YuantaiDerunItyhubhu yesikwere esinoxande inamalungelo omenzi angaphezu kwama-63, ahlangabezana nemigangatho yoshishino ekhaya nakwamanye amazwe. Le mveliso idlule kwiikhonkco zokuhlola ezingaphezu kwama-200 ukulawula umgangatho wemveliso.

"Musa ukuvumela umbhobho wentsimbi ongafanelekiyo ungene kwimarike ngokuqinileyo".

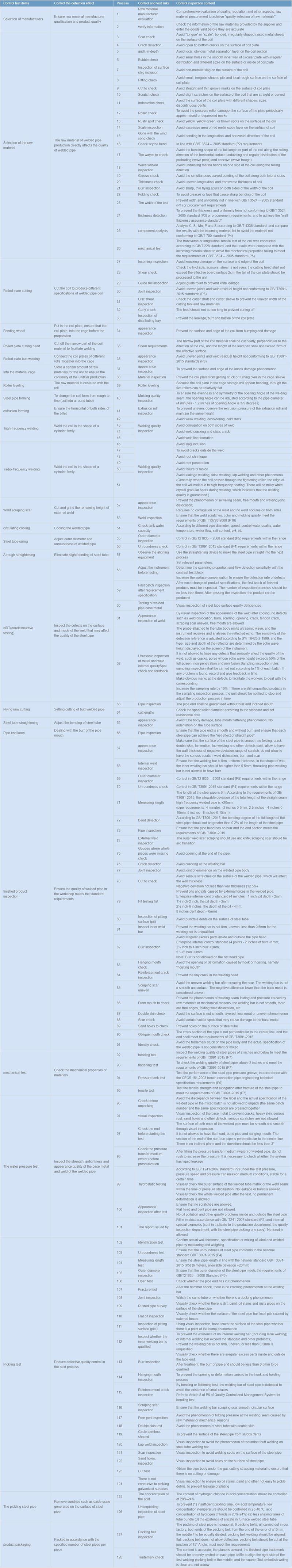

| Izinto zovavanyo lolawulo | Lawula isiphumo sokubhaqwa | Inkqubo | Ulawulo kunye namakhonkco ovavanyo | Umxholo wokuhlola ulawulo |

| Ukukhethwa kwabavelisi | Qinisekisa iziqinisekiso zomenzi wezinto eziluhlaza kunye nomgangatho wemveliso | 1 | Uvavanyo lomenzi wezinto eziluhlaza | Uvavanyo olupheleleyo lomgangatho, udumo kunye nezinye iinkalo, ukuthengwa kwezinto ezikrwada ukuze kufezekiswe "ukukhethwa komgangatho wezinto ezikrwada" |

| 2 | qinisekisa ulwazi | Jonga ulwazi lwezinto ezisetyenzisiweyo ezibonelelwe ngumthengisi uze ungene kwindawo yokubeka iimpahla ngaphambi kokuba zichaneke. | ||

| Ukukhethwa kwezinto eziluhlaza | Izinto ezisetyenziswa ekuveliseni imibhobho edibeneyo zichaphazela ngokuthe ngqo umgangatho wombhobho odibeneyo | 3 | Ukuhlolwa kwamanxeba | Kuphephe "ulwimi" okanye "isikali", amashiti esinyithi adibeneyo, anemilo engaqhelekanga aphakanyisiweyo kumphezulu wekhoyili |

| 4 | Ukufunyanwa kweentanda | Ziphephe iintanda ezivulekileyo ezisezantsi eziphezu komphezulu wepleyiti yekhoyili | ||

| 5 | uphicotho-zincwadi olupheleleyo | Kuphephe ukuba kubekho umaleko wokwahlulwa kwesinyithi ocacileyo kwindawo ethile kwicandelo lekhoyili | ||

| 6 | Ukujonga amaqamza | Ziphephe imingxuma emincinci eludongeni oluthambileyo lwangaphakathi lwepleyiti ejikelezayo enokusasazwa okungacwangciswanga kunye nobukhulu obahlukeneyo kumphezulu okanye ngaphakathi kwepleyiti yekhoyili | ||

| 7 | Ukuhlolwa kokufakwa kwe-slag yomphezulu | Kuphephe ukulahlwa kwenkunkuma okungeyonsimbi kumphezulu wekhoyili | ||

| 8 | Ukujonga ukuphosa | Ziphephe iimbobo ezincinci, ezimile ngendlela engangqalanga kunye nomphezulu orhabaxa okwindawo ethile kumphezulu wepleyiti yekhoyili | ||

| 9 | Sika ukuze ujonge | Ziphephe iimpawu ezithe tye nezincinci zomngxuma kumphezulu wepleyiti yekhoyili | ||

| 10 | Ukujonga ukukrwela | Kuphephe ukukrweleka okuncinci kumphezulu wekhoyili othe tye okanye ogobileyo | ||

| 11 | Ukujonga ukujiya | Kuphephe umphezulu wepleyiti yekhoyili enemilo eyahlukeneyo, ubukhulu, kunye neembobo ezingaguqukiyo | ||

| 12 | Ukujonga i-roller | Ukuze kuthintelwe umonakalo kwi-pressure roller, umphezulu wepleyiti ubonakala rhoqo unamabala aphakanyisiweyo okanye axinzelelweyo. | ||

| 13 | Ukujonga indawo enomhlwa | Ziphephe iindawo ezimthubi, ezimthubi-luhlaza, okanye ezimdaka kumphezulu wekhoyili | ||

| 14 | Ukuhlolwa kwesikali | Kuphephe indawo eninzi yomaleko we-oxide yesinyithi esibomvu kumphezulu wekhoyili | ||

| 15 | Ingoma yokujonga ihashe lomoya | Kuphephe ukugoba kwicala elide nelithe tye lekhoyili | ||

| 16 | Jonga ukugoba kwescythe | Ngokuhambelana neemfuno ze-GB/T 3524 -- 2005 standard (P2) | ||

| 17 | Amaza okujonga | Kuphephe ukugoba kobude obupheleleyo okanye inxalenye yekhoyili kwicala elijikelezayo lomphezulu othe tye ohamba usiya phezulu kunye nokusasazwa rhoqo kwe-protruding (wave peak) kunye ne-concave (wave trough) | ||

| 18 | Ukuhlolwa kwemibimbi yamaza | Kuphephe ukugoba kwe-marina okugobileyo kwelinye icala le-coil kwicala elijikajikayo | ||

| 19 | Ukujonga umjelo | Kuphephe ukugoba kwekhoyili ngaxeshanye kumacala omabini asecaleni | ||

| 20 | Ukujonga ukutyeba | Kuphephe ubukhulu obungalinganiyo be-longitudinal kunye ne-transverse coil | ||

| 21 | Ukuhlolwa kweBurr | Ziphephe ii-spurs ezibukhali nezincinci ezibhabhayo kumacala omabini obubanzi be-coil | ||

| 22 | Ukujonga ukugoba | Ukuthintela ukugoba okanye ukujika okubangela ukugoba okubukhali kwekhoyili | ||

| 23 | Ububanzi bovavanyo | Nqanda ububanzi kunye nokufana okungahambelani nemigangatho ye-GB/T 3524 -- 2005 (P4) okanye iimfuno zokuthenga | ||

| 24 | ukufunyanwa kobukhulu | Ukuthintela ukutyeba kunye nokufana ukuba kungahambelani nomgangatho we-GB/T 3524 -- 2005 (P3) okanye iimfuno zokuthengwa, kunye nokufezekisa "umgangatho wokuqinisekisa ukutyeba kodonga" | ||

| 25 | uhlalutyo lwecandelo | Hlalutya u-C, u-Si, u-Mn, u-P kunye no-S ngokwemigangatho ye-GB/T 4336, kwaye uthelekise iziphumo noluhlu lwezinto ezingenayo ukuze uphephe ukuba izinto zingahambelani nomgangatho we-GB/T 700 (P4) | ||

| 26 | uvavanyo loomatshini | Uvavanyo lokutsalwa kwekhoyili olunqamlezileyo okanye olude lwenziwe ngokwemigangatho ye-GB/T 228, kwaye iziphumo zathelekiswa nephepha lezinto ezingenayo ukuze kuthintelwe ukuba iipropati zoomatshini zingaphumeleli ukuhlangabezana neemfuno zomgangatho we-GB/T 3524 -- 2005 (P5). | ||

| Ukusika ipleyiti eqengqekileyo | Sika ikhoyili ukuze uvelise iinkcukacha ezahlukeneyo zekhoyili yombhobho edibeneyo | 27 | Uhlolo oluzayo | Kuphephe ukwenza umonakalo kumphezulu nasemaphethelweni ekhoyili |

| 28 | Ukujonga ukucheba | Jonga izikere ze-hydraulic, ukuba isikere asilingani, intloko yokusika mayingadluli kumphezulu webhodi osebenzayo nge-2cm, umsila wepleyiti yekhoyili kufuneka ucutshungulwe ube yiyunithi. | ||

| 29 | Ukuhlolwa komqulu wesikhokelo | Lungisa i-roller yesikhokelo ukuthintela ukuvuza kwemela | ||

| 30 | Uhlolo oludibeneyo | Ziphephe iijoyinti ezingalinganiyo kwaye weld ubude obushiyekileyo obungahambelani nemigangatho ye-GB/ T3091-2015 (P8) | ||

| 31 | Ukuhlolwa kokucheba idiski | Jonga umngxuma wokusika kunye nomkhono wokusika ukuze uthintele ububanzi obungalinganiyo besixhobo sokusika kunye nezinto eziluhlaza | ||

| 32 | Ukujonga okugobileyo | Ukutya akufuneki kube kude kakhulu ukuthintela ukugoba | ||

| 33 | Ukuhlolwa kwetreyi yokusasaza | Thintela ukuvuza, i-burr kunye ne-buckle yepleyiti ye-coil | ||

| Ivili lokutyisa | Faka ipleyiti yekhoyili, qinisekisa ukuba ipleyiti yekhoyili, ingene kwikheyiji ngaphambi kokulungiselela | 34 | ukuhlolwa kwenkangeleko | Thintela umphezulu kunye nomphetho wekhoyili ekuqhumeni nasekonakaleni |

| Intloko yokusika ipleyiti eqengqekileyo | Sika inxalenye encinci yezinto zekhoyili ukuze kube lula ukuwelda | 35 | Iimfuneko zokucheba | Inxalenye encinci yezinto zekhoyili mayinqunyulwe kakuhle, ibekwe ngokuthe nkqo kwicala lekhoyili, kwaye ubude benxalenye yelothe abuyi kudlula i-2cm yomphezulu osebenzayo. |

| Ukuwelda ipleyiti eqengqelekayo | Qhagamshela iipleyiti zekhoyili zeeroli ezahlukeneyo kunye kwikheyiji | 36 | ukuhlolwa kwenkangeleko | Ziphephe iijoyinti ezingalinganiyo kwaye weld ubude obushiyekileyo obungahambelani nemigangatho ye-GB/ T3091-2015 (P8) |

| Kwikheji yezinto ezibonakalayo | Gcina ubungakanani obuthile bezinto ezikrwada zeyunithi ukuqinisekisa ukuqhubeka kweyunithi. Imveliso yemoto | 37 | ukuhlolwa kwenkangeleko | Ukuthintela umphezulu kunye nomphetho wento yomonakalo ongqongqozayo |

| 38 | Ukuhlolwa kwezinto | Nqanda ipleyiti yekhoyili ukuba ingabambeki okanye ijike kwisleeve yekheji | ||

| Ukulinganisa i-roller | Izinto ezikrwada ziphakathi nomqulu | 39 | Ukulinganisa i-roller | Ngenxa yokuba ipleyiti yekhoyili kwindawo yokugcina iikheyiji iya kubonakala igobile, ngokusebenzisa iirola ezintlanu inokuba tyaba |

| Ukwenziwa kombhobho wentsimbi | Ukutshintsha imo yekhoyili ukusuka kwi-rough ukuya kwi-fine (ikhoyili ibe yityhubhu engqukuva) | 40 | Ukuhlolwa komgangatho wokubumba | Ukuqinisekisa ukulingana kunye nokulingana kwe-Angle yokuvula yomthungo wokuwelda, i-Angle yokuvula ingalungiswa ngokwe-diameter yombhobho. (Imizuzu emi-4 - 1.2 intshi yokuvula I-engile yi-3-5 degrees) |

| ukwakheka kwe-extrusion | Qinisekisa ukuba amacala omabini e-billet athe tye | 41 | Ukuhlolwa kwe-extrusion roll | Ukuthintela ukungalingani, jonga uxinzelelo lwe-extrusion kwi-extrusion roll kwaye ugcine ukuphakama okufanayo |

| ukuwelda okuphindaphindwayo | Yishicilele ngokuqinileyo ikhoyili ngendlela yesilinda | 42 | Ukuhlolwa komgangatho wokuwelda | Kuphephe ukuwelda okubuthathaka, ukucima i-solder, kunye ne-cold stack |

| 43 | Kuphephe ukubola kumacala omabini e-weld | |||

| 44 | Kuphephe ukuqhekeka kwe-weld kunye nokuqhekeka okungashukumiyo | |||

| 45 | Kuphephe ukwakheka komgca wokuwelda | |||

| ukuwelda kwamaza erediyo | Yishicilele ngokuqinileyo ikhoyili ngendlela yesilinda | 46 | Ukuhlolwa komgangatho wokuwelda | Kuphephe ukufakwa kwenkunkuma |

| 47 | Ukuthintela imingxunya engaphandle kwe-weld | |||

| 48 | Kuphephe ukushwabana kweengcambu | |||

| 49 | Kuphephe ukungena kweengcambu | |||

| 50 | Kuphephe ukungaphumeleli kokuhlanganiswa | |||

| 51 | Kuphephe ukuwelda okuvuzayo, ukuwelda okungekho semthethweni, ukuwelda okujijekileyo nezinye izinto. (Ngokubanzi, xa ikhoyili idlula kwi-tightening roller, umphetho wekhoyili uya kunyibilika ngenxa yokufudumeza rhoqo. Kuya kubakho i-milky white crystal granular spark ngexesha lokuwelda, nto leyo ebonisa ukuba umgangatho wokuwelda uqinisekisiwe.) | |||

| Isilonda sokukhuhla nge-Weld | Sika uze ucole ubude obuseleyo be-weld yangaphandle | 52 | ukuhlolwa kwenkangeleko | Ukuthintela isiganeko somthungo ojikelezayo, umlomo okhululekileyo kunye nokudilika kwamalungu e-welding; Ayifuni corrugation ye weld kwaye ayifuni maqhuqhuva e weld kumacala omabini. |

| 53 | Ukuhlolwa kwe-weld | Qinisekisa ukuba imikrwelo yokuwelda, umbala kunye nomgangatho wokubumba ziyahlangabezana neemfuno ze-GB/ T13793-2008 (P10) | ||

| ukupholisa okujikelezayo | Ukupholisa umbhobho odibeneyo | 54 | Jonga ubungakanani bamanzi etanki | Ngokweepayipu ezahlukeneyo ububanzi, isantya, ulawulo lomgangatho wamanzi, ubushushu bamanzi, ukuhamba kwamanzi, umxholo wetyuwa, i-pH, njl.njl. |

| Ubungakanani betyhubhu yentsimbi | Lungisa ububanzi bangaphandle kunye nokungahambi kakuhle kombhobho odibeneyo | 55 | Ukuhlolwa kobubanzi bangaphandle | Ulawulo kwiimfuno ze-GB/T21835 -- 2008 standard (P5) ngaphakathi koluhlu |

| 56 | Ukujonga ukuba akukho ngqukuva | Ulawulo kwiimfuno ze-GB/ T3091-2015 standard (P4) ngaphakathi koluhlu | ||

| Ukulungiswa okunzima | Susa ukugoba okuncinci kwetyhubhu yentsimbi | 57 | Jonga izixhobo zokulungelelanisa | Sebenzisa isixhobo sokulungisa ukuze wenze umbhobho wentsimbi ungene ngqo kwinkqubo elandelayo |

| NDT (uvavanyo olungonakalisiyo) | Hlola iziphene kumphezulu nangaphakathi kwe-weld ezinokuchaphazela umgangatho wombhobho wentsimbi | 58 | Lungisa isixhobo ngaphambi kokuvavanya | Misela iiparameter ezifanelekileyo; Misela ubungakanani bokuskena kunye novakalelo lokufumanisa iziphene ngebhloko yovavanyo lomahluko; Yandisa imbuyekezo yomphezulu ukuqinisekisa izinga lokubhaqwa kweziphene |

| 59 | Ukuhlolwa kwebhetshi yokuqala emva kweenkcukacha zokutshintshwa | Emva kotshintsho ngalunye lweenkcukacha zemveliso, iqela lokuqala leemveliso ezigqityiweyo kufuneka lihlolwe. Inani lamasebe okuhlola akufuneki libe ngaphantsi kwamathathu. Emva kokuphumelela kuhlolo, imveliso ingaveliswa. | ||

| 60 | Uvavanyo lwesinyithi esisisiseko sepayipi esitshisiweyo | Ukuhlolwa ngokubonakalayo kokungabikho komgangatho womphezulu wetyhubhu yentsimbi | ||

| 61 | Ukuhlolwa kwenkangeleko ye-weld | Ngokujonga ngokubonakalayo imbonakalo ye-weld emva kokuba ipholile, akukho ziphene ezinje ngokuphuma kwe-weld, ukutsha, amanxeba, ukuvuleka, ukuqhekeka, ukuqhekeka kwemisipha, ukukrwela isilonda esingalinganiyo, umlomo okhululekileyo ovumelekileyo. | ||

| 62 | Ukuhlolwa kwe-Ultrasonic komgangatho wangaphakathi wesinyithi kunye ne-weldUkujonga indawo kunye nempendulo | Iprobe eqhotyoshelwe emzimbeni wetyhubhu ikhupha amaza e-ultrasonic, kwaye isixhobo sifumana kwaye sihlalutye i-echo ebonisiweyo. Uvakalelo lwesalathiso sokufumanisa luhlengahlengiswa ngokwe-SY/ T6423.2-1999, kwaye uhlobo, ubungakanani kunye nobunzulu be-reflector bumiselwa bubude be-echo wave obuboniswe kwisikrini sesixhobo. Akuvumelekanga ukuba kubekho naziphi na iziphene ezichaphazela kakhulu umgangatho we-weld, ezinje ngee-cracks, ii-pores ezinokuphakama kwe-echo wave okungaphezulu kwe-50% yesikrini esipheleleyo, ukungangeni kunye nokungahlangani. Imithetho yokuhlola iisampulu: ukuhlolwa kwesampulu kufuneka kwenziwe ngokwe-1% yebhetshi nganye. Ukuba kukho nayiphi na ingxaki efunyenweyo, bhala phantsi kwaye unike ingxelo ngexesha. Yenza amanqaku acacileyo kwiziphene ukuze kube lula kubasebenzi ukujongana neziphene ezifanelekileyo; Nyusa izinga lokuvavanya nge-10%. Ukuba kusekho iimveliso ezingafanelekanga kwinkqubo yokuhlola iisampulu, iyunithi kufuneka yaziswe ukuba iyeke kwaye ilungise inkqubo yemveliso ngexesha elifanelekileyo. | ||

| Ukusika isarha ebhabhayo | Ukuseta ukusika kombhobho odityaniswe ngeempundu | 63 | Ukuhlolwa kwemibhobho | Isiphelo sombhobho siya kuqinisekiswa ngaphandle komlomo ogobileyo kunye nomlomo othe tye |

| 64 | ubude bokusika | Jonga ububanzi be-speed roller ngokwemigangatho kwaye usete idatha efanelekileyo | ||

| Ukulungisa ityhubhu yentsimbi | Lungisa ukugoba kwetyhubhu yentsimbi | 65 | ukuhlolwa kwenkangeleko | Kuphephe umonakalo womzimba wetyhubhu, into yokuthamba komlomo wetyhubhu; Akukho ukubotshwa komphezulu wetyhubhu |

| Ukugcina imibhobho | Ukujongana ne-burr yomlomo wepayipi | 66 | Ukuhlolwa kwemibhobho | Qinisekisa ukuba isiphelo sombhobho sigudile kwaye asinayo i-burr, kwaye uqinisekise ukuba umbhobho ngamnye wentsimbi unokufezekisa "isiphumo esipheleleyo sombhobho othe tye". |

| uhlolo lwemveliso olugqityiweyo | Qinisekisa ukuba umgangatho wombhobho odibeneyo kwindawo yokusebenzela uyahlangabezana neemfuno ezisemgangathweni | 67 | ukuhlolwa kwenkangeleko | Qinisekisa ukuba umphezulu wombhobho wentsimbi ugudile, akukho kusongwa, kuqhekeka, kulusu oluphindwe kabini, kukho i-lamination, kukho i-lap welding kunye nezinye iziphene ezikhoyo, vumela ukuba kubekho ubukhulu bodonga olufana nokuphambuka okungalunganga, ungavumeli ukuba kubekho ukukrwela okukhulu, ukuqhekeka kwe-weld, ukutsha kunye nesilonda. |

| 68 | Ukuhlolwa kwe-weld yangaphakathi | Qinisekisa ukuba ibha yokuwelda iqinile, ubukhulu bayo buyafana, ikwimo yocingo, ibha yokuwelda yangaphakathi kufuneka ibe ngaphezulu kwe-0.5mm, ibha yokuwelda yombhobho wokuhombisa ayivumelekanga ukuba ibe ne-burr | ||

| 69 | Ukuhlolwa kobubanzi bangaphandle | Ulawulo kwiimfuno ze-GB/T21835 -- 2008 standard (P5) ngaphakathi koluhlu | ||

| 70 | Ukujonga ukuba akukho ngqukuva | Ulawulo kwiimfuno ze-GB/ T3091-2015 standard (P4) ngaphakathi koluhlu | ||

| 71 | Ubude bokulinganisa | Ubude bombhobho wentsimbi yi-6m. Ngokweemfuno ze-GB/ T3091-2015, ukuphambuka okuvumelekileyo kobude obupheleleyo bombhobho odibeneyo we-seam othe tye yi-+20mm. (iimfuno zepayipi: imizuzu emi-4 - 2 intshi 0-5mm, 2.5 intshi - 4 intshi 0-10mm, 5 intshi - 8 intshi 0-15mm) | ||

| 72 | Ukufunyanwa kokugoba | Ngokutsho kwe-GB/ T3091-2015, inqanaba lokugoba lobude obupheleleyo bombhobho wentsimbi akufuneki libe ngaphezulu kwe-0.2% yobude bombhobho wentsimbi. | ||

| 73 | Ukuhlolwa kwemibhobho | Qinisekisa ukuba intloko yombhobho ayinayo i-burr kwaye icandelo lokugqibela liyahlangabezana neemfuno ze-GB/ T3091-2015 | ||

| 74 | Ukuhlolwa kwe-weld yangaphandle | Ukukrwela amanxeba angaphandle kwe-weld kufuneka kusetyenziswe imela ye-arc, ukukrwela amanxeba kufuneka kube yinguqu ye-arc | ||

| 75 | IiGouges apho iziqwenga ezipheleleyo zazingekho itshekhi | Kuphephe ukuvula ekupheleni kombhobho | ||

| 76 | Ukufunyanwa kweentanda | Kuphephe ukuqhekeka kwibha yokuwelda | ||

| 77 | Uhlolo oludibeneyo | Kuphephe ukwenzeka kwamalungu emzimbeni wombhobho odibeneyo | ||

| 78 | Sika ukuze ujonge | Kuphephe ukukrweleka okukhulu kumphezulu wombhobho odibeneyo, okuya kuchaphazela ubukhulu bodonga. Ukuphambuka okungalunganga kungabi ngaphantsi kobukhulu bodonga (12.5%) | ||

| 79 | Iflethi yokuvavanya umngxuma | Thintela imingxuma kunye nemingxuma ebangelwa ngamandla angaphandle kumbhobho odibeneyo. Umgangatho wolawulo lwangaphakathi lweshishini (imizuzu emi-4 - i-intshi e-1, ubunzulu bomngxuma <2mm; I-intshi eyi-1¼-intshi ezimbini, ubunzulu bomngxuma <3mm; 2½ intshi-6 intshi, ubunzulu bomngxuma <4mm; Ubunzulu be-8 intshi <6mm) | ||

| 80 | Ukuhlolwa komphezulu wemingxuma (umngxuma) | Kuphephe ukubhoboka kwamaqhuqhuva kumphezulu wetyhubhu yentsimbi | ||

| 81 | Hlola ibha yokuwelda yangaphakathi | Ukuthintela ukuba i-welding bar ayiqinanga, ayilingani, ingaphantsi kwe-0.5mm kuba i-welding bar ayifanelekanga | ||

| 82 | Ukuhlolwa kweBurr | Ziphephe iindawo ezingaqhelekanga ezingaphandle nangaphakathi kwentloko yombhobho. Umgangatho wolawulo lwangaphakathi lweshishini (amanqaku ama-4 - ii-intshi ezi-2 ze-burr <1mm; I-intshi eziyi-2½ ukuya kweziyi-4 i-burr <2mm; I-burr eyi-5 "- 8" <3mm. Qaphela: I-Burr ayivumelekanga kumbhobho wentloko ongenanto. | ||

| 83 | Ukujonga umlomo oxhonyiweyo | Kuphephe ukuvuleka okanye ukuguquka okubangelwa yi-hook okanye i-hoisting, oko kukuthi "umlomo wokuphakamisa" | ||

| 84 | Ukuhlolwa kweentanda zokuqinisa | Thintela ukuqhekeka okuncinci kwi-welding bead | ||

| 85 | Ukukrwela inxeba elingalinganiyo | Kuphephe ukuwelda okungalinganiyo emva kokukrwela isilonda. I-welding bar ayilomphezulu we-arc ogudileyo. Umahluko ongaphantsi kune-base metal uthathwa njengongalinganiyo | ||

| 86 | Ukusuka emlonyeni ukuya ekujongeni | Thintela into yokusonga umthungo kunye noxinzelelo olubangelwa zizinto eziluhlaza okanye izizathu zoomatshini, i-welding bar ayigudileyo, kukho imiphetho ekhululekileyo, ukusongana kwe-weld dislocation, njl. | ||

| 87 | Ukujonga ulusu kabini | Kuphephe ukuba umphezulu awugudileyo, unemigangatho, inyama encinci okanye ukungalingani | ||

| 88 | Ukuhlolwa kwamanxeba | Ziphephe iindawo ezityibilikayo kumphezulu ezinokubangela umonakalo kwisiseko sesinyithi | ||

| 89 | Imingxunya yesanti ekufuneka ijongwe | Thintela imingxunya kumphezulu wetyhubhu yentsimbi | ||

| 90 | Ukujonga umlomo ocacileyo | Icandelo elinqamlezileyo lombhobho alithe nkqo kumgca osembindini, kwaye isiphelo siya kuhlangabezana neemfuno ze-GB/ T3091-2015 | ||

| 91 | Ukuhlolwa kobuwena | Kuphephe uphawu lwentengiso olunamathele emzimbeni wepayipi kwaye iinkcukacha zokwenyani zepayipi edibeneyo azihambelani okanye azixutywanga. | ||

| uvavanyo loomatshini | Jonga iimpawu zoomatshini zezinto ezisetyenzisiweyo | 92 | uvavanyo lokugoba | Hlola umgangatho wokuwelda kwemibhobho yentsimbi ye-intshi ezi-2 nangaphantsi ukuze uhlangabezane neemfuno ze-GB/ T3091-2015 (P7) |

| 93 | uvavanyo lokucaba | Ukujonga umgangatho wokuwelda kweepayipi zentsimbi ezingaphezulu kwe-2 intshi kwaye uhlangabezane neemfuno ze-GB/ T3091-2015 (P7) | ||

| 94 | Uvavanyo lwetanki yoxinzelelo | Vavanya ukusebenza komjelo woxinzelelo lombhobho wentsimbi, ngokuhambelana neemfuno zobugcisa bobunjineli bombhobho woqhagamshelo lomsele we-CECS 151-2003 (P9) | ||

| 95 | uvavanyo lokuxinana | Vavanya amandla okutsalwa kunye nokwandiswa emva kokuqhekeka kombhobho wentsimbi ukuze uhlangabezane neemfuno ze-GB/ T3091-2015 (P7) | ||

| Uvavanyo loxinzelelo lwamanzi | Hlola amandla, ukungangeni komoya kunye nomgangatho wembonakalo yesinyithi esisisiseko kunye ne-weld yombhobho odibeneyo | 96 | Jonga phambi kokuba ukhuphe impahla | Kuphephe ukungangqinelani phakathi kweleyibhile kunye nenkcazo yokwenyani yombhobho odibeneyo okanye ibhetshi exutyiweyo ayivumelekanga ukuyikhupha (inombolo yebhetshi efanayo kunye nenkcazo efanayo zicinezelwe kunye |

| 97 | uhlolo olubonakalayo | Ukuhlolwa ngokubonakalayo kwesiseko sesinyithi ukuthintela ukuqhekeka, ulusu olunzima, umhlwa omkhulu, imingxunya yesanti kunye nezinye iziphene, imikrwelo emikhulu ayivumelekanga | ||

| 97 | Jonga isiphelo ngaphambi kokuba uqale uvavanyo | Umphezulu wazo zombini iziphelo zombhobho odibeneyo kufuneka ube mtyibilizi kwaye uthambe ngokujonga ngamehlo. Akuvumelekanga ukuba nentloko ethe tyaba, umbhobho ogobileyo kunye nomlomo oxhonyiweyo. Icandelo lesiphelo sombhobho ongengombhobho lithe nkqo kumgca ophakathi. Akukho ndawo ithambekileyo kwaye ukuphambuka kufuneka kube ngaphantsi kwe-3° | ||

| 98 | Jonga indawo yokudlulisa uxinzelelo (amanzi) ngaphambi kokuba ucinezeleke | Emva kokugcwalisa i-medium yokudlulisa uxinzelelo (amanzi) yombhobho odibeneyo, musa ukungxama ukunyusa uxinzelelo. Kubalulekile ukujonga ukuba inkqubo ayinayo na i-liquid leak | ||

| 99 | uvavanyo lwe-hydrostatic | Ngokwemigangatho ye-GB/ T241-2007 (P2) phantsi koxinzelelo lovavanyo, isantya soxinzelelo kunye neemeko eziphakathi zokudlulisela uxinzelelo, zizinzile ixesha elithile. Jonga ngokubonakalayo umphezulu wangaphandle we-welded tube matrix okanye umthungo we-weld ngexesha lokuzinziswa koxinzelelo. Akuvumelekanga ukuvuza okanye ukuqhuma. Jonga ngokubonakalayo yonke ipayipi edibeneyo emva kovavanyo, akukho tshintsho oluhlala luhleli oluvumelekileyo | ||

| 100 | Ukuhlolwa kwenkangeleko emva kovavanyo | Qinisekisa ukuba akukho mikrwelo ivumelekileyo; Intloko ethe tyaba kunye nombhobho ogobileyo azivumelekanga. Akukho ngcoliseko yeoyile kunye nezinye iingxaki zomgangatho ngaphakathi nangaphandle kombhobho wentsimbi | ||

| 101 | Ingxelo ekhutshwe ngu | Gcwalisa ngokuhambelana ngokungqongqo nomgangatho we-GB/ T241-2007 (P2) kunye nemizekelo ekhethekileyo yangaphakathi (ithunyelwe kathathu kwisebe lemveliso, isebe lokuhlola umgangatho, kunye nombhobho wentsimbi ococa ikopi enye). Akukho buqhetseba buvumelekileyo. | ||

| Uvavanyo lokukha | Nciphisa ulawulo lomgangatho oluneziphene kwinkqubo elandelayo | 102 | Uvavanyo lokuzazisa | Qinisekisa ubukhulu bodonga, iinkcukacha okanye ukuxuba ilebheli kunye nombhobho odibeneyo ngokulinganisa nokulinganisa |

| 103 | Uvavanyo lokungajikelezi | Qinisekisa ukuba ukungajikelezi kombhobho wentsimbi kuhambelana nomgangatho wesizwe we-GB/T 3091-2015 (P4) | ||

| 104 | Uvavanyo lokulinganisa ubude | Qinisekisa ukuba ubude bombhobho wentsimbi buhambelana nomgangatho wesizwe we-GB/T 3091-2015 (P5) (iimitha ezi-6, ukuphambuka okuvumelekileyo +20mm) | ||

| 105 | Ukuhlolwa kobubanzi bangaphandle | Qinisekisa ukuba ububanzi bangaphandle bombhobho wentsimbi buhlangabezana neemfuno ze-GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Uvavanyo oluvulekileyo | Jonga ukuba isiphelo sombhobho sinesithintelo esinqunyiweyo na | ||

| 107 | Uvavanyo lokuqhekeka | Emva kokubetheka ngesando, akukho nto ingaqhelekanga eyenzekileyo kwibha yokuwelda | ||

| 108 | Uhlolo oludibeneyo | Jonga ityhubhu efanayo ukuze ubone ukuba kukho na into yokubamba idokhi | ||

| 109 | Uphando lwemibhobho egqwalileyo | Jonga ngamehlo ukuba kukho ukungcola, ipeyinti, amabala eoyile kunye nemibhobho enomhlwa kumphezulu wombhobho wentsimbi. | ||

| 110 | Ukuhlolwa komngxuma othe tyaba | Jonga ngamehlo ukuba umphezulu wombhobho wentsimbi unemingxuma yasekuhlaleni ebangelwa yimikhosi yangaphandle | ||

| 111 | Ukuhlolwa komphezulu wemingxuma (imingxuma) | Usebenzisa uhlolo olubonakalayo, chukumisa umphezulu wombhobho wentsimbi ngesandla nokuba kukho indawo apho kukho khona iqhuma | ||

| 112 | Hlola ukuba ingaba i-inner welding bar iyafaneleka na | Ukuthintela ukubakho kwebha yokuwelda yangaphakathi (kuquka ukuwelda okungekho mthethweni) okanye ibha yokuwelda yangaphakathi idlula umgangatho kunye nezinye iingxaki; Ukuthintela ukuba i-welding bar ayiqinanga, ayilingani, okanye ingaphantsi kwe-0.5mm ayifanelekanga | ||

| 113 | Ukuhlolwa kweBurr | Jonga ngamehlo ukuba kukho iindawo ezingahambelaniyo ezigqithisileyo ngaphakathi nangaphandle kwesiphelo setyhubhu. Emva konyango, i-burr yesiphelo sepayipi kufuneka ibe ngaphantsi kwe-0.5mm ukuze ifaneleke. | ||

| 114 | Ukuhlolwa komlomo oxhonyiweyo | Ukuthintela ukuvulwa okanye ukuguqulwa okubangelwa kwinkqubo yokuhombisa kunye nokuphakamisa | ||

| 115 | Ukuhlolwa kweentanda zokuqinisa | Ngovavanyo lokugoba okanye lokusila, ibha yokuwelda yombhobho wentsimbi iyafunyanwa ukuze kuthintelwe ukubakho kwemifantu emincinci. Jonga iNqaku 8 le-P6 leNkqubo yoLawulo loMgangatho kunye noLawulo ukuze ufumane uvavanyo lokugoba | ||

| 116 | Ukuhlolwa kwamanxeba okukrwela | Qinisekisa ukuba umphezulu ojikelezayo ogudileyo nobushelelezi webha yokuwelda | ||

| 117 | Ukuhlolwa kwezibuko simahla | Ziphephe izinto ezibangela uxinzelelo olugoqekayo kumthungo we-welding ngenxa yezinto eziluhlaza okanye izizathu zoomatshini. | ||

| 118 | Uvavanyo lwesikhumba oluphindwe kabini | Kuphephe ukwenzeka kwetyhubhu yentsimbi enolusu oluphindwe kabini | ||

| 119 | Isangqa esimile okwe-bamboo | Ukuthintela umphezulu wombhobho wentsimbi ukuba ungatshixwa yi-slubby dents | ||

| 120 | Ukuhlolwa kwe-Lap weld | Ukuhlolwa ngokubonakalayo ukuze kuthintelwe isiganeko sokuwelda okungafunekiyo kwibha yokuwelda yetyhubhu yentsimbi | ||

| 121 | Ukuhlolwa kwamanxeba | Ukuhlolwa okubonakalayo ukuze kuthintelwe amabala okuwelda kumphezulu wombhobho wentsimbi | ||

| 122 | Imingxuma yesanti, ukuhlolwa | Ukuhlolwa okubonakalayo ukuze kuthintelwe imingxunya kumphezulu wombhobho wentsimbi | ||

| 123 | Uvavanyo lokusika | Fumana umzimba wombhobho phantsi kwezinto zokusikwa kwegesi ukuqinisekisa ukuba akukho kusikwa okanye monakalo | ||

| 124 | Akukho ndlela ifanelekileyo yokuqokelela izinto ezigayiweyo | Ukuhlolwa okubonakalayo ukuqinisekisa ukuba akukho mabala eoyile, ipeyinti kunye nezinye izinto ezingafunekiyo ukucola inkunkuma, ukuthintela ukuvuza kweplati | ||

| Umbhobho wentsimbi yokukha | Susa izinto ezomileyo ezifana nesikali se-oxide esenziwe kumphezulu wombhobho wentsimbi | 125 | Uxinzelelo lwe-asidi | Umxholo we-hydrogen chloride kwi-asidi kufuneka ulawulwe kwi-20%-24% |

| 126 | Ukuhlolwa kwepayipi yentsimbi phantsi kwepikethi | Ukuthintela (1) ixesha elaneleyo lokukha amanzi, ubushushu obuphantsi be-asidi, uxinaniso oluphantsi (ubushushu kufuneka bulawulwe kwi-25-40 ℃, uxinaniso lwe-asidi ye-hydrogen chloride yi-20%-24%) (2) amaxesha okushukuma amancinci e-tube bundle (3) ubukho be-silicate kwi-oven welded steel tube | ||

| ukupakishwa kwemveliso | Ipakishwe ngokuhambelana nenani elichaziweyo leepayipi zentsimbi ngesiqwenga ngasinye | 127 | Ukuhlolwa kwebhanti yokupakisha | Ukupakisha umbhobho wentsimbi kungama-hexagonal, iibhanti zokupakisha ezi-6, zonke zenziwa kumzi-mveliso wethu, zombini iziphelo zebhanti yokupakisha ukusuka esiphelweni sempazamo ye-±10mm, umbindi o-4 uza kwahlulwa ngokulinganayo, ukuwelda kwebhanti yokupakisha kufuneka kuhambelane, kube tyaba, ibhanti yokupakisha ayivumeli ukuphambuka, ibhanti yokupakisha kufuneka inqunyulwe kwindawo yokudibana kwe-45° Angle, kufuneka ihlangabezane neemfuno. |

| 128 | Ukuhlolwa kophawu lwentengiso | Umxholo uchanekile, umgangatho uphezulu, uphawu lwentengiso lombhobho olugqityiweyo kufuneka luncamathiselwe ngokufanelekileyo kwi-baffle nganye yombhobho ukuze lulungelelanise icala lasekunene lebhanti yokuqala yokupakisha ukuwelda embindini, kwaye umthombo wokubhala weTed embellish ucacile kwaye awuguquki. |