YuantaiDerunPhaephe e nang le likhutlo tse 'ne e sekoere e na le litokelo tsa molao tse fetang 63, tse fihlelang maemo a indasteri lapeng le kantle ho naha. Sehlahisoa se fetile lihokelo tsa tlhahlobo tse fetang 200 ho laola boleng ba sehlahisoa.

"Ka tieo u se ke ua lumella phaephe ea tšepe e sa tšoaneleheng ho kena 'marakeng".

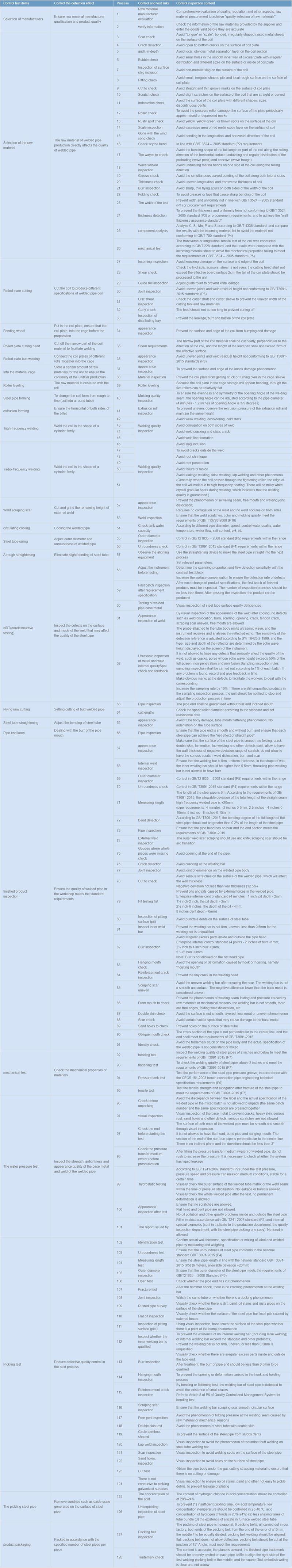

| Lintho tsa teko ea taolo | Laola phello ea ho lemoha | Tshebetso | Lihokelo tsa taolo le liteko | Dikahare tsa tlhahlobo ya taolo |

| Khetho ea bahlahisi | Netefatsa hore na moetsi oa thepa e tala o tšoaneleha hakae le hore na o na le boleng bofe ba sehlahisoa. | 1 | Tlhahlobo ea moetsi oa thepa e tala | Tlhahlobo e felletseng ea boleng, botumo le likarolo tse ling, theko ea thepa e tala ho fihlela "khetho ea boleng ba thepa e tala" |

| 2 | netefatsa tlhahisoleseling | Hlahloba tlhahisoleseding ea thepa e tala e fanoeng ke mofani oa thepa 'me u kene ka jareteng ea thepa pele e nepahala. | ||

| Khetho ea thepa e tala | Thepa e tala ea tlhahiso ea liphaephe tse phuthetsoeng e ama ka kotloloho boleng ba liphaephe tse phuthetsoeng | 3 | Tlhahlobo ea maqeba | Qoba "leleme" kapa "sekala", maqephe a tšepe a phahamisitsoeng a tlamiloeng, a nang le sebopeho se sa tloaelehang holim'a khoele |

| 4 | Ho lemoha mapetso | Qoba mapetso a tlase a ntlha e bulehileng holim'a poleiti ea coil | ||

| 5 | tlhahlobo e tebileng | Qoba lera la karohano ea tšepe le totobetseng karolong ea koili | ||

| 6 | Tlhahlobo ea lipululana | Qoba masoba a manyane leboteng le boreleli la ka hare la poleiti e chitja ka kabo e sa tloaelehang le boholo bo fapaneng holim'a kapa kahare ho poleiti ea coil. | ||

| 7 | Tlhahlobo ea ho kenyelletsoa ha slag holim'a metsi | Qoba slag e seng ea tšepe holim'a koili | ||

| 8 | Tlhahlobo ea ho lahla | Qoba masoba a manyane, a nang le sebopeho se sa tloaelehang le bokaholimo bo makukuno ba sebaka seo holim'a poleiti ea coil. | ||

| 9 | Seha ho hlahloba | Qoba matshwao a otlolohileng le a masesaane a groove holim'a poleiti ea coil | ||

| 10 | Tlhahlobo ea ho ngoapa | Qoba ho ngoatheha hanyane holim'a khoele e otlolohileng kapa e kobehileng | ||

| 11 | Tlhahlobo ea ho kenella kahare | Qoba bokaholimo ba poleiti ea koili bo nang le libopeho tse fapaneng, boholo, le matheba a sa khaotseng | ||

| 12 | Tlhahlobo ea rolara | Ho qoba tšenyo ea rolara ea khatello, bokaholimo ba poleiti bo hlaha nako le nako ka matšoao a phahamisitsoeng kapa a tepeletseng. | ||

| 13 | Tlhahlobo ea sebaka se senyehileng | Qoba matheba a mosehla, a mosehla-botala, kapa a sootho holim'a khoele | ||

| 14 | Tlhahlobo ea sekala | Qoba sebaka se feteletseng sa lera le lefubelu la tšepe oxide holim'a coil | ||

| 15 | Ke ile ka sheba pina ea ho qetela ka moea | Qoba ho kobeha ka lehlakoreng le lelelele le le otlolohileng la khoele | ||

| 16 | Hlahloba kobeho ea scythe | Ho latela litlhoko tsa maemo a GB/T 3524 -- 2005 (P2) | ||

| 17 | Maqhubu a lokelang ho hlahlojoa | Qoba sebopeho se kobehang sa bolelele bohle kapa karolo ea khoele ho latela tsela e bilikanang ea bokaholimo bo rapameng bo ntseng bo thella le kabo e tloaelehileng ea karolo e hlahellang (tlhōrō ea leqhubu) le e kobehileng (sejana sa leqhubu) | ||

| 18 | Tlhahlobo ea maqhubu a ho sosobana | Qoba ho kobeha ha marina ka lehlakoreng le leng la koili ho latela tsela eo e phethohang ka yona | ||

| 19 | Tlhahlobo ea groove | Qoba ho kobeha ha koili ka nako e le 'ngoe mahlakoreng ka bobeli | ||

| 20 | Tlhahlobo ea botenya | Qoba botenya bo sa lekanang ba koili e telele le e tšekaletseng | ||

| 21 | Tlhahlobo ea Burr | Qoba li-spurs tse bohale, tse tšesaane tse fofang mahlakoreng ka bobeli a bophara ba koili | ||

| 22 | Tlhahlobo ea ho mena | Ho qoba ho kobeha kapa ho kgutla ho bakang ho kobeha ho bohale ha khoele | ||

| 23 | Bophara ba teko | Thibela bophara le ho tšoana ho sa tsamaellaneng le maemo a GB/T 3524 -- 2005 (P4) kapa litlhoko tsa theko | ||

| 24 | ho lemoha botenya | Ho thibela botenya le ho tšoana hore li se ke tsa lumellana le maemo a GB/T 3524 -- 2005 (P3) kapa litlhoko tsa theko, le ho fihlela "maemo a netefatso ea botenya ba lebota" | ||

| 25 | tlhahlobo ea likarolo | Sekaseka C, Si, Mn, P le S ho latela maemo a GB/T 4336, 'me u bapise liphetho le lethathamo la lintho tse kenang ho qoba hore thepa e se lumellane le maemo a GB/T 700 (P4) | ||

| 26 | teko ea mechini | Teko ea ho thapolla ka tsela e tšekaletseng kapa e telele ea khoele e entsoe ho latela maemo a GB/T 228, 'me liphetho li ile tsa bapisoa le leqephe la thepa le kenang ho qoba hore thepa ea mechini e hlōlehe ho fihlela litlhoko tsa maemo a GB/T 3524 -- 2005 (P5). | ||

| Ho seha poleiti e phutholohileng | Seha khoele ho hlahisa litlhaloso tse fapaneng tsa khoele ea phaephe e welletsoeng | 27 | Tlhahlobo e tlang | Qoba ho senya bokaholimo le bohale ba khoele |

| 28 | Tlhahlobo ea ho kuta | Hlahloba sekere sa haeteroliki, ho kuta ha ho lekana, hlooho e sehang ha ea lokela ho feta bokaholimo ba boto bo sebetsang ka 2cm, mohatla oa poleiti ea koili o lokela ho sebetsoa ho ea yuniti. | ||

| 29 | Tlhahlobo ea moqolo oa tataiso | Lokisa rolara ea tataiso ho thibela ho dutla ha thipa | ||

| 30 | Tlhahlobo e kopanetsoeng | Qoba manonyeletso a sa lekanang le ho weld bolelele bo setseng ba ho tjheseletsa bo sa lateleng maemo a GB/ T3091-2015 (P8) | ||

| 31 | Tlhahlobo ea ho kuta diski | Hlahloba sehahi sa ho seha le sehahi sa ho seha ho thibela bophara bo sa lekanang ba sesebelisoa sa ho seha le thepa e tala. | ||

| 32 | Tlhahlobo e kobehileng | Sejo ha sea lokela ho ba selelele haholo ho thibela ho kobeha | ||

| 33 | Tlhahlobo ea terei ea kabo | Thibela ho dutla, ho phunya le ho kokotela ha poleiti ya khoele | ||

| Lebili la ho fepa | Kenya poleiting ea koili, etsa bonnete ba hore poleiti ea koili, e kene ka har'a lesaka pele u lokisetsa. | 34 | tlhahlobo ea ponahalo | Thibela bokaholimo le bohale ba koili hore e se ke ea thula le ho senyeha |

| Hlooho ea ho itšeha poleiti e phutholohileng | Seha karolo e tšesaane ea thepa ea koili ho nolofatsa ho tjheseletsa | 35 | Litlhoko tsa ho kuta | Karolo e moqotetsane ea thepa ea koili e lokela ho sehoa ka hloko, e otlolohile ho ea ka lehlakoreng la koili, 'me bolelele ba karolo ea lead bo ke ke ba feta 2cm ea bokaholimo bo sebetsang. |

| Ho tjheseletsa poleiti e phutholohileng | Kopanya lipoleiti tsa koili tsa meqolo e fapaneng Hammoho ka har'a lesaka | 36 | tlhahlobo ea ponahalo | Qoba manonyeletso a sa lekanang le ho weld bolelele bo setseng ba ho tjheseletsa bo sa lateleng maemo a GB/ T3091-2015 (P8) |

| Ka hara lesaka la thepa | Boloka palo e itseng ea thepa e tala bakeng sa yuniti ho netefatsa hore tlhahiso ea yuniti e tsoela pele. | 37 | tlhahlobo ea ponahalo | Ho thibela bokaholimo le bohale ba ketsahalo ea tšenyo e kokotang |

| 38 | Tlhahlobo ea thepa | Thibela poleiti ea koili hore e se ke ea khomarela kapa ea phethoha ka har'a sleeve ea lesaka | ||

| Ho leka-lekanya lirolara | Thepa e tala e bohareng ba moqolo | 39 | Ho leka-lekanya lirolara | Hobane poleiti ea koili e polokelong ea lesaka e tla bonahala e kobehile, ka har'a lirolo tse hlano e ka ba bataletse haholo. |

| Ho etsa phaephe ea tšepe | Ho fetola sebopeho sa koili ho tloha ho e khohlahetseng ho ea ho e tšesaane (koili ho ea ho tube e chitja) | 40 | Tlhahlobo ea boleng ba ho bopa | Ho netefatsa hore ho na le tekano le ho lekana ha sekhutlo sa ho bula sa moamo wa ho tjheseletsa, sekhutlo sa ho bula se ka fetoloa ho latela bophara ba phaephe. (Metsotso e 4 - lisenthimithara tse 1.2 tsa ho bula. Sekhutlo ke likhato tse 3-5) |

| ho theha extrusion | Netefatsa hore mahlakore ka bobeli a billet a rapaletse | 41 | Tlhahlobo ea moqolo oa extrusion | Ho thibela ho se lekane, hlokomela khatello ea extrusion ea moqolo oa extrusion 'me u boloke bophahamo bo lekanang. |

| ho tjheseletsa maqhubu a phahameng | Tšela khoele ka sebopeho sa silindara ka thata | 42 | Tlhahlobo ea boleng ba ho tjheseletsa | Qoba ho tjheseletsa ho fokolang, ho tlosa litšepe, le ho bokellana ho batang |

| 43 | Qoba ho tjheseletsa mahlakore ka bobedi a weld | |||

| 44 | Qoba ho petsoha ha welding le ho petsoha ho sa fetoheng | |||

| 45 | Qoba ho thehoa ha mola oa ho tjheseletsa | |||

| ho tjheseletsa maqhubu a radio | Tšela khoele ka sebopeho sa silindara ka thata | 46 | Tlhahlobo ea boleng ba ho tjheseletsa | Qoba ho kenyelletsoa ha litšila |

| 47 | Ho qoba mapetso ka ntle ho weld | |||

| 48 | Qoba ho fokotseha ha metso | |||

| 49 | Qoba ho kenella ha metso | |||

| 50 | Qoba ho hloleha ha ho kopanya | |||

| 51 | Qoba ho tjheseletsa ka ho dutla ha metsi, ho tjheseletsa ka bohata, ho tjheseletsa ka mahlakore le diketsahalo tse ding. (Ka kakaretso, ha khoele e feta ka har'a rolara e tiisang, lehlakore la khoele le tla qhibiliha ka lebaka la ho futhumala ha maqhubu a mangata. Ho tla ba le tlhase e tšoeu ea kristale e tšoeu e kang lebese nakong ea ho tjheseletsa, e leng se bontšang hore boleng ba ho tjheseletsa bo tiisitsoe.) | |||

| Lebadi la ho hohla ka weld | Seha 'me u sila bolelele bo setseng ba weld ea kantle | 52 | tlhahlobo ea ponahalo | Thibela ketsahalo ea ho potoloha ha seam, molomo o lokolohileng le ho tjheseletsa manonyeletso; Ha e hloke ho tjheseletsa ha weld mme ha e hloke di-nodule tsa weld mahlakoreng ka bobedi. |

| 53 | Tlhahlobo ea ho tjheseletsa | Netefatsa hore ho tjheseletsa, mmala le boleng ba ho bopa di fihlella ditlhoko tsa GB/ T13793-2008 (P10) | ||

| ho pholisa ho potoloha | Ho pholisa phaephe e tjheseditsweng | 54 | Hlahloba bokgoni ba metsi a tanka | Ho latela bophara bo fapaneng ba phaephe, lebelo, boleng ba metsi ba taolo, mocheso oa metsi, phallo ea metsi, letsoai, pH, jj. |

| Saese ea tube ea tšepe | Fetola bophara ba kantle le ho se tsitse ha phaephe e welletsoeng | 55 | Tlhahlobo ea bophara ba kantle | Taolo ho GB/T21835 -- litlhoko tsa maemo a tloaelehileng (P5) tsa 2008 ka har'a sebaka seo |

| 56 | Tlhahlobo ea ho se tsitse ha sekoli | Taolo ho litlhoko tsa maemo a GB/ T3091-2015 (P4) ka har'a sebaka seo | ||

| Ho otlolla ka thata | Tlosa ho kobeha hanyane ha tube ea tšepe | 57 | Sheba lisebelisoa tsa ho li hokahanya | Sebelisa sesebelisoa sa ho otlolla ho etsa hore phaephe ea tšepe e otlolohe ts'ebetsong e latelang |

| NDT (teko e sa senyeheng) | Hlahloba diphoso tse ka hodima le kahare ho weld tse ka amang boleng ba phaephe ya tshepe | 58 | Lokisa sesebelisoa pele o se leka | Beha diparamente tse amehang; Fumana tekanyo ea ho skena le kutloisiso ea ho lemoha liphoso ka block ea teko ea phapang; Eketsa puseletso ea bokaholimo ho netefatsa sekhahla sa ho lemoha liphoso |

| 59 | Tlhahlobo ea pele ea sehlopha kamora tlhaloso ea ho nkela sebaka | Kamora phetoho e 'ngoe le e 'ngoe ea litlhaloso tsa sehlahisoa, sehlopha sa pele sa lihlahisoa tse felileng se tlameha ho hlahlojoa. Palo ea makala a tlhahlobo ha ea lokela ho ba ka tlase ho a mararo. Kamora ho feta tlhahlobong, sehlahisoa se ka hlahisoa. | ||

| 60 | Teko ea tšepe ea motheo ea phaephe e bōpehileng joaloka welded | Tlhahlobo e bonahalang ea mefokolo ea boleng ba tube ea tšepe | ||

| 61 | Tlhahlobo ea ponahalo ea weld | Ka tlhahlobo ea ponahalo ea weld ka mor'a ho pholile, ha ho na liphoso tse kang ho senyeha ha weld, ho chesa, maqeba, ho buleha, ho petsoha ha tendon, leqeba le sa lekanang, molomo o lokolohileng o lumelloang. | ||

| 62 | Tlhahlobo ea Ultrasonic ea boleng ba ka hare ba tšepe le ho tjheseletsaTlhahlobo ea sebaka le maikutlo | Sesebediswa se hoketsweng mmeleng wa tube se ntsha leqhubu la ultrasound, mme sesebediswa se amohela le ho sekaseka modumo o bonahaditsweng. Kutloisiso ya referense ya ho lemoha e lokiswa ho ya ka SY/ T6423.2-1999, mme mofuta, boholo le botebo ba sebonela-hōle di laolwa ke bophahamo ba leqhubu la modumo bo bontshwang skrineng sa sesebediswa. Ha hoa lumelloa ho ba le mefokolo efe kapa efe e amang boleng ba weld ka botebo, joalo ka mapetso, masoba ao bophahamo ba leqhubu la echo bo fetang 50% ea skrine e felletseng, ho se kenelle le ho se kopane. Melao ea tlhahlobo ea disampole: tlhahlobo ea disampole e tla etsoa ho latela 1% ea sehlopha ka seng. Haeba ho fumanoa bothata, ngola 'me u fane ka maikutlo ka nako. Etsa matshwao a totobetseng diphosong ho thusa basebetsi ho sebetsana le tse tsamaellanang le tsona; Eketsa sekhahla sa ho nka sampole ka 10%. Haeba ho ntse ho e-na le lihlahisoa tse sa tšoaneleheng ts'ebetsong ea tlhahlobo ea sampole, yuniti e lokela ho tsebisoa hore e emise 'me e fetole ts'ebetso ea tlhahiso ka nako. | ||

| Ho seha sakha se fofang | Ho seta ha phaephe e tjhisitsweng ka mokokotlo | 63 | Tlhahlobo ea liphaephe | Qetello ea phaephe e tla tiisetsoa ntle le burr le molomo o sekametseng |

| 64 | bolelele ba sehiloeng | Hlahloba bophara ba rolara ea lebelo ho latela maemo a tloaelehileng 'me u behe lintlha tse utloahalang | ||

| Ho otlolla tube ea tšepe | Lokisa ho kobeha ha tube ea tšepe | 65 | tlhahlobo ea ponahalo | Qoba tšenyo ea 'mele oa tube, ketsahalo ea ho batalla ha molomo oa tube; Ha ho na ho kenella holim'a tube |

| Boloka pheletso ea liphaephe | Ho sebetsana le lesoba la molomo oa phaephe | 66 | Tlhahlobo ea liphaephe | Netefatsa hore pheletso ea phaephe e boreleli ebile ha e na burr, 'me u netefatse hore phaephe e' ngoe le e 'ngoe ea tšepe e ka fihlela "phello ea letlooa ea phaephe e otlolohileng". |

| tlhahlobo ea sehlahisoa se felileng | Netefatsa hore boleng ba phaephe e welletsoeng ka har'a workshop bo fihlela litlhoko tse tloaelehileng | 67 | tlhahlobo ea ponahalo | Etsa bonnete ba hore bokaholimo ba phaephe ea tšepe bo boreleli, ha ho na menahano, mapetso, letlalo le habeli, lamination, ho tjheseletsa mahlakore le liphoso tse ling, lumella botenya ba lebota ho ba le mefuta e fapaneng ea ho kheloha ho fosahetseng ha ho ngoatheha, u se ke ua lumella ho ba le mongobo o tebileng, ho senyeha ha weld, ho chesa le lebadi. |

| 68 | Tlhahlobo ea ho tjheseletsa ka hare | Netefatsa hore bara ea ho tjheseletsa e tiile, botenya bo ts'oanang, ka sebopeho sa terata, bara ea ho tjheseletsa e ka hare e lokela ho ba holimo ho feta 0.5mm, bara ea ho tjheseletsa ea phaephe ea khoele ha ea lumelloa ho ba le burr | ||

| 69 | Tlhahlobo ea bophara ba kantle | Taolo ho GB/T21835 -- litlhoko tsa maemo a tloaelehileng (P5) tsa 2008 ka har'a sebaka seo | ||

| 70 | Tlhahlobo ea ho se tsitse ha sekoli | Taolo ho litlhoko tsa maemo a GB/ T3091-2015 (P4) ka har'a sebaka seo | ||

| 71 | Bolelele ba ho lekanya | Bolelele ba phaephe ya tshepe ke 6m. Ho ya ka ditlhoko tsa GB/ T3091-2015, kheloho e dumelletsweng ya bolelele bohle ba phaephe e otlolohileng e welditsweng ka maqhubu a hodimo ke +20mm. (Litlhoko tsa liphaephe: Metsotso e 4 - lisenthimithara tse 2 0-5mm, lisenthimithara tse 2.5 - lisenthimithara tse 4 0-10mm, lisenthimithara tse 5 - lisenthimithara tse 8 0-15mm) | ||

| 72 | Ho lemoha ho kobeha | Ho ya ka GB/ T3091-2015, tekanyo ya ho kobeha ha bolelele bohle ba phaephe ya tshepe ha ea lokela ho feta 0.2% ya bolelele ba phaephe ya tshepe. | ||

| 73 | Tlhahlobo ea liphaephe | Netefatsa hore hlooho ea phaephe ha e na burr le hore karolo ea ho qetela e fihlela litlhoko tsa GB/ T3091-2015. | ||

| 74 | Tlhahlobo ea ho tjheseletsa kantle | Ho hohla lebadi la weld ka ntle ho lokela ho sebedisa thipa ya arc, ho hohla lebadi ho lokela ho ba phetoho ya arc | ||

| 75 | Li-gouges moo likotoana tse felletseng li neng li le sieo cheke | Qoba ho buleha qetellong ea phaephe | ||

| 76 | Ho lemoha mapetso | Qoba ho petsoha bareng ea ho tjheseletsa | ||

| 77 | Tlhahlobo e kopanetsoeng | Qoba ketsahalo ea manonyeletso 'meleng oa phaephe e svetselitsoeng | ||

| 78 | Seha ho hlahloba | Qoba ho ngoatha ho hoholo holim'a phaephe e tjheseditsweng, e leng se tla ama botenya ba lebota. Ho kheloha ho fosahetseng ho seng ka tlase ho botenya ba lebota (12.5%) | ||

| 79 | Teko ea sekoti e bataletseng | Thibela mekoti le mekoti e bakoang ke matla a kantle ka har'a phaephe e tjheselitsoeng. Tekanyetso ea taolo ea kahare ea khoebo (metsotso e 4 - intshi e le 1, botebo ba mokoti <2mm; 1¼ inch-2 inch, botebo ba mokoti <3mm; 2½ inch-6 inches, botebo ba mokoti <4mm; Botebo ba sekoti sa lisenthimithara tse 8 <6mm) | ||

| 80 | Tlhahlobo ea bokaholimo ba mokoti (mokoti) | Qoba ho phunya matheba holim'a tube ea tšepe | ||

| 81 | Hlahloba bara ea ka hare ea weld | Thibela hore bareng ea ho tjheseletsa e se ke ea tiea, e sa lekana, e ka tlase ho 0.5mm hobane bareng ea ho tjheseletsa ha e tšoanelehe | ||

| 82 | Tlhahlobo ea Burr | Qoba likarolo tse sa tloaelehang tse feteletseng kahare le ka ntle ho hlooho ea phaephe. Tekanyetso ea taolo ea ka hare ea khoebo (lintlha tse 4 - lisenthimithara tse 2 tsa burr <1mm; Bolelele ba lisenthimithara tse 2½ ho isa ho tse 4 <2mm; 5 "- 8" burr <3mm. Ela Hloko: Burr ha e dumellwe hodima phaephe ya hlooho ya netweke. | ||

| 83 | Tlhahlobo ea molomo o leketlileng | Qoba ho buleha kapa ho fetoha ho bakoang ke ho hokela kapa ho phahamisa, e leng "molomo o phahamisang" | ||

| 84 | Tlhahlobo ea mapetso a matlafatso | Thibela lekhalo le lenyenyane la sefaha sa ho welding | ||

| 85 | Ho hula lebadi ho sa leka-lekaneng | Qoba ho tjheseletsa ho sa lekanang ka mora ho hohla lebadi. Ho tjheseletsa ha se bokaholimo bo boreleli ba arc. Phapang e mpe e ka tlase ho tšepe ea motheo e nkoa e sa lekana | ||

| 86 | Ho tloha molomong ho ea ho hlahloba | Thibela ketsahalo ea ho phutha seam le khatello e bakoang ke thepa e tala kapa mabaka a mechini, bareng ea ho phutha ha e boreleli, ho na le mathoko a lokolohileng, ho phutha weld ho phutha, jj. | ||

| 87 | Tlhahlobo ea letlalo habeli | Qoba bokaholimo ha bo boreleli, bo arotsoe ka mekhahlelo, nama e nyane kapa ketsahalo e sa lekanang | ||

| 88 | Tlhahlobo ea maqeba | Qoba matheba a ho tjheseletsa a ka bakang tshenyo tshepeng ya motheo | ||

| 89 | Masoba a lehlabathe a lokelang ho hlahlojoa | Thibela masoba holim'a tube ea tšepe | ||

| 90 | Tlhahlobo ea molomo o oblique | Karolo e tšelang ea phaephe ha e otlolohe moleng o bohareng, 'me pheletso e tla fihlela litlhoko tsa GB/ T3091-2015 | ||

| 91 | Tlhahlobo ea boitsebiso | Qoba letšoao la khoebo le khomaretseng 'meleng oa phaephe 'me tlhaloso ea sebele ea phaephe e bōpehileng joaloka welded ha e lumellane kapa ha e tsoakane | ||

| teko ea mechini | Hlahloba thepa ea mechini ea thepa | 92 | teko ea ho kobeha | Hlahloba boleng ba ho tjheseletsa liphaephe tsa tšepe tsa lisenthimithara tse 2 le ka tlase ho fihlela litlhoko tsa GB/ T3091-2015 (P7) |

| 93 | teko ea ho batalatsa | Ho hlahloba boleng ba ho tjheseletsa ba liphaephe tsa tšepe tse fetang lisenthimithara tse 2 le ho fihlela litlhoko tsa GB/ T3091-2015 (P7) | ||

| 94 | Teko ea tanka ea khatello | Leka tshebetso ya mokoti wa kgatello ya phaephe ya tshepe, ho ya ka ditlhoko tsa CECS 151-2003 tsa boenjiniere ba phaephe ya kgokelo ya terenje (P9) | ||

| 95 | teko ea ho tsitlella | Leka matla a ho thapolla le ho lelefala ha phaephe ya tshepe kamora ho robeha ho fihlela ditlhoko tsa GB/ T3091-2015 (P7) | ||

| Teko ea khatello ea metsi | Hlahloba matla, ho se kene moea le boleng ba ponahalo ea tšepe ea motheo le weld ea phaephe e welded | 96 | Hlahloba pele o pakolla | Qoba phapang pakeng tsa leibole le tlhaloso ea 'nete ea phaephe e welded kapa sehlopha se kopaneng ha se lumelloe ho pakolla (nomoro e tšoanang ea sehlopha le tlhaloso e tšoanang li hatelloa hammoho |

| 97 | tlhahlobo ea pono | Tlhahlobo ea mahlo ea tšepe ea motheo ho thibela mapetso, letlalo le boima, mafome a tebileng, masoba a lehlabathe le liphoso tse ling, maqeba a tebileng ha a lumelloe | ||

| 97 | Hlahloba qetello pele o qala teko | Bokaholimo ba lipheletso ka bobeli tsa phaephe e tjheselitsoeng bo tlameha ho ba boreledi le boreledi ka tlhahlobo e bonahalang. Ha ea lumelloa ho ba le hlooho e bataletseng, phaephe e kobehileng le molomo o leketlileng. Karolo ea pheletso ea phaephe e sa burr e otlolohile ho ea moeling o bohareng. Ha ho na moeli o sekametseng 'me ho kheloha ho lokela ho ba ka tlase ho 3° | ||

| 98 | Hlahloba sebaka sa phetisetso ea khatello (metsi) pele u hatella | Kamora ho tlatsa sehatsetsi sa phetisetso ya kgatello (metsi) sa phaephe e welletsoeng, o se ke wa potlakela ho eketsa kgatello. Ho bohlokwa ho hlahloba hore na sistimi e na le ho dutla ha metsi. | ||

| 99 | tlhahlobo ea hydrostatic | Ho ya ka maemo a GB/ T241-2007 (P2) tlasa kgatello ya teko, lebelo la kgatello le maemo a mahareng a phetiso ya kgatello, a tsitsitseng ka nako e itseng. Sheba ka mahlo bokaholimo ba kantle ba matrix ea tube e welded kapa seam ea weld nakong ea ho tsitsisa khatello. Ha ho lutlehe ho lutla kapa ho phatloha. Hlahloba phaephe eohle e welletsoeng ka mahlo kamora teko, ha ho na phetoho ea kamehla e lumelloang | ||

| 100 | Tlhahlobo ea ponahalo kamora tlhahlobo | Netefatsa hore ha ho dumellehe ho ngoatha; Hlooho e bataletseng le phaephe e kobehileng ha lia lumelloa. Ha ho tšilafalo ea oli le mathata a mang a boleng kahare le kantle ho phaephe ea tšepe | ||

| 101 | Tlaleho e ntšitsoeng ke | Tlatsa ho latela maemo a GB/ T241-2007 (P2) le mehlala e ikhethang ea kahare (e rometsoe habeli lefapheng la tlhahiso, lefapheng la tlhahlobo ea boleng, 'me phaephe ea tšepe e qhibilihisoa kopi e le 'ngoe). Ha ho na bolotsana bo lumelloang. | ||

| Teko ea ho seha | Fokotsa taolo ea boleng bo nang le liphoso ts'ebetsong e latelang | 102 | Teko ea boitsebiso | Netefatsa botenya ba lebota, tlhaloso kapa ho kopanya leibole le phaephe e welletsoeng ka ho lekanya le ho bekha |

| 103 | Teko ea ho se tsitse | Netefatsa hore ho se tsitse ha phaephe ea tšepe ho latela maemo a naha a GB/T 3091-2015 (P4) | ||

| 104 | Teko ea bolelele ba ho lekanya | Netefatsa bolelele ba phaephe ea tšepe bo tsamaellana le maemo a naha a GB/T 3091-2015 (P5) (limithara tse 6, ho kheloha ho lumelletsoeng +20mm) | ||

| 105 | Tlhahlobo ea bophara ba kantle | Netefatsa hore bophara ba kantle ba phaephe ea tšepe bo fihlela litlhoko tsa GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Teko e bulehileng | Hlahloba hore na pheletso ea phaephe e na le ketsahalo e sehiloeng | ||

| 107 | Teko ea ho robeha ha moriri | Kamora ho thothomela ha hamore, ha ho na ketsahalo e phatlohileng bareng ea ho tjheseletsa | ||

| 108 | Tlhahlobo e kopanetsoeng | Shebella tube e tšoanang ho bona hore na ho na le ketsahalo ea ho emisa | ||

| 109 | Phuputso ea liphaephe tse rusitseng | Hlahloba ka mahlo hore na ho na le litšila, pente, matheba a oli le liphaephe tse rusitseng holim'a phaephe ea tšepe. | ||

| 110 | Tlhahlobo ea sekoti se bataletseng | Hlahloba ka mahlo hore na bokaholimo ba phaephe ea tšepe bo na le masoba a sebakeng seo a bakoang ke matla a kantle | ||

| 111 | Tlhahlobo ea bokaholimo ba likoti (likoti) | U sebelisa tlhahlobo ea pono, ama bokaholimo ba phaephe ea tšepe ka letsoho hore na ho na le ntlha ea ketsahalo ea bump | ||

| 112 | Hlahloba hore na bareng ea ho tjheseletsa ea ka hare e tšoaneleha | Ho thibela boteng ba ho se be le terata ya ho tjheseletsa kahare (ho kenyeletsoa le terata ya bohata) kapa terata ya ho tjheseletsa kahare e fetang maemo le mathata a mang; Thibela hore bareng ea ho tjheseletsa e se ke ea tiea, e sa leka-lekane, kapa e ka tlase ho 0.5mm ha e tšoanelehe | ||

| 113 | Tlhahlobo ea Burr | Hlahloba ka mahlo hore na ho na le likarolo tse sa tloaelehang tse feteletseng kahare le ka ntle ho pheletso ea tube. Kamora kalafo, karolo e ka tlase ea phaephe e lokela ho ba ka tlase ho 0.5mm ho tšoaneleha. | ||

| 114 | Tlhahlobo ea molomo o leketlileng | Ho thibela ho buleha kapa ho fetoha ha sebopeho ho bakoang ke ho hokela le ho phahamisa | ||

| 115 | Tlhahlobo ea mapetso a matlafatso | Ka teko ea ho kobeha kapa ho batalatsa, ho fumanoa lera la ho tjheseletsa la phaephe ea tšepe ho qoba ho ba teng ha mapetso a manyane. Sheba Athikele ea 8 ea P6 ea Tsamaiso ea Taolo le Tsamaiso ea Boleng bakeng sa teko ea ho kobeha | ||

| 116 | Tlhahlobo ea maqeba a ho hohla | Netefatsa hore lebadi la ho hohla le boreleli, le chitja holim'a welding bar | ||

| 117 | Tlhahlobo ea koung ea mahala | Qoba ketsahalo ea khatello ea ho mena ha sehokelo sa ho tjheseletsa e bakoang ke thepa e tala kapa mabaka a mechini. | ||

| 118 | Teko ea letlalo le habeli | Qoba ketsahalo ea tube ea tšepe e nang le letlalo le habeli | ||

| 119 | Selikalikoe se bōpehileng joaloka lehlaka | Ho thibela bokaholimo ba phaephe ea tšepe ho tsoa matheng a litšila | ||

| 120 | Tlhahlobo ea ho tjheseletsa mahlakore | Tlhahlobo ea pono ho qoba ketsahalo ea ho tjheseletsa marago a mangata holim'a bare ea ho tjheseletsa ea tube ea tšepe | ||

| 121 | Tlhahlobo ea maqeba | Tlhahlobo ea pono ho qoba matheba a ho tjheseletsa holim'a phaephe ea tšepe | ||

| 122 | Masoba a lehlabathe, tlhahlobo | Tlhahlobo ea pono ho qoba masoba holim'a phaephe ea tšepe | ||

| 123 | Teko ea ho seha | Fumana 'mele oa phaephe tlas'a thepa ea ho seha khase ho netefatsa hore ha ho na ho seha kapa tšenyo | ||

| 124 | Ha ho na thuso bakeng sa ho bokella di-galvanized tse ngata | Tlhahlobo ea pono ho netefatsa hore ha ho na matheba a oli, pente le lintho tse ling tse sa khoneng ho li bokella, ho thibela ho lutla ha plating | ||

| Phaephe ea tšepe e pickling | Tlosa lintho tse ommeng tse kang sekala sa oxide se hlahisitsoeng holim'a phaephe ea tšepe | 125 | Bongata ba asiti | Sekhahla sa hydrogen chloride ka har'a acid se lokela ho laoloa ho 20%-24%. |

| 126 | Tlhahlobo ea ho phunya phaephe ea tšepe | Ho thibela (1) nako e sa lekaneng ea ho bokella lintho tse tala, mocheso o tlase oa asiti, mahloriso a tlase (mocheso o lokela ho laoloa ho 25-40 ℃, mahloriso a asiti a hydrogen chloride ke 20%-24%) (2) linako tse fokolang tsa ho sisinyeha ha sephutheloana sa tube (3) boteng ba silicate ka har'a tube ea tšepe e bōpehileng joaloka ontong | ||

| sephutheloana sa sehlahisoa | E pakiloe ho latela palo e boletsoeng ea liphaephe tsa tšepe ka sengoathoana | 127 | Tlhahlobo ea lebanta la ho paka | Ho paka ha phala ea tšepe ho na le mahlakore a tšeletseng, mabanta a 6 a ho paka, kaofela a etsoa fekthering ea rona, lipheletsong ka bobeli tsa lebanta la ho paka ho tloha pheletsong ea phoso ea ± 10mm, bohareng ba 4 bo lokela ho aroloa ka ho lekana, ho tjheseletsa lebanta la ho paka ho lokela ho bapaloa, ho bataletse, lebanta la ho paka ha le lumelle ho kheloha, lebanta la ho paka le lokela ho khaoloa moo ho kopanang 45° Angle, le tlameha ho fihlela litlhoko |

| 128 | Tlhahlobo ea letšoao la khoebo | Dikahare di nepahetse, sebopeho se hodimo, letshwao la kgwebo la phaephe le fedileng le lokela ho kgomaretswa hantle hodima phaephe e nngwe le e nngwe ho hokahanya lehlakore le letona la lebanta la pele la ho paka la ho welding bohareng, mme mohlodi wa mongolo wa Ted embellish o hlakile mme ha o a hlaka. |