Malinga ndi American Petroleum Institute Standard API SPEC 5CT1988 1st edition, chitsulo cha API 5CT mafuta casing payipi chingagawidwe m'mitundu khumi, kuphatikizapo H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 ndi Q-125. Timapereka casing payipi & API 5CT K55 Casing Tubing limodzi ndi ulusi ndi cholumikizira, kapena timapereka malonda athu motsatira mafomu otsatirawa kuti musankhe.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Mafotokozedwe a API 5CT K55 Casing Tubing

| Mafotokozedwe a API 5CT K55 Casing Tubing | ||

| OD | 10.3mm-2032mm | |

| Miyezo | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Kutalika kwa Utali | 3-12M kapena malinga ndi zomwe kasitomala akufuna | |

| Giredi yachitsulo (Magiredi a Casing, Magiredi a Tubing) | Gr.A, Gr.B, Gr.C, X42, X52, X60, X65, X70 | |

| Mtundu wa Ulusi Wokulungira | Mapeto osasinthidwa a ulusi (NUE), Mapeto akunja osasinthidwa a ulusi (EUE) | |

| Zapadera |

| |

| Kutsiriza Kumaliza | Ma External Upset Ends (EUE), Flush Joint, PH6 (ndi ma connection ofanana), Integral Joint (IJ) | |

API 5CT K55 Casing Tubing Kufunika kwa Kulimba ndi Kulimba

| Gulu | Giredi | Mtundu | Kutalikirana konse pansi pa katundu % | MPa yamphamvu yotulutsa | Mphamvu yokoka ya MPa (min. MPa) | Kulimba kwakukulu. | Makulidwe a khoma otchulidwa mm | Kusintha kovomerezeka kwa kuuma b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| mphindi. | max. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 mpaka 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aNgati pali mkangano, mayeso a Rockwell C oyeserera kuuma ayenera kugwiritsidwa ntchito ngati njira yowunikira. bPalibe malire a kuuma omwe atchulidwa, koma kusiyana kwakukulu kumachepetsedwa malinga ndi 7.8 ndi 7.9 ya API Spec. 5CT. | ||||||||||

K55 Casing Tubing Miyeso

| Kukula kwa Chitoliro cha Mapaipi, Kukula kwa Chitoliro cha Mafuta & Kukula kwa Chitoliro cha Ma Drift | |

|---|---|

| Chidutswa chakunja (Makulidwe a mapaipi oikamo) | 4 1/2"-20", (114.3-508mm) |

| Makulidwe Okhazikika a Chikwama | 4 1/2"-20", (114.3-508mm) |

| Mtundu wa Ulusi | Chikwama cha ulusi chozungulira, Chikwama cha ulusi wautali wozungulira, Chikwama cha ulusi waufupi wozungulira |

| Ntchito | Ikhoza kuteteza chitoliro cha chubu. |

Chubu cha Mafuta a Mafuta ndi Mafuta Achilengedwe

| Dzina la Mapaipi | Kufotokozera | Kalasi yachitsulo | Muyezo | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Chitoliro Chopangira Mafuta | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Mapaipi a Mafuta | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Kulumikiza | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

Zinthu Zofunika pa Machubu a API 5CT K55 Casing

- Machubu a API 5CT K55 Casing akupezeka ndi kutalika kwaulere kuyambira 8m mpaka 13m kutengera muyezo wa SY/T6194-96. Komabe, amapezekanso kutalika kosachepera 6m ndipo kuchuluka kwake sikuyenera kupitirira 20%.

- Zosintha zomwe zatchulidwa pamwambapa siziloledwa kuwonekera pamwamba pa API 5CT K55 Casing Tubing coupling.

- Kusintha kulikonse monga tsitsi, kulekana, kusweka, ming'alu kapena nkhanambo sikuvomerezeka mkati ndi kunja kwa chinthucho. Zolakwika zonsezi ziyenera kuchotsedwa kwathunthu ndipo kuya kochotsedwako sikuyenera kupitirira 12.5% ya makulidwe a khoma.

- Pamwamba pa ulusi wolumikizira ndi API 5CT K55 Casing Tubing payenera kukhala kosalala popanda kuphulika, kung'ambika kapena zolakwika zina zomwe zingakhudze mphamvu ndi kulumikizana kwapafupi.

Ndikofunikira kuti ogwira ntchito zamafuta ndi gasi ateteze zitsime zawo zopangira kuti zisawonongeke pogwiritsa ntchito chitetezo cha cathodic & API 5CT OilField Tubing makamaka imagwiritsidwa ntchito potumiza mafuta ndi gasi.

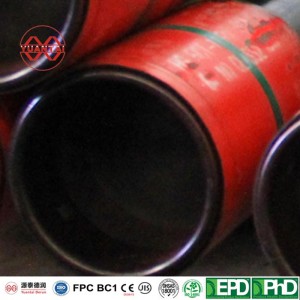

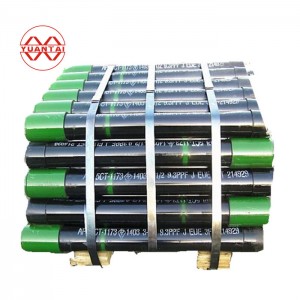

Chitsulo cha API 5CT Giredi K55 Casing Tubing Chitsulo Chokhala ndi Mtundu

| Dzina | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Chikwama | gulu lobiriwira lowala | mikanda iwiri yobiriwira yowala | gulu lofiira kwambiri | gulu lofiira kwambiri + gulu lobiriwira | gulu lofiira + gulu lofiirira | gulu loyera lowala |

| Kulumikiza | cholumikizira chobiriwira chonse + mkanda woyera | cholumikizira chobiriwira chonse | cholumikizira chofiira chonse | cholumikizira chofiira chonse + mkanda wobiriwira | cholumikizira chofiira chonse + mkanda wofiirira | cholumikizira choyera chonse |

Mafotokozedwe a ISO/API casing/ API 5CT K55 Casing Tubing

| Codea | Dia yakunja | Kulemera kodziwika (ndi ulusi ndi kuphatikiza) b,c | Kukhuthala kwa Khoma | Mtundu womaliza wa kukonza | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | makilogalamu/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Chitoliro cha API 5CT Casing | Chitoliro cha API 5CT Casing Diameter yakunja | Chitoliro cha API 5CT Casing cholemera (ndi ulusi ndi kulumikizana) b,c | Chitoliro cha API 5CT Casing Makulidwe a khoma | Chitoliro cha API 5CT Casing Mtundu wopangira mapeto | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | makilogalamu/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| Ulusi wa S-Waufupi wozungulira, Ulusi wozungulira wa L-Wautali, Ulusi wa B-Buttress | ||||||||||||

| a. Khodi imagwiritsidwa ntchito polemba zinthu. | ||||||||||||

| b. Kulemera kodziwika bwino kwa chivundikiro cholumikizidwa ndi cholumikizidwa (gawo 2) kukuwonetsedwa kuti kugwiritsidwe ntchito kokha. | ||||||||||||

| c. Chitsulo cha chromium cha Martensitic (L80 9Cr ndi 13Cr) chimasiyana ndi chitsulo cha carbon mu kuchuluka kwake. Kulemera komwe kwawonetsedwa kwa chitsulo cha chromium cha martensitic si mtengo weniweni. Chofunikira chowongolera kulemera kwa 0.989 chingagwiritsidwe ntchito. | ||||||||||||

| d. Chikwama chachitsulo cha C90, T95 ndi Q125 chiyenera kuperekedwa malinga ndi zofunikira, kulemera ndi makulidwe a khoma zomwe zalembedwa patebulo kapena dongosolo lomwe lili pamwambapa. | ||||||||||||

Kapangidwe ka Mankhwala a API 5CT K55

| Gulu | Giredi | Mtundu | C | Mn | Mo | Cr | Ndi max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mphindi. | zambiri. | mphindi. | zambiri. | mphindi. | zambiri. | mphindi. | zambiri. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Kuchuluka kwa mpweya wa L80 kungawonjezeke mpaka 0.50% ngati chinthucho chazimitsidwa ndi mafuta. b Kuchuluka kwa molybdenum kwa mtundu wa C90 Type 1 sikungatheke ngati makulidwe a khoma ndi ochepera 17.78 mm. Kuchuluka kwa mpweya wa R95 kungawonjezeke mpaka 0.55% ngati chinthucho chazimitsidwa ndi mafuta. d Kuchuluka kwa molybdenum kwa T95 Type 1 kungachepe kufika pa 0.15% ngati makulidwe a khoma ndi ochepera 17.78 mm. Pa EW Grade P110, kuchuluka kwa phosphorous kuyenera kukhala 0.020% ndipo kuchuluka kwa sulfure kuyenera kukhala 0.010%. NL = palibe malire. Zinthu zomwe zawonetsedwa ziyenera kufotokozedwa mu kusanthula kwa malonda. | |||||||||||||||

Katundu wa Makina a API 5CT k55 Gr.

| Muyezo wa API 5CT Casing | Mtundu | Mphamvu Yokoka ya API 5CT Casing MPa | Mphamvu Yotulutsa Kachikwama ka API 5CT MPa | Kulimba kwa API 5CT Casing Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Kampaniyo imaona kuti zinthu zili bwino kwambiri, imaika ndalama zambiri poyambitsa zida zamakono komanso akatswiri, ndipo imachita zonse zomwe ingathe kuti ikwaniritse zosowa za makasitomala kunyumba ndi kunja.

Zomwe zili mkati mwake zitha kugawidwa m'magulu awiri: kapangidwe ka mankhwala, mphamvu yokolola, mphamvu yokoka, mphamvu yogwira, ndi zina zotero.

Nthawi yomweyo, kampaniyo imathanso kuchita njira zodziwira zolakwika pa intaneti komanso njira zina zochizira kutentha malinga ndi zosowa za makasitomala.

https://www.ytdrintl.com/

Imelo:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.ndi fakitale ya mapaipi achitsulo yovomerezedwa ndiEN/ASTM/ JISYodziwika bwino pakupanga ndi kutumiza mitundu yonse ya mapaipi amakona anayi, mapaipi opangidwa ndi galvanized, mapaipi opangidwa ndi ERW, mapaipi ozungulira, mapaipi opangidwa ndi arc, mapaipi olunjika, mapaipi osasinthika, coil yachitsulo yokutidwa ndi utoto, coil yachitsulo yopangidwa ndi galvanized ndi zinthu zina zachitsulo. Ndi mayendedwe osavuta, ili pamtunda wa makilomita 190 kuchokera ku Beijing Capital International Airport komanso makilomita 80 kuchokera ku Tianjin Xingang.

WhatsApp:+8613682051821