ERW welded simbi pombi

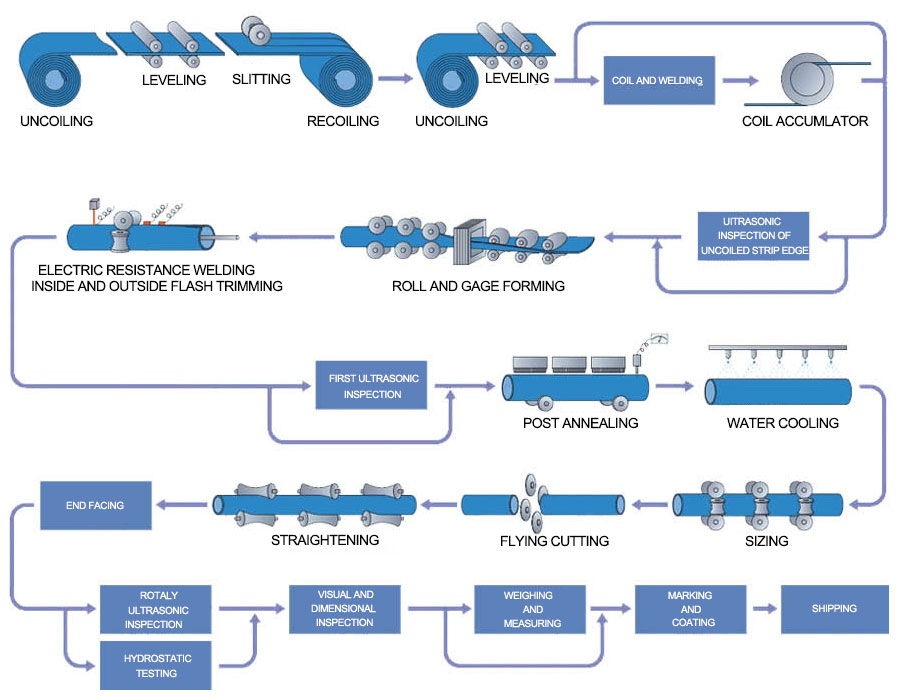

Maitiro ekugadzira mapaipi esimbi eERW anosanganisira HFW. Kubatanidza ERW kunosanganisira kusanganisa low, medium, uye high frequency, nepo HFW yakakodzera zvakanyanya kusanganisa high-frequency resistance.

Pombi yeERW: pombi yakasungirirwa nemishongaDhayamita yekunze (dhayamita yekunze): 10.3mm-609mm, ukobvu: 0.5-20mm kana kuti yakagadzirirwa iwe. Kune mapaipi makuru, welding ye arc inonyudzwa pasi ichashandiswa pakugadzira.

Pombi yeHFW: pombi yakasungirirwa kakawanda

Chii chinonzi HFW steel pipe?

Zvinofanira kucherechedzwa kuti pombi yeHFW rudzi rwePombi yeERW.

Pombi yesimbi yeHigh frequency welded (HFW) inoreva pombi yeERW ine welding current frequency yakaenzana kana kupfuura 70kHZ. Kuburikidza nehigh frequency current welding resistance, kupisa kunokonzerwa nekubata chinhu kunoita kuti pamusoro pechinhu papiswe kuita purasitiki, uye ipapo forging inoitwa kana kusaita kuti simbi isanganiswe. HFW isimba rekupisa rakasimba. Kana high frequency current inopfuura nepakati pesimbi, mhedzisiro mbiri dzakakosha, mhedzisiro yeganda uye mhedzisiro yepedyo, zvichaitika. Maitiro eHFW anoshandisa mhedzisiro yeganda kutarisisa pamusoro pechinhu chesimbi uye mhedzisiro yepedyo kudzora nzvimbo nesimba renzira yekuyerera kwemhepo ine frequency yakakwira. Nekuda kwekumhanya kwakakwira, mipendero yemaplate ekubatana inogona kupiswa nekunyungudutswa pamhenderekedzo, uye yozoburitswa kuburikidza nemaitiro ebutt.

Zvinofanira kucherechedzwa kuti chubhu yeHFW imhando yechubhu yeERW.

Kuwelda kweHigh-frequency (HFW) isimba rekupisa rinopikisa zvakasimba. Kuburikidza nekuwelda kweHigh-frequency current, kupisa kunogadzirwa muchinhu chinobata, kuitira kuti pamusoro pechinhu chacho papiswe kuita purasitiki, uye ipapo pagove kana kuti kwete kuti pave nemusanganiswa wesimbi.

Kushandiswa uye zvakanakira ERW steel pombi

ERW inomiririra resistance welding, iyo ine hunhu hwekushanda zvakanaka kwekugadzira, mutengo wakaderera, kuchengetedza zvinhu, uye otomatiki nyore. Nokudaro, inoshandiswa zvakanyanya muzvikamu zvakasiyana-siyana zvemaindasitiri zvakaita sendege, ndege, simba, zvemagetsi, mota, uye indasitiri yemwenje, uye ndeimwe yenzira dzakakosha dzewelding.

Mabhenefiti echubhu yeHFW

Munguva yekupinza, mapaipi esimbi eHFW haadi kuwedzerwa simbi yekuzadza. Saka, kumhanya kwekupinza kunokurumidza uye kushanda zvakanaka kwekugadzira kwakanyanya. Mapaipi eHFW anoshandiswa zvakanyanya mukufambisa mafuta negesi, mapaipi emafuta, zvivakwa, uye mapaipi akasiyana-siyana emakanika. Zvisinei, mhando yemapaipi esimbi eHFW inokanganiswa nezvinhu zvakasiyana-siyana zvakaita sezvinhu zvakagadzirwa uye maitiro. Uye kudzora kunaka kwekugadzira kwave kwakaoma. Saka goho uye maitiro ekupinza achiri kuda kuvandudzwa nguva dzose.

Musiyano uripo pakati peERW (straight seam resistance welding) neHFW (high-frequency welding) ndiwo musimboti mukuru.

Kusunga simbi, sezvinoreva zita racho, inzira yekusunga nekushandisa kudzvanya kuburikidza nema electrodes mushure mekunge weldment yabatanidzwa, uye uchishandisa kupisa kwekudzivirira kunokonzerwa nemagetsi anopfuura nepanzvimbo yekubatana nenzvimbo dziri pedyo dzejoinhi. Kusunga simbi zvine frequency yakakura: Kana magetsi ane frequency yakawanda achipinda nemuchina wesimbi, panobva pabuda migumisiro miviri yakasiyana: ganda rine mhedzisiro uye kuva pedyo. Kusunga simbi zvine frequency yakakura kunoshandisa mhedzisiro iyi miviri kusanganisa mapaipi esimbi. Migumisiro iyi miviri ndiyo hwaro hwekusanganisa simbi zvine frequency yakawanda.

Kuwedera kwemagetsi kwakakwirira kunoshandisa ganda kuti riwedzere simba remagetsi akakwira pamusoro pechinhu chebasa; uye kunoshandisa mhedzisiro yepedyo kudzora nzvimbo uye huwandu hwenzira yekuyerera kwemagetsi akakwira. Kumhanya kwemagetsi kwacho kunokurumidza zvikuru. Inogona kupisa nekunyungudutsa mipendero yesimbi dziri pedyo munguva pfupi, uye kuita kuti ikwanise kudhonzwa kuburikidza ne extrusion. Imwe neimwe ine zvayakanakira nezvayakaipira. Kazhinji, zvinodikanwa kuongorora nekusarudza zvichienderana nemamiriro ezvinhu chaiwo.

Nguva yekutumira: Ndira-06-2025