Iityhubhu zesikwere zeGalvanised zibonelela ngokumelana nokugqwala, iimpawu zokuhombisa, ukupeyintwa, kunye nokukwazi ukwakheka kakuhle. Kwiminyaka yakutshanje, ukusetyenziswa kwazo kwiimoto kuye kwanda, kwaba lolona hlobo luphambili lwesinyithi seemoto. Amazwe kwihlabathi liphela aphanda iindlela zokwandisa iintlobo ngeentlobo kunye neenkcukacha zesinyithi seemoto esigqunywe ngeglavu, ukuphucula inkqubo yokugquma, kwaye ekugqibeleni kuphucule umgangatho wokugquma, ngakumbi ukuqinisekisa ukugquma, ukumelana nokugqwala, ukuwelda, kunye nokumelana nokuqhekeka komgubo kunye nokuqhekeka. Umgangatho weetyhubhu zesikwere zegalvanised ubusoloko uyinto ephambili kuluntu. Ngexesha lovavanyo, eyona nto ibalulekileyo kukusebenza kweetyhubhu zesikwere zegalvanised. Izinto ezichaphazela umgangatho wokugquma kweetyhubhu zesikwere zegalvanised ziquka:

1. Isantya sokuSebenza: Iityhubhu zesikwere ze-galvanized kufuneka zintywiliswe ngokukhawuleza kangangoko kunokwenzeka ngelixa kuqinisekiswa ukhuseleko lomsebenzi kunye nabasebenzi. Oku kuqinisekisa ubukhulu befilimu obufanayo kuyo yonke ityhubhu yentsimbi ye-galvanized. Isantya sokuphakamisa kufuneka sahluke ngokuxhomekeke kwisakhiwo setyhubhu, izinto kunye nobude. Ngokubanzi, isantya sokuphakamisa se-1.5 m/min siqinisekisa i-zinc reflux elungileyo kunye nokukhanya komphezulu.

2. Izixhobo: Izixhobo zokusebenzisa i-galvanizing zinzima kakhulu ngexesha lenkqubo yokusetyenziswa kwe-galvanizing.

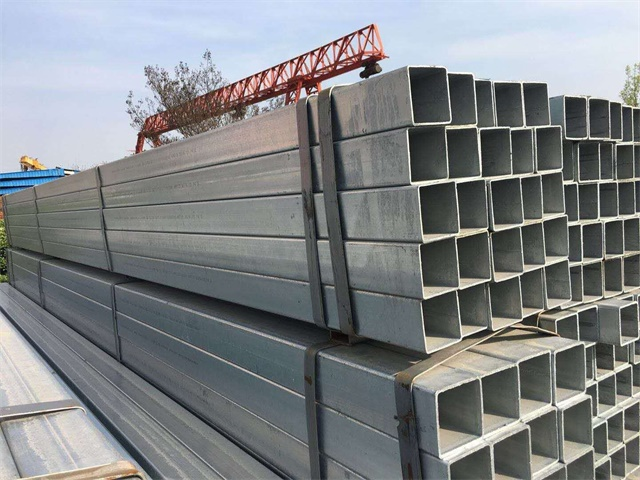

Iityhubhu zesikwere zeGalvanishi zinika amandla agqwesileyo, ukuqina, iplastiki, kunye nokudityaniswa, kunye nokuguquguquka okuhle. Umaleko wazo we-alloy unamathela ngokuqinileyo kwisiseko sentsimbi, uvumela ukuba zifakwe isitampu esibandayo, ziqengqelwe, zitsalwe, zigotywe, kunye nezinye iintlobo ngaphandle kokonakalisa uphahla. Zikwafanelekile ukucubungula ngokubanzi, njengokubhola, ukusika, ukuwelda, kunye nokugoba okubandayo. Umphezulu wegalvanishi ukhanya kwaye umhle, uvumela ukuba zisetyenziswe ngokuthe ngqo kwiiprojekthi njengoko kufuneka.

Ixesha leposi: Agasti-27-2025