A cewar American Petroleum Institute Standard API SPEC 5CT1988 bugu na farko, ana iya raba bututun mai na API 5CT mai nauyin ƙarfe zuwa nau'i goma, ciki har da H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 da Q-125. Muna samar da bututun casing da API 5CT K55 Casing Tube tare da zare da haɗin kai, ko kuma muna bayar da samfurinmu daidai da waɗannan fom ɗin don zaɓi.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Bayanin Bututun Casing API 5CT K55

| BAYANIN TUBEN KASUWA NA API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Ma'auni | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Nisan Tsawon | 3-12M ko kuma bisa ga buƙatar abokin ciniki | |

| Karfe Mai Girma (Matsakaicin Casing, Matakai na Bututu) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Nau'in Zaren Sukuri | Ƙarshen zare mara matsala (NUE), Ƙarshen zare mara matsala na waje (EUE) | |

| Ƙwarewa |

| |

| Ƙarshen Kammalawa | Ƙarshen Fuska na Waje (EUE), Haɗin Ruwa, PH6 (da haɗin da ya yi daidai), Haɗin Haɗaka Mai Haɗaka (IJ) | |

Bukatar Taurin Kai da Taurin Kai na API 5CT K55

| Rukuni | Matsayi | Nau'i | Jimlar tsawaitawa da ke ƙarƙashin kaya % | Ƙarfin yawan amfanin ƙasa MPa | Ƙarfin tensile min. MPa | Taurin kai. | Kauri na bango da aka ƙayyade mm | Bambancin taurin da aka yarda da shi b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| minti. | mafi girma. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 zuwa 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aIdan aka samu takaddama, za a yi amfani da gwajin taurin dakin gwaje-gwaje na Rockwell C a matsayin hanyar alkalanci. bBa a ƙayyade iyakokin tauri ba, amma an takaita matsakaicin bambancin daidai da 7.8 da 7.9 na API Spec. 5CT. | ||||||||||

Girman Tubin Kafa na K55

| Girman Akwatin Bututu, Girman Akwatin Filin Mai & Girman Akwatin Bututu | |

|---|---|

| Diamita na Waje (Girman Bututun Rufi) | 4 1/2"-20", (114.3-508mm) |

| Girman Akwatin Daidaitacce | 4 1/2"-20", (114.3-508mm) |

| Nau'in Zaren | Akwatin zare mai ƙarfi, Akwatin zare mai tsayi, Akwatin zare mai gajeren zagaye |

| aiki | Zai iya kare bututun bututun. |

Bututun Mai Don Masana'antar Man Fetur Da Iskar Gas

| Sunan Bututu | Ƙayyadewa | Karfe Grade | Daidaitacce | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Bututun Man Fetur | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | Bayanin API 5CT (8) |

| Bututun Mai | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Bayanin API 5CT (8) |

| Haɗin kai | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Bayanin API 5CT (8) |

Siffofin Bututun Casing API 5CT K55

- Ana bayar da bututun casing na API 5CT K55 tare da tsawon lokaci kyauta daga mita 8 zuwa mita 13 bisa ga ƙa'idar SY/T6194-96. Duk da haka, ana samunsa ba ƙasa da mita 6 ba kuma adadinsa bai kamata ya wuce kashi 20% ba.

- Ba a yarda da canje-canjen da aka ambata a sama su bayyana a saman waje na haɗin bututun casing API 5CT K55 ba.

- Duk wani nakasu kamar layin gashi, rabuwa, ƙuraje, tsagewa ko ƙura ba za a yarda da shi ba a saman ciki da waje na samfurin. Ya kamata a cire duk waɗannan lahani gaba ɗaya kuma zurfin da aka cire bai kamata ya wuce kashi 12.5% na kauri na bango ba.

- Ya kamata saman zaren da ke haɗewa da bututun API 5CT K55 ya zama santsi ba tare da wata matsala ba, ko tsagewa ko wasu lahani waɗanda ka iya yin mummunan tasiri ga ƙarfi da haɗin kai.

Yana da mahimmanci ga masu aikin mai da iskar gas su kare ramukan rijiyoyin samar da su daga tsatsa tare da kariyar cathodic & API 5CT OilField Tubing galibi yana aiki ne don canja wurin mai da iskar gas.

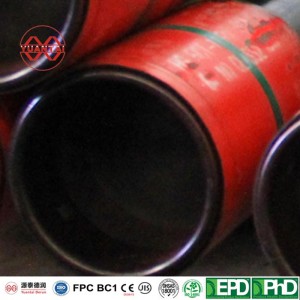

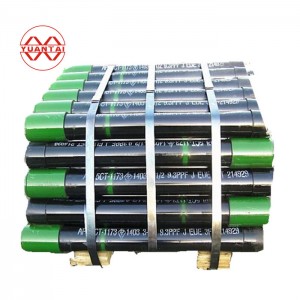

Lambar Launi ta Bakin Karfe ta API 5CT Grade K55

| Suna | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Kafet | wata ƙungiya mai haske kore | sanduna biyu masu haske kore | wata ƙaramar riga mai haske ja | zobe mai haske ja + zobe mai kore | zobe ja + zobe ruwan kasa | farin madauri mai haske |

| Haɗin kai | haɗin kore gaba ɗaya + farin madauri | haɗin kore gaba ɗaya | haɗin ja gaba ɗaya | haɗin ja gaba ɗaya + sandar kore | haɗin ja gaba ɗaya + haɗin ruwan kasa | cikakken haɗin farin |

Bayanin Tushen Akwatin ISO/API/ API 5CT K55

| Codea | Dia na waje | Nauyin da aka ƙayyade (tare da zare da kuma haɗin) b,c | Kauri a Bango | Nau'in sarrafa ƙarshen | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Fam/ƙafa | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Bututun Casing API 5CT Codea | Bututun Casing API 5CT Diamita na waje | Bututun Casing API 5CT Nauyin da aka ƙayyade (tare da zaren da haɗin kai) b,c | Bututun Casing API 5CT Kauri a bango | API 5CT bututun casing Nau'in aikin ƙarshe | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Fam/ƙafa | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S- Zaren zagaye mai gajere, L-Zaren zagaye mai tsayi, B-Buttress zare | ||||||||||||

| a. Ana amfani da lambar don yin oda. | ||||||||||||

| b. An nuna nauyin da ba a saba gani ba na maƙallin zare da haɗe-haɗe (shafi na 2) don amfani kawai. | ||||||||||||

| c. Karfe mai siffar Martensitic chromium (L80 9Cr da 13Cr) ya bambanta da ƙarfe mai siffar carbon a yawansa. Nauyin da aka nuna na ƙarfe mai siffar martensitic chromium ba shi da ƙima daidai. Ana iya amfani da ma'aunin gyaran taro mai lamba 0.989. | ||||||||||||

| d. Ya kamata a samar da murfin ƙarfe na C90, T95 da Q125 bisa ga ƙayyadadden tsari, nauyi da kauri na bango da aka jera a cikin tebur ko tsari na sama. | ||||||||||||

Tsarin Sinadaran API 5CT K55

| Rukuni | Matsayi | Nau'i | C | Mn | Mo | Cr | Ni max. | Cu max. | P mafi girma. | S mafi girma. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| minti. | matsakaicin | minti. | matsakaicin | minti. | matsakaicin | minti. | matsakaicin | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a. Ana iya ƙara yawan sinadarin carbon na L80 zuwa matsakaicin kashi 0.50% idan an kashe samfurin da mai. b Abubuwan da ke cikin molybdenum na Grade C90 Type 1 ba su da ƙaramin haƙuri idan kauri na bango bai wuce 17.78 mm ba. c Za a iya ƙara yawan sinadarin carbon na R95 har zuwa 0.55% idan an kashe samfurin da mai. d Za a iya rage yawan sinadarin molybdenum na T95 Type 1 zuwa mafi ƙarancin kashi 0.15% idan kauri na bango bai kai 17.78 mm ba. e Ga EW Grade P110, yawan sinadarin phosphorus zai zama mafi girma 0.020% kuma yawan sinadarin sulfur zai zama mafi girma 0.010%. NL = babu iyaka. Za a bayar da rahoton abubuwan da aka nuna a cikin nazarin samfur. | |||||||||||||||

API 5CT k55 Gr. Kayayyakin Inji

| Ma'aunin Akwatin API 5CT | Nau'i | Ƙarfin Taurin Kai na API 5CT MPa | Ƙarfin Yawa na Akwatin API 5CT MPa | Taurin Akwati na API 5CT Mafi girma. |

|---|---|---|---|---|

| API TAMBAYOYI 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Kamfanin yana ba da muhimmanci sosai ga ingancin kayayyaki, yana zuba jari sosai wajen gabatar da kayan aiki da ƙwararru na zamani, kuma yana yin duk mai yiwuwa don biyan buƙatun abokan ciniki a gida da waje.

Ana iya raba abubuwan da ke ciki zuwa kashi uku: sinadaran da ke cikin sinadaran, ƙarfin yawan amfanin ƙasa, ƙarfin tensile, ƙarfin tasiri, da sauransu.

A lokaci guda, kamfanin zai iya gudanar da bincike da kuma gyara lahani ta intanet da sauran hanyoyin magance zafi bisa ga buƙatun abokan ciniki.

https://www.ytdrintl.com/

Imel:sales@ytdrgg.com

Kamfanin Tianjin YuantaiDerun Steel Manufacturing Group Co., Ltd.masana'antar bututun ƙarfe ce da aka ba da takardar shaida taEN/ASTM/ JISƙwararre a fannin samarwa da fitar da duk wani nau'in bututu mai siffar murabba'i mai siffar murabba'i, bututun galvanized, bututun walda na ERW, bututun karkace, bututun walda mai zurfi a ƙarƙashin ruwa, bututun dinki madaidaiciya, bututu mara sumul, na'urar ƙarfe mai launi, na'urar ƙarfe mai galvanized da sauran kayayyakin ƙarfe. Tare da jigilar kayayyaki masu sauƙi, yana da nisan kilomita 190 daga Filin Jirgin Sama na Babban Birnin Beijing da kuma kilomita 80 daga Tianjin Xingang.

Whatsapp:+8613682051821