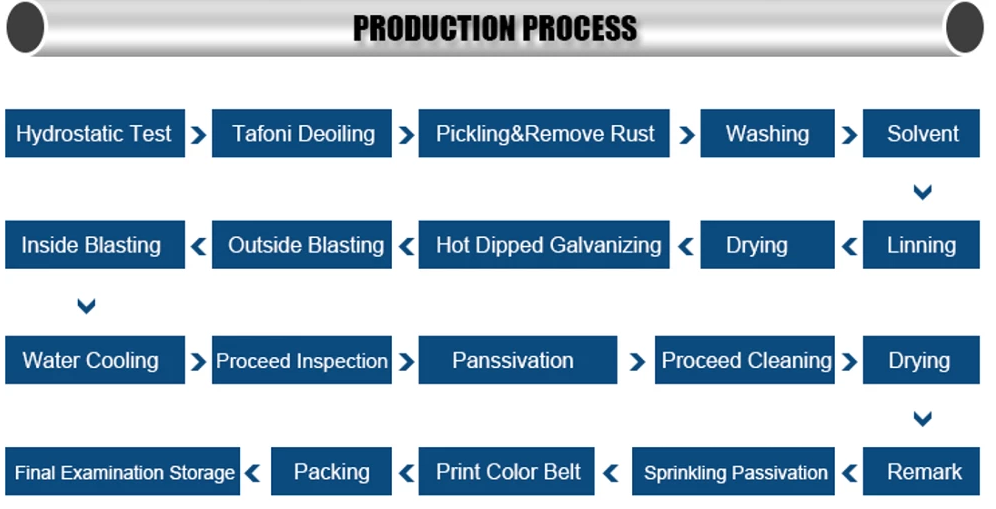

I-Hot dip galvanizing kukuntywilisela umbhobho wentsimbi kwi-asidi yokuhlamba, kwaye ulungiselele isisombululo samanzi ngesisombululo samanzi se-ammonium chloride okanye i-zinc chloride kunye ne-zinc chloride, uze uyithulule emngxunyeni. I-Hot dip galvaning coating iyafana, inamathela ngokuqinileyo kwaye ihlala ixesha elide. I-matrix yombhobho wentsimbi e-hot-dip galvaning sisisombululo esintsonkothileyo se-electroplating esiyinkimbinkimbi, ngoko ke i-chemical reaction yenza ulwakhiwo oluncinci kunye nokumelana nokugqwala. Umaleko we-alloy udityaniswe nomaleko we-zinc ococekileyo kunye nesiseko sombhobho wentsimbi, ngoko ke unokumelana nokugqwala okunamandla.

Umbhobho ogqunyiweyo obandayo ugqunyiwe ngombane, kwaye kukho umahluko omkhulu phakathi kokuxhathisa ukugqwala kunye nombhobho ogqunyiweyo oshushu. Ukuze kuqinisekiswe umgangatho, uninzi lwabavelisi bolawulo lwe-galvanizing abafaki i-electro galvanizing (i-cold plating). Loo mashishini amancinci angekho sesikweni aya kusebenzisa i-electro galvanizing kuba ixabiso liphantsi kakhulu. Umaleko ogqunyiweyo wombhobho wentsimbi ogqunyiweyo obandayo luphawu. Umaleko we-zinc ubekwe ngokuzimeleyo nge-matrix yombhobho wentsimbi. Umaleko we-zinc ubhityile, oqhagamshelwe nje kumbhobho wentsimbi kwaye kulula ukuwa kuwo. Ke ngoko, ukuxhathisa kwawo ukugqwala kuphantsi. Ke ngoko, kwezinye iipayipi ezingcwatywe ngqo, iipayipi zesinyithi zesinyithi ezenziwe ngabavelisi abaqhelekileyo zisasetyenziswa.

Ungayisusa njani ipayipi yentsimbi erhangqiweyo nenomhlwa?

Okokuqala, faka isinyibilikisi ngaphandle kwentsimbi ukuze ususe izinto eziphilayo. Umhlwa ungasuswa ngokuwugalela emva kokuwuxuba, ukuthintela ukugqwala, ukucoca okanye ukuyila intsimbi, umhlwa, ukuwelda, njl. I-Galvanizing yahlulwe yaba yi-thermoelectric coating kunye ne-cold coating. I-thermoelectric coating ayilula ukuyigqwala kwaye i-cold coating ilula ukuyigqwala.

Umbhobho wamanzi ombane okhoyo ngoku usebenzisa umbhobho we-galvanized, kwaye umaleko wangaphandle wombhobho we-galvanized ufakwa kumaleko wepeyinti. Kuyabonakala ukuba umbhobho womlilo une-galvanized. Kwisakhiwo sentsimbi, ubunjineli bokuwelda bunenxaxheba yalo. Ke ngoko, ukusetyenziswa rhoqo kombhobho wentsimbi we-galvanized kunokuthintela ukwenzeka kweemeko zokugqwala ixesha elide.

1. OD 219mm nangaphantsi Kwiibhanti ezilungele ulwandle ezinamacala asixhenxe ezipakishwe ngemicu yentsimbi, Zinee-sling ezimbini ze-nylon kwibhanti nganye

2. ngaphezulu kwe-OD 219mm ngobuninzi okanye ngokwembono yesiko

3. Iitoni ezingama-25/isikhongozeli kunye neetoni ezi-5/ubungakanani beodolo yovavanyo;

4. Kwisikhongozeli esingama-20" ubude obuphezulu yi-5.8m;

5. Kwisikhongozeli esingama-40" ubude obuphezulu yi-11.8m.

EWE SINAYO

I-YUANTAIDERUN Brand TOP 500 China

Umxube osekelwe kwisinyithi uthathwa njengentsimbi ye-alloy xa i-manganese ingaphezulu kwe-1.65%, i-silicon ingaphezulu kwe-0.5%, ubhedu olungaphezulu kwe-0.6%, okanye ezinye izinto ezincinci ze-alloying ezifana ne-chromium, i-nickel, i-molybdenum, okanye i-tungsten zikhona. Iindidi ezininzi zeempawu ezahlukeneyo zinokwenziwa kwintsimbi ngokufaka ezi zinto kwiresiphi.

Inkqubo yokuphucula ngakumbi intsimbi engagqwaliyo ngokunciphisa umxholo wekhabhoni

Ubungakanani bekhabhoni kwintsimbi engatyiwayo kufuneka bube ngaphantsi kunobo bukwintsimbi yekhabhoni okanye kwintsimbi ye-alloy ephantsi (oko kukuthi, intsimbi enomxholo we-alloying element ngaphantsi kwe-5%). Ngelixa ii-oven zombane ze-arc (EAF) ziyindlela eqhelekileyo yokunyibilikisa nokucoca intsimbi engatyiwayo, i-AOD sisongezelelo esingabizi kakhulu, njengoko ixesha lokusebenza lifutshane kwaye amaqondo obushushu aphantsi kunokwenziwa kwentsimbi ye-EAF. Ukongeza, ukusebenzisa i-AOD ekucoceni intsimbi engatyiwayo kwandisa ukufumaneka kwe-EAF ngeenjongo zokunyibilikisa.

Intsimbi enyibilikisiweyo nengacocwanga idluliselwa kwi-EAF iye kwisitya esahlukileyo. Umxube we-argon kunye ne-oksijini uvuthelwa ezantsi kwesitya ngentsimbi enyibilikisiweyo. Izinto zokucoca zongezwa kwisitya kunye nezi gesi ukuze kususwe ukungcola, ngelixa i-oksijini idibana ne-carbon kwintsimbi engakhange icocwe ukunciphisa amanqanaba ekhabhoni. Ubukho be-argon buphucula ukuhambelana kwekhabhoni ne-oksijini kwaye ngaloo ndlela kwenza kube lula ukususwa kwekhabhoni.

Ukubola kwentsimbi yolwakhiwo yinkqubo ye-electrochemical efuna ubukho bomswakama kunye neoksijini ngaxeshanye. Ukuba akukho nokuba yeyiphi na kwezi, ukubola akwenzeki. Ngokwenyani, isinyithi esikwintsimbi siyanyibilikiswa ukuze sivelise ukubola, okuthatha malunga nezihlandlo ezi-6 zomthamo wezinto zokuqala ezisetyenzisiweyo kule nkqubo. Inkqubo yokubola ngokubanzi iboniswe apha. Ngaphandle kokubola ngokubanzi, kukho iintlobo ezahlukeneyo zokubola kwendawo ezinokwenzeka; ukubola kwe-bimetallic, ukubola kwemigodi kunye nokubola kwe-crevice. Nangona kunjalo, ezi azibalulekanga kumsebenzi wentsimbi yolwakhiwo. Isantya apho inkqubo yokubola iqhubeka khona sixhomekeke kwizinto ezininzi ezinxulumene 'nemozulu encinci' ejikeleze isakhiwo, ngokuyintloko ixesha lokumanzi kunye nenqanaba longcoliseko lomoya. Ngenxa yokwahluka kwiindawo zomoya, idatha yesantya sokubola ayinakulinganiswa ngokubanzi. Nangona kunjalo, iindawo zokusingqongileyo zinokuhlulwa ngokubanzi, kwaye amazinga okubola entsimbi alinganayo abonelela ngesalathiso esiluncedo samazinga okubola anokubakho. Ulwazi oluthe kratya lunokufumaneka kwi-BS EN ISO 12944-2 kunye ne-BS EN ISO 9223

IpeyintiweI-SHS (amacandelo angenanto anesikwere)kunye ne-RHS (iinxalenye ezingenanto eziziingxande) ziinxalenye zentsimbi engenanto eziqinileyo ezifakwe ipeyinti yeprimer yokukhusela ngexesha lokugcina nokuphatha.

Isiphumo somfanekiso wepayipi yesinyithi esikwere esirhangqiweyo esishushu

Xa isetyenziswa ixesha elide, iqhubeka nokuvezwa, ubushushu obuphezulu obucetyiswayo kwintsimbi egqunywe nge-hot-dip yi-200 °C (392 °F), ngokutsho kwe-American Galvanizers Association. Ukusetyenziswa kwentsimbi egqunywe nge-galvanized kumaqondo obushushu angaphezu kwala kuya kubangela ukuba i-zinc ixobuke kumaleko we-inter metallic.

Lithetha icandelo elingenanto elisikwere elifinyeziweyo njenge-SHS

Lithetha icandelo elijikelezayo elingenanto, elifinyezwa ngokuthi yi-SHS.

Malunga nokuhanjiswa

Ngokwesiqhelo ziintsuku ezi-3-5 ukuba iimpahla zisesitokhweni, okanye malunga neentsuku ezingama-25 ukuba iimpahla azikho esitokhweni kwaye ngokweemfuno ze-odolo.

Ukuya eMzantsi Afrika: iintsuku ezingama-45

Ukuya eMbindi Mpuma: iintsuku ezingama-30

Ukuya eMzantsi Melika: iintsuku ezingama-60

Ukuya eMntla Melika: iintsuku ezingama-30

Ukuya eRashiya: iintsuku ezisi-7

Ukuya eYurophu: iintsuku ezingama-45

Ukuya eMzantsi Korea: iintsuku ezi-5

Ukuya eJapan: iintsuku ezi-5

Ukuya eVietnam: iintsuku ezili-15

Ukuya eThailand: iintsuku ezili-15

Ukuya eIndiya: iintsuku ezingama-30

Ukuya eIndonesia: iintsuku ezili-15

Ukuya eSingapore: iintsuku ezili-10

Malunga nenkonzo

I-YUANTAIDERUN EMgangathweni Olungileyo Ixabiso Elihle Inkonzo Elungileyo.

Sinelabhoratri yobungcali,

Kunye nabasebenzi abangochwephesha bovavanyo.

Amabango Omgangatho/Ubungakanani: Umthengi unelungelo lokwenza ibango lomgangatho kunye nobungakanani ngokubhaliweyo nxamnye nomthengisi zingadlulanga iintsuku ezingama-90 emva kokufika kwizibuko apho uya khona.

EN210 EN219 BC1 API UL ISO FPC CE EPD PHD JIS3466 GB

A: 1. Sigcina umgangatho olungileyo kunye namaxabiso akhuphisanayo ukuqinisekisa inzuzo yabathengi bethu.

2. Siyabahlonipha bonke abathengi bethu njengabahlobo bethu kwaye ngokunyaniseka senza ushishino kwaye senza ubuhlobo nabo, nokuba bavela phi.

Ewe, ungazifumana iisampulu ezikhoyo kwisitokhwe sethu. Zisimahla kwiisampulu zokwenyani, kodwa abathengi kufuneka bahlawule iindleko zokuthutha.

Amathuba okusebenzisa intsimbi kwizakhiwo nakwiziseko zophuhliso awapheli. Ezona zicelo zixhaphakileyo zidweliswe ngezantsi. Kwizakhiwo, amacandelo esakhiwo: la anika isakhelo esomeleleyo nesiqinileyo sesakhiwo kwaye enza i-25% yentsimbi esetyenziswa kwizakhiwo. Iibhari zokuqinisa: ezi zongeza amandla okutsalwa kunye nokuqina kwikhonkrithi kwaye zenza i-44% yentsimbi esetyenziswa kwizakhiwo. Intsimbi isetyenziswa kuba ibopha kakuhle kwikhonkrithi, inomlinganiselo ofanayo wokwandisa ubushushu kwaye inamandla kwaye ayibizi kakhulu. Ikhonkrithi eqinisiweyo ikwasetyenziselwa ukubonelela ngeziseko ezinzulu kunye namagumbi angaphantsi komhlaba kwaye okwangoku zezona zinto zokwakha ziphambili kwihlabathi. Iimveliso zeshiti: i-31% ikwiimveliso zeshiti ezifana nophahla, ii-purlin, iindonga zangaphakathi, iisilingi, ii-cladding, kunye neepaneli zokukhusela iindonga zangaphandle. Intsimbi engeyiyo eyakhiwo: intsimbi ikwafumaneka kwiindawo ezininzi ezingezizo ezakhiwo kwizakhiwo, ezifana nezixhobo zokufudumeza nokupholisa kunye ne-interior ducting. Izinto zangaphakathi kunye nezixhobo ezifana neereli, iishelufu kunye nezitebhisi nazo zenziwe ngentsimbi. Kwiziseko zophuhlisoUthungelwano lwezothutho: intsimbi iyafuneka kwiibhulorho, kwiitonela, kumzila kaloliwe nasekukhiweni kwezakhiwo ezifana nezikhululo zokufutha amafutha, izikhululo zikaloliwe, amazibuko kunye nezikhululo zeenqwelo-moya. Malunga ne-60% yentsimbi esetyenziswayo kwesi sicelo yi-rebar kwaye enye inxalenye yi-sections, iipleyiti kunye nomzila kaloliwe. Izixhobo (ipetroli, amanzi, umbane): ngaphezulu kwe-50% yentsimbi esetyenzisiweyo kwesi sicelo ikwiipayipi ezingaphantsi komhlaba ukuhambisa amanzi ukuya nokubuya ezindlini, kunye nokusasaza igesi. Enye inxalenye ikakhulu yi-rebar yezikhululo zamandla kunye nezindlu zokumpompa.