1. Papiso ea ts'ebetso ea tlhahiso

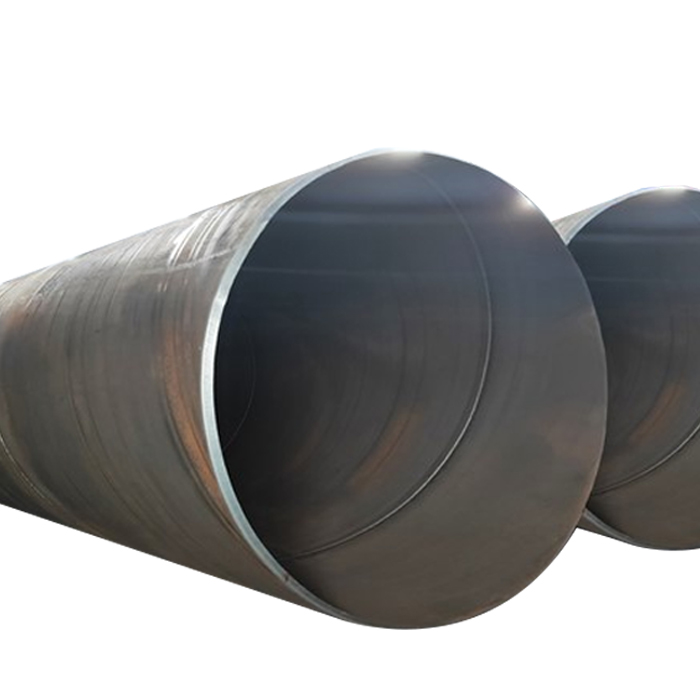

Ts'ebetso ea tlhahiso eaphala ea tšepe ea seam e otlolohilengho bonolo haholo. Mekhoa e meholo ea tlhahiso ke seam e otlolohileng e phuthetsoeng ka maqhubu a phahamengphaephe ea tšepelephala ea tšepe ea seam e otlolohileng e phuthetsoeng ka har'a arcPhaephe ea tšepe e otlolohileng e nang le seam e na le katleho e phahameng ea tlhahiso, litšenyehelo tse tlase le nts'etsopele e potlakileng.

Matla aphala ea tšepe e potolohanghangata e phahame ho feta ea phaephe ea tšepe e otlolohileng e nang le seam. Ts'ebetso e kholo ea tlhahiso ke ho tjheseletsa arc e ka tlas'a metsi. Liphaephe tsa tšepe tse potolohang li ka hlahisa liphaephe tse tjheselitsoeng tse nang le bophara bo fapaneng ba li-billet tsa bophara bo lekanang, kapaliphaephe tse tjhitliloengka bophara bo boholo ho tloha ho di-billet tse moqotetsane.

Leha ho le jwalo, ha ho bapiswa le diphaephe tsa tshepe tse otlolohileng tse nang le bolelele bo tshwanang, bolelele ba ho tjheseletsa bo eketsehile ka 30% le 100% ka ho latellana, mme lebelo la tlhahiso le tlase. Ka hona, diphaephe tsa tshepe tse bophara bo boholo di tjheselletswa haholo ka ho tjheseletsa ka spiral, mme diphaephe tse nyane tsa tshepe tse bophara bo boholo di tjheselletswa haholo ka ho tjheseletsa ka ho otloloha.

Ha o hlahisaliphaephe tsa tšepe tse otlolohileng tsa seam tse bophara bo boholoindastering, ho sebelisoa theknoloji ea ho tjheseletsa e bōpehileng joaloka T, ke hore, palo e nyenyane ea liphaephe tsa tšepe tse otlolohileng tse kopantsoeng lia kopanngoa 'me li hokahanngoa ho fihlela bolelele bo hlokahalang ba projeke. Liphoso tsa phaephe ea tšepe e otlolohileng e bōpehileng joaloka T li tla eketseha haholo, 'me khatello e setseng ea ho tjheseletsa ea weld e bōpehileng joaloka T e kholo. Tšepe ea weld hangata e tlas'a khatello ea triaxial, e leng se eketsang monyetla oa ho petsoha.

Ho phaella moo, ho ya ka melao ya botekgeniki ya ho tjheseletsa arc e kentsweng ka metsing, tjheseletso e nngwe le e nngwe e tla lokela ho tjheseletsa arc le ho e tima. Leha ho le jwalo, phaephe e nngwe le e nngwe ya tshepe e ke ke ya fihlella boemo bona nakong ya ho tjheseletsa seam e potolohang, kahoo diphoso tse ding tsa ho tjheseletsa di ka hlaha nakong ya ho tjheseletsa arc.

2. Papiso ea liparamente tsa ts'ebetso

Ha phaephe e le tlas'a khatello ea ka hare, hangata ho hlahisoa likhatello tse peli tse kholo leboteng la phaephe, e leng khatello ea radial le khatello ea axial. Khatello e felletseng ho weld, moo α Ke sekhutlo sa weld spiral saphaephe ea tšepe e potolohang.

Kgatelelo e felletseng ho weld ya spiral ke kgatelelo e kgolo ya phaephe ya tshepe e otlolohileng ya seam. Tlas'a kgatello e tshwanang ya ho sebetsa, botenya ba lebota la diphaephe tsa tshepe tse potolohang tse nang le bophara bo tshwanang ba phaephe bo bonyenyane ho feta ba diphaephe tsa tshepe tse otlolohileng tsa seam.

Nako ea poso: Pherekhong-03-2023