Umehluko phakathi kokugoqa okushisayo nokugoqa okubandayo ikakhulukazi izinga lokushisa lenqubo yokugoqa. "Okubandayo" kusho izinga lokushisa elijwayelekile, kanti "okushisayo" kusho izinga lokushisa eliphezulu. Ngokombono we-metallurgy, umngcele phakathi kokugoqa okubandayo nokugoqa okushisayo kufanele uhlukaniswe ngokushisa kokuphinda kusetshenziswe. Okusho ukuthi, ukugoqa ngaphansi kwezinga lokushisa lokuphinda kusetshenziswe kabusha kuwukugoqa okubandayo, kanti ukugoqa ngaphezu kwezinga lokushisa lokuphinda kusetshenziswe kabusha kuwukugoqa okushisayo. Izinga lokushisa lokuphinda kusetshenziswe kabusha kwensimbi lingu-450-600 ℃.

Okulandelayo umbono jikelele wezimpendulo zemibuzo mayelana [nomehluko phakathi kwe-hot rolling kanye ne-cold rolling]:

Umehluko phakathi kokugoqa okubandayo nokugoqa okushisayo ikakhulukazi izinga lokushisa lenqubo yokugoqa. "Okubandayo" kusho izinga lokushisa elijwayelekile, kanti "okushisayo" kusho izinga lokushisa eliphezulu. Ngokombono we-metallurgy, umngcele phakathi kokugoqa okubandayo nokugoqa okushisayo kufanele uhlukaniswe ngokushisa kokuphinda kusetshenziswe. Okusho ukuthi, ukugoqa ngaphansi kwezinga lokushisa lokuphinda kusetshenziswe kugoqa okubandayo, kanti ukugoqa ngaphezu kwezinga lokushisa lokuphinda kusetshenziswe kugoqa okushisayo. Izinga lokushisa lokuphinda kusetshenziswe lensimbi lingu-450-600 ℃

Ukugoqa okushisayo kanye nokugoqa okubandayo kuyizinqubo zokwakha amapuleti ensimbi noma amaphrofayili, anomthelela omkhulu esakhiweni nasezimpahleni zensimbi. Ukugoqa kwensimbi ikakhulukazi ukugoqa okushisayo, kanti ukugoqa okubandayo kusetshenziselwa kuphela ukukhiqiza insimbi encane enezingxenye kanye nepuleti elincane. Ama-ingots noma ama-billet kunzima ukuwaguqula nokuwacubungula emazingeni okushisa egumbi. Ngokuvamile, ashiswa ku-1100-1250 ℃ ukuze agoqe. Le nqubo yokugoqa ibizwa ngokuthi ukugoqa okushisayo. Izinga lokushisa lokugcina lokugoqa okushisayo ngokuvamile lingu-800-900 ℃, bese kuba yilapho kuphola emoyeni, ngakho-ke isimo sokugoqa okushisayo silingana nokwelashwa okuvamile. Iningi lensimbi ligoqwa ngokugoqa okushisayo. Ukugoqa okubandayo kubhekisela endleleni yokugoqa yokukhipha insimbi nokushintsha isimo sensimbi ngokucindezela kwama-rolls emazingeni okushisa egumbi. Nakuba inqubo yokucubungula izokwenza ipuleti lensimbi lifudumale, lisabizwa ngokuthi ukugoqa okubandayo.

Lo mbhalo ucacisa izimo zokulethwa kwezobuchwepheshe zamandla aphezulu kanye nezingxenye zensimbi ezihlanganisiwe ezihlanganisiwe ezifakwe ugesi kanye nezihlanganisiwe ezifakwe ngaphansi kwe-arc ezifakwe ngaphansi kwe-arc ezihlanganisiwe ezibandayo ezakhiwe ngesakhiwo esingenalutho zezinhlobo eziyindilinga, eziyisikwele, eziyisikwele noma ezi-elliptical kanye nezibandayo ezakhiwe ngaphandle kokwelashwa kokushisa okulandelayo ngaphandle kokwelashwa kokushisa komugqa wokushisela. INOTHI 1 Izidingo zokubekezelelana, ubukhulu kanye nezakhiwo zesigaba zingatholakala ku-EN 10219 2. INOTHI 2 Ukunaka kwabasebenzisi kudonselwa eqinisweni lokuthi yize amamaki akhiwe abandayo kulo mbhalo angaba nezakhiwo ezilinganayo zemishini namamaki aqediwe ashisayo ku-EN 10210 3, izakhiwo zesigaba zezingxenye eziyisikwele neziyisikwele ezingenalutho ku-EN 10219 2 kanye ne-EN 10210 2 azilingani. INOTHI 3 Uhlu lwemamaki ensimbi luchazwe kulo mbhalo futhi umsebenzisi angakhetha ibanga elifanele kakhulu ukusetshenziswa okuhlosiwe kanye nezimo zesevisi. Amabanga kanye nezakhiwo zemishini, kodwa hhayi isimo sokugcina sokuphakelwa kwezingxenye ezibandayo ezakhiwe ngokubandayo ngokuvamile kufana nalezo eziku-EN 10025 3, EN 10025 4, EN 10025 5, EN 10025 6, EN 10149 2 kanye ne-EN 10149 3.

EN 10210-3-2020

Izingxenye ezingenalutho zesakhiwo sensimbi esiqediwe esishisayo- Ingxenye 3: Izimo zokulethwa kobuchwepheshe zezinsimbi ezinamandla aphezulu kanye nezimelana nesimo sezulu

Lo mbhalo ucacisa izimo zokulethwa kwezobuchwepheshe zezingxenye zesakhiwo zensimbi eziqinile nezingenamthungo eziqediwe ngokushisa, ezihlanganisiwe ngogesi kanye nezingaphansi kwamanzi ezihlanganisiwe nge-arc ezihlanganisiwe zezinhlobo eziyindilinga, eziyisikwele, eziyisikwele noma ezi-elliptical. Usebenza ezingxenyeni ezingenalutho ezakhiwe zishisa, ngokushisa okulandelayo noma ngaphandle kokwelashwa, noma ezibandayo ezakhiwe ngokushisa okulandelayo ngaphezu kwama-580 °C ukuthola izakhiwo ezilinganayo zemishini nalezo ezitholakale kumkhiqizo oshisayo owenziwe. INOTHI 1 Izidingo zokubekezelelana, ubukhulu kanye nezakhiwo zesigaba zichazwe ku-EN 10210-2. INOTHI 2 Ukunaka kwabasebenzisi kudonselwa eqinisweni lokuthi ngenkathi amazinga abandayo e-EN 10219-3 angaba nezakhiwo ezilinganayo zemishini nezigaba eziqediwe ngokushisa kulo mbhalo, izakhiwo zesigaba zezingxenye eziyisikwele neziyisikwele eziyisikwele ku-EN 10210-2 kanye ne-EN 10219-2 azilingani. INOTHI 3 Uhlu lwamazinga ezinto ezibonakalayo luchazwe kulo mbhalo futhi umsebenzisi angakhetha ibanga elifanele kakhulu ukusetshenziswa okuhlosiwe kanye nezimo zesevisi. Amabanga kanye nezakhiwo zemishini zezingxenye ezingenalutho eziqediwe ngokuvamile ziyafana nalezo eziku-EN 10025-4, EN 10025-5 kanye ne-EN 10025-6. INOTHI 4 Izidingo zezingxenye ezingenalutho zesakhiwo sensimbi ezingenalutho nezihlanganisiwe ukuze zisetshenziswe ezakhiweni ezikude zimbozwe ochungechungeni lwe-EN 10225. INOTHI 5 Izingxenye ezingenalutho ezihlanganisiwe ezihlanganisiwe ezijikelezayo kulindeleke ukuthi zisetshenziswe ngokuqapha ezinhlelweni ezihilela ukuziphatha okuguqukayo (ukucindezeleka kokukhathala) njengoba, kuze kube manje, kungekho idatha eyanele mayelana nokusebenza kwazo.

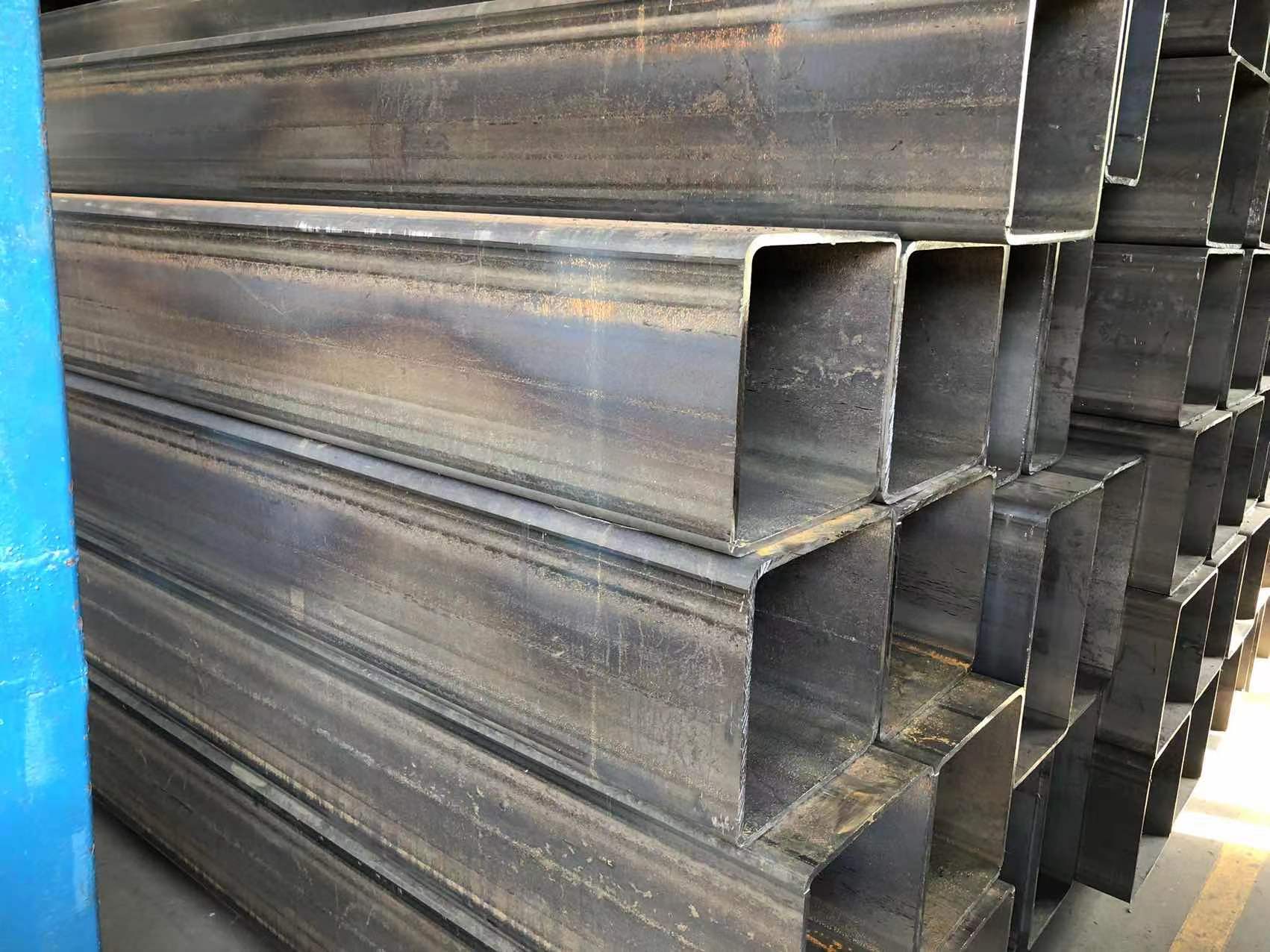

Yethula ukusetshenziswa okubanzi kwepayipi elingunxande elenziwe ngendlela ebandayo

Ezakhiweni zezimboni nezomphakathi zaseShayina, ukhonkolo oqinisiwe ubulokhu usetshenziswa iminyaka eminingi

Umjikelezo omude kanye nokungcola okukhulu. Eminyakeni yamuva nje, ngempumelelo ye-hot rolledUkukhanya kwe-Himikhiqizo ye-Ma Steel ne-Lai Steel

Ngokwesingeniso semakethe, ukusetshenziswa kwesakhiwo sensimbi embonini yokwakha kuye kwanda. Izakhiwo ezahlukahlukene zokuhlola izakhiwo zensimbi, izindlu zamamodeli kanye nezakhiwo eziphawulekayo ziye zethulwa ngokulandelana. Izindinganiso kanye nezincazelo zokuklama nokwakha nazo seziqalile ukungena esigabeni sokuthuthuka kancane kancane. Imboni yesakhiwo sensimbi yaseShayina yenze intuthuko enkulu eminyakeni yamuva nje.

Kodwa-ke, njengamanje, izakhiwo zensimbi zokwakha zaseShayina zisetshenziselwa kakhulu insimbi egoqwe ngokushisa enomumo we-H kanye nezakhiwo zensimbi ezahlukahlukene ezigoqwe ngokushisa. Umthamo wensimbi egoqwe ngokushisa enomumo we-H eShayina usufinyelele amathani ayizigidi ezi-3, kanti umkhiqizo wensimbi ekhanyayo enomumo we-H kanye nezakhiwo zensimbi ezahlukahlukene nawo ungamathani ayizinkulungwane ezingamakhulu amaningana. Umkhiqizo wamapayipi agoqwe ngokushisa eShayina ungaphezu kwamathani ayizigidi ezi-7 ngonyaka, okuwumphumela wawoamapayipi ayisikwele nangunxande akhiwe ngendlela ebandayofuthi izakhiwo zensimbi ezahlukahlukene ezakhiwe ngokubandayo zokwakha izakhiwo zensimbi zingaphansi kuka-5% womkhiqizo ophelele wensimbi eyakhiwe ngokubandayo. Ukusetshenziswa kwensimbi eyakhiwe ngokubandayo ezakhiweni zensimbi ezakhiweni zezimboni nezomphakathi eShayina kusesigabeni sokuqala. Ipayipi elihlanganisiwe elenziwe ngokubandayo eliyisikwele neliyindilinga elihlanganisiwe seliqalile ukufaka esikhundleni sensimbi egoqwe ngokushisa efana no-H njengekholomu yesakhiwo sensimbi. Enye insimbi eyakhiwe ngokubandayo ayisetshenziswa kakhulu embonini yokwakha.

ingxenye engenalutho yensimbi ye-yuantai ye-crane,isigaba esingenalutho se-yuantai,isigaba esingenalutho sesikwele se-yuantai

Njengamanje, uMnyango Wezokwakha wakhe izakhiwo ezithile zokuhlola isakhiwo sensimbi ezakhiweni zezimboni nezomphakathi, njenge

Izindlu ezimbili zokubonisa izakhiwo zensimbi zoMnyango Wezokwakha zakhiwa eTianjin ngo-2002. Amapayipi ensimbi asetshenziswa kulo msebenzi.

Uhlelo lwesakhiwo se-concrete column steel beam frame (SRC) steel concrete core tube (SRC), indawo yephrojekthi iyonke

8000m2, umzimba oyinhloko unezitezi eziyishumi nanye, ikholomu eyodwa yenziwe ngepayipi eliyindilinga, kanti enye ikholomu yenziwe ngepayipi lensimbi eliyisikwele.

350x350mm, ubukhulu buyahlukahluka kuye ngophansi, lapho izitezi ezingu-1~3 zingama-16mm, 4~

I-14mm yesitezi sesi-6, i-12mm yesitezi sesi-7 kuya kwesi-9, i-10mm yesitezi se-10 kuya kwesi-11, bese kuthululwa ipayipi lensimbi

Ukhonkolo we-C40.

I-beam yenziwe nge-welded I-beam enemininingwane engu-350x200x10x18mm, kanye ne-floor slab.

Kuyi-slab ehlanganisiwe eqinisiwe enokuqinisa izimbambo ezijikelezayo ezinamandla aphezulu. Ngaleso sikhathi, akekho umenzi eShayina owakhiqiza amashubhu asikwele anobubanzi obukhulu kangaka, ngakho-ke amashubhu ensimbi asikwele asetshenziswa kulo msebenzi, okwakungamakholomu amane e-BOX ahlanganiswe ngamapuleti.

Iphrojekthi yezindlu zokubonisa izakhiwo zensimbi yoMnyango Wokwakha weTianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd. ithola ugqozi olubili ekusetshenzisweni kwensimbi eyakhiwe ngendlela ebandayo (ikakhulukazi ishubhu elingunxande) ezindlini zesakhiwo sensimbi:

Okokuqala, indawo yemakethe yamashubhu amakhulu aqinile akhiwe ngokubandayo inkulu, futhi inani elifanele lezitezi zesakhiwo sensimbi liyi

Njengoba zinezitezi ezingu-10-18, izakhiwo ezinjalo eziphakeme eziphakathi nendawo neziphakeme nazo zinezidingo ezithile zemininingwane yamapayipi angunxande akhiwe ngendlela ebandayo.

Okwesibili, amapayipi ensimbi ayisikwele anezinzuzo ezisobala kunamapayipi ensimbi ayindilinga ngezizathu ezintathu:

Okokuqala, amapayipi ayisikwele nayindilinga anobude obufanayo nobubanzi obufanayo ohlangothini anomthamo ongcono wokuthwala kanye nokusebenza kokuzamazama komhlaba.

Kuhle. Ngokusho kokuhlolwa okwenziwe yiyunivesithi eTianjin kuthubhu yesikwele enezitezi ezintathu enezipini ezimbili kanye nohlaka lwekholomu yekhonkrithi yethubhu eliyindilinga.

Ubude obuseceleni bekholomu yepayipi buyi-150mm, kanti ububanzi bepayipi eliyindilinga buyi-150mm. Imiphumela yokuhlolwa ikhombisa ukuthi elokuqala liyamelana nokuthwala kwamandla okugoba eceleni.

Umthamo womthwalo kanye nomthamo wokugcina wokuthwala uphakeme ngo-80% kunewokugcina, kanti inkomba yokusebenza kokuzamazama komhlaba cishe iphindwe kabili kuneyokugcina;

Okwesibili, ukwakhiwa kwamapayipi ayisikwele kulula kakhulu. Ikholomu yekhonkrithi yesakhiwo sensimbi idinga ukuba kude.

Ukuze kwakhiwe, ingxenye eyindilinga ishintshwa ibe yingxenye yesikwele;

Okwesithathu, kunzima ukubhekana nokuxhumana phakathi kwamakholomu ekhonkrithi ayindilinga kanye nemishayo. Isakhiwo sensimbi sesikhathi esizayo eShayina

Emakethe, amashubhu ayisikwele nawayindilinga akhiwe ngendlela ebandayo azoba nesabelo esibalulekile.

Ukwelashwa ngokushisa okuphezulu kwepayipi lensimbi kungathuthukisa kakhulu umkhawulo wokukhathala kwento yokusebenza yomkhiqizo. Isibonelo, ubuchwepheshe bokuqala bokucubungula be-half axle yemoto eyenziwe ngensimbi buyindlela evamile yokwelapha ngokushisa, futhi impilo yayo yesevisi inyuswe cishe izikhathi ezingama-20 ngokushintsha kusuka ekwelashweni ngokushisa okuphezulu kuya ekwelashweni ngokushisa. Ngaphezu kwalokho, ukwelashwa ngokushisa okuphezulu kunciphisa ukuzwela kwezikhala zezingxenye. Inhloso yokwelashwa ngokushisa okuphezulu ukuthuthukisa kangcono izici zemikhiqizo. Isetshenziswa kabanzi emikhakheni ehlukahlukene, okuhlobene eduze nezici zazo zombili.

Isikhathi sokuthunyelwe: Disemba-21-2022