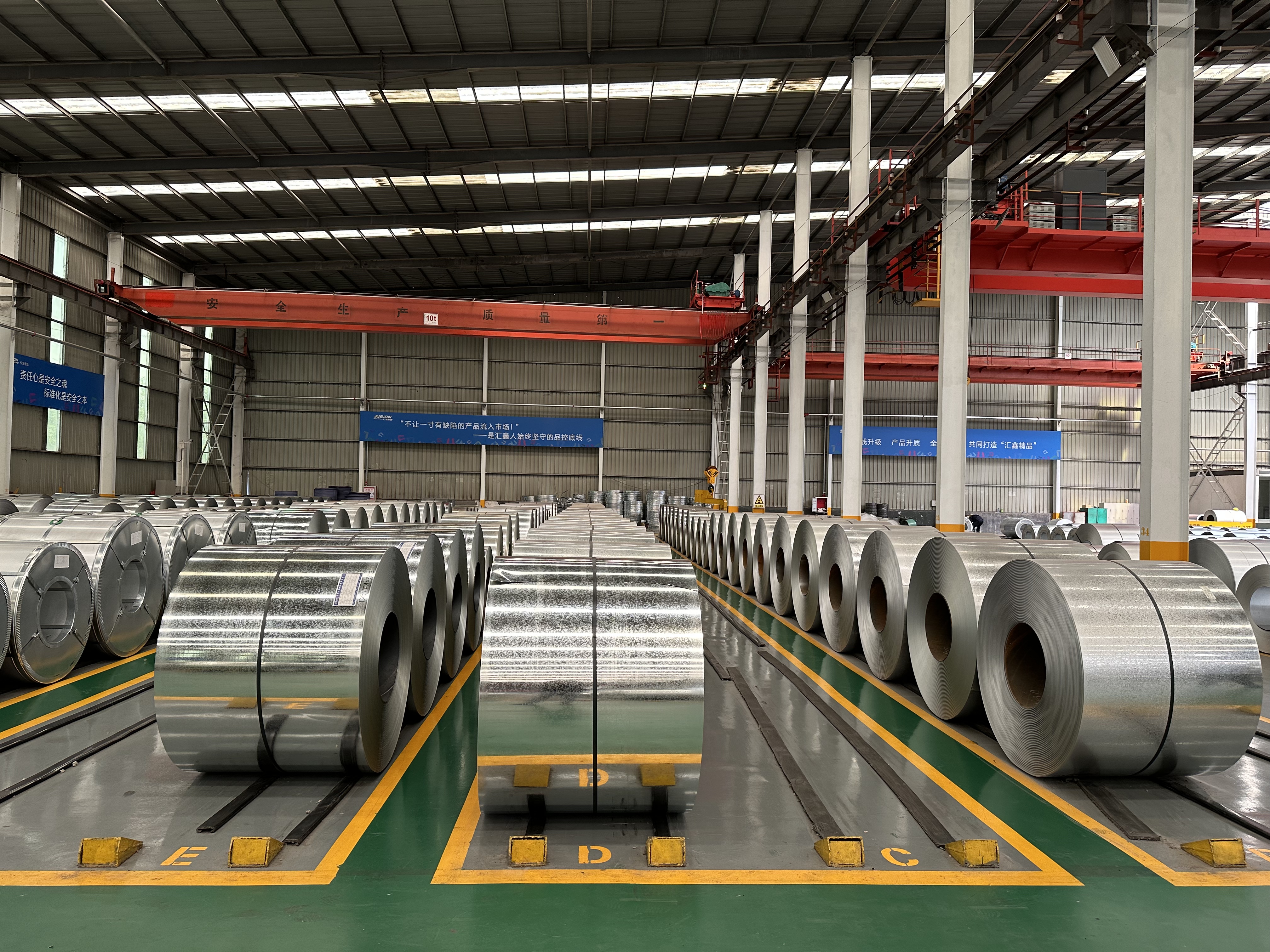

Cold-rolled Steel Coil

During the cold rolling process, the hot rolled steel is first pickled to remove the oxide scale or impurities on the surface. Then, the steel passes through a series of rollers that apply pressure, and the thickness is gradually reduced, and the surface finish is improved. This process can also increase the strength and hardness of the steel.

Cold rolled steel coils have excellent performance, and cold rolling can produce cold rolled strips and plates with thinner thickness and higher precision. Cold rolled sheets have high straightness, surface finish and smoothness, and the surface is clean and bright. Cold rolled steel coils are easy to paint and process, have high stamping performance and low yield point, so they are widely used, mainly in automobiles and building materials. At the same time, cold rolled steel coils are also the base material for the production of galvanized steel coils and galvanized steel coils.

Cold rolled steel coil grades

The grade classification of cold rolled steel coils is usually based on factors such as its mechanical properties, surface quality, use, and chemical composition. Different countries and standard systems (such as China GB, US ASTM, Japan JIS, Europe EN, etc.) have different classification methods for the grades of cold rolled steel coils.

1. Classification by use and mechanical properties

SPCC: General purpose cold rolled carbon steel, equivalent to SPCC in JIS standard, commonly used for general stamping and forming.

SPCD: Stamping grade cold rolled steel, has better ductility than SPCC, suitable for medium deep drawing.

SPCE: Deep drawing grade cold rolled steel, has higher ductility, used for complex stamping parts (such as automotive parts)

(2) High Strength Steel

HSS (High Strength Steel): includes high strength low alloy steel (HSLA), dual phase steel (DP), martensitic steel (MS), etc., used for lightweighting of automobiles.

BH Steel (Bake Hardening): Bake hardening steel, which increases strength through heat treatment.

(3) Special purpose steels

Electrical steel (silicon steel): such as DW (non-oriented silicon steel) or DQ (oriented silicon steel), used for motor and transformer cores.

Coated steel sheet substrates: such as DC04 (European standard), used for subsequent galvanizing (GI), galvanizing (GL), etc.

Advantages of cold rolled steel coil:

1. High dimensional accuracy, smooth surface, uniform thickness The cold rolling process can produce thinner (down to 0.1mm) and uniform thickness steel coils with small tolerances (±0.02mm).

2. Excellent mechanical properties and process performance are very good (such as higher strength, lower yield limit, good weight deep drawing performance, etc.).

3. Material properties can be customized to achieve high-speed rolling, full continuous rolling, and high productivity.

Cold-rolled Steel Coil has a wide range of applications

Cold rolled steel coils have become the core materials of modern industry due to their high precision, high strength, excellent surface quality and outstanding forming performance. They are widely used in the following fields:

1. Automobile manufacturing

Application parts: body panels, chassis parts, seat frames, suspension systems, structural reinforcements, exhaust systems, etc.

Core advantages:

High-precision dimensions: ensure that parts fit perfectly and improve assembly efficiency.

Excellent surface quality: can be directly sprayed or electroplated to reduce post-processing costs.

High strength and lightweight: help automobiles save energy and reduce emissions, while improving safety performance.

2. Home appliance industry

Typical products: refrigerators, washing machines, ovens, air conditioners and other housings, internal brackets and structural parts.

Core advantages:

Smooth and beautiful: meet the high requirements of high-end home appliances for appearance.

Corrosion-resistant and durable: extend product life and adapt to humid environments.

Easy to process and shape: suitable for stamping, bending and other complex structure manufacturing.

3. Architecture and decoration

Main uses: metal roofs, curtain walls, steel structures, door and window frames, etc.

Core advantages:

High strength & lightweight: optimize building structure and reduce construction costs.

Stable dimensions: ensure installation accuracy and reduce processing errors.

Smooth surface: can be directly painted or laminated to improve the beauty of the building.

4. Furniture and storage

Applied products: office desks and chairs, cabinets, shelves, storage systems, etc.

Core advantages:

Stable structure: strong load-bearing capacity, suitable for high-load scenarios.

Smooth surface: various surface treatments (such as spraying, brushing) can be performed to improve the product grade.

Easy to process: easy to cut, weld, bend, and adapt to customized needs.

5. Pipes and hardware

Applicable fields: water pipes, gas pipes, building structure pipes, hardware, etc.

Core advantages:

Strict tolerance: ensure pipeline sealing and connection reliability.

Pressure and corrosion resistance: suitable for harsh environments and extend service life.

Excellent formability: easy for welding, flaring and other processing.

6. Electrical equipment

Typical applications: electrical cabinets, chassis, transformer housings, precision electronic components, etc.

Core advantages:

High precision: meet the assembly requirements of precision electronic components.

Electromagnetic shielding: suitable for protection of sensitive electronic equipment.

Easy to stamp and form: suitable for manufacturing complex structural parts.

7. Packaging industry

Main products: food cans, chemical barrels, metal containers, etc.

Core advantages:

High strength and pressure resistance: ensure transportation and storage safety.

Anti-corrosion: extend the life of food and chemical packaging.

Recyclable and environmentally friendly: in line with the trend of green packaging.

Differences between cold rolled steel coil and hot rolled steel coil

1. Production process comparison

Cold-rolled steel coil: room temperature rolling, obvious work hardening, annealing is required to restore plasticity, suitable for the production of thin plates and high-precision materials. Process flow: hot-rolled plate → pickling → cold rolling → annealing → finishing

Hot-rolled steel coil: high temperature rolling, easy deformation, suitable for the production of thicker plates. Process flow: continuous casting → heating → hot rolling → coiling

2. Physical property comparison

Hot rolling: Compared with cold-rolled steel, hot-rolled steel coils have lower strength and hardness. They are generally more ductile and more tolerant to deformation. Suitable for general structural parts, low cost but low precision.

Cold rolling: Cold-rolled steel coils have higher strength and hardness due to strain hardening that occurs during cold rolling. They have higher dimensional accuracy and precise mechanical properties. Suitable for high-precision, high-strength parts, such as automotive panels and electronic housings

3. Surface treatment

Hot-rolled steel coil: Rough surface, with oxide scale (needs pickling), low finish, requires rust removal, sandblasting and other pretreatments

Cold-rolled steel coil: Smooth surface, no oxide scale (can be directly electroplated or sprayed), high finish, can be directly painted or plated

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821