Miturut Standar American Petroleum Institute API SPEC 5CT1988 edisi kaping 1, kualitas baja pipa casing lenga API 5CT bisa dipérang dadi sepuluh jinis, kalebu H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 lan Q-125. Kita nyedhiyakake pipa casing & Pipa Casing API 5CT K55 sing dibarengi karo ulir lan kopling, utawa kita nawakake produk miturut formulir ing ngisor iki kanggo pilihan.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Spesifikasi Pipa Casing API 5CT K55

| SPESIFIKASI TUBING CASING API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Standar | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Rentang Dawane | 3-12M utawa miturut kabutuhan klien | |

| Kelas Baja (Kelas Casing, Kelas Pipa) | Gr.A, Gr.B, Gr.C, X42, X52, X60, X65, X70 | |

| Jinis Ulir Sekrup | Ujung ulir non-upset (NUE), Ujung ulir eksternal upset (EUE) | |

| Spesialisasi |

| |

| Rampung Rampung | Ujung Upset Eksternal (EUE), Sambungan Flush, PH6 (lan sambungan sing padha), Sambungan Integral (IJ) | |

Persyaratan Tarik & Kekerasan Pipa Casing API 5CT K55

| Grup | Kelas | Tipe | Total elongasi ing sangisore beban % | Kekuatan luluh MPa | Kekuwatan tarik minimal MPa | Kekerasan maksimal. | Kekandelan tembok sing ditemtokake mm | Variasi kekerasan sing diidinake b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| menit. | maksimal. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12,70 12,71 nganti 19,04 19,05 nganti 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12,70 12,71 nganti 19,04 19,05 nganti 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12,70 12,71 kanggo 19,04 19,05 kanggo 25,39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12,70 12,71 nganti 19,04 ≥ 19,05 | 3.0 4.0 5.0 |

| aYen ana regejegan, uji atose Rockwell C laboratorium kudu digunakake minangka metode wasit. bOra ana watesan atose sing ditemtokake, nanging variasi maksimal diwatesi miturut 7.8 lan 7.9 saka API Spec. 5CT. | ||||||||||

Dimensi Pipa Casing K55

| Ukuran Casing Pipa, Ukuran Casing Lapangan Minyak & Ukuran Drift Casing | |

|---|---|

| Diameter Luar (Ukuran Pipa Casing) | 4 1/2"-20", (114.3-508mm) |

| Ukuran Casing Standar | 4 1/2"-20", (114.3-508mm) |

| Jinis Utas | Selubung ulir penopang, Selubung ulir bunder dawa, Selubung ulir bunder cendhak |

| Fungsi | Iku bisa nglindhungi pipa selang. |

Tabung Lenga Kanggo Industri Minyak Bumi Lan Gas Alam

| Jeneng Pipa | Spesifikasi | Kelas Baja | Standar | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pipa Casing Petroleum | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | Spesifikasi API 5CT (8) |

| Pipa Petroleum | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Spesifikasi API 5CT (8) |

| Kopling | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Spesifikasi API 5CT (8) |

Fitur Pipa Casing API 5CT K55

- API 5CT K55 Casing Tubing ditawakake kanthi rentang dawa bebas saka 8m nganti 13m adhedhasar norma SY/T6194-96. Nanging, uga kasedhiya dawane ora kurang saka 6m lan jumlahe ora luwih saka 20%.

- Deformasi sing kasebut ing ndhuwur ora diidini katon ing permukaan njaba kopling Casing Tubing API 5CT K55.

- Sembarang deformasi kayata garis rambut, pamisahan, lipatan, retakan utawa koreng ora bisa ditampa ing permukaan njero lan njaba produk. Kabeh cacat iki kudu diilangi kanthi lengkap lan ambane sing diilangi ora kena ngluwihi 12,5% saka kekandelan tembok nominal.

- Permukaan ulir kopling lan Pipa Casing API 5CT K55 kudu alus tanpa gerigi, suwek, utawa cacat liyane sing bisa nduweni dampak negatif marang kekuatan lan kenceng sambungan.

Penting kanggo operator lenga lan gas kanggo nglindhungi selubung sumur produksi saka korosi nganggo proteksi katodik & Pipa Lapangan Minyak API 5CT utamane berfungsi kanggo nransfer lenga lan gas.

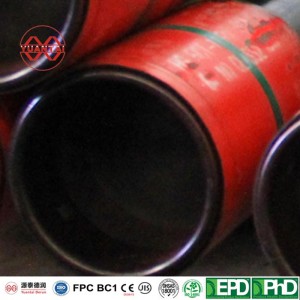

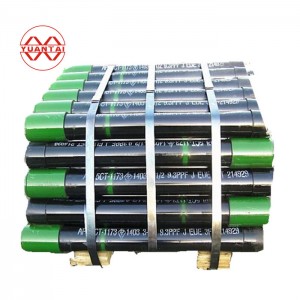

Kode Warna Baja Pipa Casing K55 Kelas API 5CT

| Jeneng | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | pita ijo padhang | rong pita ijo padhang | pita abang padhang | pita abang padhang + pita ijo | pita abang + pita coklat | pita putih sing padhang |

| Kopling | kopling ijo kabeh + pita putih | kopling ijo kabeh | kopling abang kabeh | kopling abang kabeh + pita ijo | kopling abang kabeh + pita coklat | kopling putih kabeh |

Spesifikasi Pipa Casing ISO/API/ API 5CT K55

| Kodea | Diameter njaba | Bobot nominal (karo benang lan kopling) b,c | Kekandelan Tembok | Jinis pamrosesan pungkasan | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Pipa Casing API 5CT Codea | Diameter njaba pipa selubung API 5CT | Pipa selubung API 5CT Bobot nominal (karo benang lan kopling) b,c | Kekandelan tembok pipa selubung API 5CT | Pipa Casing API 5CT Jinis pangolahan pungkasan | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Utas bunder cendhak, L-Utas bunder dawa, B-Utas penopang | ||||||||||||

| a. Kode digunakake kanggo referensi pesenan. | ||||||||||||

| b. Bobot nominal selubung ulir lan gandheng (kolom 2) dituduhake mung kanggo referensi. | ||||||||||||

| c. Baja kromium martensitik (L80 9Cr lan 13Cr) beda karo baja karbon ing babagan kapadhetan. Bobot baja kromium martensitik sing dituduhake dudu nilai sing pas. Faktor koreksi massa 0,989 bisa digunakake. | ||||||||||||

| d. Casing baja kelas C90, T95 lan Q125 kudu disedhiyakake miturut spesifikasi, bobot, lan kekandelan tembok sing kadhaptar ing tabel utawa pesenan ing ndhuwur. | ||||||||||||

Komposisi Kimia API 5CT K55

| Grup | Kelas | Tipe | C | Mn | Mo | Cr | Ni maks. | Cu maksimal. | P maksimal. | S maksimal. | Si maks. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| menit. | maksimal. | menit. | maksimal. | menit. | maksimal. | menit. | maksimal. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0,25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 dina | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Kandungan karbon kanggo L80 bisa ditambah nganti maksimal 0,50% yen produk kasebut didinginkan nganggo lenga. b Kandungan molibdenum kanggo Kelas C90 Tipe 1 ora duwe toleransi minimal yen kekandelan tembok kurang saka 17,78 mm. Kandungan karbon kanggo R95 bisa ditambah nganti maksimal 0,55% yen produk kasebut didinginkan nganggo lenga. Kandungan molibdenum kanggo T95 Tipe 1 bisa dikurangi dadi minimal 0,15% yen kekandelan tembok kurang saka 17,78 mm. Kanggo EW Grade P110, kandungan fosfor kudu maksimal 0,020% lan kandungan sulfur maksimal 0,010%. NL = tanpa watesan. Unsur sing dituduhake kudu dilapurake ing analisis produk. | |||||||||||||||

API 5CT k55 Gr. Sifat Mekanik

| Standar Casing API 5CT | Tipe | Kekuatan Tarik Selubung API 5CT MPa | Kekuatan Asil Casing API 5CT MPa | Kekerasan Casing API 5CT Maks. |

|---|---|---|---|---|

| API SPESIFIKASI 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80 (13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Perusahaan iki ngutamakake kualitas produk, nandur modal akeh kanggo ngenalake peralatan canggih lan profesional, lan ngupayakake kabeh kanggo nyukupi kabutuhan pelanggan ing njero lan luar negeri.

Isine bisa dipérang dadi: komposisi kimia, kekuatan luluh, kekuatan tarik, sifat impak, lan liya-liyane.

Ing wektu sing padha, perusahaan uga bisa nindakake deteksi cacat lan anil online lan proses perawatan panas liyane miturut kabutuhan pelanggan.

https://www.ytdrintl.com/

Email:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.minangka pabrik pipa baja sing disertifikasi deningEN/ASTM/ JISspesialisasine ing produksi lan ekspor kabeh jinis pipa persegi panjang, pipa galvanis, pipa las ERW, pipa spiral, pipa las busur terendam, pipa sambungan lurus, pipa seamless, koil baja dilapisi warna, koil baja galvanis lan produk baja liyane. Kanthi transportasi sing trep, adohé 190 kilometer saka Bandara Internasional Ibukota Beijing lan 80 kilometer saka Tianjin Xingang.

Whatsapp:+8613682051821