Zgodnie z normą API SPEC 5CT1988 Amerykańskiego Instytutu Naftowego, wydanie 1, gatunek stali rur osłonowych API 5CT można podzielić na dziesięć typów, w tym H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 i Q-125. Dostarczamy rury osłonowe i rury osłonowe API 5CT K55 wraz z gwintem i złączką lub oferujemy nasz produkt zgodnie z poniższymi formularzami.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Specyfikacje rur osłonowych API 5CT K55

| SPECYFIKACJE RURY OSŁONOWEJ API 5CT K55 | ||

| OD | 10,3 mm-2032 mm | |

| Standardy | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Zakres długości | 3-12M lub zgodnie z wymaganiami klienta | |

| Gatunek stali (gatunki obudów, gatunki rur) | Grupa A, Grupa B, Grupa C, X42, X52, X60, X65, X70 | |

| Rodzaj gwintu śruby | Koniec gwintowany bez spęczenia (NUE), koniec gwintowany zewnętrznie spęczeniem (EUE) | |

| Specjalizacje |

| |

| Wykończenie końcowe | Zewnętrzne końce spęczone (EUE), połączenie płaskie, PH6 (i połączenia równoważne), połączenie integralne (IJ) | |

Wymagania dotyczące wytrzymałości i twardości rur osłonowych API 5CT K55

| Grupa | Stopień | Typ | Całkowite wydłużenie pod obciążeniem % | Granica plastyczności MPa | Wytrzymałość na rozciąganie min. MPa | Twardość maks. | Określona grubość ścianki mm | Dopuszczalna zmienność twardości b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | Rada Praw Człowieka | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0,5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0,5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0,5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0,5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0,5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0,5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12,70 12,71 do 19,04 19,05 do 25,39 ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| T95 | 1 | 0,5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12,70 12,71 do 19,04 19,05 do 25,39 ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| C110 | - | 0,7 | 758 | 828 | 793 | 30 | 286 | ≤ 12,70 12,71 do 19,04 19,05 do 25,39. ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| 3 | P110 | - | 0,6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0,65 | 862 | 1034 | 931 | b | - | ≤ 12,70 12,71 do 19,04 ≥ 19,05 | 3,0 4,0 5,0 |

| aW razie sporu, jako metodę rozstrzygającą należy posłużyć się badaniem twardości metodą Rockwella C. bNie określono żadnych ograniczeń twardości, ale maksymalne odchylenia są ograniczone zgodnie z punktami 7.8 i 7.9 normy API Spec. 5CT. | ||||||||||

Wymiary rury osłonowej K55

| Rozmiary obudów rur, rozmiary obudów złóż naftowych i rozmiary dryftu obudowy | |

|---|---|

| Średnica zewnętrzna (rozmiary rur osłonowych) | 4 1/2"-20", (114,3-508 mm) |

| Standardowe rozmiary obudowy | 4 1/2"-20", (114,3-508 mm) |

| Typ gwintu | Osłona gwintu podporowego, długa osłona gwintu okrągłego, krótka osłona gwintu okrągłego |

| Funkcjonować | Może chronić rurę. |

Rura olejowa dla przemysłu naftowego i gazowego

| Nazwa rur | Specyfikacja | Gatunek stali | Standard | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (M) | |||

| Rura osłonowa naftowa | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | Specyfikacja API 5CT (8) |

| Rury naftowe | 26,7-114,3 | 2,87-16,00 | 6-12 | J55. M55. K55. L80. N80. P110. | Specyfikacja API 5CT (8) |

| Sprzęganie | 127-533.4 | 12,5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Specyfikacja API 5CT (8) |

Cechy rur osłonowych API 5CT K55

- Rury osłonowe API 5CT K55 oferowane są w dowolnym zakresie długości od 8 do 13 m, zgodnie z normą SY/T6194-96. Dostępne są również rury o długości nie mniejszej niż 6 m, a ich ilość nie powinna przekraczać 20%.

- Odkształcenia, o których mowa powyżej, nie mogą pojawić się na zewnętrznej powierzchni łącznika rury osłonowej API 5CT K55.

- Wszelkie deformacje, takie jak włoskowatość, rozwarstwienie, zagniecenia, pęknięcia lub strupy, są niedopuszczalne zarówno na powierzchni wewnętrznej, jak i zewnętrznej produktu. Wszystkie te wady powinny zostać całkowicie usunięte, a głębokość usunięcia nie może przekraczać 12,5% nominalnej grubości ścianki.

- Powierzchnia gwintu złącza i rury osłonowej API 5CT K55 powinna być gładka, bez zadziorów, rozdarć lub innych wad, które mogą negatywnie wpłynąć na wytrzymałość i szczelność połączenia.

Dla operatorów złóż ropy naftowej i gazu ważne jest zabezpieczenie obudów odwiertów produkcyjnych przed korozją za pomocą ochrony katodowej. Rury do pól naftowych API 5CT służą przede wszystkim do przesyłu ropy naftowej i gazów.

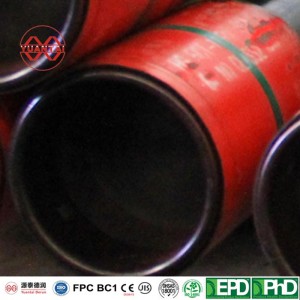

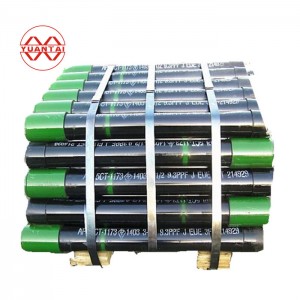

Kod kolorów rur osłonowych ze stali API 5CT klasy K55

| Nazwa | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Obudowa | jasnozielony pasek | dwa jasnozielone paski | jasnoczerwony pasek | jasnoczerwony pasek + zielony pasek | czerwony pasek + brązowy pasek | jasny biały pas |

| Sprzęganie | całe zielone sprzęgło + biały pas | całe zielone sprzęgło | całe czerwone sprzęgło | całe czerwone sprzęgło + zielony pas | całe czerwone sprzęgło + brązowy pas | całe białe sprzęgło |

Specyfikacje rur osłonowych ISO/API/API 5CT K55

| Koda | Średnica zewnętrzna | Waga nominalna (z nicią i sprzężenie) b, c | Grubość ścianki | Typ przetwarzania końcowego | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Funt/stopa | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9,5 | 114,3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114,3 | 15.63 | 5,69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114,3 | 17.26 | 6,35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13,5 | 114,3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114,3 | 22,47 | 8,56 | - | - | - | - | - | - | LB | LB |

| 5 | 11,5 | 127 | 17.11 | 5,59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19,35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7,52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26,79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31,85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34,53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35,86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139,7 | 20,83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15,5 | 139,7 | 23.07 | 6,98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139,7 | 25.3 | 7,72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139,7 | 29,76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139,7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168,28 | 29,76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168,28 | 35,72 | 8,94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168,28 | 41,67 | 10,59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168,28 | 47,62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177,8 | 25.3 | 5,87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177,8 | 29,76 | 6,91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177,8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177,8 | 38,69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177,8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177,8 | 47,62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177,8 | 52.09 | 12,65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193,68 | 35,72 | 7,62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193,68 | 39,29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29,7 | 193,68 | 44.2 | 9,52 | - | - | LB | LB | - | |||

| 7-5-8 | 33,7 | 193,68 | 50,15 | 10,92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193,68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42,8 | 193,68 | 63,69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193,68 | 67,41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193,68 | 70.09 | 15,88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219,08 | 35,72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219,08 | 41,67 | 7,72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219,08 | 47,62 | 8,94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219,08 | 53,57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219,08 | 59,53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219,08 | 65,48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219,08 | 72,92 | 14.15 | - | - | - | LB | LB | LB | ||

| Rura osłonowa API 5CT Codea | Średnica zewnętrzna rury osłonowej API 5CT | Rura osłonowa API 5CT Masa nominalna (z gwintem i sprzężenie) b, c | Rura osłonowa API 5CT Grubość ścianki | Typ obróbki końcowej rury osłonowej API 5CT | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Funt/stopa | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244,48 | 48.07 | 7,92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244,48 | 53,57 | 8,94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244,48 | 59,53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43,5 | 244,48 | 64,73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244,48 | 69,94 | 11,99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53,5 | 244,48 | 79,62 | 13,84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58,4 | 244,48 | 86,91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32,75 | 273,05 | 48,74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40,5 | 273,05 | 60,27 | 8,89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45,5 | 273,05 | 67,71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273,05 | 75,9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55,5 | 273,05 | 82,59 | 12,57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60,7 | 273,05 | 90,33 | 13,84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65,7 | 273,05 | 97,77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298,45 | 62,5 | 8,46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298,45 | 69,94 | 9,53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298,45 | 80,36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298,45 | 89,29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339,72 | 71,43 | 8,38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54,5 | 339,72 | 81.1 | 9,65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339,72 | 90,78 | 10,92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339,72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339,72 | 107,15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406,4 | 96,73 | 9,53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406,4 | 111,61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406,4 | 125,01 | 12,57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87,5 | 473,08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139,89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106,5 | 508 | 158,49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197,93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S - Krótki gwint okrągły, L - Długi gwint okrągły, B - Gwint trapezowy | ||||||||||||

| a. Kod służy do zamawiania. | ||||||||||||

| b. Nominalna masa obudowy gwintowanej i sprzężonej (kolumna 2) jest podana wyłącznie w celach informacyjnych. | ||||||||||||

| c. Martenzytyczna stal chromowa (L80 9Cr i 13Cr) różni się gęstością od stali węglowej. Podana masa martenzytycznej stali chromowej nie jest wartością dokładną. Można zastosować współczynnik korekcji masy 0,989. | ||||||||||||

| d. Obudowy ze stali C90, T95 i Q125 powinny być dostarczane zgodnie ze specyfikacją, wagą i grubością ścianki podaną w powyższej tabeli lub zamówieniu. | ||||||||||||

Skład chemiczny API 5CT K55

| Grupa | Stopień | Typ | C | Mn | Mo | Cr | Maks. niklowanie. | Cu max. | P maks. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | min. | maks. | min. | maks. | min. | maks. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| R95 | - | - | 0,45 c | - | 1.9 | - | - | - | - | - | - | 0,03 | 0,03 | 0,45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| L80 | 1 | - | 0,43 a | - | 1.9 | - | - | - | - | 0,25 | 0,35 | 0,03 | 0,03 | 0,45 | |

| L80 | 9Cr | - | 0,15 | 0,3 | 0,6 | 0,9 | 1.1 | 8 | 10 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| L80 | 13Cr | 0,15 | 0,22 | 0,25 | 1 | - | - | 12 | 14 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| C90 | 1 | - | 0,35 | - | 1.2 | 0,25 b | 0,85 | - | 1,5 | 0,99 | - | 0,02 | 0,01 | - | |

| T95 | 1 | - | 0,35 | - | 1.2 | 0,25 dnia | 0,85 | 0,4 | 1,5 | 0,99 | - | 0,02 | 0,01 | - | |

| C110 | - | - | 0,35 | - | 1.2 | 0,25 | 1 | 0,4 | 1,5 | 0,99 | - | 0,02 | 0,005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0,030 e | 0,030 e | - |

| 4 | Q125 | 1 | - | 0,35 | 1,35 | - | 0,85 | - | 1,5 | 0,99 | - | 0,02 | 0,01 | - | |

| a Zawartość węgla w przypadku L80 może zostać zwiększona maksymalnie do 0,50%, jeśli produkt jest hartowany w oleju. b Zawartość molibdenu dla gatunku C90 typu 1 nie ma minimalnej tolerancji, jeśli grubość ścianki jest mniejsza niż 17,78 mm. c Zawartość węgla w przypadku R95 może zostać zwiększona maksymalnie do 0,55%, jeśli produkt jest hartowany w oleju. d Zawartość molibdenu w przypadku stali T95 typu 1 może zostać zmniejszona do minimum 0,15%, jeżeli grubość ścianki jest mniejsza niż 17,78 mm. e W przypadku gatunku EW P110 zawartość fosforu nie może przekraczać 0,020%, a zawartość siarki nie może przekraczać 0,010%. NL = bez ograniczeń. Podane pierwiastki należy uwzględnić w analizie produktu. | |||||||||||||||

API 5CT k55 Gr. Właściwości mechaniczne

| Norma obudowy API 5CT | Typ | Wytrzymałość na rozciąganie obudowy API 5CT MPa | Wytrzymałość na rozciąganie obudowy API 5CT MPa | Twardość obudowy API 5CT Maks. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Firma przywiązuje dużą wagę do jakości swoich produktów, inwestuje znaczne środki w rozwój zaawansowanego sprzętu i zatrudnia specjalistów, a także dokłada wszelkich starań, aby sprostać oczekiwaniom klientów w kraju i za granicą.

Zawartość można ogólnie podzielić na: skład chemiczny, granicę plastyczności, wytrzymałość na rozciąganie, udarność itp.

Jednocześnie firma może także przeprowadzać on-line wykrywanie wad, wyżarzanie i inne procesy obróbki cieplnej zgodnie z potrzebami klienta.

https://www.ytdrintl.com/

Adres e-mail:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.jest certyfikowaną fabryką rur stalowychEN/ASTM/ JISSpecjalizujemy się w produkcji i eksporcie wszystkich rodzajów rur kwadratowych i prostokątnych, rur ocynkowanych, rur spawanych metodą ERW, rur spiralnych, rur spawanych łukiem krytym, rur z prostym szwem, rur bez szwu, stalowych kręgów powlekanych kolorowo, stalowych kręgów ocynkowanych i innych produktów stalowych. Dzięki dogodnemu transportowi firma znajduje się 190 kilometrów od międzynarodowego lotniska w Pekinie i 80 kilometrów od Tianjin Xingang.

WhatsApp: +8613682051821