YuantaiDerunʻOi aku ka nui o nā patents square rectangular tube ma mua o 63, e kū ana i nā kūlana ʻoihana ma ka home a ma waho.Ua hala ka huahana ma mua o 200 mau loulou nānā e hoʻomalu i ka maikaʻi o ka huahana.

"Mai hoʻokuʻu i kahi paipu kila kūpono ʻole i ka mākeke".

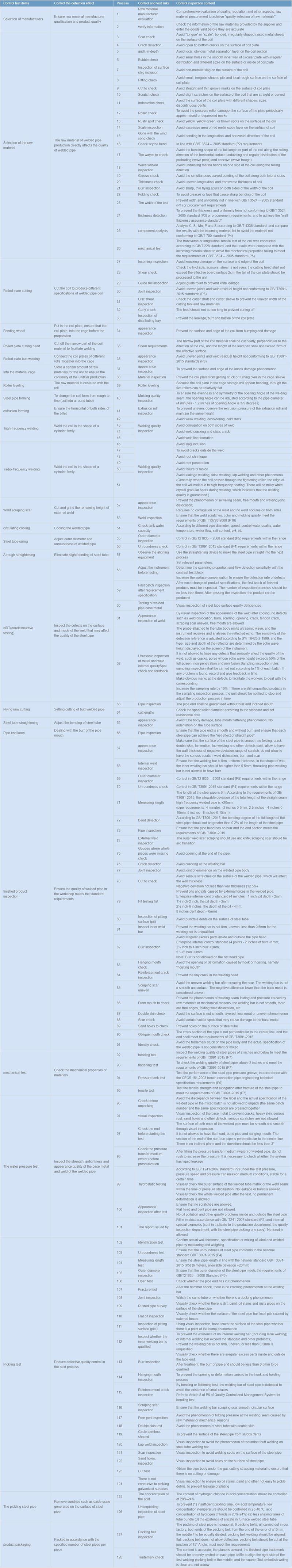

| E hoʻomalu i nā mea hoʻāʻo | E kāohi i ka hopena ʻike | Kaʻina hana | Nā loulou hoʻomalu a hoʻāʻo | E hoʻomalu i ka ʻike nānā |

| Ke kohoʻana i nā mea hana | E hōʻoia i ka hōʻoia ʻana o ka mea hana maka a me ka maikaʻi o ka huahana | 1 | Loiloi ana o ka mea hana mea maka | ʻO ka loiloi piha o ka maikaʻi, ka inoa a me nā ʻano ʻē aʻe, ke kūʻai ʻana i nā mea waiwai e hoʻokō ai i "koho maikaʻi o nā mea maka" |

| 2 | hōʻoia i ka ʻike | E nānā i ka ʻike o nā mea maka i hāʻawi ʻia e ka mea hoʻolako a komo i ka pā waiwai ma mua o ka pololei | ||

| Ke koho ʻana i ka mea maka | ʻO ka mea maka o ka hana paipu welded pili pono i ka maikaʻi o ka paipu welded | 3 | Nānā ʻula | Hōʻalo i ka "alelo" a i ʻole "scale", i hoʻopaʻa ʻia, ʻano like ʻole ke ʻano o nā ʻili metala ma luna o ka ʻili o ka wili. |

| 4 | ʻIke māwae | E pale i nā māwae hāmama o lalo ma ka ʻili o ka pā coil | ||

| 5 | hoʻokolo-hohonu | E pale i ka ʻāpana hoʻokaʻawale metala ma ka ʻāpana coil | ||

| 6 | Hōʻoia ʻōhū | E hōʻalo i nā puka liʻiliʻi ma ka paia o loko o ka pā pōʻai pōʻai me ka puʻupuʻu like ʻole a me nā ʻano nui like ʻole ma ka ʻili a i ʻole i loko o ka pā coil. | ||

| 7 | ʻO ka nānā ʻana i ka hoʻokomo ʻana o ka slag surface | E hōʻalo i ka slag non-metallic ma ka ʻili o ka coil | ||

| 8 | Nānā lua | Hōʻalo i nā lua liʻiliʻi, ʻano ʻano like ʻole a me ka ʻili o ka ʻāina ma luna o ka ʻili o ka pā coil | ||

| 9 | E ʻoki e nānā | E hōʻalo i nā kaha ʻāʻī pololei a lahilahi ma ka ʻili o ka pā wili | ||

| 10 | Nānā ʻōpala | E pale i nā ʻumeke liʻiliʻi ma luna o ka ʻili o ka pōʻai pololei a i ʻole ka pihi | ||

| 11 | Nānā hoʻopaʻa | Hōʻalo i ka ʻili o ka pā wili me nā ʻano like ʻole, ka nui, nā niho ʻoki ʻole | ||

| 12 | Nānā kaʻa | No ka pale ʻana i ka pōʻino o ka roller pressure, ʻike ʻia ka ʻili o ka pā i kēlā me kēia manawa he mau hōʻailona hoʻokiʻekiʻe a kaumaha paha | ||

| 13 | Nānā wahi ʻāʻī | Hōʻalo i nā kiko melemele, melemele-'ōmaʻomaʻo, a ʻeleʻele paha ma ka ʻili o ka wili | ||

| 14 | Nānā unahi | E pale i ka nui o ka ʻāpana ʻulaʻula metala oxide ma ka ʻili o ka wili | ||

| 15 | Hele me ka nānā mele makani | E pale i ka piko ʻana ma ka ʻaoʻao longitudinal a me ka ʻaoʻao o ka wili | ||

| 16 | E nānā i ka piko scythe | I ka laina me GB/T 3524 -- 2005 maʻamau (P2) koi | ||

| 17 | ʻO nā nalu e nānā | Hōʻalo i ke ʻano piʻo o ka lōʻihi piha a i ʻole ʻāpana o ka wili ma ka ʻaoʻao o ka ʻōwili ʻana o ka ʻili ākea e hoʻoheheʻe ʻia a me ka puʻunaue maʻamau o ka puka ʻana (wave peak) a me ka concave (wave trough) | ||

| 18 | Nānā wrinkle nalu | E hōʻalo i ka piʻo ʻana o ka marina ma kekahi ʻaoʻao o ka wili ma ka ʻaoʻao ʻōwili | ||

| 19 | Hōʻoia Groove | Hōʻalo i ka piʻo like ʻana o ka ʻōwili ma nā ʻaoʻao ʻaoʻao ʻelua | ||

| 20 | Nānā mānoanoa | E pale i ka mānoanoa like ʻole o ka longitudinal a me ka transverse o ka coil | ||

| 21 | Nānā Burr | Hōʻalo i nā ʻōpuʻu lele ʻoi aku ka lahilahi ma nā ʻaoʻao ʻelua o ka laula o ka pōʻai | ||

| 22 | Ke kāʻei pelu | No ka pale ʻana i nā ʻeke a i ʻole nā ʻūhā e hiki ai ke piʻo ʻoi o ka wili | ||

| 23 | Ka laula o ka hoao ana | Kāohi i ka laulā a me ka like ʻole i ka laina me GB/T 3524 -- 2005 standard (P4) a i ʻole nā koi kūʻai. | ||

| 24 | ʻike mānoanoa | No ka pale ʻana i ka mānoanoa a me ka like ʻole ʻana i ka GB / T 3524 - 2005 maʻamau (P3) a i ʻole nā koi kūʻai, a e hoʻokō i ka "paʻa mānoanoa o ka mānoanoa o ka paia" | ||

| 25 | kālailai ʻāpana | E noʻonoʻo i ka C, Si, Mn, P a me S e like me ka maʻamau GB/T 4336, a e hoʻohālikelike i nā hopena me ka papa inoa o nā mea e hiki mai ana e pale aku i ka mea i kūlike ʻole i ka maʻamau GB/T 700 (P4) | ||

| 26 | hoao mechanical | Ua hana ʻia ka hoʻāʻo transverse a i ʻole longitudinal tensile o ka coil e like me ka maʻamau GB / T 228, a ua hoʻohālikelike ʻia nā hopena me ka pepa mea e hiki mai ana e pale aku i nā waiwai mechanical i hiki ʻole ke hoʻokō i nā koi o GB / T 3524 - 2005 standard (P5). ). | ||

| ʻOki pāpaʻi ʻōwili ʻia | E ʻoki i ka wili e hana i nā kikoʻī like ʻole o ka wili paipu welded | 27 | Ka nānā ʻana mai | E pale i ke kīkēkē ʻana i ka pōʻino ma ka ʻili a me ka ʻaoʻao o ka wili |

| 28 | Nānā ʻāhi | E nānā i nā ʻoki hydraulic, ʻaʻole like ka ʻoki ʻana, ʻaʻole e ʻoi aku ke poʻo ʻokiʻoki ma mua o ka 2cm papa kūpono, pono e hana ʻia ka huelo o ka pā coil i ka ʻāpana. | ||

| 29 | Nānā ʻōwili alakaʻi | E hoʻoponopono i ka huila alakaʻi e pale i ka leaka o ka pahi | ||

| 30 | Nānā hui | Hōʻalo i nā hui like ʻole a weld i ke koena kiʻekiʻe ʻaʻole i kūlike i nā kūlana GB/T3091-2015 (P8) | ||

| 31 | Ka nānā ʻana i ka shear disc | E nānā i ka lāʻau ʻoki a me ka lima ʻoki e pale i ka laulā ʻole o ka mea ʻoki a me nā mea maka | ||

| 32 | Nānā ʻolino | ʻAʻole pono ka lōʻihi o ka hānai ʻana e pale aku i ka wili | ||

| 33 | Ka nānā ʻana i ka pā hoʻolaha | Kāohi i ka leakage, burr a me ka pale o ka pā coil | ||

| Huila hanai | E hoʻokomo i loko o ka pā wili, e hōʻoia i ka pā coil, i loko o ka hale ma mua o ka hoʻomākaukau | 34 | nānā maka | Kāohi i ka ʻili a me ka ʻaoʻao o ka wili mai ke kuʻi ʻana a me ka pōʻino |

| Poʻo ʻoki pāpaʻi ʻōwili ʻia | E ʻoki i ka ʻāpana haiki o ka mea wili i mea e maʻalahi ai ka wili | 35 | Nā koi ʻoki | ʻO ka ʻāpana haiki o ka mea wili e ʻoki pono ʻia, e kū pono ana i ke kuhikuhi o ka wili, a ʻaʻole ʻoi aku ka lōʻihi o ka ʻāpana alakaʻi ma mua o 2cm o ka ʻili kūpono. |

| ʻO ka wiliwili pāpaʻi ʻōwili ʻia | E hoʻohui i nā pā wili o nā ʻōwili like ʻole i loko o ka hale | 36 | nānā maka | Hōʻalo i nā hui like ʻole a weld i ke koena kiʻekiʻe ʻaʻole i kūlike i nā kūlana GB/T3091-2015 (P8) |

| I loko o ka hīnaʻi mea | E mālama i kahi nui o nā mea maka no ka ʻāpana e hōʻoia i ka hoʻomau o ka hana unitCar | 37 | nānā maka | No ka pale ʻana i ka ʻili a me ka ʻaoʻao o ke kīkēkē ʻino |

| 38 | Nānā waiwai | Kāohi i ka paʻa ʻana o ka pā wili a i ʻole ka huli ʻana i ka lima o ka hale | ||

| Hoʻolālikelike ʻia | Hoʻokumu ʻia ka mea maka me ka ʻōwili | 39 | Hoʻolālikelike ʻia | No ka mea, e ʻike ʻia ana ke kulou ʻana o ka pā coil i loko o ka hale mālama hale, ma o nā ʻelima ʻelima hiki ke palahalaha |

| Piula kila | No ka hoʻololi ʻana i ke ʻano o ka wili mai ka ʻalaʻala a i ka maikaʻi (hoʻopili i loko o kahi paipu poepoe) | 40 | Ka nānā ʻana i ka maikaʻi | No ka hōʻoia i ka evenness a me ka symmetry o ka Angle wehe o ka wili kuʻi, hiki ke hoʻololi i ka Angle wehe e like me ke anawaena paipu. (4 mau minuke - 1.2 iniha o ka wehe ʻana ʻO ka Angle he 3-5 degere) |

| hana extrusion | E hōʻoia i ka pae o nā ʻaoʻao ʻelua o ka billet | 41 | Ka nānā ʻana i ka ʻōwili extrusion | No ka pale ʻole ʻana, e nānā i ke kaomi extrusion o ka extrusion roll a mālama i ke kiʻekiʻe like |

| kiʻekiʻe-frequency wiliwili | E hoʻopaʻa paʻa i ka wili i ke ʻano o ka cylinder | 42 | Nānā maikaʻi wiliwili | E pale i ka welding nāwaliwali, desoldering, ke anu |

| 43 | E pale i ka corrugation ma nā ʻaoʻao ʻelua o ka weld | |||

| 44 | E pale i ka māwae weld a me ka māwae paʻa | |||

| 45 | E pale i ka hoʻokumu ʻana i ka laina weld | |||

| hoʻoheheʻe radio-frequency | E hoʻopaʻa paʻa i ka wili i ke ʻano o ka cylinder | 46 | Nānā maikaʻi wiliwili | E pale i ka hoʻokomo ʻana i ka slag |

| 47 | No ka pale ʻana i nā māwae ma waho o ka weld | |||

| 48 | E pale i ka emi ʻana o ke aʻa | |||

| 49 | Hōʻalo i ke komo ʻana o ke aʻa | |||

| 50 | Hōʻalo i ka hiki ʻole o ka hui ʻana | |||

| 51 | Hōʻalo i ka leakage welding, hoʻopunipuni hoʻopunipuni, wili ʻūhā a me nā mea ʻē aʻe. (Ma ka maʻamau, i ka wā e hele ai ka wili i ka roller tightening, e heheʻe ka lihi o ka coil ma muli o ka hoʻomehana ʻana i ke alapine. | |||

| Weld scraping scar | E ʻoki a wili i ke kiʻekiʻe i koe o ka weld waho | 52 | nānā maka | Kāohi i ke ʻano o ka swiveling seam, ka waha manuahi a me ka welding joint dislocation; ʻAʻole makemake i ka corrugation o ka weld a ʻaʻohe weld nodules ma nā ʻaoʻao ʻelua. |

| 53 | Nānā weld | E hōʻoia i ka loaʻa ʻana o ka weld scratches, ka waihoʻoluʻu a me ka maikaʻi o ka hoʻoheheʻe ʻana i nā koi o GB / T13793-2008 (P10) | ||

| kaapuni hooluu | E hooluolu ana i ka paipu wiliwili | 54 | E nānā i ka nui o ka wai pahu | E like me ke anawaena paipu like ʻole, ka wikiwiki, ka mālama ʻana i ka maikaʻi o ka wai, ka mahana o ka wai, ka kahe wai, ka paʻakai, ka pH, etc |

| Ka nui o ka paipu kila | E hoʻoponopono i ke anawaena o waho a me ka pōʻai ʻole o ka paipu welded | 55 | Nānā anawaena o waho | Mana ma GB/T21835 -- 2008 maʻamau (P5) koi i loko o ka laulā |

| 56 | Ka nānā ʻole ʻana | Mana ma GB/ T3091-2015 maʻamau (P4) koi i loko o ka laulā | ||

| He hoʻopololei ʻoʻoleʻa | E hoʻopau i ka piko iki o ka paipu kila | 57 | E nānā i nā mea hana hoʻoponopono | E hoʻohana i ka mea hoʻopololei e hana pololei i ka paipu kila i ka hana aʻe |

| NDT | E nānā i nā hemahema ma ka ʻili a me loko o ka weld e pili ana i ka maikaʻi o ka paipu kila | 58 | E hoʻoponopono i ka mea kani ma mua o ka hoʻāʻo ʻana | E hoʻonohonoho i nā palena kūpono; E hoʻoholo i ka ʻāpana scanning a me ka ʻike hemahema me ka poloka hoʻāʻo ʻokoʻa; E hoʻonui i ka uku pānaʻi e hōʻoia i ka helu ʻike o nā hemahema |

| 59 | ʻO ka nānā mua ʻana ma hope o ka hoʻololi ʻana | Ma hope o kēlā me kēia hoʻololi o nā kikoʻī huahana, pono e nānā ʻia ka pūʻulu mua o nā huahana i hoʻopau ʻia.ʻAʻole i emi iho ka nui o nā lālā nānā i ʻekolu.Ma hope o ka hala ʻana o ka nānā ʻana, hiki ke hana ʻia ka huahana | ||

| 60 | ʻO ka hoʻāʻo ʻana o ka metala kumu paipu welded | ʻO ka nānā ʻana i nā hemahema o ka maikaʻi o ka ʻili o ka paipu kila | ||

| 61 | Nānā hiʻona o ka weld | Ma ka nānā ʻana i ke ʻano o ka weld ma hope o ka hoʻoluʻu ʻana, ʻaʻohe kīnā e like me ka weld dislocation, puhi, ʻulaʻula, wehe, māwae, māwae tendon, ʻoki ʻoki ʻole ʻole, ʻae ʻia ka waha manuahi. | ||

| 62 | Nānā kani kani o ka metala a weld i ka qualitySpot nānā a me ka pane | ʻO ka ʻimi i hoʻopili ʻia i ke kino paipu e hoʻopuka i ka hawewe kani ultrasonic, a loaʻa i ka mea kani a hoʻopaʻa ʻia ka leo i ʻike ʻia.Hoʻoponopono ʻia ka sensitivity o ka ʻike ʻike e like me SY/T6423.2-1999, a ʻo ke ʻano, ka nui a me ka hohonu o ka reflector e hoʻoholo ʻia e ke kiʻekiʻe o ka nalu echo i hōʻike ʻia ma ka pale o ka mea kani. ʻAʻole ʻae ʻia ka loaʻa ʻana o nā hemahema e pili ana i ka maikaʻi o ka weld, e like me nā māwae, pores nona ke kiʻekiʻe o ka hawewe echo ma mua o 50% o ka pale piha, ʻaʻole komo a me ka hui ʻole. hana ʻia e like me ka 1% o kēlā me kēia pūʻulu.Inā loaʻa kekahi pilikia, e hoʻopaʻa a hāʻawi i nā manaʻo i ka manawa. E hōʻailona maopopo i nā hemahema i mea e maʻalahi ai nā limahana e hana i nā mea pili; E hoʻonui i ka helu hōʻailona ma 10%.Inā loaʻa nā huahana kūpono ʻole i ke kaʻina hana hoʻohālikelike, pono e haʻi ʻia ka ʻāpana e hoʻōki a hoʻoponopono i ke kaʻina hana i ka manawa. | ||

| ʻoki ʻike lele | Ke hoʻonohonoho ʻana i ka ʻoki ʻana i ka paipu i hoʻopaʻa ʻia | 63 | Nānā paipu | E hōʻoiaʻiʻo ʻia ka hopena o ka paipu me ka ʻole o ka burr a me ka waha hili |

| 64 | ʻoki lōʻihi | E nānā i ke anawaena roller speed e like me ka maʻamau a hoʻonohonoho i nā ʻikepili kūpono | ||

| ʻO ka hoʻopololei ʻana i ka paipu kila | Hoʻoponopono i ka piko o ka paipu kila | 65 | nānā maka | Hōʻalo i ka pōʻino o ke kino o ka paipu, ke ʻano hoʻopalapala waha;ʻAʻohe indentation ma ka ʻili o ka paipu |

| Mālama ʻia ka hopena paipu | Ka hana ʻana me ka ʻūhā o ka waha paipu | 66 | Nānā paipu | E hōʻoia i ka maʻalahi o ka hopena o ka paipu a me ka ʻole o ka burr, a e hōʻoia i kēlā me kēia paipu kila e hiki ke hoʻokō i ka "hopena upena o ka paipu pololei". |

| ka nānā ʻana i nā huahana i pau | E hōʻoia i ka maikaʻi o ka paipu welded i loko o ka hale hana e hoʻokō i nā koi maʻamau | 67 | nānā maka | E hōʻoia i ka maʻemaʻe o ka ʻili o ka paipu kila, ʻaʻohe pelu, māwae, ʻili pālua, lamination, wili puʻupuʻu a me nā hemahema ʻē aʻe, e ʻae i ka mānoanoa o ka pā o ke ʻano ʻino ʻole o ka ʻōpala, ʻaʻole e ʻae i ka ʻōpala koʻikoʻi. , weld dislocation, kuni a me ka ili |

| 68 | Nānā weld kūloko | E hōʻoia i ka paʻa o ka pahu kuʻihao, ka mānoanoa like ʻole, i ke ʻano o ka uea, ʻoi aku ka kiʻekiʻe o ka pahu kuʻihao o loko ma mua o 0.5mm, ʻaʻole ʻae ʻia ka pahu kuʻihao wiliwili i ka burr | ||

| 69 | Nānā anawaena o waho | Mana ma GB/T21835 -- 2008 maʻamau (P5) koi i loko o ka laulā | ||

| 70 | Ka nānā ʻole ʻana | Mana ma GB/ T3091-2015 maʻamau (P4) koi i loko o ka laulā | ||

| 71 | Ana lōʻihi | ʻO 6m ka lōʻihi o ka paipu kila.E like me nā koi o GB / T3091-2015, ʻo ka ʻae ʻia ʻana o ka ʻae ʻana o ka lōʻihi holoʻokoʻa o ka paipu welded kiʻekiʻe kiʻekiʻe kiʻekiʻe alapine kūpono he +20mm. (koi paipu: 4 mau minuke - 2 iniha 0-5mm, 2.5 iniha - 4 iniha 0-10mm, 5 iniha - 8 iniha 0-15mm) | ||

| 72 | ʻIke piko | Wahi a GB / T3091-2015, ʻaʻole pono e ʻoi aku ka nui o ka piko o ka lōʻihi o ka paipu kila ma mua o 0.2% o ka lōʻihi o ka paipu kila. | ||

| 73 | Nānā paipu | E hōʻoia i ka loaʻa ʻole o ka burr o ke poʻo paipu a hoʻokō ka pauku hope i nā koi o GB / T3091-2015 | ||

| 74 | Nānā weld waho | Pono e ho'ohana i ka pahi arc ka weld weld scaring scaring, arc transition | ||

| 75 | ʻO Gouges kahi i nele ai nā ʻāpana holoʻokoʻa | E pale i ka wehe ʻana ma ka hope o ka paipu | ||

| 76 | ʻIke māwae | Hōʻalo i ka haki ʻana ma ka pā wili | ||

| 77 | Nānā hui | Hōʻalo i ka hanana hui ma ke kino paipu welded | ||

| 78 | E ʻoki e nānā | E pale i nā ʻōpala koʻikoʻi ma ka ʻili o ka paipu welded, e hoʻopilikia i ka mānoanoa o ka pā. ʻAʻole emi mai ka mānoanoa o ka pā (12.5%). | ||

| 79 | ʻO ka lua hoʻāʻo pālahalaha | Kāohi i nā lua a me nā lua i hana ʻia e nā mana o waho i ka paipu welded. ʻO ke kūlana mana o loko o ka ʻoihana (4 mau minuke - 1 iniha, hohonu lua <2mm; 1¼ iniha-2 iniha, ka hohonu o ka lua <3mm; 2½ iniha-6 iniha, ka hohonu o ka lua <4mm; 8 iniha ka hohonu niho <6mm) | ||

| 80 | Nānā i ka ʻili lua (lua) | E hōʻalo i nā pohō ma luna o ka ʻili o ka paipu kila | ||

| 81 | E nānā i ka pā weld i loko | ʻAʻole paʻa ka paʻa kuʻihao, ʻaʻole kūlike, ʻoi aku ka liʻiliʻi ma mua o 0.5mm no ka mea ʻaʻole kūpono ka pā kuʻi. | ||

| 82 | Nānā Burr | E pale i nā ʻāpana keu ʻole i loko a i waho o ke poʻo paipu. ʻO ke kūlana mana o loko o ka ʻoihana (4 mau helu - 2 iniha o ka burr <1mm; 2½ iniha a i 4 iniha burr <2mm; 5 "- 8" pahu <3mm. Nānā: ʻAʻole ʻae ʻia ʻo Burr ma ka paipu poʻo upena. | ||

| 83 | Nānā waha waha | E pale i ka wehe ʻana a i ʻole ka hoʻololi ʻana i hana ʻia e ka makau a i ʻole ka hāpai ʻana, ʻo ia hoʻi "hoisting mouth" | ||

| 84 | Nānā māwae hoʻoikaika | Kāohi i ka māwae liʻiliʻi o ka wiliwili | ||

| 85 | ʻO ka ʻili ʻili ʻole | E hōʻalo i ka pā wiliwili ʻole ma hope o ka ʻoki ʻana i ka ʻili.ʻAʻole ʻo ka pā kuʻi ʻana he ʻili arc maʻemaʻe.ʻO ka ʻokoʻa maikaʻi ʻole ma lalo o ka metala kumu i manaʻo ʻia ʻaʻole like | ||

| 86 | Mai ka waha e nānā | Kāohi i ka hanana o ka welding seam folding a me ke kaomi i kumu ʻia e nā kumu kumu a i ʻole nā kumu mechanical, ʻaʻole maʻalahi ka pā kuʻi, aia nā ʻaoʻao manuahi, pelu ʻana i ka weld dislocation, etc. | ||

| 87 | Nānā ʻili pālua | E pale i ka ʻili ʻaʻole maʻemaʻe, papa, liʻiliʻi ka ʻiʻo a i ʻole ke ʻano like ʻole | ||

| 88 | Nānā ʻula | E hōʻalo i nā kiko solder ma luna e hiki ke hōʻino i ka metala kumu | ||

| 89 | Nā lua one e nānā | Kāohi i nā puka ma ka ʻili o ka paipu kila | ||

| 90 | Nānā waha oblique | ʻAʻole kū pololei ka ʻāpana keʻa o ka paipu i ka laina waena, a e hoʻokō ka hopena i nā koi o GB / T3091-2015 | ||

| 91 | Nānā ʻike | E hōʻalo i ka hōʻailona kālepa i paʻa i ke kino paipu a ʻaʻole kūlike a hui pū ʻia ka kikoʻī maoli o ka paipu welded. | ||

| hoao mechanical | E nānā i nā pono mechanical o nā mea | 92 | ho'āʻo kūlou | E nānā i ka maikaʻi wili o nā paipu kila o 2 iniha a ma lalo e hoʻokō i nā koi o GB / T3091-2015 (P7) |

| 93 | hoao hoopalahalaha | No ka nānā ʻana i ka maikaʻi kuʻi ʻana o nā paipu kila ma luna o 2 iniha a hoʻokō i nā koi o GB / T3091-2015 (P7) | ||

| 94 | Hoʻāʻo pahu paʻi | E ho'āʻo i ka hana o ka puʻu paipu kila, e like me ka CECS 151-2003 auwaha pili paipu 'enekinia koi kiko'ī kiko'ī (P9) | ||

| 95 | hoʻāʻo tensile | E ho'āʻo i ka ikaika tensile a me ka elongation ma hope o ka haki ʻana o ka paipu kila e hoʻokō i nā koi o GB / T3091-2015 (P7) | ||

| ʻO ka hoʻāʻo kaomi wai | E nānā i ka ikaika, ka ea a me ka hiʻona o ka metala kumu a me ka weld o ka paipu welded | 96 | E nānā ma mua o ka wehe ʻana | Hōʻalo i ka ʻokoʻa ma waena o ka lepili a me ka kikoʻī maoli o ka paipu welded a ʻaʻole ʻae ʻia ka hui hui ʻia e wehe (ʻo ka helu pūʻulu like a me nā kikoʻī like i kaomi pū ʻia. |

| 97 | nānā maka | ʻO ka nānā ʻana i ka metala kumu no ka pale ʻana i nā māwae, ka ʻili kaumaha, ka ʻōpala koʻikoʻi, nā lua one a me nā hemahema ʻē aʻe, ʻaʻole ʻae ʻia nā ʻōpala koʻikoʻi. | ||

| 97 | E nānā i ka hopena ma mua o ka hoʻomaka ʻana i ka hoʻāʻo | Pono ka ʻili o nā ʻaoʻao ʻelua o ka paipu welded ma o ka nānā ʻana. 'A'ole 'ae 'ia ke po'o palahalaha, ka paipu piko a me ka waha e kau ana.ʻO ka ʻāpana o ka hopena o ka paipu non-burr e kū pololei i ka laina waena.ʻAʻohe pae inclined a ʻo ka deviation pono e emi ma lalo o 3° | ||

| 98 | E nānā i ka mea hoʻololi kaomi (wai) ma mua o ke kaomi ʻana | Ma hope o ka hoʻopiha ʻana i ke kaomi hoʻololi (wai) o ka paipu welded, mai wikiwiki e hoʻonui i ke kaomi.Pono e nānā inā loaʻa ka wai leakage o ka ʻōnaehana | ||

| 99 | hoʻāʻo hydrostatic | Wahi a GB / T241-2007 maʻamau (P2) ma lalo o ke kaomi hoʻāʻo, ka wikiwiki o ke kaomi a me ke kaomi ʻana i nā kūlana medium, paʻa no kekahi manawa. E nānā maka i ka ʻili o waho o ka matrix welded tube a i ʻole ka weld seam i loko o ka manawa o ka hoʻopaʻa ʻana i ke kaomi.ʻAʻole ʻae ʻia ka leakage a i ʻole pohā. E nānā pono i ka paipu welded holoʻokoʻa ma hope o ka hoʻāʻo ʻana, ʻaʻole ʻae ʻia ka deformation mau | ||

| 100 | Nānā hiʻona ma hope o ka hoʻāʻo | E hōʻoia ʻaʻole ʻae ʻia nā ʻōpala; ʻAʻole ʻae ʻia ke poʻo palahalaha a me ka paipu piko. ʻAʻohe haumia aila a me nā pilikia maikaʻi ʻē aʻe i loko a i waho o ka paipu kila | ||

| 101 | ʻO ka hōʻike i hoʻopuka ʻia e | E hoʻopihapiha e like me GB/ T241-2007 maʻamau (P2) a me nā laʻana kūikawā kūloko (i hoʻouna ʻia i triplicate i ka ʻoihana hana, ke keʻena nānā maikaʻi, me ka paipu kila pickling hoʻokahi kope).ʻAʻole ʻae ʻia ka hoʻopunipuni | ||

| Hoʻāʻo pickling | E hōʻemi i ka mana maikaʻi ʻole i ka hana aʻe | 102 | Hōʻike hōʻike | E hōʻoia i ka mānoanoa o ka pā maoli, kikoʻī a i ʻole ka hui ʻana o ka lepili a me ka paipu welded ma ke ana ʻana a me ke kaupaona ʻana. |

| 103 | Ho'āʻo unroundness | E hōʻoia i ka unroundness o ka paipu kila e like me ke kūlana aupuni GB/T 3091-2015 (P4) | ||

| 104 | Ho'āʻo ana i ka lōʻihi | E hōʻoia i ka lōʻihi o ka paipu kila ma ka laina me ka pae aupuni GB/T 3091-2015 (P5) (6 mika, ʻae ʻia ʻae ʻae +20mm) | ||

| 105 | Nānā anawaena o waho | E hōʻoia i ke anawaena o waho o ka paipu kila i nā koi o GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Hōʻike wehe | E nānā inā ua ʻoki ʻia ka hopena o ka paipu | ||

| 107 | Hoʻāʻo haʻihaʻi | Ma hope o ka hammer haʻalulu, ʻaʻohe mea pohā ma ka pā kuʻi | ||

| 108 | Nānā hui | E nānā i ka paipu hoʻokahi no ka loaʻa ʻana o kahi hanana docking | ||

| 109 | Nānā paipu ʻāwili | E nānā maka inā he lepo, pena, ʻaila ʻaila a me nā paipu ʻele ma ka ʻili o ka paipu kila | ||

| 110 | Nānā lua palahalaha | E nānā maka inā he mau lua kūloko ka ʻili o ka paipu kila ma muli o nā mana o waho | ||

| 111 | Nānā i ka ʻili o ka lua (lua) | Ke hoʻohana nei i ka nānā ʻike maka, e hoʻopā lima i ka ʻili o ka paipu kila inā aia kahi kiko o ka mea ʻeha | ||

| 112 | E nānā inā kūpono ka pahu kuʻihao o loko | No ka pale ʻana i ka loaʻa ʻole o ka pā kuʻi kūloko (me ka wili hoʻopunipuni) a i ʻole ka pahu kuʻi kūloko ma mua o ka maʻamau a me nā pilikia ʻē aʻe; ʻAʻole paʻa, ʻaʻole kūlike, a i ʻole ka liʻiliʻi ma mua o 0.5mm | ||

| 113 | Nānā Burr | E nānā maka inā he mau ʻāpana keu ʻole i loko a i waho o ka hopena paipu. Ma hope o ka hoʻomaʻamaʻa ʻana, pono e emi ka burr o ka hopena o ka paipu ma mua o 0.5mm i mea kūpono | ||

| 114 | Nānā waha waha | No ka pale ʻana i ka wehe ʻana a i ʻole ka deformation i hana ʻia i ka makau a me ka hana hosting | ||

| 115 | Nānā māwae hoʻoikaika | Ma ka hoʻopololei ʻana a i ʻole ka hoʻāʻo palahalaha, ʻike ʻia ka pahu kuʻi o ka paipu kila e pale aku i ka noho ʻana o nā māwae liʻiliʻi. E nānā i ka Paukū 8 o ka P6 o ka Quality Control and Management System no ka hoʻāʻo ʻana | ||

| 116 | Ka nānā ʻana i ka ʻōpala | E hōʻoia i ka ʻili ʻana o ka lāʻau kuʻihao i ka ʻili maʻemaʻe, ka ʻili poepoe | ||

| 117 | Nānā awa kūʻokoʻa | E hōʻalo i ke ʻano o ke kaomi pelu ʻana ma ka hili kuʻi ʻana i hoʻokumu ʻia e nā kumu kumu a i ʻole nā kumu mechanical | ||

| 118 | Hoʻāʻo ʻili pālua | E hōʻalo i ka hanana o ka paipu kila me ka ʻili pālua | ||

| 119 | Poʻai i ke ʻano ʻohe | No ka pale ʻana i ka ʻili o ka paipu kila mai nā slubby dents | ||

| 120 | Ka nānā ʻana i ka lap weld | ʻO ka nānā ʻana i mea e pale aku ai i ke ʻano o ka hoʻoheheʻe ʻia ʻana ma luna o ka pahu wili kila | ||

| 121 | Nānā makaʻala | Nānā maka e pale aku i nā kiko wiliwili ma ka ʻili o ka paipu kila | ||

| 122 | Puka one, nānā | Nānā maka e pale aku i nā puka ma ka ʻili o ka paipu kila | ||

| 123 | Oki hoao | E kiʻi i ke kino paipu ma lalo o ka mea ʻoki kinoea i mea e hōʻoia ai ʻaʻohe ʻoki a poino paha | ||

| 124 | ʻAʻole kūpono i ka pickling galvanized sundries | ʻO ka nānā ʻana e hōʻoia i ka ʻole o ka aila, ka pena a me nā mea ʻē aʻe ʻaʻole maʻalahi e huki i nā ʻōpala, e pale i ka leakage o ka plating. | ||

| ʻO ka paipu kila pickling | Wehe i nā mea like ʻole e like me ka unahi oxide i hana ʻia ma ka ʻili o ka paipu kila | 125 | ʻO ke kuʻina o ka ʻakika | Pono e mālama ʻia ka maʻiʻo o ka hydrogen chloride i loko o ka ʻakika ma 20% -24% |

| 126 | Ka nānā ʻana i lalo o ka paipu kila | No ka pale ʻana i (1) lawa ʻole ka manawa pickling, haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa, haʻahaʻa haʻahaʻa (pono e hoʻomalu ʻia ka mahana ma 25-40 ℃, ʻoi aku ka nui o ka waikawa o ka hydrogen chloride he 20% -24%) (2) nā manawa haʻalulu liʻiliʻi o ka pūpū paipu (3) ka noho ana o ka silicate i loko o ka umu ahi welded paipu kila | ||

| hoʻopili huahana | Hoʻopili ʻia e like me ka helu o nā paipu kila i kēlā me kēia ʻāpana | 127 | Nānā kāʻei paʻi | ʻO ka paʻi ʻana o ka paipu kila he hexagonal, 6 mau kāʻei paʻi, hana ʻia i loko o kā mākou hale hana, nā ʻaoʻao ʻelua o ke kāʻei packing mai ka hopena o ka hewa o ± 10mm, e hoʻokaʻawale like ʻia ka waena 4, pono e hoʻopili ʻia ka hoʻopili ʻana i ke kāʻei. ʻAʻole ʻae ke kāʻei paʻa i ka deflection, pono e ʻoki ʻia ke kāʻei packing ma ka hui o 45 ° Angle, pono e hoʻokō i nā koi. |

| 128 | Nānā hōʻailona | Pono ka ʻike, piʻi ka mokulele i luna, pono e hoʻopili pono ʻia ka hōʻailona paipu i hoʻopau ʻia ma kēlā me kēia paipu paipu e hoʻolike i ka ʻaoʻao ʻākau o ke kāʻei hoʻopili kuʻihao mua i waenakonu, a ʻo ke kumu ʻo Ted embellish kākau i akaka a ʻaʻole piʻi. |