The difference between hot rolling and cold rolling is mainly the temperature of rolling process. "Cold" means normal temperature, and "hot" means high temperature. From the viewpoint of metallurgy, the boundary between cold rolling and hot rolling should be distinguished by recrystallization temperature. That is, the rolling below the recrystallization temperature is cold rolling, and the rolling above the recrystallization temperature is hot rolling. The recrystallization temperature of steel is 450-600 ℃.

The following is an overview of the answers to the questions about [Difference between hot rolling and cold rolling]:

The difference between cold rolling and hot rolling is mainly the temperature of rolling process. "Cold" means normal temperature, and "hot" means high temperature. From the viewpoint of metallurgy, the boundary between cold rolling and hot rolling should be distinguished by recrystallization temperature. That is, the rolling below the recrystallization temperature is cold rolling, and the rolling above the recrystallization temperature is hot rolling. The recrystallization temperature of steel is 450-600 ℃

Hot rolling and cold rolling are processes of forming steel plates or profiles, which have a great impact on the structure and properties of steel. The rolling of steel is mainly hot rolling, and cold rolling is only used to produce small section steel and thin plate. Ingots or billets are difficult to deform and process at room temperature. Generally, they are heated to 1100-1250 ℃ for rolling. This rolling process is called hot rolling. The end temperature of hot rolling is generally 800-900 ℃, and then it is generally cooled in air, so the hot rolling state is equivalent to normalizing treatment. Most steel is rolled by hot rolling. Cold rolling refers to the rolling method of extruding steel and changing the shape of steel with the pressure of rolls at room temperature. Although the processing process will also make the steel plate warm, it is still called cold rolling.

This document specifies the technical delivery conditions for high strength and weather resistant electric welded and submerged arc welded cold formed steel structural hollow sections of circular, square, rectangular or elliptical forms and formed cold without subsequent heat treatment other than the heat treatment of the weld line. NOTE 1 The requirements for tolerances, dimensions and sectional properties can be found in EN 10219 2. NOTE 2 The attention of users is drawn to the fact that whilst cold formed grades in this document can have equivalent mechanical properties to hot-finished grades in EN 10210 3, the sectional properties of square and rectangular hollow sections in EN 10219 2 and EN 10210 2 are not equivalent. NOTE 3 A range of steel grades is specified in this document and the user can select the grade most appropriate to the intended use and service conditions. The grades and mechanical properties, but not the final supply condition of cold formed hollow sections are generally comparable with those in EN 10025 3, EN 10025 4, EN 10025 5, EN 10025 6, EN 10149 2 and EN 10149 3.

EN 10210-3-2020

Hot finished steel structural hollow sections - Part 3: Technical delivery conditions for high strength and weather resistant steels

This document specifies technical delivery conditions for high strength and weather resistant hot-finished seamless, electric welded and submerged arc welded steel structural hollow sections of circular, square, rectangular or elliptical forms. It applies to hollow sections formed hot, with or without subsequent heat treatment, or formed cold with subsequent heat treatment above 580 °C to obtain equivalent mechanical properties to those obtained in the hot formed product. NOTE 1 The requirements for tolerances, dimensions and sectional properties are specified in EN 10210-2. NOTE 2 The attention of users is drawn to the fact that whilst cold formed grades in EN 10219-3 can have equivalent mechanical properties to hot-finished grades in this document the sectional properties of square and rectangular hollow sections in EN 10210-2 and EN 10219-2 are not equivalent. NOTE 3 A range of material grades is specified in this document and the user can select the grade most appropriate to the intended use and service conditions. The grades and mechanical properties of the finished hollow sections are generally comparable with those in EN 10025-4, EN 10025-5 and EN 10025-6. NOTE 4 The requirements for seamless and welded steel structural hollow sections for use in offshore structures are covered in the EN 10225 series. NOTE 5 Spiral welded hollow sections are expected to be used with caution in applications involving dynamic behaviour (fatigue stress) as, up to now, there is insufficient data regarding their performance.

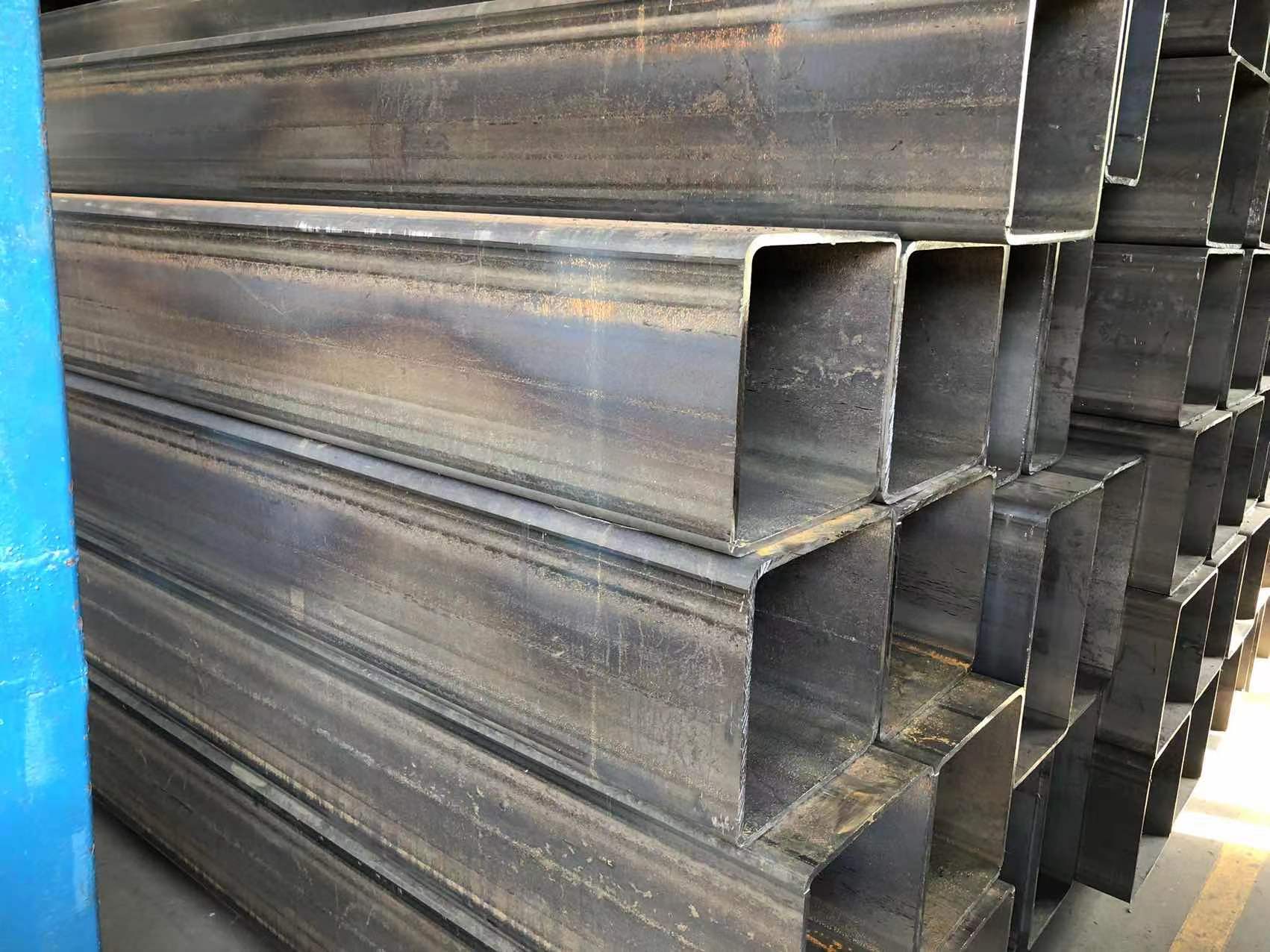

Introduce the wide application of cold-formed rectangular tube

In China's industrial and civil buildings, reinforced concrete has been used for many years

Long cycle and heavy pollution. In recent years, with the success of hot rolled H-beam products of Ma Steel and Lai Steel

According to the market introduction, the application of steel structure in the construction industry has been expanding. Various steel structure experimental buildings, model houses and landmark buildings have been introduced one after another. The standards and specifications for design and construction have also begun to enter the stage of gradual improvement. China's steel structure industry has made great strides in recent years.

However, at present, China's building steel structures are mainly used for hot rolled H-shaped steel and various welded steel structures. The capacity of hot rolled H-shaped steel in China has reached 3 million tons, and the output of welded light H-shaped steel and various steel structures is also several hundred thousand tons. The output of welded pipes in China is more than 7 million tons a year, of which the output of cold-formed square and rectangular pipes and various cold-formed steel structures for building steel structures is less than 5% of the total output of cold-formed steel. The application of cold-formed steel in industrial and civil building steel structures in China is at the initial stage. The cold-formed square and rectangular structure welded pipe has just begun to replace the hot-rolled H-shaped steel as the steel structure column. Other cold-formed steel is less used in the construction industry.

yuantai steel hollow section for crane,yuantai seamless hollow section,yuantai square hollow section

At present, the Ministry of Construction has built some steel structure test buildings in industrial and civil buildings, such as

Two steel structure demonstration residences of the Ministry of Construction were built in Tianjin in 2002. Steel pipes were used in this project

Concrete column steel beam frame steel reinforced concrete core tube (SRC) structural system, total project area

8000m2, the main body has eleven floors, one column is made of round pipe, and the other column is made of square steel pipe

350x350mm, the thickness varies with the floor, of which the 1~3 floors are 16mm, 4~

14mm for the 6th floor, 12mm for the 7th to 9th floor, 10mm for the 10th to 11th floor, and poured in the steel pipe

C40 concrete.

The beam is made of welded I-beam with the specification of 350x200x10x18mm, and the floor slab

It is a prestressed composite slab with high-strength spiral rib reinforcement. At that time, no manufacturer in China produced square tubes with such a large diameter, so square steel tubes were used in the project, which were four plate welded BOX columns.

The steel structure demonstration housing project of the Ministry of Construction of Tianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd. draws two inspirations from the application of cold-formed section steel (mainly rectangular tube) in steel structure housing:

First, the market space for large-sized cold-formed rectangular tubes is large, and the reasonable number of floors for steel structure residence is

With 10~18 floors, such middle and high rise structures also have certain requirements for the specifications of cold-formed rectangular tubes.

Second, square steel pipes have obvious advantages over round steel pipes for three reasons:

First, square and round pipes with the same side length and diameter have better bearing capacity and seismic performance

Good. According to the test conducted by a university in Tianjin on a three story two span square tube and circular tube concrete column frame

The side length of the pipe column is 150mm, and the diameter of the round pipe is 150mm. The test results show that the former is resistant to lateral force yield bearing

The load capacity and ultimate bearing capacity are 80% higher than the latter, and the seismic performance index is about twice of the latter;

Second, square pipe construction is more convenient. The concrete column of steel structure residence needs to be further

For construction, round section is changed to square section;

Third, it is difficult to deal with the connection between circular concrete columns and beams. Future steel structure in China

In the market, cold-formed square and rectangular tubes will have an important share.

The surface heat treatment of steel pipe can significantly improve the fatigue limit of product workpiece. For example, the original processing technology of automobile half axle made of steel is ordinary heat treatment, and its service life has been increased by nearly 20 times by changing from surface heat treatment to heat treatment. In addition, surface heat treatment reduces the vacancy sensitivity of parts. The purpose of surface heat treatment is to better improve the characteristics of products. It is widely used in various fields, which is closely related to the characteristics of both.

Post time: Dec-21-2022