Simbi Yakamonerwa Nechando

Munguva yekumonera simbi inotonhora, simbi inomonera inopisa inotanga yabviswa oxide scale kana tsvina iri pamusoro. Zvadaro, simbi inopfuura nemumaroller akawanda anoshandisa kumanikidzwa, uye ukobvu hunodzikira zvishoma nezvishoma, uye kupenya kwepasi kunovandudzwa. Maitiro aya anogonawo kuwedzera simba nekuoma kwesimbi.

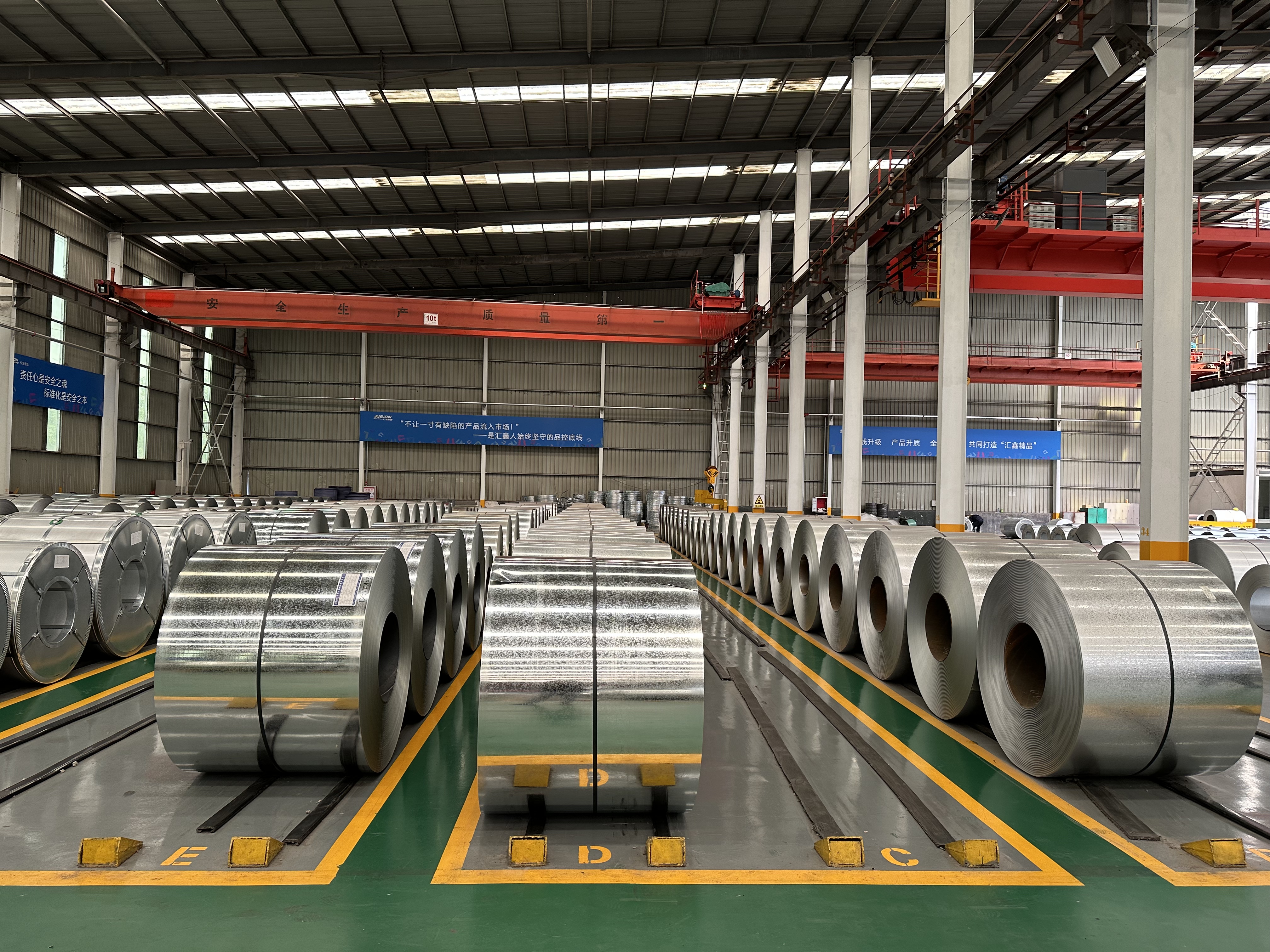

Makoiri esimbi anomonereka anotonhora anoshanda zvakanaka, uye anomonereka anotonhora anogona kugadzira mitsetse nemaplate anomonereka anotonhora ane ukobvu hwakatetepa uye akanyatsojeka. Mapepa anomonereka anotonhora ane kutwasuka kwakanyanya, kupenya kwepamusoro uye kutsvedzerera, uye pamusoro pacho pakachena uye pakajeka. Makoiri esimbi anomonereka anotonhora ari nyore kupenda nekugadzirisa, ane simba repamusoro rekuisa stamping uye ane goho diki, saka anoshandiswa zvakanyanya, kunyanya mumotokari nezvinhu zvekuvaka. Panguva imwe chete, makoiri esimbi anomonereka anotonhora ndiwowo anonyanya kushandiswa pakugadzira makoiri esimbi anomonereka uye makoiri esimbi anomonereka.

Magiredhi esimbi akaputirwa nechando

Kurongwa kwemagiredhi esimbi dzakaputirwa dzinotonhora kunowanzo enderana nezvinhu zvakaita sehunhu hwadzo hwemakanika, mhando yenzvimbo, mashandisirwo adzo, uye kuumbwa kwemakemikari. Nyika dzakasiyana uye masisitimu akajairwa (akadai seChina GB, US ASTM, Japan JIS, Europe EN, nezvimwewo) dzine nzira dzakasiyana dzekupatsanura magiredhi esimbi dzakaputirwa dzinotonhora.

1. Kupatsanura nekushandiswa uye hunhu hwemakanika

SPCC: Simbi yekabhoni inotonhorera inoshandiswa zvakanyanya, yakaenzana neSPCC muJIS standard, inowanzoshandiswa pakudhinda nekuumba.

SPCD: Simbi inoputirwa nechando inokwira, ine ductility iri nani pane SPCC, yakakodzera kudhirowa nepakati nepakati.

SPCE: Simbi inotonhorera yakadzika, ine ductility yakakwira, inoshandiswa pakugadzira zvikamu zvakaoma (senge zvikamu zvemotokari)

(2) Simbi Yakasimba Kwazvo

HSS (Simbi Yakasimba): inosanganisira simbi ine simba rakawanda (HSLA), simbi ine mapoinzi maviri (DP), simbi ine martensitic (MS), nezvimwewo, zvinoshandiswa pakurerutsa mota.

BH Steel (Kuomesa Kubika): Simbi inoomesa Kubika, iyo inowedzera simba kuburikidza nekupisa.

(3) Simbi dzebasa rakakosha

Simbi yemagetsi (simbi yesilicon): yakaita seDW (simbi yesilicon isina kurongeka) kana DQ (simbi yesilicon yakarongeka), inoshandiswa pakugadzira mota ne transformer cores.

Zvigadziko zvesimbi zvakaputirwa: zvakaita seDC04 (European standard), zvinoshandiswa pakugadzira galvanizing inotevera (GI), kugadzira galvanizing (GL), nezvimwewo.

Zvakanakira zve coil yesimbi inotonhorera inotonhora:

1. Kururama kwepamusoro-soro, pamusoro pakanyatsotsetseka, ukobvu hwakafanana Maitiro ekumonereka anotonhora anogona kugadzira matete (kusvika 0.1mm) uye ukobvu hwakafanana hwesimbi dzine madiki anoshivirira (± 0.02mm).

2. Hunhu hwakanaka hwemakanika uye mashandiro ekuita zvakanaka kwazvo (zvakadai sesimba rakakwirira, muganho wakaderera wegoho, kushanda zvakanaka kwekudhirowa kwakadzika huremu, nezvimwewo).

3. Hunhu hwezvinhu zvinogona kugadziriswa kuti zvikwanise kutenderera nekukurumidza, kutenderera kwakazara, uye kubereka zvakawanda.

Cold-rolled Steel Coil ine mashandisirwo akasiyana-siyana

Makoiri esimbi anomonereka atonhora ave chinhu chikuru muindasitiri yemazuva ano nekuda kwekunyatsorongeka kwawo, simba rawo guru, kunaka kwawo pamusoro uye kugona kwawo kugadzira zvinhu zvakanaka. Anoshandiswa zvakanyanya muminda inotevera:

1. Kugadzira mota

Zvikamu zvekushandisa: mapaneru emuviri, zvikamu zvechasi, mafuremu echigaro, masisitimu ekumisikidza, kusimbiswa kwechimiro, masisitimu ekubuda kwemhepo, nezvimwewo.

Zvakanakira zvepakati:

Zviyero zvakanyatsonaka: ita shuwa kuti zvikamu zvinokodzera zvakakwana uye zvinovandudza kushanda zvakanaka kwekubatanidza.

Hunhu hwakanaka hwepamusoro: hunogona kupfapfaidzwa zvakananga kana kuputirwa nemagetsi kuderedza mari yekushanda mushure mekugadzirisa.

Simba guru uye rakareruka: zvinobatsira mota kuchengetedza simba uye kuderedza kusvibiswa kwemhepo, ukuwo zvichivandudza mashandiro ekuchengetedza.

2. Indasitiri yemidziyo yemumba

Zvigadzirwa zvakajairika: mafiriji, michina yekuwachisa, maovheni, ma air conditioner nezvimwe zvinhu, mabhureki emukati uye zvikamu zvechivakwa.

Zvakanakira zvepakati:

Yakapfava uye yakanaka: inosangana nezvinodiwa zvepamusoro zvemidziyo yepamusoro yekumba kuti iratidzike zvakanaka.

Haina ngura uye inogara kwenguva refu: wedzera hupenyu hwechigadzirwa uye chijairane nenzvimbo dzine hunyoro.

Zviri nyore kugadzirisa uye kugadzira: zvakakodzera kudhinda, kukotama uye zvimwe zvigadzirwa zvakaoma.

3. Magadzirirwo ezvivakwa nekushongedza

Mashandisirwo makuru: matenga esimbi, madziro emaketeni, zvivakwa zvesimbi, mafuremu emusuwo nemahwindo, nezvimwewo.

Zvakanakira zvepakati:

Simba rakakwirira uye rakareruka: gadzirisa chimiro chekuvaka uye deredza mari yekuvaka.

Zviyero zvakagadzikana: simbisa kururama kwekuisa uye kuderedza zvikanganiso zvekugadzirisa.

Nzvimbo yakatsetseka: inogona kupendwa zvakananga kana kunamirwa kuti ivandudze runako rwechivako.

4. Fenicha nekuchengetera zvinhu

Zvishandiso zvinoshandiswa: madhesiki ehofisi nezvigaro, makabati, masherufu, masisitimu ekuchengetera zvinhu, nezvimwewo.

Zvakanakira zvepakati:

Chimiro chakagadzikana: kugona kwakasimba kwekutakura mutoro, kwakakodzera mamiriro ezvinhu ane mutoro wakawanda.

Nzvimbo yakapfava: Kurapa kwakasiyana-siyana pamusoro (sekupfapfaidza, kukwesha) kunogona kuitwa kuti chigadzirwa chiwedzere kunaka.

Zviri nyore kugadzirisa: zviri nyore kucheka, kupeta, kukotama, uye kugadzirisa zvinoenderana nezvinodiwa.

5. Mapaipi nemidziyo yemagetsi

Minda inoshanda: mapaipi emvura, mapaipi egasi, mapaipi ekuvaka, hardware, nezvimwewo.

Zvakanakira zvepakati:

Kushivirira kwakasimba: simbisa kuvharwa kwepombi uye kuvimbika kwekubatanidza.

Kudzivirira kumanikidzwa uye ngura: yakakodzera nharaunda dzakaoma uye inowedzera hupenyu hwebasa.

Kugadzirwa kwakanaka kwazvo: kuri nyore pakushongedza, kuputira uye kugadzirisa zvimwe zvinhu.

6. Midziyo yemagetsi

Mashandisirwo akajairika: makabati emagetsi, chassis, ma transformer housings, zvikamu zvemagetsi zvakanyatsonaka, nezvimwewo.

Zvakanakira zvepakati:

Kunyatsojeka: kusangana nezvinodiwa zvekugadzira zvinhu zvemagetsi zvakanyatsonaka.

Kudzivirira magineti: kwakakodzera kuchengetedza michina yemagetsi inobatwa nemagetsi.

Zviri nyore kudhindwa uye kugadzirwa: zvakakodzera kugadzira zvikamu zvakaoma zvechivakwa.

7. Indasitiri yekurongedza

Zvigadzirwa zvikuru: magaba ezvekudya, mabhare emakemikari, midziyo yesimbi, nezvimwewo.

Zvakanakira zvepakati:

Simba guru uye kuramba kumanikidzwa: chengetedza kutakurwa nekuchengetwa kwekuchengetedza.

Kudzivirira ngura: kuwedzera hupenyu hwekurongedza chikafu nemakemikari.

Inogona kudzokororwa uye isingakuvadzi nharaunda: zvinoenderana nemaitiro ekurongedza kwegirini.

Musiyano uripo pakati pe coil yesimbi inotonhorera inotonhora ne coil yesimbi inotonhorera inopisa

1. Kuenzanisa maitiro ekugadzira

Coil yesimbi inomonereka nechando: kutenderedza tembiricha yemukamuri, kuomarara kwebasa, kunamatira zvinodiwa kuti pave nepurasitiki, zvakakodzera kugadzirwa kwemaplate matete nezvinhu zvakanyatsonaka. Kuyerera kwemaitiro: ndiro inomonereka nechando → kuputira → kutenderedza nechando → kunamatira → kupedzisa

Coil yesimbi inopfurwa nekupisa: inopfurwa nekupisa kwakanyanya, inoshanduka nyore nyore, yakakodzera kugadzirwa kwemaplate akakora. Kuyerera kwemaitiro: kukanda kunoenderera mberi → kupisa → kupfurwa kunopisa → kupomba

2. Kuenzanisa pfuma chaiyo

Kutenderedza kunopisa: Kana tichienzanisa nesimbi inomonereka inotonhora, macoil esimbi anomonereka anodziya ane simba shoma uye kuomarara kushoma. Kazhinji haapindi zvakanyanya uye anotsungirira kuchinjika. Akakodzera zvikamu zvechimiro, anodhura zvishoma asi anonyatsoita zvinhu nemazvo.

Kutenderedza nechando: Masimbi anotenderedza nechando ane simba guru uye kuomarara nekuda kwekuomarara kunoitika panguva yekutenderedza nechando. Ane kurongeka kwakanyanya uye hunhu hwakarurama hwemakanika. Akakodzera zvikamu zvine hungwaru uye simba guru, zvakaita semapaneru emotokari uye magadziko emagetsi.

3. Kurapa pamusoro

Coil yesimbi inopfurwa nekupisa: Nzvimbo isina kusimba, ine oxide scale (inoda kuchekwa), ine finish shoma, inoda kubviswa ngura, jecha rinoputika uye mamwe magadzirirwo epamberi.

Coil yesimbi inomonereka inotonhora: Nzvimbo yakatsetseka, isina oxide scale (inogona kuputirwa zvakananga nemagetsi kana kupfapfaidzwa), finish yakakwirira, inogona kupendwa zvakananga kana kuputirwa zvakananga

Kambani iyi inonyanya kukoshesa mhando yezvigadzirwa, inoisa mari yakawanda mukugadzira michina yepamusoro nenyanzvi, uye inoita zvese zvainogona kuti igutse zvinodiwa nevatengi vari kumba nekune dzimwe nyika.

Zviri mukati zvinogona kukamurwa kuita: makemikari, simba rekugadzira, simba rekudhonza, hunhu hwekurova, nezvimwewo

Panguva imwe chete, kambani inogonawo kuita mabasa ekuona zvikanganiso paindaneti uye ekugadzirisa zvikanganiso pamwe nemamwe maitiro ekurapa kupisa zvichienderana nezvinodiwa nevatengi.

https://www.ytdrintl.com/

E-mail:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.ifekitari yemapaipi esimbi ine chitupa cheEN/ASTM/ JISInonyanya kugadzira nekuburitsa marudzi ese emapaipi akaenzana, mapaipi akarukwa, mapaipi akarukwa eERW, mapaipi anotenderera, mapaipi akarukwa akadzika pasi, mapaipi akarukwa akatwasuka, mapaipi asina musono, coil yesimbi yakaputirwa nemavara, coil yesimbi yakarukwa nezvimwe zvigadzirwa zvesimbi. Nekutakurwa kuri nyore, iri makiromita zana nemakumi mapfumbamwe kubva kuBeijing Capital International Airport uye makiromita makumi masere kubva kuTianjin Xingang.

WhatsApp:+8613682051821