1. Uthelekiso lwenkqubo yemveliso

Inkqubo yemvelisoumbhobho wentsimbi yomthungo othe tyeilula kakhulu. Iinkqubo eziphambili zemveliso zi-welded straight seam ezidityanisiweyo rhoqoumbhobho wentsimbikwayeumbhobho wentsimbi yomthungo othe tye odityanisiweyo we-arc engaphantsi komhlabaUmbhobho wentsimbi othe tye onomthungo usebenza kakuhle kakhulu, unexabiso eliphantsi kwaye uphuhliswa ngokukhawuleza.

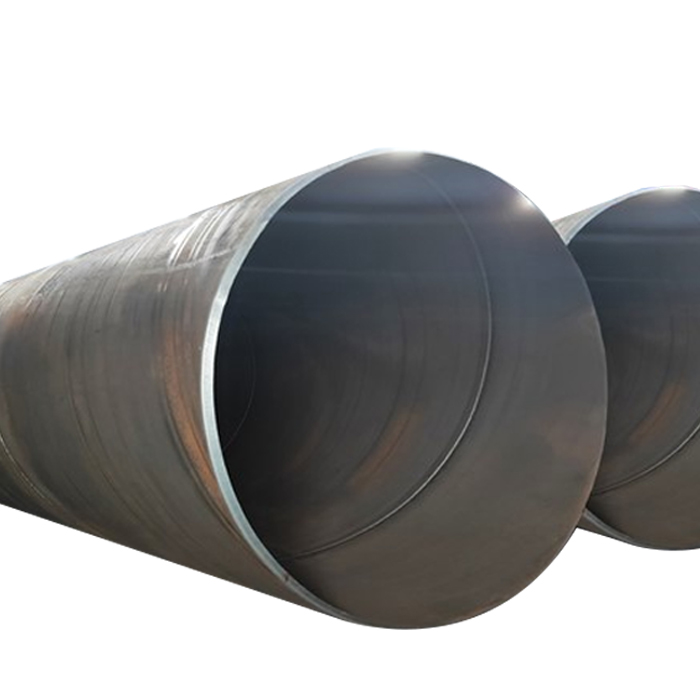

Amandlaumbhobho wentsimbi ejikelezayoidla ngokuba phezulu kuneyombhobho wentsimbi ethe tye. Inkqubo ephambili yemveliso kukuwelda kwe-arc engaphantsi komhlaba. Iityhubhu zentsimbi ezijikelezayo zinokuvelisa iityhubhu eziwelding ezineedayamitha ezahlukeneyo zeebhilethi ezinobubanzi obufanayo, okanyeiityhubhu ezidityanisiweyongobubanzi obukhulu obuvela kwiibhilethi ezincinci.

Nangona kunjalo, xa kuthelekiswa nemibhobho yentsimbi enomthungo othe tye enobude obufanayo, ubude bokudityaniswa kwentsimbi bunyuke ngama-30% kunye nama-100% ngokulandelelanayo, kwaye isantya semveliso siphantsi. Ke ngoko, imibhobho yentsimbi enobubanzi obukhulu idityaniswa kakhulu nge-spiral welding, kwaye imibhobho yentsimbi enobubanzi obuncinci idityaniswa kakhulu nge-straight seam welding.

Xa uvelisaimibhobho yentsimbi yomthungo othe tye enobubanzi obukhuluKushishino, kusetyenziswa iteknoloji yokuwelda enomfanekiso we-T, oko kukuthi, inani elincinci leemibhobho zentsimbi yomthungo othe tye zidibene kwaye ziqhagamshelwe ukuhlangabezana nobude obufunekayo beprojekthi. Iziphene zombhobho wentsimbi yomthungo othe tye onomfanekiso we-T ziya kwanda kakhulu, kwaye uxinzelelo olushiyekileyo lwe-welding lwe-weld enomfanekiso we-T lukhulu. Isinyithi se-weld sihlala siphantsi koxinzelelo lwe-triaxial, nto leyo eyandisa amathuba okuqhekeka.

Ukongeza, ngokwemigaqo yobugcisa yokuwelda i-arc engaphantsi komhlaba, i-weld nganye iya kujongana nonyango lokutshayelwa kwe-arc kunye nokucima i-arc. Nangona kunjalo, umbhobho ngamnye wentsimbi awunakuhlangabezana nale meko ngexesha lokuwelda kwe-circumferential seam, ngoko ke iziphene ezininzi zokuwelda zinokwenzeka ngexesha lokucinywa kwe-arc.

2. Uthelekiso lweeparamitha zokusebenza

Xa umbhobho uphantsi koxinzelelo lwangaphakathi, uxinzelelo oluphambili ludla ngokuveliswa eludongeni lombhobho, oluyi-radial stress kunye noxinzelelo lwe-axial. Uxinzelelo olupheleleyo kwi-weld, apho i-α yi-weld spiral angle yeumbhobho wentsimbi ejikelezayo.

Uxinzelelo olupheleleyo kwi-spiral weld lolona xinzelelo luphambili lombhobho wentsimbi yomthungo othe tye. Phantsi koxinzelelo olufanayo lokusebenza, ubukhulu bodonga lwemibhobho yentsimbi yomthungo enobubanzi obufanayo bombhobho buncinci kunobo bemibhobho yentsimbi yomthungo othe tye.

Ixesha lokuthumela: Jan-03-2023