Advanced Anti-Corrosion Spiral Pipes

Our company has strong experimental technical force and perfect testing equipment, and in 2022, it passed the national high-tech enterprise certification, and passed the product quality inspection of the national testing center, established a perfect quality management

Spiral welded steel pipe unit

Our company is now invested in the spiral welding steel pipe 820-4020 unit, using double-sided double-wire submerged arc automatic welding, with an annual output of 200,000 tons, as the most advanced spiral welded pipe production equipment at home and abroad, from feeding and leveling to milling and forming welding as a whole, strictly control the quality of each spiral welded steel pipe produced by our company. The products are widely used in petroleum, gas, natural gas, water supply, thermal power generation, sewage discharge and other industries.

Flat head chamfering machine

Flat-head chamfering machine is a pipe end processing equipment specially designed for the national standard spiral welded pipe production line. The equipment uses servo motor to drive the ball screw feed, which has the characteristics of easy operation and stable cutting. According to customer needs, the groove angle is polished to facilitate welding.

Hydrostatic testing machine

This hydraulic press is a steel pipe pressure testing equipment specially designed for the spiral welded pipe production line. It is suitable for the hydrostatic test of steel pipes for pipeline transmission systems in the oil and gas industry according to GB/T9711-2018 standards. It has the characteristics of easy operation.

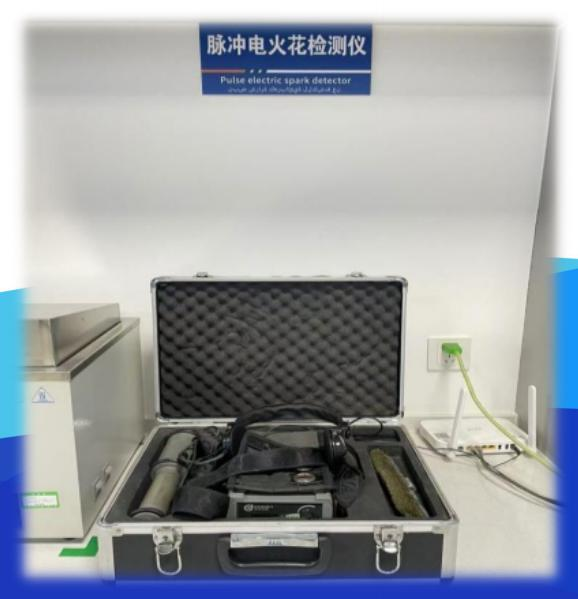

Spiral welded pipe mobile X-ray flaw detector

The quality control of spiral welded pipes is very important in the production of products, and afteryears of unremitting efforts, a series of efficient quality control solutions for different longitudinalseam and spiral welded pipe products have been summarized. Among them, the 225kv seriesdetection system is a real-time imaging detection system specially designed for the quality controlof the production process of special pipe fittings. Intuitive real-time inspection of defects in weldmanufacturing, such as cracks, porosity, slag inclusions, etc.

Outer 3PE anti-corrosion unit

Curing water-cooled room

The water is pumped from the reservoir through a high-pressure water pump, and then dispersed to each water nozzle through the water pipe, which can not only achieve a large water flow rate, fast curing, but also not easy to form water droplets on the surface of the anti-corrosion coating. The surface coating of the produced anti-corrosion steel pipe is quickly cured and the anti-corrosion coating is quickly formed.

Internal FBE anti-corrosion steel pipe

Inner wall epoxy coating features: - Chemically resistant. - It is suitable for transporting corrosive media (such as acid, alkali, salt, oil and gas, chemical rawmaterials, etc.) to prevent the inner wall of the pipeline from being corroded. - Commonly found in oil, gas, chemical, sewage treatment and other industries. - Epoxy coating has a smooth surface, which reduces fluid friction, improves conveying efficiency andsaves energy. (Reduced fluid resistance)

Post time: Oct-11-2025