Numutkeun Standar American Petroleum Institute API SPEC 5CT1988 édisi ka-1, kualitas baja pipa selubung minyak API 5CT tiasa dibagi kana sapuluh jinis, kalebet H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 sareng Q-125. Kami nyayogikeun pipa selubung & Pipa Selubung API 5CT K55 anu dibarengan ku ulir sareng kopling, atanapi kami nawiskeun produk kami saluyu sareng formulir ieu pikeun pilihan.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Spésifikasi Pipa Casing API 5CT K55

| SPESIFIKASI TUBE CASING API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Standar | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Rentang Panjang | 3-12M atanapi numutkeun sarat klien | |

| Kelas Baja (Kelas Casing, Kelas Pipa) | Gr.A, Gr.B, Gr.C, X42, X52, X60, X65, X70 | |

| Jenis Ulir Sekrup | Tungtung ulir anu teu kaganggu (NUE), Tungtung ulir éksternal kaganggu (EUE) | |

| Spésialisasi |

| |

| Rengse Ngaréngsékeun | Ujung Upset Éksternal (EUE), Sambungan Siram, PH6 (sareng sambungan anu sami), Sambungan Integral (IJ) | |

Sarat Tarik & Karasa Pipa Casing API 5CT K55

| Grup | Kelas | Tipe | Total elongasi dina beban % | Kakuatan ngahasilkeun MPa | Kakuatan tarik min. MPa | Karasa maksimal. | Ketebalan témbok anu ditangtukeun mm | Variasi karasa anu diidinan b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| menit. | maks. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12,70 12,71 nepi ka 19,04 19,05 nepi ka 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12,70 12,71 nepi ka 19,04 19,05 nepi ka 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12,70 12,71 ka 19,04 19,05 ka 25,39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12,70 12,71 nepi ka 19,04 ≥ 19,05 | 3.0 4.0 5.0 |

| aUpami aya sengketa, uji karasa Rockwell C laboratorium kedah dianggo salaku metode wasit. bTeu aya wates karasa anu ditangtukeun, tapi variasi maksimum diwatesan luyu sareng 7.8 sareng 7.9 tina API Spec. 5CT. | ||||||||||

Diménsi Pipa Casing K55

| Ukuran Selubung Pipa, Ukuran Selubung Lapangan Minyak & Ukuran Hanyutan Selubung | |

|---|---|

| Diaméter Luar (Ukuran Pipa Casing) | 4 1/2"-20", (114.3-508mm) |

| Ukuran Casing Standar | 4 1/2"-20", (114.3-508mm) |

| Jenis Benang | Selongsong benang penopang, Selongsong benang buleud panjang, Selongsong benang buleud pondok |

| Fungsi | Éta tiasa ngajaga pipa selang. |

Tabung Minyak Pikeun Industri Perminyakan Sareng Gas Alam

| Ngaran Pipa | Spésifikasi | Kelas Baja | Standar | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pipa Casing Perminyakan | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | Spésifikasi API 5CT (8) |

| Pipa Minyak Bumi | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Spésifikasi API 5CT (8) |

| Kopling | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Spésifikasi API 5CT (8) |

Fitur Pipa Casing API 5CT K55

- API 5CT K55 Casing Tubing ditawarkeun kalayan rentang panjang bébas ti 8m dugi ka 13m dumasar kana norma SY/T6194-96. Nanging, éta ogé sayogi kalayan panjang teu kirang ti 6m sareng kuantitasna teu kedah langkung ti 20%.

- Deformasi anu kasebat di luhur teu diidinan némbongan dina permukaan luar kopling Casing Tubing API 5CT K55.

- Sagala rupa deformasi sapertos garis rambut, pamisahan, lipatan, retakan atanapi koreng henteu tiasa ditampi dina permukaan jero sareng luar produk. Sadaya cacad ieu kedah dipiceun sapinuhna sareng jerona anu dipiceun henteu kedah ngaleuwihan 12,5% tina ketebalan témbok nominal.

- Beungeut ulir kopling sareng API 5CT K55 Casing Tubing kedah lemes tanpa aya gerigi, cimata atanapi cacad sanés anu tiasa gaduh dampak négatif kana kakuatan sareng sambungan anu raket.

Penting pikeun operator minyak sareng gas pikeun ngajaga selubung sumur produksi na tina korosi nganggo panyalindungan katodik & Pipa Lapangan Minyak API 5CT utamina fungsina pikeun mindahkeun minyak sareng gas.

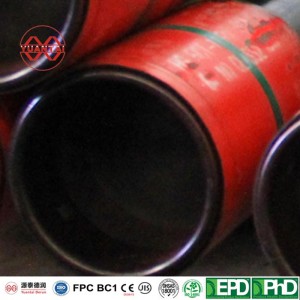

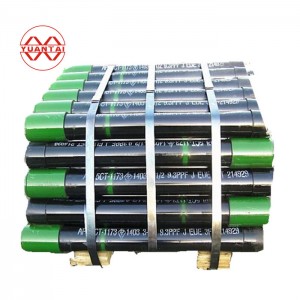

Kode Warna Baja Pipa Casing K55 Kelas API 5CT

| Ngaran | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | pita héjo caang | dua pita héjo caang | pita beureum caang | pita beureum caang + pita héjo | pita beureum + pita coklat | pita bodas caang |

| Kopling | kopling héjo sadayana + pita bodas | kopling héjo sadayana | kopling beureum sadayana | kopling beureum sadayana + pita héjo | kopling beureum sadayana + pita coklat | kopling bodas sadayana |

Spésifikasi Pipa Casing ISO/API/ API 5CT K55

| Kodea | Diaméter Luar | Beurat nominal (kalayan benang sareng kopling) b,c | Kandel Témbok | Jenis pamrosésan ahir | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Pipa Casing API 5CT Codea | Diaméter luar pipa selubung API 5CT | Pipa selubung API 5CT Beurat nominal (kalayan benang jeung gandeng) b,c | Ketebalan témbok pipa selubung API 5CT | Pipa Casing API 5CT Tipe pamrosésan tungtung | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Utas buleud pondok, L-Utas buleud panjang, B-Utas penopang | ||||||||||||

| a. Kode dianggo pikeun rujukan mesen. | ||||||||||||

| b. Beurat nominal selubung anu diulir sareng digandeng (kolom 2) dipidangkeun kanggo rujukan hungkul. | ||||||||||||

| c. Baja kromium martensitik (L80 9Cr sareng 13Cr) béda ti baja karbon dina kapadetanna. Beurat baja kromium martensitik anu dipidangkeun sanés nilai anu pasti. Faktor koreksi massa 0,989 tiasa dianggo. | ||||||||||||

| d. Casing baja kelas C90, T95 sareng Q125 kedah disayogikeun numutkeun spésifikasi, beurat sareng ketebalan témbok anu didaptarkeun dina tabel atanapi pesenan di luhur. | ||||||||||||

Komposisi Kimia API 5CT K55

| Grup | Kelas | Tipe | C | Mn | Mo | Cr | Ni maks. | Cu maks. | P maks. | S maks. | Si maks. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| menit. | maksimal. | menit. | maksimal. | menit. | maksimal. | menit. | maksimal. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 hiji | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0,25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 dinten | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Kandungan karbon pikeun L80 tiasa ningkat dugi ka maksimal 0,50% upami produkna di-quenching ku oli. b Kandungan molibdenum pikeun Kelas C90 Tipe 1 teu boga toleransi minimum upami ketebalan témbokna kirang ti 17,78 mm. Kandungan karbon pikeun R95 tiasa ningkat dugi ka maksimal 0,55% upami produkna dipareuman ku minyak. d Kandungan molibdenum pikeun T95 Tipe 1 tiasa dikirangan janten minimum 0,15% upami ketebalan témbokna kirang ti 17,78 mm. e Pikeun EW Grade P110, kandungan fosfor maksimal 0,020% sareng kandungan walirang maksimal 0,010%. NL = teu aya watesna. Unsur-unsur anu dipidangkeun kedah dilaporkeun dina analisis produk. | |||||||||||||||

API 5CT k55 Gr. Sipat Mékanis

| Standar Casing API 5CT | Tipe | Kakuatan Tarik Casing API 5CT MPa | Kakuatan Hasil Casing API 5CT MPa | Karasa Casing API 5CT Maks. |

|---|---|---|---|---|

| API Spésifikasi 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Perusahaan ieu ngutamakeun kualitas produk, investasi ageung dina ngenalkeun peralatan canggih sareng para ahli, sareng ngalakukeun sagala rupa pikeun minuhan kabutuhan para nasabah di jero sareng di luar negeri.

Eusina sacara kasar tiasa dibagi kana: komposisi kimia, kakuatan luluh, kakuatan tarik, sipat dampak, jsb.

Dina waktos anu sami, perusahaan ogé tiasa ngalaksanakeun deteksi cacad sareng annealing online sareng prosés perlakuan panas anu sanés numutkeun kabutuhan palanggan.

https://www.ytdrintl.com/

Surélék:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.nyaéta pabrik pipa baja anu disertipikasi kuEN/ASTM/ JISspesialisasi dina produksi sareng ékspor sadaya jinis pipa pasagi pasagi, pipa galvanis, pipa dilas ERW, pipa spiral, pipa dilas busur terendam, pipa jahitan lempeng, pipa seamless, koil baja dilapis warna, koil baja galvanis sareng produk baja sanésna. Kalayan transportasi anu merenah, éta 190 kilométer jauhna ti Bandara Internasional Ibukota Beijing sareng 80 kilométer jauhna ti Tianjin Xingang.

Whatsapp:+8613682051821