YuantaiDerunChigadziko chesimbi chemativi mana chine mapatent anopfuura makumi matanhatu nematatu, izvo zvinosangana nezvinodiwa neindasitiri iyi kumba nekune dzimwe nyika. Chigadzirwa ichi chapfuura malink ekuongorora anopfuura mazana maviri ekudzora mhando yechigadzirwa.

"Musabvumira zvakasimba pombi yesimbi isina kukodzera kupinda mumusika".

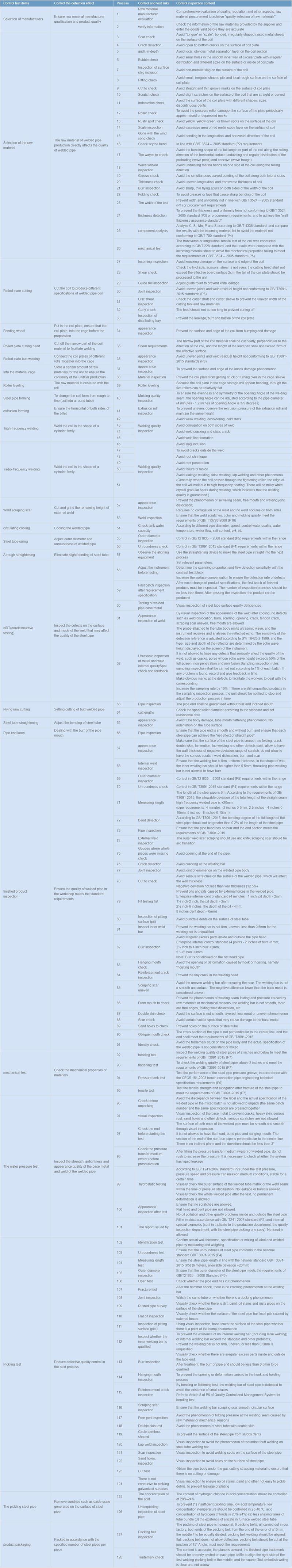

| Zvinhu zvekuyedza zvekutonga | Dzora mhedzisiro yekuona | Maitiro | Zvinongedzo zvekudzora nekuyedza | Zvemukati zvekutarisa kudzora |

| Kusarudzwa kwevagadziri | Iva nechokwadi chekuti mugadziri wezvinhu zvakagadzirwa zvakanaka uye mhando yechigadzirwa | 1 | Kuongororwa kwemugadziri wezvinhu zvisina kugadzirwa | Kuongororwa kwakakwana kwemhando, mukurumbira nezvimwe zvinhu, kutenga zvinhu zvisina kucheneswa kuti uwane "kusarudzwa kwemhando yezvinhu zvisina kucheneswa" |

| 2 | simbisa ruzivo | Tarisa ruzivo rwezvinhu zvakagadziriswa zvinopihwa nemutengesi uye pinda muchivanze chezvinhu zvisati zvanyatsojeka. | ||

| Kusarudzwa kwezvinhu zvakagadziriswa | Zvinhu zvakabikwa zvekugadzirwa kwepombi dzakasungirirwa zvinokanganisa zvakananga kunaka kwepombi dzakasungirirwa | 3 | Kuongorora mavanga | Dzivisa "rurimi" kana "chikero", machira esimbi akasimudzwa asina kurongeka, akasungirirwa pamusoro pe coil |

| 4 | Kuonekwa kwetsvina | Dzivisa kutsemuka kwepasi pemazasi akavhurika pamusoro pe coil plate | ||

| 5 | kuongorora kwakadzama | Dzivisa kupatsanurwa kwesimbi kwenzvimbo yacho, kuri pachena pachikamu checoil | ||

| 6 | Kuongorora mabara | Dzivisa maburi madiki mumadziro emukati akatsetseka eplate yakatenderera ane kupararira kusina kurongeka uye saizi dzakasiyana pamusoro kana mukati meplate yecoil. | ||

| 7 | Kuongororwa kwekuiswa kweslag pamusoro | Dzivisa tsvina isiri yesimbi pamusoro pe coil | ||

| 8 | Kuongorora kukanda | Dzivisa makomba madiki, asina kurongeka uye nzvimbo isina kurongeka iri pamusoro pe coil plate | ||

| 9 | Cheka kuti uone | Dzivisa mavara akatwasuka uye matete pamusoro pe coil plate | ||

| 10 | Kuongorora kukwenya | Dzivisa kukwenya kudiki pamusoro pe coil yakatwasuka kana kuti yakakombama | ||

| 11 | Kutarisa mukati meganda | Dzivisa pamusoro peplate ye coil ine maumbirwo akasiyana, saizi, uye maburi akasiyana | ||

| 12 | Kutarisa roller | Kuti dzidzivise kukuvara kwe pressure roller, pamusoro peplate panoonekwa mavanga akasimudzwa kana akaderedzwa nguva nenguva. | ||

| 13 | Kuongorora nzvimbo ine ngura | Dzivisa mavara eyero, yero-girini, kana madonhwe ebrown pamusoro pe coil | ||

| 14 | Kuongorora zviyero | Dzivisa nzvimbo yakawandisa ye red metal oxide layer pamusoro pe coil | ||

| 15 | Kutarisa rwiyo rweGone with the wind | Dzivisa kukotama munzira refu uye yakatwasuka ye coil | ||

| 16 | Tarisa scythe bend | Zvichienderana nezvinodiwa zveGB/T 3524 -- 2005 standard (P2) | ||

| 17 | Mafungu ekutarisa | Dzivisa chimiro chekukombama chehurefu hwese kana chikamu checoil uchitevedza nzira yekutenderera yenzvimbo yakatwasuka ichidzika uye kupararira kwakajairika kwenzvimbo inobuda (wave peak) uye yakakombama (wave trough) | ||

| 18 | Kuongorora makwinya emafungu | Dzivisa kukotama kwemarina kune rumwe rutivi rwekoiri uchitevedza nzira yekumonereka | ||

| 19 | Kutarisa groove | Dzivisa kukotama kwesimbi panguva imwe chete kumativi ese ari maviri | ||

| 20 | Kuongorora ukobvu | Dzivisa ukobvu husina kuenzana hwe coil hwakareba uye hwakachinjika | ||

| 21 | Kuongorora Burr | Dzivisa ma spurs akapinza, matete anobhururuka kumativi ese ehupamhi hwe coil | ||

| 22 | Kutarisa kupeta | Kudzivirira makombama kana kutenderera kunokonzera kukotama kwakanyanya kwecoil | ||

| 23 | Upamhi hwebvunzo | Dzivisa hupamhi uye kufanana kusingaenderane neGB/T 3524 -- 2005 standard (P4) kana zvinodiwa zvekutenga | ||

| 24 | kuonekwa kweukobvu | Kudzivirira ukobvu nekufanana kuti zvisaenderane neGB/T 3524 -- 2005 standard (P3) kana zvinodiwa pakutenga, uye kuzadzisa "chiyero chekusimbisa ukobvu hwemadziro" | ||

| 25 | kuongorora zvikamu | Ongorora C, Si, Mn, P naS zvichienderana neGB/T 4336 standard, uye enzanisa mhedzisiro nerunyorwa rwezvinhu zviri kuuya kudzivirira kuti zvinhu zvisaenderane neGB/T 700 standard (P4) | ||

| 26 | bvunzo yemakanika | Kuyedzwa kwekudhonza kwecoil kwakachinjika kana kuti kwenguva refu kwakaitwa zvichienderana neGB/T 228 standard, uye mhedzisiro yacho yakaenzaniswa nepepa rezvinhu raiuya kudzivirira kuti hunhu hwemakanika husakwanise kuzadzisa zvinodiwa zveGB/T 3524 -- 2005 standard (P5). | ||

| Kucheka ndiro dzakamonerwa | Cheka coil kuti ugadzire magadzirirwo akasiyana epombi yakasungirirwa | 27 | Kuongorora kuri kuuya | Dzivisa kukuvadza pamusoro nepamucheto wekoiri |

| 28 | Kucheka kwekucheka | Tarisa chigero che hydraulic, kana kucheka kwacho kusina kuenzana, musoro wekucheka haufanirwe kudarika bhodhi rinoshanda ne 2cm, muswe we coil plate unofanira kugadziriswa kuita unit. | ||

| 29 | Kuongorora gwaro rekutungamira | Gadzirisa chinotenderera chinonongedzera kuti mapanga asabude | ||

| 30 | Kuongorora pamwe chete | Dzivisa majoini asina kuenzana uye wedzera urefu hwasara husingaenderane nezvinodiwa zveGB/ T3091-2015 (P8) | ||

| 31 | Kuongororwa kwekucheka kwedhisiki | Tarisa mubato wekucheka neruoko rwekucheka kudzivirira hupamhi husina kuenzana hwechinhu chekucheka nezvinhu zvakagadziriswa. | ||

| 32 | Kutarisa kwakakombama | Chikafu hachifanirwe kureba zvakanyanya kudzivirira kukotama | ||

| 33 | Kuongororwa kwetireyi yekugovera | Dzivirira kubuda kwemvura, burr uye buckle ye coil plate | ||

| Vhiri rekudyisa | Isa mundiro yekoira, iva nechokwadi chekuti koira, inopinda mukeji usati wagadzirira. | 34 | kuongorora chitarisiko | Dzivirira pamusoro nepamucheto pecoil kuti isaputike kana kukuvara |

| Musoro wekucheka ndiro yakakungurutswa | Cheka chikamu chakamanikana chesimbi yekoira kuti zvive nyore kupinza | 35 | Zvinodiwa zvekuchekerera | Chikamu chakamanikana chesimbi inofanira kuchekwa zvakanaka, yakatwasuka zvichienderana nekwakatangira simbi, uye kureba kwesimbi hakufanirwe kudarika 2cm yenzvimbo inoshanda. |

| Kusonwa kwesimbi yeplate yakamonerwa | Batanidza ma coil plates ema rolls akasiyana pamwe chete mu cage | 36 | kuongorora chitarisiko | Dzivisa majoini asina kuenzana uye wedzera urefu hwasara husingaenderane nezvinodiwa zveGB/ T3091-2015 (P8) |

| Mukati mekeji yezvinhu | Chengeta huwandu hwakati hwezvinhu zvakagadzirwa zveyuniti kuti uve nechokwadi chekuti kugadzirwa kweyuniti yemotokari kunoramba kuripo. | 37 | kuongorora chitarisiko | Kudzivirira pamusoro nepamucheto pechiitiko chekukuvadza kunogogodza |

| 38 | Kuongorora zvinhu | Dzivirira kuti coil plate isabatirire kana kutendeuka mubepa rekeji | ||

| Kuenzanisa kweroller | Zvinhu zvakatsvuka zviri pakati pemupumburu | 39 | Kuenzanisa kweroller | Nekuti ndiro yekoira iri mukeji inochengeterwa zvinhu ichaonekwa ichikotama, kuburikidza nemarori mashanu anogona kunge akati sandara. |

| Kugadzira pombi yesimbi | Kuchinja chimiro chekoiri kubva pakukora kusvika pakukora (koiri kuita chubhu yakatenderera) | 40 | Kuongorora mhando yekuumba | Kuti ive nechokwadi chekuti Angle yekuvhura yemusono wekuwelding yakaenzana uye yakaenzana, Angle yekuvhura inogona kugadziriswa zvichienderana nedhayamita yepombi. (Maminetsi mana - 1.2 inches yekuvhura Angle iri 3-5 degrees) |

| kuumbwa kweextrusion | Iva nechokwadi chekuti mativi ese ebhillet akatwasuka | 41 | Kuongorora roll yekuwedzera | Kuti udzivise kusaenzana, tarisa kumanikidzwa kwekubuda kwemupumburu wekubvisa uye chengetedza kukwirira kwakafanana. |

| kushongedza kwepamusoro-soro | Sunga coil yacho muchimiro chesirinda zvakasimba | 42 | Kuongorora mhando yekuwedera | Dzivisa kupinza kusina simba, kubvisa zvisungo, uye kutonhora kwemurwi |

| 43 | Dzivisa corrugation kumativi ese ekunamira | |||

| 44 | Dzivisa kupwanya kweweld uye kupwanya kusingachinji | |||

| 45 | Dzivisa kuumbwa kwemutsetse we weld | |||

| kushongedza mafrequency eredhiyo | Sunga coil yacho muchimiro chesirinda zvakasimba | 46 | Kuongorora mhando yekuwedera | Dzivisa kuiswa kwetsvina |

| 47 | Kudzivirira kutsemuka kunze kweweld | |||

| 48 | Dzivisa kuderera kwemidzi | |||

| 49 | Dzivisa kupinda kwemidzi | |||

| 50 | Dzivisa kutadza kwekubatana | |||

| 51 | Dzivisa kupinza mvura inobuda, kupinza nhema, kupinza pamakumbo nezvimwe zviitiko. (Kazhinji, kana coil ikapfuura nepa tightening roller, mupendero we coil unonyunguduka nekuda kwekupisa kwakawanda. Pachava ne glaze chena yakaita se glaze ye glaze panguva ye welding, izvo zvinoratidza kuti welding yemhando yepamusoro inovimbiswa.) | |||

| Vanga rekukwesha weld | Cheka wobva wakuya kukwirira kwasara kweweld yekunze | 52 | kuongorora chitarisiko | Dzivirira chiitiko chekutenderera kwemusono, muromo wakasununguka uye kupatsanurwa kwemajoini; Hazvidi kuti weld iome uye maronda eweld aendeswe kumativi ese. |

| 53 | Kuongorora weld | Iva nechokwadi chekuti mavanga eweld, ruvara uye mhando yekuumba zvinosangana nezvinodiwa zveGB/ T13793-2008 (P10) | ||

| kutonhora kwemhepo | Kutonhodza pombi yakasungirirwa | 54 | Tarisa huwandu hwemvura mutangi | Zvichienderana nedhayamita yepombi dzakasiyana, kumhanya, hunhu hwemvura, tembiricha yemvura, kuyerera kwemvura, huwandu hwemunyu, pH, nezvimwewo |

| Saizi yechubhu yesimbi | Gadzirisa dhayamita yekunze uye kusatenderera kwepombi yakasungirirwa | 55 | Kuongororwa kwedhayamita yekunze | Kudzora zvinodiwa zveGB/T21835 -- 2008 standard (P5) mukati mechikamu |

| 56 | Kuongorora kusatenderera | Kudzora zvinodiwa zveGB/ T3091-2015 standard (P4) mukati mechikamu | ||

| Kururamisa kwakaomarara | Bvisa kukotama kudiki kwechubhu yesimbi | 57 | Tarisa michina yekurongedza | Shandisa mudziyo wekutwasanudza kuti ugadzire pombi yesimbi zvakananga mukuita kunotevera |

| NDT (kuyedza kusingaparadze) | Ongorora zvikanganiso zviri pamusoro nemukati me weld zvinogona kukanganisa kunaka kwepombi yesimbi | 58 | Gadzirisa chishandiso usati waedza | Gadza maparamita akakodzera; Sarudza chiyero chekuskena uye kunzwisisika kwekuona zvikanganiso uchishandisa block yekuyedza yekuenzanisa; Wedzera muripo wepamusoro kuti uve nechokwadi chekuti pane huwandu hwekuonekwa kwezvikanganiso |

| 59 | Kuongororwa kwekutanga kwebhechi mushure mekutsanangurwa kwekutsiva | Mushure mekuchinja kwega kwega kwezvinodiwa zvechigadzirwa, boka rekutanga rezvigadzirwa zvakapedzwa rinofanira kuongororwa. Huwandu hwematavi ekuongorora hahufanirwe kunge huri pasi pematatu. Mushure mekupasa ongororo, chigadzirwa chinogona kugadzirwa | ||

| 60 | Kuedzwa kwesimbi yesimbi yepombi yakasungirirwa | Kuongororwa kwemaonero ekushomeka kwehunhu hwechubhu yesimbi pamusoro | ||

| 61 | Kuongororwa kwechitarisiko che weld | Nekutarisa chitarisiko cheweld mushure mekutonhora, hapana zvikanganiso zvakaita sekubviswa kweweld, kutsva, mavanga, kuvhurika, kutsemuka, kutsemuka kwetendon, kukwenya vanga risina kuenzana, muromo wakasununguka unobvumidzwa. | ||

| 62 | Kuongororwa kwesimbi nesimbi yemukati neUltrasonic. Kuongorora nzvimbo uye mhinduro. | Chinoongorora mafambiro echinhu chinobuda mumuviri wechubhu chinoburitsa mafungu e-ultrasonic, uye chishandiso chinogashira uye chinoongorora mafungu anoonekwa. Kunzwa kwechiratidzo chekuona kunogadziriswa zvichienderana neSY/ T6423.2-1999, uye mhando, saizi uye kudzika kwechiratidzo zvinotsanangurwa nekukwirira kwemafungu e-echo kunoratidzwa pachiratidziro chechishandiso. Hazvibvumirwi kuva nezvikanganiso zvinokanganisa zvakanyanya kunaka kweweld, zvakaita sekutsemuka, maburi ane urefu hwemafungu e echo hunopfuura 50% yechidzitiro chose, kusapinda uye kusabatana. Mitemo yekuongorora sampuro: kuongororwa kwemasampuli kunofanirwa kuitwa zvichienderana ne1% yebatch yega yega. Kana paine dambudziko rakawanikwa, nyora pasi uye upe mhinduro nenguva. Nyora zviratidzo zvakajeka pane zvikanganiso kuti zvive nyore kuti vashandi vagadzirise zvikanganiso zvinoenderana nazvo; Wedzera huwandu hwesampuli ne10%. Kana kuchine zvigadzirwa zvisina kukodzera muongororo yesampuli, dhipatimendi rinofanira kuziviswa kuti rimire uye rigadzirise maitiro ekugadzira nekufamba kwenguva. | ||

| Kucheka saha rinobhururuka | Kugadzika kwekucheka kwepombi yakasungirirwa pamatako | 63 | Kuongorora mapaipi | Mugumo wepombi unofanira kuvimbiswa pasina burr uye muromo wakakombama |

| 64 | kureba kwekucheka | Tarisa dhayamita ye speed roller zvichienderana ne standard uye sarudza data rinonzwisisika | ||

| Kururamisa chubhu yesimbi | Gadzirisa kukotama kwechubhu yesimbi | 65 | kuongorora chitarisiko | Dzivisa kukuvara kwemuviri wechubhu, chiitiko chekupfava kwemuromo wechubhu; Hapana kudzika kweganda pamusoro pechubhu |

| Kuchengeta magumo epombi | Kugadzirisa burr yemuromo wepombi | 66 | Kuongorora mapaipi | Iva nechokwadi chekuti magumo epombi akatsetseka uye asina burr, uye iva nechokwadi chekuti pombi yega yega yesimbi inogona kuwana "mhedzisiro chaiyo yepombi yakatwasuka". |

| kuongorora chigadzirwa chapera | Ita shuwa kuti mhando yepombi dzakasungirirwa muworkshop inosangana nezvinodiwa zvakajairwa | 67 | kuongorora chitarisiko | Ita shuwa kuti pamusoro pepombi yesimbi pakanaka, hapana kupeta, kutsemuka, ganda rakapetwa kaviri, lamination, lap welding nezvimwe zvikanganiso zviripo, bvumira kuti pave neukobvu hwemadziro hwekutsauka kwakashata, usabvumira kuti pave nekukwenya kwakakomba, kutsemuka kweweld, kutsva uye vanga. |

| 68 | Kuongorora kwe weld yemukati | Iva nechokwadi chekuti bhaa rekuwelda rakasimba, ukobvu hwakaenzana, hwakaita sewaya, bhaa rekuwelda remukati rinofanira kunge rakareba kupfuura 0.5mm, bhaa rekuwelda repaipi rinopinda neshinda haritenderwe kuva neburr | ||

| 69 | Kuongororwa kwedhayamita yekunze | Kudzora zvinodiwa zveGB/T21835 -- 2008 standard (P5) mukati mechikamu | ||

| 70 | Kuongorora kusatenderera | Kudzora zvinodiwa zveGB/ T3091-2015 standard (P4) mukati mechikamu | ||

| 71 | Kuyera kureba | Kureba kwepombi yesimbi i6m. Zvichienderana nezvinodiwa neGB/ T3091-2015, kutsauka kunobvumidzwa kwehurefu hwese hwepombi yakasungirirwa ine tambo yakatwasuka i +20mm. (zvinodiwa zvepaipi: maminetsi mana - 2 inches 0-5mm, 2.5 inches - 4 inches 0-10mm, 5 inches - 8 inches 0-15mm) | ||

| 72 | Kuonekwa kwekukombama | Zvichienderana neGB/ T3091-2015, mwero wekukombama kwehurefu hwese hwepombi yesimbi haufanirwe kupfuura 0.2% yehurefu hwepombi yesimbi. | ||

| 73 | Kuongorora mapaipi | Iva nechokwadi chekuti musoro wepombi hauna burr uye chikamu chekupedzisira chinosangana nezvinodiwa zveGB/ T3091-2015 | ||

| 74 | Kuongorora kwekunze kwe weld | Kukwenya mavanga ekunze kweweld kunofanira kushandiswa banga re arc, kukwenya mavanga kunofanira kushandiswa ne arc transition | ||

| 75 | Makomba apo zvidimbu zvese zvaisavapo cheki | Dzivisa kuvhura pamucheto wepombi | ||

| 76 | Kuonekwa kwetsvina | Dzivisa kutsemuka pabhawa rekunamira | ||

| 77 | Kuongorora pamwe chete | Dzivisa chiitiko chemajoini pamuviri wepombi yakasungirirwa | ||

| 78 | Cheka kuti uone | Dzivisa kukwenya kwakakomba pamusoro pepombi yakasungirirwa, izvo zvinokanganisa ukobvu hwemadziro. Kutsauka kusina kunaka kwete pasi peukobvu hwemadziro (12.5%) | ||

| 79 | Furati yekuyedza gomba | Dzivirira makomba nemakomba anokonzerwa nemasimba ekunze ari mupombi yakasungirirwa. Mutemo wekudzora mukati mebhizinesi (maminitsi mana - 1 inch, kudzika kwegomba <2mm; 1¼ inch-2 inch, kudzika kwegomba <3mm; 2½ inch-6 inches, kudzika kwegomba <4mm; Kudzika kwegomba remasendimita masere <6mm) | ||

| 80 | Kuongororwa kwenzvimbo ine makomba (gomba) | Dzivisa kupwanyika kwemaburi pamusoro pechubhu yesimbi | ||

| 81 | Ongorora bhaa remukati re weld | Kudzivirira welding bar haina kusimba, isina kuenzana, isingasviki 0.5mm nekuti welding bar haina kukodzera | ||

| 82 | Kuongorora Burr | Dzivisa zvikamu zvisina kurongeka mukati nekunze kwemusoro wepombi. Mutemo wekudzora mukati mebhizinesi (mapoinzi mana - 2 inches ye burr <1mm; 2½ inch kusvika 4 inch burr <2mm; 5 "- 8" burr <3mm. Cherechedza: Burr haibvumidzwe papombi yemusoro wenet. | ||

| 83 | Kuongorora muromo wakarembera | Dzivisa kuvhurika kana kushanduka kunokonzerwa nekukweva kana kukwidza, kureva "muromo wekukwidza" | ||

| 84 | Kuongorora kupwanyika kwekusimbisa | Dzivirira kucheka kudiki kwebead rekunamira | ||

| 85 | Kukwenya vanga risina kuenzana | Dzivisa bhaa rekuwelda risina kuenzana mushure mekukwenya vanga. Bhaa rekuwelda harisi pamusoro pearc yakatsetseka. Musiyano uri pasi pesimbi yepasi unoonekwa seusina kuenzana | ||

| 86 | Kubva pamuromo kusvika pakuongorora | Dzivirira chiitiko chekupeta misono yewelding uye kumanikidzwa kunokonzerwa nezvinhu zvakagadziriswa kana zvikonzero zvemakanika, welding bar haina kutsetseka, kune mipendero yakasununguka, kupeta weld dislocation, nezvimwewo. | ||

| 87 | Kuongorora ganda kaviri | Dzivisa pamusoro hauna kutsetseka, wakatsetseka, nyama shoma kana chiitiko chisina kuenzana | ||

| 88 | Kuongorora mavanga | Dzivisa nzvimbo dzinosungirirwa pamusoro dzinogona kukanganisa simbi yepasi | ||

| 89 | Makomba ejecha ekutarisa | Dzivirira maburi pamusoro pechubhu yesimbi | ||

| 90 | Kuongororwa kwemuromo kwakavharwa | Chikamu chepombi hachina kuenderana nemutsetse wepakati, uye mugumo wacho unofanirwa kusangana nezvinodiwa zveGB/ T3091-2015 | ||

| 91 | Kuongorora hunhu | Dzivisa chiratidzo chekutengeserana chakanamirwa papombi uye zvirevo chaizvo zvepombi yakasungirirwa hazvienderane kana kusanganiswa. | ||

| bvunzo yemakanika | Tarisa hunhu hwemakanika hwezvinhu | 92 | bvunzo yekukombama | Ongorora hunhu hwekunamira kwemapaipi esimbi ane masendimita maviri zvichidzika kuti usvike pazvinodiwa zveGB/ T3091-2015 (P7) |

| 93 | bvunzo yekutsvedza | Kutarisa kunaka kwekunamira kwemapaipi esimbi pamusoro pemasendimita maviri uye kusangana nezvinodiwa zveGB/ T3091-2015 (P7) | ||

| 94 | Kuedzwa kwetangi rekumanikidza | Edza mashandiro emugero wesimbi wepombi yesimbi, zvichienderana nezvinodiwa zveCECS 151-2003 trench connection pipe engineering technical specification requirements (P9) | ||

| 95 | bvunzo yekukwesha | Edza kusimba kwekusimba uye kureba kwepombi yesimbi mushure mekutyoka kuti usvike pazvinodiwa zveGB/ T3091-2015 (P7) | ||

| Kuedzwa kwekumanikidzwa kwemvura | Ongorora kusimba, kusapinda kwemhepo uye kunaka kwechitarisiko chesimbi yepasi uye weld yepombi yakasungirirwa | 96 | Tarisa usati wabvisa zvinhu zvako | Dzivisa musiyano uripo pakati pechinyorwa uye zvirevo chaizvo zvepombi yakasungirirwa kana kuti batch yakasanganiswa haibvumirwi kuburitsa (nhamba yebatch yakafanana uye zvirevo zvakafanana zvinodzvinyirirwa pamwe chete |

| 97 | kuongorora nemaziso | Kutarisa nemaziso simbi yepasi kudzivirira kutsemuka, ganda rinorema, ngura yakakura, maburi ejecha nezvimwe zvikanganiso, kukwenya kwakakomba hazvitenderwi | ||

| 97 | Tarisa magumo usati watanga bvunzo | Pamusoro pemativi ese ari maviri epombi yakasungirirwa panofanira kunge pakanyatsonaka uye pakanyatsonaka kuburikidza nekutarisa nemaziso. Hazvibvumirwi kuva nemusoro wakatsetseka, pombi yakakombama uye muromo wakarembera. Chikamu chemugumo wepombi isina burr chakatarisana nepakati pemutsetse. Hapana denderedzwa rakanamira uye kutsauka kunofanira kunge kuri pasi pe3° | ||

| 98 | Tarisa nzvimbo inofambiswa nepressure (mvura) usati waisa pressure. | Mushure mekuzadza mvura inoyerera kubva papombi yakasungirirwa, musakurumidza kuwedzera kumanikidzwa. Zvakakosha kutarisa kana system yacho isina mvura inobuda. | ||

| 99 | kuyedzwa kwemvura | Zvinoenderana neGB/ T241-2007 standard (P2) pasi pekuyedzwa kwekumanikidzwa, kumhanya kwekumanikidzwa uye mamiriro epakati ekufambisa kumanikidzwa, yakagadzikana kwenguva yakati. Tarisa nemaziso pamusoro pechiso chekunze che welded tube matrix kana weld seam mukati menguva yekudzikamiswa kwedzvinyiriro. Hapana kudonha kana kuputika kunobvumidzwa. Tarisa nemaziso pombi yese yakasungirirwa mushure mekuyedza, hapana kuchinja kwechigarire kunobvumidzwa | ||

| 100 | Kuongororwa kwechitarisiko mushure mekuyedzwa | Iva nechokwadi chekuti hapana kukwenya kunobvumirwa; Musoro wakatsetseka uye pombi yakakombama hazvibvumirwi. Hapana kusvibiswa kwemafuta nezvimwe zvinetso zvemhando yepamusoro mukati nekunze kwepombi yesimbi | ||

| 101 | Mushumo wakabudiswa na | Zadza zvinoenderana nezvinodiwa neGB/ T241-2007 standard (P2) uye mienzaniso yemukati (inotumirwa katatu kudhipatimendi rekugadzira, dhipatimendi rekuongorora mhando, nepombi yesimbi ichitora kopi imwe chete). Hapana hunyengeri hunotenderwa. | ||

| Kuedza kusvuta | Deredza kudzora kwemhando isina kunaka mukuita kunotevera | 102 | Bvunzo rekuzivikanwa | Simbisa ukobvu chaihwo hwemadziro, zvinodiwa kana kusanganiswa kwelabel nepaipi yakasungirirwa nekuyera nekuyera |

| 103 | Bvunzo rekusatenderera | Ita shuwa kuti kusatenderera kwepombi yesimbi kunoenderana nechiyero chenyika cheGB/T 3091-2015 (P4) | ||

| 104 | Kuyerwa kwehurefu | Iva nechokwadi chekuti urefu hwepombi yesimbi hunoenderana nechiyero chenyika cheGB/T 3091-2015 (P5) (mamita matanhatu, kutsauka kunobvumidzwa +20mm) | ||

| 105 | Kuongororwa kwedhayamita yekunze | Ita shuwa kuti dhayamita yekunze yepombi yesimbi inosangana nezvinodiwa zveGB/T21835 -- 2008 Standard (P5) | ||

| 106 | Bvunzo rakavhurika | Tarisa kana mugumo wepombi uine chitarisiko chekucheka | ||

| 107 | Kuedzwa kwekutyoka | Mushure mekurovera nenyundo, hapana chiitiko chekutsemuka pabhawa rekuwelding | ||

| 108 | Kuongorora pamwe chete | Tarisa chubhu imwe chete kuti uone kana paine chiitiko chekumisa dhoki | ||

| 109 | Ongororo yepombi ine ngura | Tarisa nemaziso kana paine tsvina, pendi, mavara emafuta uye mapaipi ane ngura pamusoro pepombi yesimbi. | ||

| 110 | Kuongorora gomba rakati sandara | Tarisa nemaziso kana pamusoro pepombi yesimbi paine makomba emunharaunda anokonzerwa nemasimba ekunze | ||

| 111 | Kuongororwa kwenzvimbo ine makomba (makomba) | Uchishandisa kuongorora nemaziso, bata pamusoro pepombi yesimbi neruoko kana paine poindi yebundu | ||

| 112 | Tarisa kana bhaa remukati re welding rinokodzera | Kudzivirira kusavapo kwebhawa rekushongedza mukati (kusanganisira kusanganisa kwenhema) kana bhawa rekushongedza mukati rinodarika mwero wezvinotarisirwa nezvimwe zvinetso; Kudzivirira welding bar haina kusimba, isina kuenzana, kana kuti iri pasi pe0.5mm haina kukodzera | ||

| 113 | Kuongorora Burr | Tarisa nemaziso kana paine zvikamu zvisina kurongeka mukati nekunze kwechepfu. Mushure mekurapwa, gomba remupombi rinofanira kunge riri pasi pe0.5mm kuti rikwanise kusimbiswa. | ||

| 114 | Kuongorora muromo wakarembera | Kudzivirira kuvhurika kana kushanduka kunokonzerwa nekushanda kwechiredzo nekusimudza | ||

| 115 | Kuongorora kupwanyika kwekusimbisa | Nekuyedza kukotama kana kuti kupfava, bhaa rekunamira repaipi yesimbi rinowanikwa kudzivirira kuvapo kwezvimedu zvidiki. Tarisa Chinyorwa 8 cheP6 cheQuality Control and Management System kuti uone bvunzo yekukombama | ||

| 116 | Kuongorora mavanga ekukwenya | Iva nechokwadi chekuti pamusoro peganda rekukwesha bhawa rekukwesha ganda rakatsetseka uye rakatenderera | ||

| 117 | Kuongororwa kwechiteshi chemahara | Dzivisa chiitiko chekupeta kumanikidzwa pamusono we welding kunokonzerwa nezvinhu zvisina kugadzirwa kana zvikonzero zvemakanika. | ||

| 118 | Kuedzwa kweganda kaviri | Dzivisa chiitiko chechubhu yesimbi ine ganda rakapetwa kaviri | ||

| 119 | Denderedzwa rakaita semushenjere | Kudzivirira pamusoro pepombi yesimbi kubva pakupwanyika kwetsvina | ||

| 120 | Kuongorora kwe weld yemakumbo | Kuongorora nemaziso kudzivirira chiitiko chekushongedza matako zvakanyanya pabhawa rekushongedza machubhu esimbi | ||

| 121 | Kuongororwa kwemavanga | Kuongorora nemaziso kudzivirira mavanga ekunamira pamusoro pepombi yesimbi | ||

| 122 | Makomba ejecha, kuongorora | Kuongorora zvinoonekwa kudzivirira maburi pamusoro pepombi yesimbi | ||

| 123 | Bvunzo rekucheka | Isa pombi pasi pechinhu chinosunga gasi kuti uve nechokwadi chekuti hapana kucheka kana kukuvara | ||

| 124 | Hazvina kunaka kuti zvinhu zvakabikwa zvisanyanya kubikwa | Kuongorora nemaziso kuti pasave nemavara emafuta, pendi nezvimwe zvinhu zvisiri nyore kubvisa tsvina, kudzivirira kubuda kwepurasitiki. | ||

| Pombi yesimbi inotonhorera | Bvisa zvinhu zvakaomesesa zvakaita se oxide scale inogadzirwa pamusoro pepombi yesimbi | 125 | Kuwanda kweasidhi | Huremu hwehydrogen chloride mu acid inofanira kudzorwa pa20%-24%. |

| 126 | Kuongororwa kwepasi pepombi yesimbi | Kudzivirira (1) nguva isina kukwana yekusvira, tembiricha yakaderera yeasidhi, huwandu hushoma (tembiricha inofanira kudzorwa mu25-40 ℃, huwandu hweasidhi yehydrogen chloride i20%-24%) (2) nguva shoma yekuzunungusa yechubhu (3) kuvapo kwesilicate muchubhu yesimbi yakasungirirwa muchoto | ||

| kurongedza zvigadzirwa | Yakarongedzwa zvichienderana nehuwandu hwakatarwa hwemapaipi esimbi pachidimbu chimwe nechimwe | 127 | Kuongorora bhandi rekurongedza | Kurongedza mapaipi esimbi kwakagadzirwa nehexagonal, mabhandi matanhatu ekurongedza, ese ari mufekitori yedu, magumo ese ari maviri ebhandi rekurongedza kubva kumagumo echikanganiso che±10mm, pakati pe4 kuti pave nekukamurwa zvakaenzana, welding yebhandi rekurongedza inofanira kunge yakarongeka, yakati sandara, bhandi rekurongedza haribvumidze kutsauka, bhandi rekurongedza rinofanira kuchekwa panosangana 45° Angle, rinofanira kusangana nezvinodiwa. |

| 128 | Kuongorora zviratidzo zvekutengeserana | Zviri mukati mazvo zvakarurama, denderedzwa riri kumusoro, chiratidzo chepombi chapera chinofanira kunamirwa zvakanaka pabhafu rega rega repombi kuti rienderane nerutivi rwerudyi rwebhandi rekutanga rekuputira welding riri pakati, uye chinyorwa cheTed embellish chakajeka uye hachina kutsveyama. |