Yn ôl Safon API SPEC 5CT1988 rhifyn 1af Sefydliad Petrolewm America, gellir rhannu gradd ddur pibell gasin olew API 5CT yn ddeg math, gan gynnwys H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 a Q-125. Rydym yn cyflenwi'r bibell gasin a Thiwbiau Casin API 5CT K55 ynghyd ag edau a chyplydd, neu rydym yn cynnig ein cynnyrch yn unol â'r ffurflenni canlynol ar gyfer opsiwn.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Manylebau Tiwbiau Casin API 5CT K55

| MANYLEBAU TIWBIO CASIN API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Safonau | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Ystod Hyd | 3-12M neu yn ôl gofynion y cleient | |

| Gradd Dur (Graddau Casin, Gradau Tiwbiau) | Gradd A, Gradd B, Gradd C, X42, X52, X60, X65, X70 | |

| Math o Edau Sgriw | Pen edau heb ei gynhyrfu (NUE), Pen edau allanol wedi'i gynhyrfu (EUE) | |

| Arbenigeddau |

| |

| Gorffen | Pennau Allanol wedi'u Cynhyrfu (EUE), Cymal Fflysio, PH6 (a chysylltiadau cyfatebol), Cymal Integredig (IJ) | |

Gofyniad Tynnol a Chaledwch Tiwbiau Casio API 5CT K55

| Grŵp | Gradd | Math | Cyfanswm ymestyn o dan lwyth % | Cryfder cynnyrch MPa | Cryfder tynnol min. MPa | Caledwch uchafswm. | Trwch wal penodedig mm | Amrywiad caledwch a ganiateir b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| munud | uchafswm | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 i 19.04 19.05 i 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 i 19.04 19.05 i 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 i 19.04 19.05 i 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | C125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 i 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aMewn achos o anghydfod, defnyddir prawf caledwch Rockwell C labordy fel y dull dyfarnwr. bNi nodir unrhyw derfynau caledwch, ond mae'r amrywiad mwyaf wedi'i gyfyngu yn unol â 7.8 a 7.9 o Fanyleb API 5CT. | ||||||||||

Dimensiynau Tiwbiau Casin K55

| Meintiau Casin Pibellau, Meintiau Casin Maes Olew a Meintiau Drifft Casin | |

|---|---|

| Diamedr Allanol (Meintiau Pibellau Casin) | 4 1/2"-20", (114.3-508mm) |

| Meintiau Casin Safonol | 4 1/2"-20", (114.3-508mm) |

| Math o Edau | Casin edau bwtres, Casin edau crwn hir, Casin edau crwn byr |

| Swyddogaeth | Gall amddiffyn y bibell tiwbiau. |

Tiwb Olew ar gyfer Diwydiannau Petrolewm a Nwy Naturiol

| Enw'r Pibellau | Manyleb | Gradd Dur | Safonol | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pibell Casin Petroliwm | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80. P110. | Manyleb API 5CT (8) |

| Tiwbiau Petrolewm | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Manyleb API 5CT (8) |

| Cyplu | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Manyleb API 5CT (8) |

Nodweddion Tiwbiau Casin API 5CT K55

- Cynigir Tiwbiau Casin API 5CT K55 gydag ystod hyd rhydd o 8m i 13m ar sail y norm SY/T6194-96. Fodd bynnag, mae hefyd ar gael o leiaf 6m o hyd a ni ddylai ei faint fod yn fwy na 20%.

- Ni chaniateir i anffurfiadau a grybwyllir uchod ymddangos ar wyneb allanol cyplu Tiwbiau Casin API 5CT K55.

- Ni dderbynnir unrhyw anffurfiad fel llinell flewog, gwahanu, crych, crac neu gragen ar arwynebau mewnol ac allanol y cynnyrch. Dylid cael gwared ar yr holl ddiffygion hyn yn llwyr a rhaid i'r dyfnder a dynnwyd beidio â bod yn fwy na 12.5% o drwch wal enwol.

- Dylai wyneb edau'r cyplu a Thiwbiau Casin API 5CT K55 fod yn llyfn heb unrhyw fwrw, rhwygo na diffygion eraill a allai gael effaith negyddol ar y cryfder a'r cysylltiad agos.

Mae'n bwysig i weithredwyr olew a nwy amddiffyn casinau eu ffynhonnau cynhyrchu rhag cyrydiad gydag amddiffyniad cathodig ac mae Tiwbiau Maes Olew API 5CT yn bennaf yn gwasanaethu i drosglwyddo olew a nwyon.

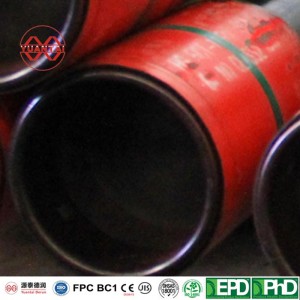

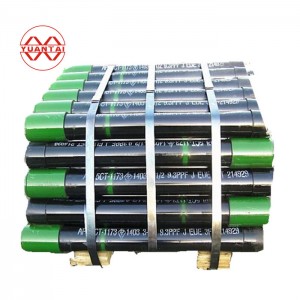

Cod Lliw Dur Tiwbiau Casin Gradd K55 API 5CT

| Enw | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casin | band gwyrdd llachar | dau fand gwyrdd llachar | band coch llachar | band coch llachar + band gwyrdd | band coch + band brown | band gwyn llachar |

| Cyplu | cyplu gwyrdd cyfan + band gwyn | cyplu gwyrdd cyfan | cyplu coch cyfan | cyplu coch cyfan + band gwyrdd | cyplu coch cyfan + band brown | cyplu gwyn cyfan |

Manylebau Tiwbiau Casin ISO/API/API 5CT K55

| Codea | Dia Allanol | Pwysau enwol (gyda edau a cyplu) b,c | Trwch y Wal | Math o brosesu terfynol | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Pwys/tr | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Pibell casin API 5CT Codea | Pibell casin API 5CT Diamedr allanol | Pibell casio API 5CT Pwysau enwol (gyda edau a chyplu) b,c | Pibell casin API 5CT Trwch wal | Pibell casio API 5CT Math o brosesu diwedd | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Pwys/tr | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| Edau crwn byr - S, Edau crwn hir - L, Edau bwtres - B | ||||||||||||

| a. Defnyddir y cod ar gyfer cyfeirnod archebu. | ||||||||||||

| b. Dangosir pwysau enwol y casin edau a chyplysedig (colofn 2) at ddibenion cyfeirio yn unig. | ||||||||||||

| c. Mae dur cromiwm martensitig (L80 9Cr a 13Cr) yn wahanol i ddur carbon o ran dwysedd. Nid yw pwysau dur cromiwm martensitig a ddangosir yn werth union. Gellir defnyddio'r ffactor cywiro màs o 0.989. | ||||||||||||

| d. Dylid cyflenwi casin dur gradd C90, T95 a Q125 yn unol â'r fanyleb, y pwysau a'r trwch wal a restrir yn y tabl neu'r archeb uchod. | ||||||||||||

Cyfansoddiad Cemegol API 5CT K55

| Grŵp | Gradd | Math | C | Mn | Mo | Cr | Ni uchafswm. | Uchafswm Cu. | P uchafswm. | S uchafswm. | Si uchafswm. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| munud | uchafswm | munud | uchafswm | munud | uchafswm | munud | uchafswm | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 diwrnod | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | C125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Gellir cynyddu cynnwys carbon L80 hyd at uchafswm o 0.50% os yw'r cynnyrch yn cael ei ddiffodd ag olew. b Nid oes gan gynnwys molybdenwm Gradd C90 Math 1 unrhyw oddefgarwch lleiaf os yw trwch y wal yn llai na 17.78 mm. c Gellir cynyddu cynnwys carbon R95 hyd at uchafswm o 0.55% os yw'r cynnyrch wedi'i ddiffodd ag olew. Gellir lleihau cynnwys molybdenwm T95 Math 1 i o leiaf 0.15% os yw trwch y wal yn llai na 17.78 mm. e Ar gyfer EW Gradd P110, rhaid i'r cynnwys ffosfforws fod yn uchafswm o 0.020% a'r cynnwys sylffwr fod yn uchafswm o 0.010%. NL = dim terfyn. Dylid adrodd ar yr elfennau a ddangosir yn y dadansoddiad cynnyrch. | |||||||||||||||

Priodweddau Mecanyddol API 5CT k55 Gr.

| Safon Casio API 5CT | Math | Cryfder Tensiwn Casin API 5CT MPa | Cryfder Cynnyrch Casio API 5CT MPa | Caledwch Casio API 5CT Uchafswm |

|---|---|---|---|---|

| MANYLEB API 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Mae'r cwmni'n rhoi pwys mawr ar ansawdd cynhyrchion, yn buddsoddi'n helaeth mewn cyflwyno offer a gweithwyr proffesiynol uwch, ac yn gwneud popeth posibl i ddiwallu anghenion cwsmeriaid gartref a thramor.

Gellir rhannu'r cynnwys yn fras yn: cyfansoddiad cemegol, cryfder cynnyrch, cryfder tynnol, priodwedd effaith, ac ati

Ar yr un pryd, gall y cwmni hefyd gynnal canfod diffygion ar-lein ac anelio a phrosesau trin gwres eraill yn ôl anghenion y cwsmer.

https://www.ytdrintl.com/

E-bost:sales@ytdrgg.com

Grŵp Gweithgynhyrchu Tiwbiau Dur Tianjin YuantaiDerun Co., Ltd.yn ffatri pibellau dur ardystiedig ganEN/ASTM/ JISyn arbenigo mewn cynhyrchu ac allforio pob math o bibell betryal sgwâr, pibell galfanedig, pibell weldio ERW, pibell droellog, pibell weldio arc tanddwr, pibell sêm syth, pibell ddi-dor, coil dur wedi'i orchuddio â lliw, coil dur galfanedig a chynhyrchion dur eraill. Gyda chludiant cyfleus, mae 190 cilomedr i ffwrdd o Faes Awyr Rhyngwladol Prifddinas Beijing ac 80 cilomedr i ffwrdd o Tianjin Xingang.

Whatsapp: +8613682051821