1. Kuenzanisa maitiro ekugadzira

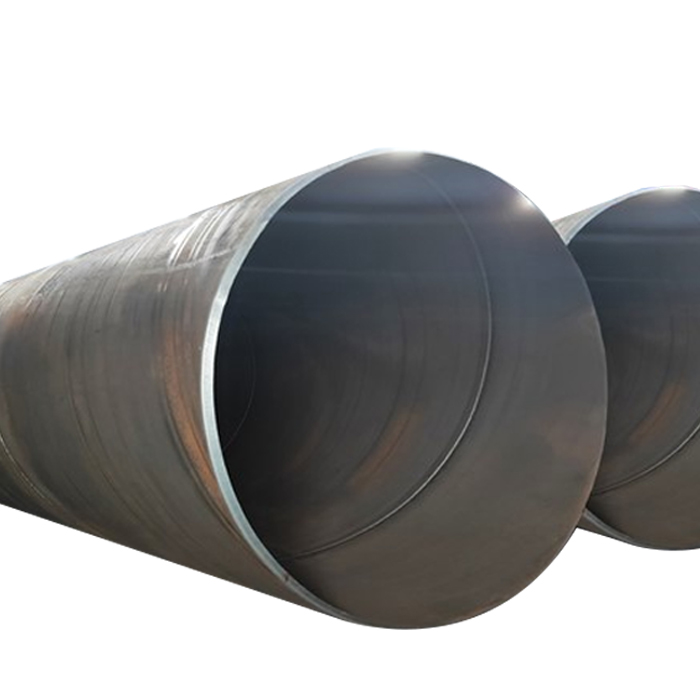

Maitiro ekugadzirasimbi yesimbi yakatwasukazviri nyore. Maitiro makuru ekugadzira ndeekusunganidzwa kwakatwasuka kwakapetwa kakawandapombi yesimbiuyepombi yesimbi yakasungirirwa pasi pemvura yakasungirirwa yakatwasuka.Mapaipi esimbi ane musono wakatwasuka ane simba guru rekugadzira, mutengo wakaderera uye kugadzirwa nekukurumidza.

Simba repombi yesimbi inotendererakazhinji yakakwira kupfuura yemapaipi esimbi akapatsanurwa. Maitiro makuru ekugadzira ndeyekusanganisa arc pasi pemvura. Machubhu esimbi anotenderera anogona kugadzira machubhu akasungirirwa ane dhayamita dzakasiyana dzemabhiritsi ane upamhi hwakaenzana, kanamachubhu akasungirirwaine dhayamita yakakura kubva kumapapiro matete.

Zvisinei, kana tichienzanisa nemapaipi esimbi ane musono wakatwasuka ane urefu hwakafanana, urefu hwewelding hwakawedzera ne30% ne100% zvichiteerana, uye kumhanya kwekugadzira kwakaderera. Naizvozvo, mapaipi esimbi ane dhayamita yakakura anowanzo sungirirwa ne spiral welding, uye mapaipi esimbi ane dhayamita diki anowanzo sungirirwa ne straight seam welding.

Paunenge uchigadziramapaipi esimbi akatwasuka ane dhayamita hombeMuindasitiri, tekinoroji yekuwelda ine chimiro cheT inoshandiswa, kureva kuti, mapaipi esimbi ane musono wakatwasuka akabatanidzwa uye akabatanidzwa kuti asvike pakureba kunodiwa kweprojekiti. Kukanganisika kwepaipi yesimbi ine musono wakatwasuka ine chimiro cheT kuchawedzera zvakanyanya, uye kushushikana kwewelda kweT-shaped weld kwakakura. Simbi yeweld inowanzo kuve ne triaxial stress, izvo zvinowedzera mukana wekutsemuka.

Pamusoro pezvo, zvichienderana nemitemo yehunyanzvi hwekusanganisa arc nepasi pemvura, weld yega yega inofanira kugadziriswa nekubaya arc uye kudzima arc. Zvisinei, pombi yega yega yesimbi haigone kusangana nemamiriro aya panguva yekusanganisa seam circumferential, saka zvimwe zvikanganiso zvekusanganisa zvinogona kuitika panguva yekudzima arc.

2. Kuenzanisa kwezviyero zvekushanda

Kana pombi iri pasi pekumanikidzwa kwemukati, kumanikidzwa kukuru kunowanzo gadzirwa pamadziro epombi, kureva kumanikidzwa kweradial uye kumanikidzwa kweaxial. Kumanikidzwa kwakazara pa weld, uko α Ndiyo weld spiral angle yepombi yesimbi inotenderera.

Kumanikidzwa kwakazara pa spiral weld ndiko kumanikidzwa kukuru kwepombi yesimbi yakamonerwa yakatwasuka. Pasi pekumanikidzwa kwakafanana, ukobvu hwemadziro epombi dzesimbi dzakamonerwa dzine dhayamita imwe chete yepombi hudiki pane hwepombi dzesimbi dzakamonerwa yakatwasuka.

Nguva yekutumira: Ndira-03-2023