1. What is a Penstock Pipe?

Penstock Pipe belong to special equipment, and according to the definition of the "Regulations on Safety Supervision of Special Equipment", they refer to tubular equipment that uses a certain pressure to transport gas or liquid. The scope is defined as gas, liquefied gas, steam medium with a maximum working pressure greater than or equal to 0.1MPa (gauge pressure), or flammable, explosive, toxic, corrosive liquid medium with a maximum working temperature greater than or equal to the standard boiling point, and pipelines with a nominal diameter greater than 25mm.

Working principle:

For a single Penstock Pipe, it relies on external power or the driving force of the medium itself to transport the medium from the source of the pressure pipeline to the endpoint of the pressure pipeline.

Characteristics of Penstock Pipe:

Penstock Pipe is a system that is interrelated and affects each other, pulling and moving the entire body.

Pressure pipelines have a large aspect ratio and are prone to instability, resulting in more complex stress situations than pressure vessels.

The fluid flow state in pressure pipelines is complex, with small buffer space, and the frequency of changes in working conditions is higher than that of pressure vessels (such as high temperature, high pressure, low temperature, low pressure, displacement deformation, wind, snow, earthquake, etc.).

There are various types of pipeline components and pipeline support components, each with its own characteristics and specific technical requirements, and the selection of materials is complex.

There are more possible leakage points on the pipeline than on the pressure vessel, and there are usually five points for a single valve.

There are many types and quantities of pressure pipelines, and there are many links in design, manufacturing, installation, inspection, and application management, which are greatly different from pressure vessels.

Purpose of Penstock Pipe:

Transport medium (main purpose)

Storage function (for long-distance pipelines)

Heat exchange (for industrial pipelines)

Design steps for Penstock Pipe:

Select pipeline materials based on the type of medium, pressure, and temperature.

Calculate the pipe diameter and wall thickness, and prepare or determine a pipeline grade table.

Develop pipeline layout plans, determine pipeline routing, and laying methods.

Draw pipeline layout and axial side view.

Develop a pipeline characteristic table.

Perform stress, thermal compensation, and support thrust calculations.

Provide civil engineering materials to relevant majors.

Complete design drawings and drawing countersignature.

2. Problems in the layout design of pressure pipelines

Are there any specific knowledge points in the design steps that you want to understand?

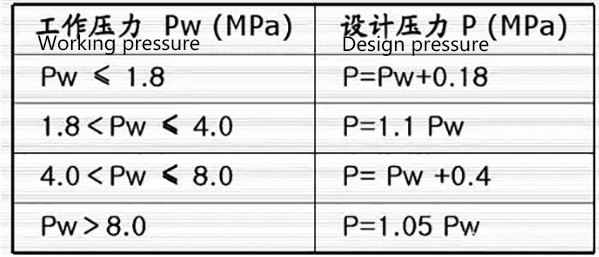

How to determine the design pressure:

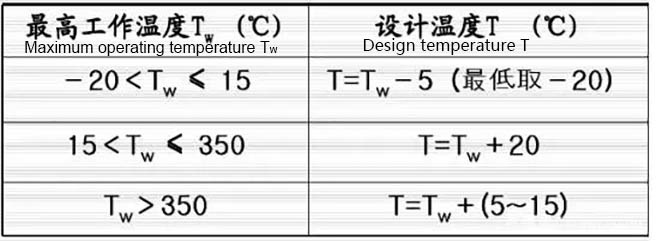

How to determine the design temperature:

Requirements for pipeline layout:

Pipelines should be laid overhead as much as possible, and if necessary, they can also be buried or laid in trenches. (Easy to install, produce, and maintain)

Try to use hanger design to make the pipeline as close as possible to existing buildings and structures, but avoid flexible components bearing large loads.

Pipelines should not be arranged within the scope of building lifting holes, equipment internal parts extraction areas, and flange disassembly areas.

The pipeline layout should be arranged in parallel rows, with straight lines and fewer bends and intersections as much as possible. This can reduce the number of pipe racks, save materials, and be aesthetically pleasing and easy to install.

The pipelines should be arranged in rows as much as possible, and the bottom of the bare pipes should be aligned with the ground of the pipe support to facilitate the design of the support.

When the elevation or direction of the pipeline changes, it is necessary to avoid the formation of "bags" of accumulated gas or liquid in the pipeline. If this cannot be avoided, exhaust valves should be installed at high points and liquid discharge valves should be installed at low points.

The plane laying of pipeline shall have a slope, and the slope direction is generally the same as the material flow direction, but there are exceptions, which shall be determined according to the specific process.

Pipelines above roads and railways should not be equipped with components that may leak, such as flanges, threaded joints, compensators with fillers, etc.

When pipelines pass through roofs, floors, platforms, and walls, casing protection is generally required.

Buried pipelines should consider the impact of vehicle loads, and when crossing roads, casing should be added. The distance between the top of the pipeline and the road surface should not be less than 0.6m, and it should be below the depth of frozen soil.

When connecting a branch pipe from a horizontal gas main pipe, it should be connected from the top of the main pipe.

For the layout of multi-layer shared pipelines, gas pipelines, hot pipelines, utility pipelines, and electrical instrument racks should be located in the upper layer, while corrosive medium pipelines and low-temperature pipelines should be located in the lower layer.

Flammable, explosive, toxic, and corrosive materials should not be laid in living rooms, stairs, corridors, and other places. The vent pipe should be led to a designated outdoor location or 2m above the roof.

Pipes without insulation do not require pipe supports or supports. Large diameter thin-walled bare pipes and pipes with insulation layers should be supported by pipe brackets or supports.

The conditions for direct burial of pipelines are:

◇Pipelines that transport non-toxic, non corrosive, and non explosive media cannot be laid on the ground due to certain reasons.

◇ Process medium pipelines related to underground storage tanks or underground pump rooms.

◇ Cooling water and fire water or foam fire pipes.

◇ Heating pipelines with operating temperature less than 150 ℃.

3. Principles for selecting commonly used pipe materials for pressure pipelines?

The use of commonly used pipe materials for pressure pipelines is determined by the operating conditions of the medium being transported (such as pressure, temperature) and the characteristics of the medium under these conditions. Consider the following factors:

Preferred pipe materials:

When selecting pipe materials, metal materials are generally considered first. When metal materials are not suitable, non-metallic materials are then considered. Priority should be given to selecting steel pipes for metal materials, followed by non-ferrous metal materials. In steel pipes, carbon steel should be considered first, and stainless steel should be used when not applicable. When considering carbon steel materials, welded steel pipes should be considered first, and seamless steel pipes should be selected when not applicable.

The influence of medium pressure:

》The higher the pressure of the conveying medium, the thicker the wall thickness of the pipe, and the higher the requirements for the pipe material generally.

》When the medium pressure is above 1.6MPa, seamless steel pipes or non-ferrous metal pipes can be selected.

》When the pressure is very high, such as in the production of synthetic ammonia, urea, and methanol, some pipes have a medium pressure of up to 32MPa, and generally use high-pressure seamless steel pipes made of 20 steel or 15MnV material.

》The pipes on vacuum equipment and oxygen pipes with a pressure greater than 10MPa are generally made of copper and brass pipes.

》When the medium pressure is below 1.6MPa, welded steel pipes, Cast iron pipe or non-metallic pipes can be considered. However, the pressure of medium borne by cast iron pipe shall not be greater than 1.0MPa. The medium pressure that non-metallic pipes can withstand is related to the variety of non-metallic materials, such as hard polyvinyl chloride pipes, with a service pressure less than or equal to 1.6MPa; Reinforced polypropylene pipes with a service pressure of less than or equal to 1.0MPa; ABS pipes, with a working pressure less than or equal to 0.6MPa.

》For water pipes, when the water pressure is below 1.0MPa, welded steel pipes made of Q235A are usually used; When the pressure of water is greater than 2.5MPa, seamless steel pipes made of 20 steel are generally used.

The influence of medium chemical properties:

The impact of medium chemical properties is mainly reflected in corrosion and should be highly valued.

The medium is neutral and generally does not require high material requirements. Ordinary carbon steel pipes can be used.

If the medium is acidic or alkaline, it is necessary to choose acid or alkali resistant pipes.

Pipes made of carbon steel are used to transport water and steam.

The impact of the function of the pipe itself:

In addition to the function of conveying medium, some pipes also have the function of shock absorption, thermal expansion absorption, and can move frequently under working conditions.

The impact of pressure drop:

After the initial selection of the pipe material, a calculation of the pipe pressure drop is also required to determine the inner diameter of the pipe. Calculate the pressure drop to see if the selected material meets the requirements. Especially when initially selecting plastic pipes, it is important to pay more attention to the review of pressure drop.

4. Principles for selecting commonly used steel pipe materials for pressure pipelines

What are the principles for selecting commonly used pipe materials for pressure pipelines? Today, the editor will talk about this matter.

(1) Preferred Pipe Materials

When selecting pipe materials, metal materials are generally considered first. When metal materials are not suitable, non-metallic materials are then considered. Steel pipes are preferred for metal materials, followed by non-ferrous metal materials. In steel pipes, carbon steel should be considered first, and stainless steel should be used when not applicable. When considering carbon steel materials, welded steel pipes should be considered first, and seamless steel pipes should be selected when not applicable.

(2) The influence of medium pressure

The higher the pressure of the conveying medium, the thicker the wall thickness of the pipe, and the higher the requirements for the pipe material generally.

When the medium pressure is above 1.6MPa, seamless steel pipes or non-ferrous metal pipes can be selected. When the pressure is very high, such as in the production of synthetic ammonia, urea, and methanol, some pipes have a medium pressure of up to 32MPa, and high-pressure seamless steel pipes with materials of 20 # or 15CrMo are generally selected. Copper and brass pipes are generally used for pipes on vacuum equipment and oxygen pipes with a pressure greater than 10MPa.

When the medium pressure is below 1.6MPa, welded steel pipes, Cast iron pipe or non-metallic pipes can be considered. However, the pressure of medium borne by cast iron pipe shall not be greater than 1.0MPa. The medium pressure that non-metallic pipes can withstand is related to the variety of non-metallic materials, such as hard polyvinyl chloride pipes, with a service pressure less than or equal to 1.6MPa; Reinforced polypropylene pipes with a service pressure of less than or equal to 1.0MPa; ABS pipes, with a working pressure less than or equal to 0.6MPa.

For water pipes, when the water pressure is below 1.0MPa, welded steel pipes made of Q235A are usually used; When the pressure of water is greater than 2.5MPa, 20 # seamless steel pipes are generally used.

(3) The influence of medium temperature

Pipes made of different materials are suitable for different temperature ranges. When the temperature of hydrogen gas is less than 350 ℃, 20 # seamless steel pipes are generally used for hydrogen gas with a pressure of 1.0MPa. When the temperature of hydrogen gas is within the range of 351-400 ℃, 15CrMo or 12CrMo seamless steel pipes are generally used.

(4) The influence of medium chemical properties

Transport different media using different pipes. Some media are neutral and generally do not require high material requirements. Ordinary carbon steel pipes can be used; Some media are acidic or alkaline, so it is necessary to choose acid or alkali resistant pipes. The requirements for the use of pipes are different between strong and weak acids and bases. The same acid or base, with different concentrations, also has different requirements for the material of the pipes. If transporting water and steam, pipes made of carbon steel material are sufficient. In urea plants, stainless steel pipes are generally used for transporting carbon dioxide, as carbon dioxide forms carbon dioxide when it encounters water, which has a corrosive effect on general steel pipes. If producing sulfuric acid, carbon steel pipes can be used, while for dilute sulfuric acid, carbon steel pipes cannot be used because dilute sulfuric acid and carbon steel can react chemically and corrode carbon steel. Therefore, hard aluminum pipes can be used.

(5) The impact of the function of the pipe itself

In addition to the function of conveying medium, some pipes also have the function of shock absorption and coefficient of thermal expansion. Under working conditions, they can move frequently, such as liquefied petroleum gas, oxygen and acetylene gas for civil use at the bottle filling position. High pressure steel wire woven rubber pipes are often used for pipes, instead of hard steel pipes that are inconvenient to move.

(6) The impact of pressure drop

After the initial selection of the pipe material, a calculation of the pipe pressure drop is also required to determine the inner diameter of the pipe. Calculate the pressure drop to see if the selected material meets the requirements. Especially when initially selecting plastic pipes, it is important to pay more attention to the review of pressure drop.

For the calculation of pressure pipeline, in engineering design, the material balance, energy balance and equipment calculation are generally carried out according to the production scale to preliminarily determine the material flow. With reference to relevant data, assume a material flow rate, calculate the inner diameter of the pipe, check the manual or standard, and select the standard pipe. The inner diameter of the standard pipe usually selected should be equal to or slightly greater than the calculated inner diameter of the pipe. Calculate the pressure drop of the pipeline again.

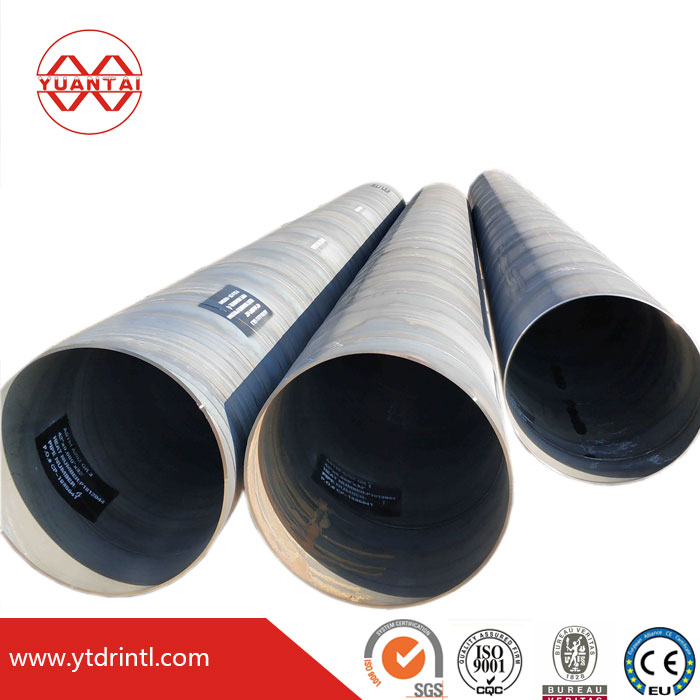

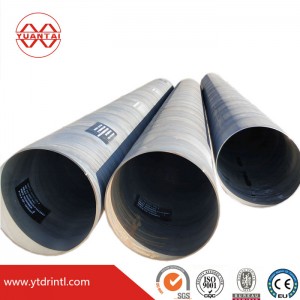

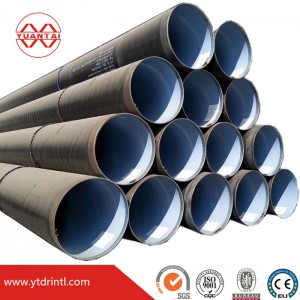

Specification table and weight per meter table for spiral welded steel pipes

With an annual output of 8 million tons, Yuantai Derun is the largest ERW square pipe, rectangular pipe, hollow pipe, galvanized pipe, and spiral welded steel pipe manufacturer in China. Annual sales reached $15 billion. Yuantai Derun has 51 black ERW steel pipe production lines, 10 galvanized steel pipe production lines, and 3 spiral welded steel pipe production lines. Square steel pipe 10 * 10 * 0.5mm to 1000 * 1000 * 60MM, rectangular steel pipe 10 * 15 * 0.5mm to 800 * 1200 * 60MM, spiral steel pipe(SSAW) Ø 219-4020mm can be made, steel grades from Q (s) 195 to Q (s) 650 / Gr.A-Gr.D. Yuantai Derun can produce spiral steel tubes according to API 5L, SY/T6475, JIS g3466, En10219/EN10210, Din2240, and AS1163. Yuantai Derun has the largest mild steel tube inventory in China, which can meet the direct purchasing demand of customers.

Welcome everyone to contact Yuantai Derun, E-mail:sales@ytdrgg.com, and Real-time connection inspection plant or factory visit!

| Product Name | Spiral welded steel pipe |

| Standard | API 5L psl1/psl2, ISO9000, DIN2240, ASTM A500, A501, A53 EN10219/EN10210, JIS G3466, GB/T6728,GB/T3094,GB/T3091,GB/T9711,SY/T5037,SY/T6475 |

| Sizes | 219mm to 4020mm |

| Thickness | 4mm to 30mm |

| NDT Test | UT, RT, hydrostatic, |

| Beveled Edges | 30DEG,(-0, +5) |

| Length | 3M-max.24meters,or as required |

| Surface treatment | Black painted/galvanizing etc. |

| Hot Expanded Ends | Available |

| Packing | Loosed PCS/nylon rope(for the coating pipes) |

| Transportation | by 20/40FT containers or by bulk vessels as per condition |

| Pile shoe | OEM/ODM(for piling) |

| Third-party inspection | SGS/BV/JIS/ISO/API/GB/BC1/EPD&PHD |

| Payment Term | TT, LC |

| Application | water/fluid transportation, piling, structural supports, dredging, etc. |

WORK SHOP SHOW

Yuantai people with firm faith are committed to making the world fall in love with made in China. The pure and simple Yuantai spirit has injected a dream temperature into the cold steel.

Time can change everything, but time may not change everything, such as the original heart.

Consistent persistence has achieved a single champion of a category

In Yuantai's workshop,The weaker sex is no inferior to the male.

Yuantai people shine and fight in their ordinary posts

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821