1. Uthelekiso lwenkqubo yokuvelisa

Inkqubo yemveliso yeumbhobho wentsimbi yomthungo othe ngqoilula ngokwentelekiso.Iinkqubo eziphambili zemveliso zi-high-frequency welded straight seamumbhobho wentsimbikwayei-arc entywiliselweyo idityaniselwe umbhobho wentsimbi womthungo othe tye.Umbhobho wentsimbi yomthungo othe ngqo unomgangatho ophezulu wokuvelisa, ixabiso eliphantsi kunye nophuhliso olukhawulezayo.

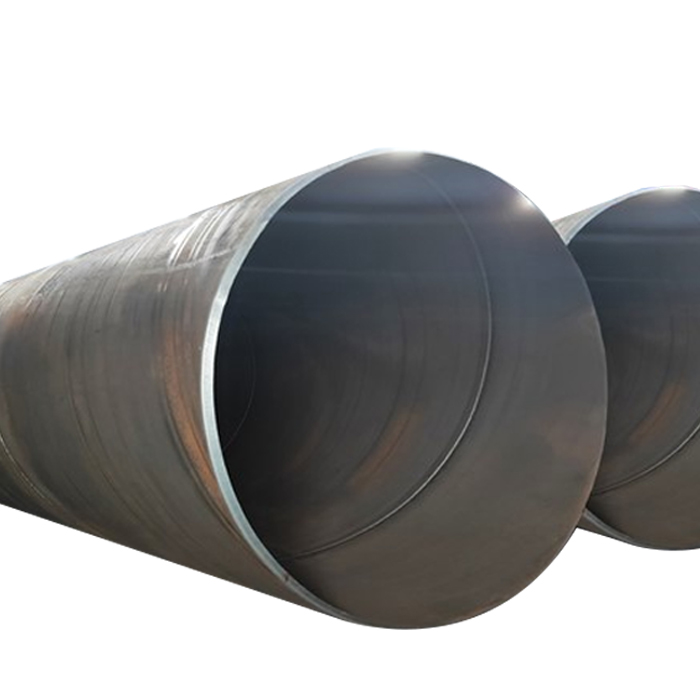

Amandla eumbhobho wentsimbi ejikelezayoidla ngokuba phezulu kunombhobho wentsimbi yomthungo othe ngqo.Eyona nkqubo yemveliso kukuntywiliselwa kwe-arc welding.Iityhubhu zetsimbi ezijikelezayo zinokuvelisa iibhubhu ezidityanisiweyo ezinobubanzi obuhlukeneyo beebhilidi ezinobubanzi obufanayo, okanyeiityhubhu ezidityanisiweyongeedamitha ezinkulu ukusuka kwiibhilithi ezimxinwa.

Nangona kunjalo, xa kuthelekiswa nemibhobho yentsimbi yomthungo yobude obufanayo, ubude be-welding bunyuke nge-30% kunye ne-100% ngokulandelanayo, kwaye isantya sokuvelisa siphantsi.Ke ngoko, imibhobho yentsimbi edayamitha emikhulu idityaniswa ikakhulu ngokudibanisa i-spiral welding, kwaye imibhobho yentsimbi edayamitha emincinci idityaniswa kakhulu ngokuwelda komthungo othe ngqo.

Xa kuveliswaimibhobho yentsimbi yomthungo emikhulu enobubanzikumashishini, iteknoloji yokuwelda i-T isetyenziswa, oko kukuthi, inani elincinci lemibhobho yentsimbi yomthungo ethe tye i-butt idityaniswe kwaye idityaniswe ukuhlangabezana nobude obufunekayo beprojekthi.Iziphene zombhobho wentsimbi yomthungo omile okwe-T ziya kwandiswa kakhulu, kwaye uxinzelelo olushiyekileyo lwe-welding ye-T-shaped weld lukhulu.Intsimbi ye-weld ngokuqhelekileyo iphantsi koxinzelelo lwe-triaxial, okwandisa amathuba okuqhekeka.

Ukongeza, ngokwemigaqo yobugcisa ye-arc welding ephantsi kwamanzi, i-weld nganye iya kuba phantsi kwe-arc striking kunye ne-arc yokucima unyango.Nangona kunjalo, umbhobho ngamnye wentsimbi awukwazi ukuhlangabezana nale meko ngexesha lokuthungelwa kwe-seam ye-circumferential, ngoko ke iziphene ze-welding zinokuthi zenzeke ngexesha lokucima i-arc.

2. Ukuthelekiswa kweeparamitha zentsebenzo

Xa umbhobho uphantsi koxinzelelo lwangaphakathi, iingcinezelo ezimbini eziphambili zivame ukuveliswa eludongeni lombhobho, oko kukuthi uxinzelelo lwe-radial kunye noxinzelelo lwe-axial.Uxinzelelo olubanzi kwi-weld, apho α Yi-engile ye-weld spiralumbhobho wentsimbi ejikelezayo.

Uxinzelelo olubanzi kwi-spiral weld lolona xinzelelo luphambili lombhobho wentsimbi yomthungo othe ngqo.Ngaphantsi koxinzelelo olufanayo lokusebenza, ubukhulu bodonga lwemibhobho yentsimbi ejikelezayo kunye nobubanzi bombhobho obufanayo buncinci kunobo bemibhobho yentsimbi yomthungo othe tye.

Ixesha lokuposa: Jan-03-2023