Mayelana nomkhiqizo

Singakuthumela imininingwane ejwayelekile ngesevisi ye-LCL.

Ukupenda uwoyela omelene nokugqwala,

ukupenda nge-varnish,

i-ral3000 ependiwe,

i-galvanized,

3LPE, 3PP

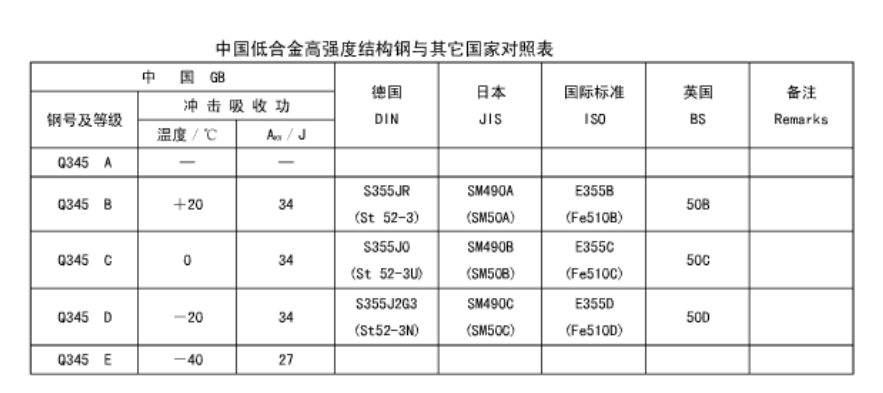

Q195 = S195 / A53 Ibanga A

Q235 = S235 / A53 Ibanga B / A500 Ibanga A / STK400 / SS400 / ST42.2

Q345 = S355JR / A500 Ibanga B Ibanga C

Q235 Al wabulawa = EN39 S235GT

L245 = Api 5L / ASTM A106 Ibanga B

Ipayipi elimnyama liyipayipi lensimbi elivamile elingenazo izembozo zokuvikela. Ipayipi elimnyama lisetshenziselwa izinhlelo ezahlukene ekhaya. Kuvamile kakhulu ukubona ipayipi elimnyama lisetshenziswa emigqeni yakho yegesi yemvelo kanye nemigqa yesistimu yokufafaza. Njengoba ipayipi elimnyama lingenazo izembozo zokuvikela, lingase ligqwale kalula ezindaweni ezimanzi noma ezinomswakama. Ukuze uvimbele ipayipi ekugqwaleni noma ekuboleni ngaphandle, kufanele unikeze ungqimba lokuvikela ngaphandle kwepayipi. Indlela elula ukuyipenda.

YEBO. Sinobambiswano oluqinile ne-SINOSURE

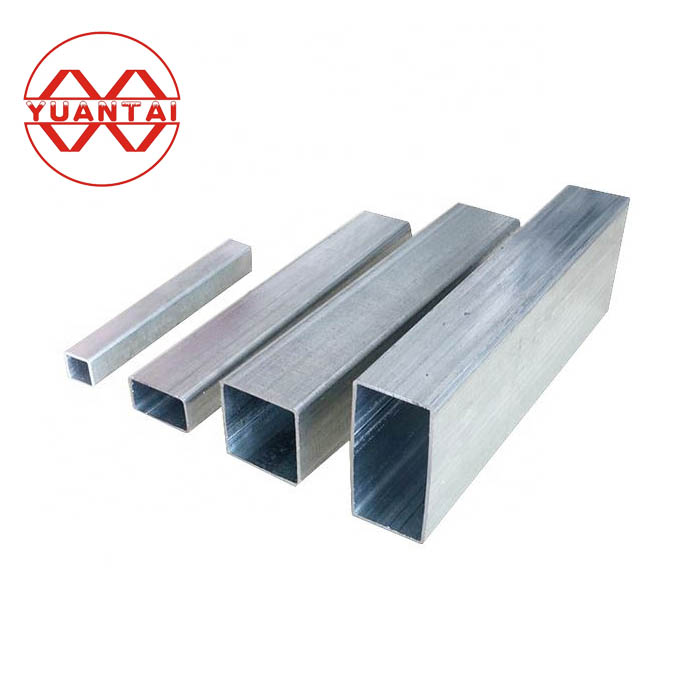

I-RHS imele i-Rectangular Hollow Section, okungukuthi ipayipi lensimbi elingunxande.

Siphinde sibe nepayipi lensimbi eliyisikwele elinengxenye engenalutho, ngokwezinga elijwayelekile: ASTM A500, EN10219, JIS G3466, GB/T6728 ipayipi lensimbi eliyisikwele neliyindilinga elibandayo.

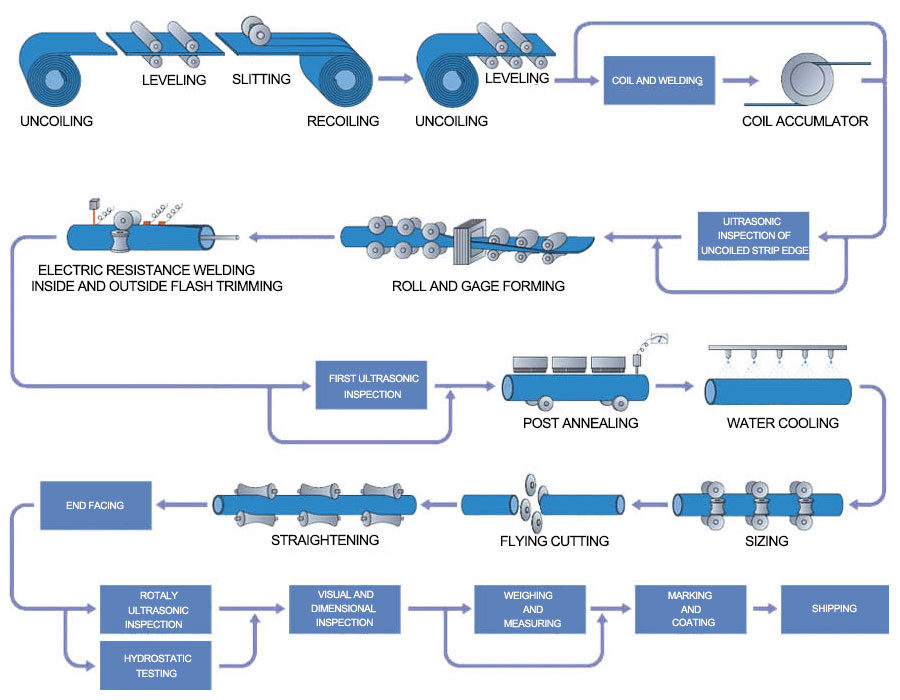

Ipayipi lensimbi le-ERW, ipayipi lensimbi le-SSAW, ipayipi lensimbi le-LSAW, ipayipi lensimbi elihlanganisiwe, ipayipi lensimbi engagqwali, ipayipi le-casing and tube, i-elbow, i-reducer, i-tee, i-cap, i-coupling, i-flange, i-weldolet, ipayipi lensimbi elingenamthungo

TT, L/C (Nge-oda elikhulu, izinsuku ezingama-30-90 zingamukeleka).

Amapayipi ensimbi ahlanganisiwe ahlukaniswe ngamapayipi ensimbi ahlanganisiwe abandayo kanye namapayipi ensimbi ahlanganisiwe ashisayo. Amapayipi ahlanganisiwe avame ukusetshenziselwa amanzi, igesi, uwoyela kanye neminye ipayipi evamile yoketshezi olunomfutho ophezulu. Asetshenziswa futhi embonini kaphethroli, ikakhulukazi amapayipi ensimu kawoyela ezindaweni zikawoyela ezingasogwini, ezindaweni zokupholisa, amapayipi okushintshana ngomusi wamalahle kanye nezinqwaba zamapayipi ebhuloho, amapayipi okusekela imayini, njll.

Amapayipi ensimbi ahlanganisiwe ahlukaniswe ngamapayipi ensimbi ahlanganisiwe abandayo kanye namapayipi ensimbi ahlanganisiwe ashisayo. Amapayipi ahlanganisiwe avame ukusetshenziselwa amanzi, igesi, uwoyela kanye neminye ipayipi evamile yoketshezi olunomfutho ophezulu. Asetshenziswa futhi embonini kaphethroli, ikakhulukazi amapayipi ensimu kawoyela ezindaweni zikawoyela ezingasogwini, ezindaweni zokupholisa, amapayipi okushintshana ngomusi wamalahle kanye nezinqwaba zamapayipi ebhuloho, amapayipi okusekela imayini, njll.

Kuthiwa ipayipi lensimbi elenziwe nge-galvanized lisetshenziselwa igesi nokushisa. Njengepayipi lamanzi, inani elincane lokugqwala lizotholakala ngemva kweminyaka embalwa. Aligcini nje ngokungcolisa izinto zangasese, kodwa futhi nama-bacteria akhula odongeni lwangaphakathi lwepayipi. Ukugqwala kubangela okuqukethwe okuphezulu kwensimbi emanzini futhi kubeka impilo yabantu engozini.

Ukugaya i-hot dip kuwukucwilisa ipayipi lensimbi ku-asidi yokugeza, bese ulungisa isixazululo samanzi ngesisombululo samanzi se-ammonium chloride noma i-zinc chloride kanye ne-zinc chloride, bese uyithela emseleni. I-hot dip galvanized coating iyafana, inokunamathela okuqinile kanye nokuphila isikhathi eside. I-matrix yepayipi lensimbi eligayiwe eligayiwe eligayiwe eliyi-electroplating eyinkimbinkimbi, ngakho-ke ukusabela kwamakhemikhali kwakha ukwakheka okuhlangene kanye nokumelana nokugqwala. Ingqimba ye-alloy ihlanganiswe nengqimba ye-zinc emsulwa kanye nesisekelo sepayipi lensimbi, ngakho-ke inokumelana okuqinile kokugqwala.

Ipayipi elibandayo elihlanganisiwe liyi-electro galvanized, futhi kunomehluko omkhulu phakathi kokumelana nokugqwala kanye nepayipi elishisayo elihlanganisiwe. Ukuze kuqinisekiswe ikhwalithi, abakhiqizi abaningi abasemthethweni bokuphatha i-galvanizing abafaki i-electro galvanizing (i-cold plating). Lawo mabhizinisi amancane angakahleleki azosebenzisa i-electro galvanizing ngoba intengo ishibhile. Ingqimba elihlanganisiwe lepayipi lensimbi elihlanganisiwe elihlanganisiwe liyi-coating. Ingqimba le-zinc lihlanganiswe ngokuzimela nge-matrix yepayipi lensimbi. Ingqimba le-zinc lincane, elixhunywe nje nepayipi lensimbi futhi kulula ukuliyeka. Ngakho-ke, ukumelana kwalo nokugqwala kubi. Ngakho-ke, kwamanye amapayipi angcwatshwe ngqo, amapayipi ensimbi ensimbi ahlanganisiwe akhiqizwa abakhiqizi abavamile asasetshenziswa.

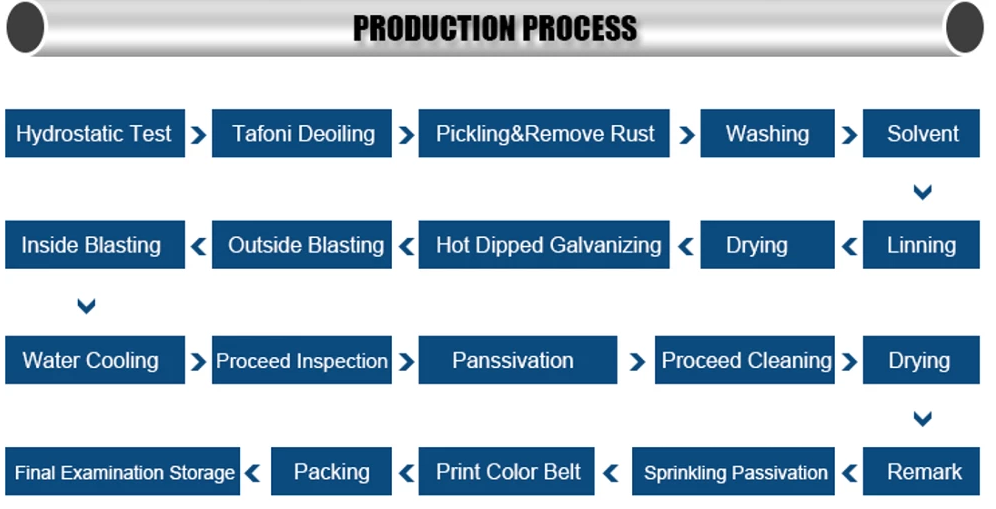

Ungasusa kanjani ipayipi lensimbi eligobile?

Okokuqala, faka isinyibilikisi ngaphandle kwensimbi ukuze ususe izinto eziphilayo. Ukugqwala kungasuswa nangokufaka i-pickling ngemva kokuxubha ukuvimbela ukugqwala, ukuhlanza noma i-ayina, ukugqwala, i-welding slag, njll. I-Galvanizing ihlukaniswe nge-thermoelectric coating kanye ne-coating ebandayo. I-thermoelectric coating akulula ukuyigqwala kanti i-coating ebandayo kulula ukuyigqwala.

Ipayipi lamanzi omlilo lamanje manje lisebenzisa ipayipi elihlanganisiwe, kanti ungqimba lwangaphandle lwepayipi elihlanganisiwe lufakwa engqimbeni yopende. Kungabonakala ukuthi ipayipi lomlilo empeleni lihlanganisiwe. Esakhiweni sensimbi, ubunjiniyela bokushisela bunengxenye yalo. Ngakho-ke, ukusetshenziswa njalo kwepayipi lensimbi elihlanganisiwe kungavimbela ukugqwala isikhathi eside.

1. OD 219mm nangaphansi Ezinqwabeni ezilungele ulwandle ezigoqwe ngemicu yensimbi, Ezinezihlikihli ezimbili ze-nylon zenqwabeni ngayinye

2. ngenhla kwe-OD 219mm ngobuningi noma ngokusho kombono wangokwezifiso

3. Amathani angu-25/isitsha kanye namathani angu-5/usayizi we-oda lokuhlola;

4. Kwisitsha esingama-intshi angu-20 ubude obuphezulu bungu-5.8m;

5. Kwisitsha esingamasentimitha angu-40 ubude obuphezulu bungu-11.8m.

YEBO SINAYO

I-YUANTAIDERUN Brand TOP 500 China

Ingxube esekelwe ensimbini ibhekwa njengensimbi ye-alloy lapho i-manganese ingaphezu kuka-1.65%, i-silicon ingaphezu kuka-0.5%, ithusi lingaphezu kuka-0.6%, noma ezinye izinto ezincane kakhulu ze-alloy ezifana ne-chromium, i-nickel, i-molybdenum, noma i-tungsten zikhona. Izinhlobo eziningi zezakhiwo ezihlukile zingadalwa ngensimbi ngokufaka lezi zinto endaweni yeresiphi.

Inqubo yokuqhubeka nokuthuthukisa insimbi engagqwali ngokunciphisa okuqukethwe yikhabhoni

Inani lekhabhoni ensimbini engagqwali kumele libe ngaphansi kwelensimbi yekhabhoni noma ensimbini ye-alloy ephansi (okungukuthi, insimbi enokuqukethwe kwe-alloying element ngaphansi kuka-5%). Ngenkathi ama-arc furniture kagesi (i-EAF) kuyindlela evamile yokuncibilikisa nokucwenga insimbi engagqwali, i-AOD iyisengezo esingabizi, njengoba isikhathi sokusebenza sifushane futhi amazinga okushisa aphansi kune-EAF steelmaking. Ngaphezu kwalokho, ukusebenzisa i-AOD ekucwengisiseni insimbi engagqwali kwandisa ukutholakala kwe-EAF ngezinjongo zokuncibilikisa.

Insimbi encibilikisiwe, engacwengiwe idluliselwa kusuka ku-EAF iye esitsheni esihlukile. Ingxube ye-argon nomoya-mpilo iyapheshulwa kusukela phansi kwesitsha ngensimbi encibilikisiwe. Izinto zokuhlanza zengezwa esitsheni kanye nala magesi ukuze kususwe ukungcola, kuyilapho umoya-mpilo uhlangana nekhabhoni ensimbini engacwengiwe ukuze kuncishiswe izinga lekhabhoni. Ukuba khona kwe-argon kuthuthukisa ukusondelana kwekhabhoni nomoya-mpilo futhi ngaleyo ndlela kusiza ekususweni kwekhabhoni.

Ukugqwala kwensimbi yesakhiwo kuyinqubo ye-electrochemical edinga ukuba khona komswakama nomoya-mpilo ngasikhathi sinye. Uma kungekho noma yikuphi, ukugqwala akwenzeki. Empeleni, insimbi ensimbini iyashiswa ukuze ikhiqize ukugqwala, okuthatha cishe izikhathi ezi-6 zomthamo wezinto zokuqala ezisetshenziswe kule nqubo. Inqubo yokugqwala ejwayelekile iboniswe lapha. Ngaphezu kokugqwala okuvamile, kunezinhlobo ezahlukene zokugqwala kwendawo okungase kwenzeke; ukugqwala kwe-bimetallic, ukugqwala kwemigodi kanye nokugqwala kwe-crevice. Kodwa-ke, lokhu akuvamile ukuba yigugu emsebenzini wensimbi yesakhiwo. Izinga lapho inqubo yokugqwala iqhubeka khona lincike ezintweni eziningana ezihlobene 'nesimo sezulu esincane' esizungeze isakhiwo, ikakhulukazi isikhathi somswakama kanye nezinga lokungcola komoya. Ngenxa yokwehluka ezindaweni zomoya, idatha yesilinganiso sokugqwala ayikwazi ukuhlanganiswa. Kodwa-ke, izindawo zingahlukaniswa kabanzi, futhi amazinga okugqwala ensimbi alinganisiwe ahambisanayo anikeza inkomba ewusizo yamazinga okugqwala okungenzeka. Ulwazi olwengeziwe lungatholakala ku-BS EN ISO 12944-2 kanye ne-BS EN ISO 9223

KupendweI-SHS (izingxenye ezingenalutho eziyisikwele)kanye ne-RHS (izingxenye ezingenalutho ezingunxande) ziyizingxenye zensimbi ezingenalutho ezakhiwe ngokubandayo ezipendwe nge-primer ukuze zivikeleke ngesikhathi sokugcina nokuphatha.

Umphumela wesithombe sepayipi lensimbi eliyisikwele elishisayo eligayiwe

Uma ubhekene nokushisa okuqhubekayo isikhathi eside, izinga lokushisa eliphakeme elinconywayo lensimbi egayiwe eshisayo lingu-200 °C (392 °F), ngokusho kwe-American Galvanizers Association. Ukusetshenziswa kwensimbi egayiwe emazingeni okushisa angaphezu kwalokhu kuzoholela ekuqhekekeni kwe-zinc engqimbeni yensimbi ephakathi.

Kusho ingxenye engenalutho eyisikwele efushaniswe ngokuthi i-SHS

Kusho ingxenye eyindilinga engenalutho, efushaniswe ngokuthi i-SHS.

Mayelana nokulethwa

Ngokuvamile kuba yizinsuku ezi-3-5 uma izimpahla zisesitokweni, noma cishe izinsuku ezingama-25 uma izimpahla zingekho esitokweni futhi kuya ngokwesidingo se-oda.

Ukuya eNingizimu Afrika: izinsuku ezingu-45

Ukuya eMpumalanga Ephakathi: izinsuku ezingu-30

Ukuya eNingizimu Melika: izinsuku ezingu-60

Ukuya eNyakatho Melika: izinsuku ezingu-30

Ukuya eRussia: izinsuku eziyi-7

Ukuya eYurophu: izinsuku ezingu-45

Ukuya eNingizimu Korea: izinsuku ezi-5

Ukuya eJapan: izinsuku ezi-5

Ukuya eVietnam: izinsuku ezingu-15

Ukuya eThailand: izinsuku ezingu-15

Ukuya eNdiya: izinsuku ezingu-30

Ukuya e-Indonesia: izinsuku ezingu-15

Ukuya eSingapore: izinsuku eziyi-10

Mayelana nesevisi

I-YUANTAIDERUN IKHWALITHI ELIHLE INTENGO ELIHLE ISEVISI ELIHLE.

Sine-laboratory yobungcweti,

Nabasebenzi bokuhlola abangochwepheshe.

Izimangalo Zekhwalithi/Ubuningi: Umthengi unelungelo lokwenza isimangalo sekhwalithi kanye nobuningi ngokubhala ngokumelene noMthengisi zingakapheli izinsuku ezingu-90 ngemuva kokufika echwebeni lapho eya khona.

I-EN210 EN219 BC1 API UL ISO FPC CE EPD PHD JIS3466 GB

A: 1. Sigcina ikhwalithi enhle kanye nentengo yokuncintisana ukuqinisekisa izinzuzo zamakhasimende ethu.

2. Siyahlonipha wonke amakhasimende njengomngane wethu futhi senza ibhizinisi ngobuqotho futhi sakha ubungane nawo, kungakhathaliseki ukuthi avelaphi.

Yebo, ungathola amasampula atholakalayo esitokweni sethu. Mahhala kumasampula angempela, kodwa amakhasimende kudingeka akhokhe izindleko zokuthutha.

Amathuba okusebenzisa insimbi ezakhiweni nasezingqalasizinda awapheli. Izinhlelo ezivame kakhulu zibhalwe ngezansi. Ezakhiweni Izingxenye zesakhiwo: lezi zinikeza uhlaka oluqinile noluqinile lwesakhiwo futhi zakha u-25% wokusetshenziswa kwensimbi ezakhiweni. Imigoqo yokuqinisa: lezi zengeza amandla okunamathela nokuqina kukhonkolo futhi zakha u-44% wokusetshenziswa kwensimbi ezakhiweni. Insimbi isetshenziswa ngoba ibopha kahle kukhonkolo, ine-coefficient efanayo yokwandisa ukushisa futhi iqinile futhi ingabizi kakhulu. Ikhonkolo eqinisiwe isetshenziselwa futhi ukuhlinzeka ngezisekelo ezijulile kanye nezindawo ezingaphansi komhlaba futhi njengamanje iyinto yokwakha eyinhloko emhlabeni. Imikhiqizo yeshidi: u-31% usezikhiqizweni zeshidi ezifana nophahla, ama-purlin, izindonga zangaphakathi, ophahleni, ukumbozwa, kanye namaphaneli okuvikela izindonga zangaphandle. Insimbi engeyona eyakhekile: insimbi itholakala nasezinhlelweni eziningi ezingeyona eyakhekile ezakhiweni, njengemishini yokushisa nokupholisa kanye nemigudu yangaphakathi. Izinto zangaphakathi kanye nezinto zokufaka ezifana nezitimela, amashelufu nezitebhisi nazo zenziwe ngensimbi. NgengqalasizindaAmanethiwekhi ezokuthutha: insimbi iyadingeka emabhulohweni, emihubheni, emzileni wesitimela kanye nasekwakheni izakhiwo ezifana neziteshi zikaphethiloli, iziteshi zesitimela, amachweba kanye nezikhumulo zezindiza. Cishe u-60% wokusetshenziswa kwensimbi kulolu hlelo lokusebenza uyi-rebar kanti okunye kuyizingxenye, amapuleti kanye nomzila wesitimela. Izinsiza (uphethiloli, amanzi, ugesi): ngaphezu kuka-50% wensimbi esetshenziselwa lolu hlelo lokusebenza isezipayipini ezingaphansi komhlaba ukusabalalisa amanzi ukuya nokubuya ezindlini, kanye nokusabalalisa igesi. Okunye ikakhulukazi kuyi-rebar yeziteshi zikagesi kanye nezindlu zokupompa.