Txias-kuav hlau kauj

Thaum lub sijhawm dov txias, cov hlau kub dov yuav raug muab cov hlau kub dov ua ntej kom tshem tawm cov oxide scale lossis cov khoom tsis huv ntawm qhov chaw. Tom qab ntawd, cov hlau hla dhau ntau lub rollers uas siv lub zog, thiab qhov tuab maj mam txo qis, thiab qhov tiav ntawm qhov chaw tau zoo dua. Cov txheej txheem no kuj tseem tuaj yeem ua rau lub zog thiab qhov nyuaj ntawm cov hlau.

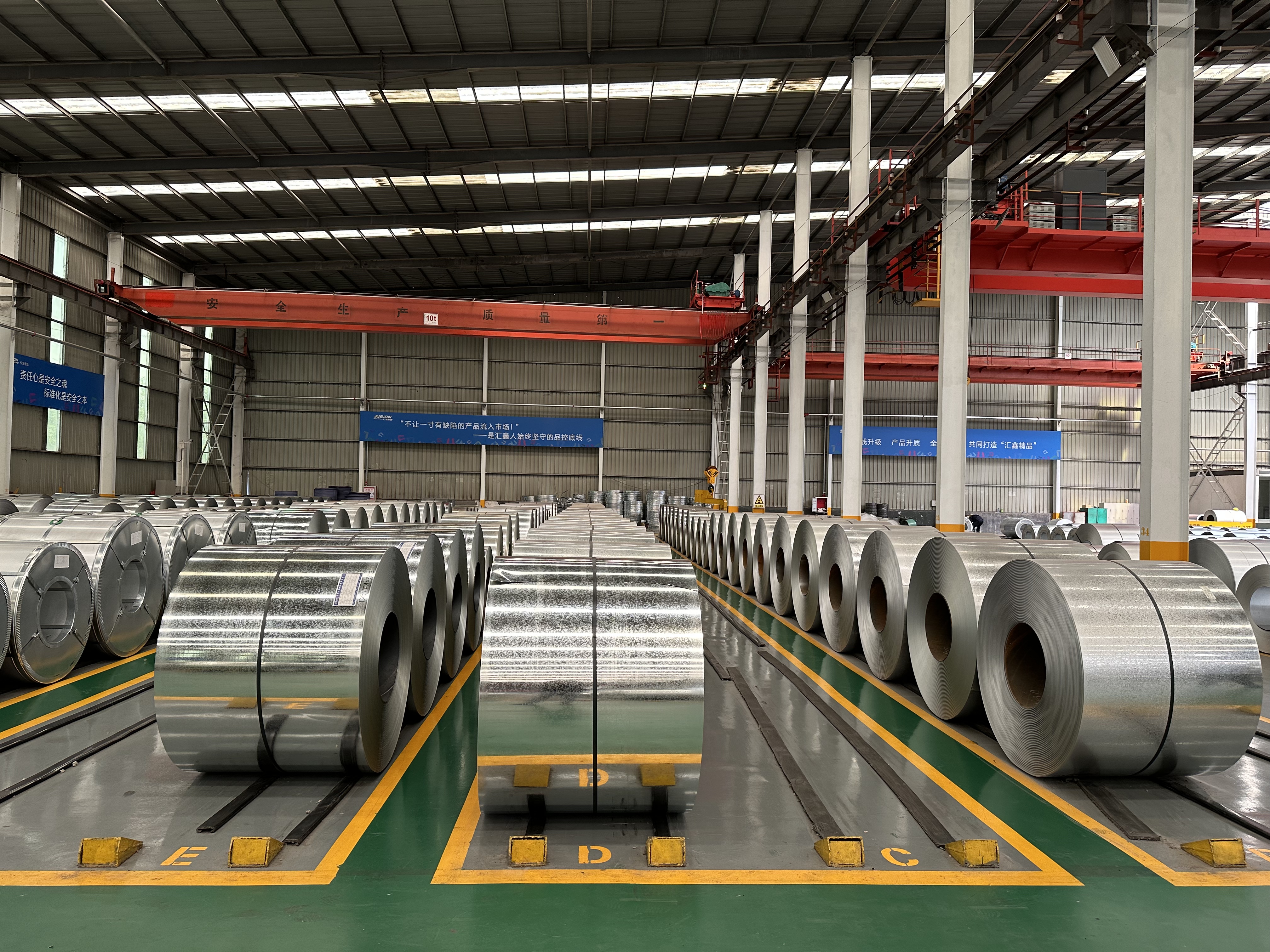

Cov hlau dov txias muaj kev ua tau zoo heev, thiab dov txias tuaj yeem tsim cov hlau dov txias thiab cov phaj nrog cov tuab nyias dua thiab qhov tseeb dua. Cov ntawv dov txias muaj qhov ncaj siab, qhov chaw tiav thiab du, thiab qhov chaw huv thiab ci. Cov hlau dov txias yooj yim rau pleev xim thiab ua tiav, muaj kev ua haujlwm siab stamping thiab qhov tso zis qis, yog li lawv siv dav, feem ntau hauv tsheb thiab cov ntaub ntawv tsim kho. Tib lub sijhawm, cov hlau dov txias kuj yog cov khoom siv tseem ceeb rau kev tsim cov hlau galvanized thiab hlau galvanized.

Cov qib hlau dov txias

Cov qib kev faib tawm ntawm cov hlau dov txias feem ntau yog raws li cov yam ntxwv xws li nws cov khoom siv kho tshuab, qhov zoo ntawm qhov chaw, kev siv, thiab cov tshuaj lom neeg sib xyaw. Cov teb chaws sib txawv thiab cov txheej txheem txheem (xws li Tuam Tshoj GB, Tebchaws Meskas ASTM, Nyiv JIS, Tebchaws Europe EN, thiab lwm yam) muaj cov txheej txheem faib tawm sib txawv rau cov qib ntawm cov hlau dov txias.

1. Kev faib tawm los ntawm kev siv thiab cov khoom siv kho tshuab

SPCC: Cov hlau carbon txias dov rau lub hom phiaj dav dav, sib npaug rau SPCC hauv tus qauv JIS, feem ntau siv rau kev luam ntawv thiab kev tsim khoom dav dav.

SPCD: Cov hlau dov txias uas raug nias, muaj qhov ductility zoo dua li SPCC, tsim nyog rau kev kos duab tob nruab nrab.

SPCE: Cov hlau txias dov uas sib sib zog nqus, muaj kev ywj pheej ntau dua, siv rau cov khoom sib dhos nyuaj (xws li cov khoom siv hauv tsheb)

(2) Cov Hlau Muaj Zog Siab

HSS (High Strength Steel): suav nrog cov hlau tsis muaj zog siab (HSLA), hlau ob theem (DP), hlau martensitic (MS), thiab lwm yam, siv rau kev ua kom lub tsheb sib dua.

BH Steel (Ci Hardening): Ci hardening steel, uas ua rau muaj zog ntxiv los ntawm kev kho cua sov.

(3) Cov hlau tshwj xeeb

Cov hlau hluav taws xob (silicon steel): xws li DW (non-oriented silicon steel) lossis DQ (oriented silicon steel), siv rau lub cev muaj zog thiab transformer cores.

Cov ntawv hlau coated: xws li DC04 (European tus qauv), siv rau kev galvanizing tom qab (GI), galvanizing (GL), thiab lwm yam.

Qhov zoo ntawm cov hlau dov txias:

1. Qhov tseeb ntawm qhov ntev, qhov du, qhov tuab sib xws Cov txheej txheem dov txias tuaj yeem tsim cov hlau nyias dua (mus txog 0.1 hli) thiab cov hlau tuab sib xws nrog kev kam rau me me (± 0.02 hli).

2. Cov khoom siv kho tshuab zoo heev thiab kev ua haujlwm zoo heev (xws li lub zog siab dua, qis dua qhov txwv, kev ua tau zoo ntawm kev kos duab tob, thiab lwm yam).

3. Cov khoom siv tuaj yeem hloov kho kom ua tiav kev dov ceev ceev, dov tas mus li, thiab tsim khoom siab.

Cov Hlau Txias-Dov Coil muaj ntau yam kev siv

Cov hlau dov txias tau dhau los ua cov ntaub ntawv tseem ceeb ntawm kev lag luam niaj hnub no vim lawv qhov kev ua haujlwm siab, lub zog siab, qhov zoo ntawm qhov chaw thiab kev ua tau zoo heev. Lawv siv dav hauv cov teb hauv qab no:

1. Kev tsim tsheb

Cov khoom siv rau kev siv: lub cev vaj huam sib luag, cov khoom chassis, cov thav rooj zaum, cov tshuab ncua kev kawm, cov khoom siv txhawb nqa, cov tshuab pa tawm, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Qhov ntev precision: xyuas kom meej tias cov khoom haum zoo meej thiab txhim kho kev sib dhos ua haujlwm.

Qhov zoo ntawm qhov chaw: tuaj yeem txau ncaj qha los yog electroplated kom txo cov nqi tom qab ua tiav.

Lub zog siab thiab lub teeb yuag: pab cov tsheb txuag hluav taws xob thiab txo cov pa phem, thaum txhim kho kev ua haujlwm kev nyab xeeb.

2. Kev lag luam khoom siv hauv tsev

Cov khoom lag luam ib txwm muaj: cov tub yees, cov tshuab ntxhua khaub ncaws, qhov cub, cov cua txias thiab lwm yam tsev, cov khoom siv sab hauv thiab cov khoom siv.

Cov txiaj ntsig tseem ceeb:

Du thiab zoo nkauj: ua tau raws li qhov xav tau siab ntawm cov khoom siv hauv tsev siab rau qhov zoo nkauj.

Tiv taus xeb thiab ruaj khov: ntev lub neej khoom thiab hloov kho rau cov chaw noo noo.

Yooj yim rau kev ua thiab duab: tsim nyog rau kev stamping, bending thiab lwm yam kev tsim khoom nyuaj.

3. Kev tsim vaj tsev thiab kho kom zoo nkauj

Kev siv tseem ceeb: cov ru tsev hlau, cov phab ntsa ntaub thaiv, cov qauv hlau, cov qhov rooj thiab cov qhov rai, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Lub zog siab & lub teeb yuag: ua kom zoo dua cov qauv tsev thiab txo cov nqi tsim kho.

Qhov ntev ruaj khov: xyuas kom meej tias qhov tseeb ntawm kev teeb tsa thiab txo cov kev ua yuam kev.

Qhov nto du: tuaj yeem pleev xim ncaj qha lossis laminated kom txhim kho qhov zoo nkauj ntawm lub tsev.

4. Rooj tog thiab chaw cia khoom

Cov khoom siv: cov rooj ua haujlwm thiab cov rooj zaum, cov txee, cov txee, cov tshuab cia khoom, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Cov qauv ruaj khov: muaj peev xwm thauj khoom tau zoo, tsim nyog rau cov xwm txheej siab.

Qhov nto du: ntau yam kev kho qhov chaw (xws li txau, txhuam) tuaj yeem ua tau los txhim kho qib khoom.

Yooj yim rau kev ua tiav: yooj yim txiav, vuam, khoov, thiab hloov kho rau cov kev xav tau tshwj xeeb.

5. Cov kav dej thiab cov khoom siv kho vajtse

Cov teb siv tau: cov kav dej, cov kav roj, cov kav dej qauv tsev, kho vajtse, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Kev kam rau siab nruj: xyuas kom meej tias cov kav dej sib khi thiab kev sib txuas ruaj khov.

Kev kub siab thiab kev tiv thaiv corrosion: tsim nyog rau cov chaw ib puag ncig hnyav thiab ntev lub neej kev pabcuam.

Zoo heev formability: yooj yim rau welding, flaring thiab lwm yam kev ua.

6. Cov khoom siv hluav taws xob

Cov ntawv thov ib txwm muaj: cov txee hluav taws xob, chassis, transformer housings, precision electronic components, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Kev ntsuas siab: ua tau raws li qhov yuav tsum tau sib dhos ntawm cov khoom siv hluav taws xob precision.

Kev tiv thaiv hluav taws xob: tsim nyog rau kev tiv thaiv cov khoom siv hluav taws xob rhiab heev.

Yooj yim rau kev luam ntawv thiab tsim: tsim nyog rau kev tsim cov khoom sib xyaw ua ke.

7. Kev lag luam ntim khoom

Cov khoom tseem ceeb: cov kaus poom zaub mov, cov thoob tshuaj lom neeg, cov thawv hlau, thiab lwm yam.

Cov txiaj ntsig tseem ceeb:

Lub zog siab thiab kev tiv taus siab: xyuas kom muaj kev nyab xeeb ntawm kev thauj mus los thiab kev cia khoom.

Tiv thaiv xeb: ntev lub neej ntawm cov khoom noj thiab cov tshuaj ntim khoom.

Siv tau dua tshiab thiab zoo rau ib puag ncig: ua raws li qhov sib txawv ntawm cov ntim khoom ntsuab.

Qhov sib txawv ntawm cov hlau dov txias thiab cov hlau dov kub

1. Kev sib piv ntawm cov txheej txheem tsim khoom

Cov hlau dov txias: dov kub hauv chav tsev, ua haujlwm kom tawv, xav tau kev annealing kom rov qab tau plasticity, tsim nyog rau kev tsim cov phaj nyias thiab cov ntaub ntawv siab. Cov txheej txheem ntws: phaj kub dov → pickling → dov txias → annealing → tiav

Cov hlau kub dov: dov kub siab, yooj yim deformation, haum rau kev tsim cov phaj tuab dua. Cov txheej txheem ntws: kev sib txuas ntxiv mus → cua sov → dov kub → coiling

2. Kev sib piv ntawm cov khoom siv lub cev

Kub dov: Piv nrog cov hlau txias dov, cov hlau kub dov muaj zog thiab tawv dua. Lawv feem ntau ductile dua thiab tiv taus kev hloov pauv ntau dua. Haum rau cov khoom siv dav dav, tus nqi qis tab sis qhov tseeb qis.

Dov Txias: Cov hlau dov txias muaj zog dua thiab tawv dua vim yog kev tawv tawv uas tshwm sim thaum dov txias. Lawv muaj qhov tseeb dua thiab cov khoom siv kho tshuab meej. Haum rau cov khoom siv siab, muaj zog, xws li cov vaj huam sib luag tsheb thiab cov tsev hluav taws xob.

3. Kev kho qhov chaw

Cov hlau kub dov: Qhov chaw ntxhib, nrog rau qhov ntsuas oxide (xav tau pickling), qhov tiav qis, xav tau kev tshem tawm xeb, xuab zeb thiab lwm yam kev kho ua ntej

Cov hlau dov txias: Qhov chaw du, tsis muaj oxide nplai (tuaj yeem ncaj qha electroplated lossis txau), tiav siab, tuaj yeem ncaj qha pleev xim lossis plated

Lub tuam txhab muab qhov tseem ceeb rau qhov zoo ntawm cov khoom, nqis peev ntau rau kev qhia txog cov cuab yeej siv siab heev thiab cov kws tshaj lij, thiab mus txhua yam kom tau raws li qhov xav tau ntawm cov neeg siv khoom hauv tsev thiab txawv teb chaws.

Cov ntsiab lus tuaj yeem muab faib ua: tshuaj lom neeg muaj pes tsawg leeg, lub zog tawm los, lub zog tensile, cov khoom cuam tshuam, thiab lwm yam

Tib lub sijhawm, lub tuam txhab kuj tseem tuaj yeem ua qhov kev tshawb pom qhov tsis zoo hauv online thiab annealing thiab lwm yam txheej txheem kho cua sov raws li cov neeg siv khoom xav tau.

https://www.ytdrintl.com/

Email:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.yog lub Hoobkas ua yeeb nkab hlau uas tau ntawv pov thawj los ntawmEN/ASTM/ JIStshwj xeeb hauv kev tsim khoom thiab xa tawm txhua yam ntawm cov yeeb nkab plaub fab, yeeb nkab galvanized, yeeb nkab ERW welded, yeeb nkab kauv, yeeb nkab submerged arc welded, yeeb nkab ncaj seam, yeeb nkab seamless, xim coated steel kauj, galvanized steel kauj thiab lwm yam khoom hlau. Nrog kev thauj mus los yooj yim, nws yog 190 kilometers ntawm Beijing Capital International Airport thiab 80 kilometers ntawm Tianjin Xingang.

Whatsapp: +8613682051821