In order to provide more reference information for users who want to place an order for zinc aluminum magnesium steel pipes but have not yet placed an order, the editor has compiled this article in the hope of providing customers with more reference value.

Overview:

In recent years, the overall production capacity of domestic coating is still expanding, with manufacturers with hot coil production capacity mainly extending their product lines downwards. In the context of national carbon reduction and promotion of new energy, relatively high-end galvanized aluminum magnesium products have become a popular variety of attention. In recent years, more and more steel mills have joined the production of zinc aluminum magnesium sheet coils, and competition has become increasingly fierce. This article will briefly analyze the current development status and prospects of domestic zinc aluminum magnesium sheet coils based on the current market situation.

Introduction and classification of zinc aluminum magnesium products:

01 .Introduction to Zinc Aluminum Magnesium Products

Galvanized aluminum magnesium steel plate is a new type of highly corrosion-resistant coated steel plate, mainly composed of zinc, 1.5% -11% aluminum, 1.5% -3% magnesium, and trace amounts of silicon (with slight differences in the proportion between different manufacturers). It is mainly used for surface anti-corrosion treatment of steel and steel products, including various zinc series coatings and a large number of whole steel parts for immersion corrosion protection. With the continuous development of technology, zinc aluminum magnesium alloy coated steel plates are mainly used in the construction industry due to their excellent corrosion resistance, good formability, weldability, and decorative appearance. They are gradually being promoted and applied to industries such as home appliances and automotive manufacturing.

Nippon Steel, Nippon Steel, ThyssenKrupp and other international famous steel companies began to study this steel plate in the 1980s, and realized industrial production and application in the early 21st century. Four years ago, most of the zinc aluminum magnesium products used in China were imported from countries such as Japan and South Korea. With the continuous fermentation of the photovoltaic industry in recent years, in addition to state-owned steel mills such as Baosteel, Jiuquan Steel, Shougang, and Tangshan Steel, a large number of private steel mills have also entered the industry, such as Tianjin Xinyu and Hebei Zhaojian. Some strip steel production enterprises have also joined the industry. At present, the thickness range that can be produced in China is 0.4mm-4.0mm, and the width range that can be produced is 580mm-2080mm. At present, the steel mills in China that produce zinc aluminum magnesium sheet coils are mainly low aluminum zinc aluminum magnesium, and only a small number of enterprises can produce medium (high) aluminum zinc aluminum magnesium. For example, Shougang has a full series of zinc aluminum magnesium, and has the only production line in the country that can provide zinc aluminum magnesium coated steel plates with a thickness of 3.0 mm or more for structural purposes.

02. Classification and Product Characteristics of Zinc Aluminum Magnesium Products

At present, according to China Baowu's analysis of existing commercial magnesium coated steel plates, the vast majority of the coatings contain magnesium and magnesium content ≤ 3%. Based on the different aluminum content in the coatings, zinc aluminum magnesium coatings are divided into:

Low aluminum zinc aluminum magnesium coating: Aluminum content: 1% -3.5%. This coating is formed by adding a certain amount of aluminum magnesium and other elements on the basis of hot-dip galvanizing. This coating is an upgraded version of the corrosion resistance of hot-dip pure zinc coating.

Medium aluminum zinc aluminum magnesium coating: aluminum content: 5% -11%.

High aluminum zinc aluminum magnesium coating: Aluminum content: 55%. This coating is formed by adding a certain amount of magnesium and other elements on the basis of hot-dip aluminum zinc coating. This coating is an upgraded version of the corrosion resistance of hot-dip aluminum zinc coating.

At present, the main production in China is low aluminum zinc aluminum magnesium, and some enterprises such as Shougang and Baosteel can also produce high aluminum zinc aluminum magnesium. Zinc aluminum magnesium can not only be directly processed, but also serve as a substrate for color coated sheet coils. At the beginning of 2022, the first roll of Baosteel Zhanjiang Steel's color coating was officially launched and mass production began at the end of February. Baosteel Zhanjiang Steel's color coating can use a full range of zinc aluminum magnesium as the substrate, making it the only global production base for a full range of zinc aluminum magnesium color coatings.

The behavior of zinc aluminum magnesium products has become a hot topic currently, closely related to their good product characteristics. The biggest quality advantage of zinc aluminum magnesium coating products is reflected in high corrosion resistance, followed by processing performance.

Table 1: Comparison between Zinc Aluminum Magnesium Products and Pure Zinc Products

| Serial Number | Product characteristics | Comparison between Zinc Aluminum Magnesium and Pure Zinc |

| 1 | Flat corrosion resistance | Neutral salt spray test: Zinc aluminum magnesium coating is 3-10 times higher than traditional pure zinc coating. Atmospheric long-term corrosion: Zinc aluminum magnesium coating can reach more than 2 times higher than pure zinc coating. |

| 2 | The corrosion resistance of incisions | The corrosion resistance of the zinc aluminum magnesium notch position is much higher than that of traditional pure zinc coatings |

| 3 | Low friction coefficient | The friction coefficient of zinc aluminum magnesium coating is 15% lower than that of pure zinc coating |

| 4 | wear resistance | The hardness of zinc aluminum magnesium coating is about three times that of pure zinc coating |

Overall development background of domestic zinc aluminum magnesium products

01 .Relatively differentiated development of coating production capacity

As mentioned at the beginning of the above article, before 2016, domestic galvanized aluminum magnesium products were basically blank. With a few central enterprises, state-owned enterprises, and large private coating enterprises gradually entering the domestic market, the production capacity of zinc aluminum magnesium is gradually developing. According to incomplete statistics, the production capacity of zinc aluminum magnesium is expected to be around 7 million tons per year, and the current product is in a stage of rapid growth. However, in the context of China Steel's huge steel production and coating capacity of more than 160 million tons, the overall share of zinc aluminum magnesium coating is still small.

The gradual development of new products highlights the relative excess production capacity of the entire coating industry: although China's coating production capacity is huge, the overall utilization rate of actual production capacity is less than 60%, and private enterprises are relatively insufficient in terms of construction and actual utilization. Galvanized aluminum magnesium products have high technical difficulties and process requirements, as well as good market value and prospects, and have become a hot direction for research and production in the same industry at home and abroad.

02. Under the intense competition, there is still some profit potential for new products

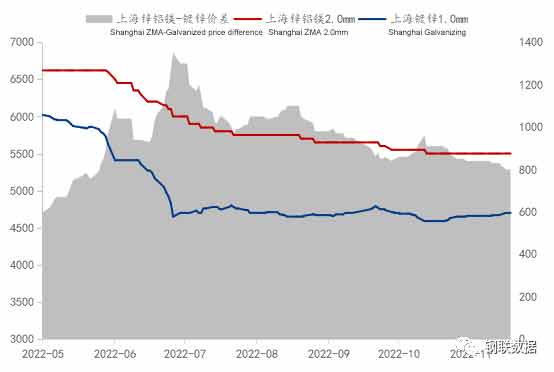

Figure 1: Price trend and price difference between zinc, aluminum, magnesium, and zinc plating in Shanghai (unit: yuan/ton)

As of December 7th, Mysteel's mainstream specification 2.0mm Ansteel zinc aluminum magnesium sheet coil in the Shanghai market has a price of 5500 yuan/ton, while the mainstream galvanized product 1.0mm Ansteel galvanized sheet coil has a price of 4700 yuan/ton, and the price difference between zinc aluminum magnesium sheet coil and galvanized sheet coil is 800 yuan/ton. According to the calculation of zinc layer and specification markup in the steel plant, the zinc aluminum magnesium plate coil is 275g zinc layer, and the markup for zinc layer in the steel plant is around 300 yuan/ton. Based on this calculation, even for products with the same zinc layer thickness, the price of zinc aluminum magnesium is much higher than that of galvanized sheet coils, which indirectly proves that there is still a certain profit potential for zinc aluminum magnesium products, whether from the perspective of traders or steel mills. Of course, it is worth noting that in July, the price difference between zinc aluminum magnesium and galvanized sheet coil once climbed to 1350 yuan/ton, and then remained basically within 1000 yuan/ton, indicating that there is also some competition in the current zinc aluminum magnesium market. The price difference between Tianjin zinc aluminum magnesium and galvanized sheet is a good example, as shown in Figure 2.

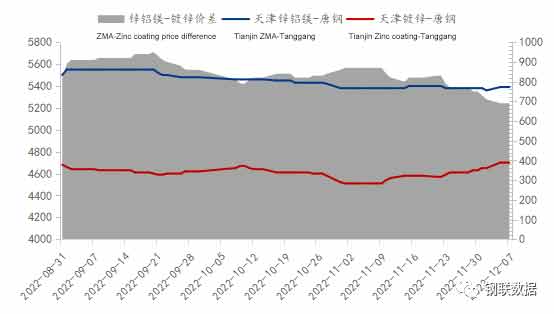

In the photovoltaic consumer market, in addition to the East China market, there is also a concentrated market, which is Tianjin, especially concentrated in Daqiuzhuang. This concentrated production area of photovoltaic brackets has also become a key target for many steel mills. Currently, in the Tianjin market, the main circulating steel mill resources include state-owned steel mills Shougang, Ansteel, Tangshan Steel, and Handan Steel; Private steel mills such as Hebei Zhaojian, Tianjin Xinyu, Shandong Huafeng, etc. From the perspective of price difference comparison, the price difference between Tianjin zinc aluminum magnesium and zinc plating is significantly lower than that in the Shanghai market. In order to seize market share, steel mills have also adjusted their policies accordingly.

03 The rapid development of the photovoltaic industry in the context of new energy and carbon reduction environment

The downstream industry of domestic coating industry is showing a differentiation trend, and the hot growth stage of automobile and household appliance consumption has basically passed, but new energy is developing rapidly. On November 21st, the National Passenger Car Market Information Joint Conference released a report on the trend of China's new energy vehicle market: China's new energy vehicle production from January to October was 5.59 million units, a year-on-year increase of 108.4%, with a cumulative penetration rate of 24.7% and a contribution rate of over 80% to the growth of the automotive market. Similarly, in the context of the country actively promoting New Infrastructure and new energy consumption, the consumption demand of zinc aluminum magnesium industry has stage growth space and explosive force.

China's photovoltaic industry has reached international leading levels in various aspects, especially since 2022, under the pressure of frequent outbreaks of COVID-19 and economic downturn, the overall development momentum of the photovoltaic industry has remained stable. In the first three quarters of 2022, China's production of polycrystalline silicon, silicon wafers, batteries, and components has made significant progress, and the production of various links in the industrial chain has reached a historic high. The industry technology continues to innovate and progress, and the conversion efficiency of silicon heterojunction solar cells has set a new world record of 26.81%. New breakthroughs have also been made in the research and development and pilot testing of perovskite stacked cells, and the "photovoltaic+" model is also constantly expanding. In the first three quarters, the newly installed capacity of domestic photovoltaics reached 52.6GW. From January to October, the total export value of photovoltaics in China exceeded 44 billion US dollars, strongly supporting the growing demand of the domestic and foreign photovoltaics markets.

Analysis of the Development Prospects of Zinc Aluminum Magnesium Sheet and Roll

01 Continuously improving product standards in industry application fields

Against the backdrop of rapid growth in overall coating production capacity, there is still a situation of high coating production capacity with low utilization rate. Enterprises will continue to expand market sales channels and increase market share. For the continuous expansion of coated laminates themselves, it is understandable, but in the continuous competition of the industry, there is a certain degree of substitutability between the broad range of coated laminates and rolls.

In the field of galvanized aluminum magnesium product industry, in the current lack of product standards, it is crucial for large state-owned enterprises in China to take the lead in formulating relevant standards. In order to standardize the development and production of zinc aluminum magnesium, a new product, along a healthy track, renowned expert Professor Xu Xiufei from China Metallurgical Corporation (MCC), with the support and assistance of the National Steel Standards Committee, organized excellent coating enterprises across the country to revise the industry standard of "Continuous Hot Dip Coated Steel Plate and Strip for Construction". For the first time in the world, all coating components, including three major categories of zinc aluminum magnesium, were included in the same standard, which is not only convenient for purchasers to compare and use, It can also promote the reasonable selection of materials and high-quality and cost-effective plating products.

With the improvement of the competitiveness of domestic enterprises' zinc aluminum magnesium products, the trend of importing zinc aluminum magnesium products from abroad has been reversed, and a large number of high-quality products have been exported to advanced countries such as Europe and America. Due to the lack of international standards, it has not only hindered the import and export trade of zinc aluminum magnesium steel products, but also caused industry technical barriers. Therefore, striving for international discourse and formulating international standards have become a major measure for Chinese products to go global. It can be expected that the promotion of the international standard project for zinc aluminum magnesium sheets will open up a new situation for Chinese coated sheet enterprises to compete on the international stage.

02 The future development of the product is still worth looking forward to

The pressure faced by the coated sheet and coil industry cannot be overstated. Overcapacity is still severe, and the price center is still sluggish. The growth rate of domestic industrial manufacturing such as home appliances and automobiles will continue to slow down, making it difficult to increase demand. In addition, the profitability of the metal sheet industry, including coated products, continues to decline, and internal structural adjustments will continue to increase industry reshuffle.

However, galvanized aluminum magnesium products have unique product functions and application attributes based on coating products, and the technical threshold at home and abroad is still high. At the same time, its usage in key projects and high-end downstream consumer industries is still growing, and its usage areas are still expanding. The future development prospects are still worth looking forward to. If one can join the whitelist of procurement enterprises, they will also have a unique advantage in this competition.

The current market competition for low aluminum zinc aluminum magnesium has gradually intensified, and more and more enterprises are joining in the production and sales of zinc aluminum magnesium products in order to share the product dividend. Based on consumer characteristics and industry development trends, it is recommended to prioritize the positioning of galvanized aluminum magnesium products in the (medium) high aluminum zinc aluminum magnesium direction. The bright market and large profit margin of the industry are exactly what everyone is looking forward to.

Contact our account manager immediately to request information on zinc aluminum magnesium products

Post time: Jul-04-2023