Phaephe ea tšepe e welded ea ERW

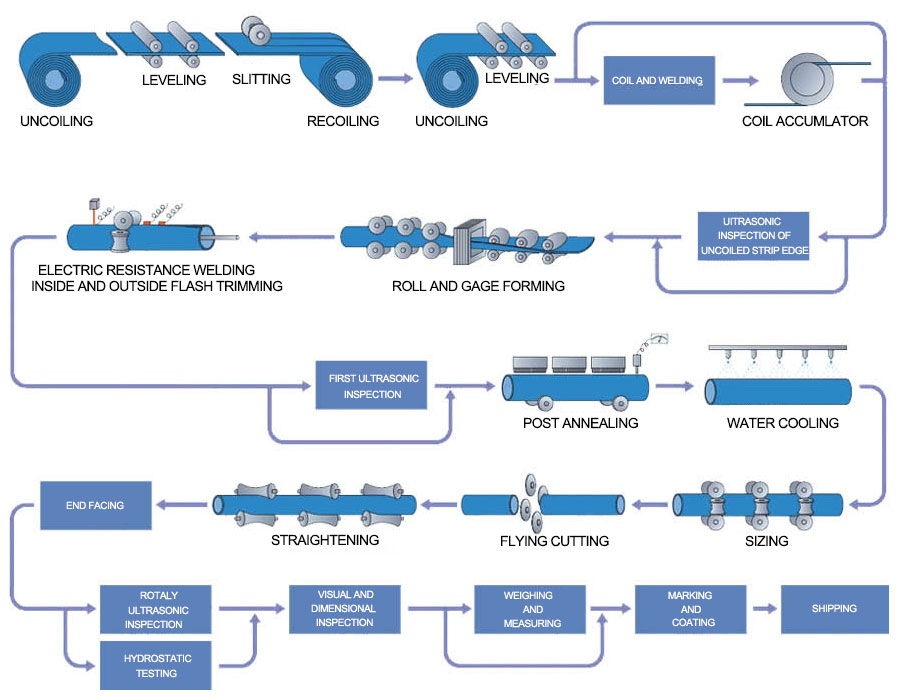

Ts'ebetso ea tlhahiso ea liphaephe tsa tšepe tsa ERW e kenyelletsa HFW. Ho tjheseletsa ha ERW ho kenyelletsa ho tjheseletsa ha maqhubu a tlase, a mahareng le a phahameng, ha HFW e loketse haholo bakeng sa ho tjheseletsa ha maqhubu a phahameng.

Phaephe ea ERW: phaephe e svetselitsoeng ea khanyetsoBophara ba kantle (bophara ba kantle): 10.3mm-609mm, botenya: 0.5-20mm kapa bo etselitsoeng uena. Bakeng sa liphaephe tse kholoanyane, ho tla sebelisoa ho tjheseletsa arc e ka tlas'a metsi bakeng sa tlhahiso.

Phaephe ea HFW: phaephe e tjheseletsoeng ka maqhubu a phahameng

Phaephe ea tšepe ea HFW ke eng?

Ho lokela ho hlokomeloa hore phaephe ea HFW ke mofuta oaPhaephe ea ERW.

Phaephe ea tšepe e nang le maqhubu a phahameng a welded (HFW) e bolela phaephe ea ERW e nang le maqhubu a hona joale a welding a lekanang kapa a fetang 70kHZ. Ka khanyetso ea ho weld ea hona joale ea maqhubu a phahameng, mocheso o hlahisoang ha o kopana le ntho o etsa hore bokaholimo ba ntho bo futhumale ho fihlela boemong ba polasetiki, ebe ho etsoa forging kapa che ho fihlela motsoako oa tšepe. HFW ke matla a mocheso a hanyetsanang a tiileng. Ha maqhubu a holimo a feta ka har'a mokhanni oa tšepe, ho tla etsahala liphello tse peli tse khethehileng, phello ea letlalo le phello ea bohaufi. Ts'ebetso ea HFW e sebelisa phello ea letlalo ho tsepamisa maikutlo holim'a ntho ea tšepe le phello ea bohaufi ho laola boemo le matla a tsela ea phallo ea hona joale ea maqhubu a phahameng. Ka lebaka la lebelo le phahameng, mathōko a lipoleiti tse hokahanyang a ka futhumatsoa le ho qhibilihisoa lebopong, ebe a ntšoa ka ts'ebetso ea butt.

Ho lokela ho hlokomeloa hore tube ea HFW ke mofuta oa tube ea ERW.

Ho tjheseletsa ka maqhubu a phahameng (HFW) ke matla a mocheso a hanyetsanang ka matla a tiileng. Ka ho hanyetsa ho tjheseletsa ka maqhubu a phahameng a hona joale, mocheso o hlahisoa nthong e hokahaneng, e le hore bokaholimo ba ntho bo futhumatsoe ho fihlela boemong ba polasetiki, ebe bo tjheseletsa kapa ha bo tjheseletse ho fihlela motsoako oa tšepe.

Tšebeliso le melemo ea phala ea tšepe ea ERW

ERW e emetse ho tjheseletsa ho hanyetsa, e nang le litšobotsi tsa bokgoni bo phahameng ba tlhahiso, litšenyehelo tse tlase, poloko ea thepa, le boiketsetso bo bonolo. Ka hona, e sebelisoa haholo makaleng a fapaneng a indasteri joalo ka lifofane, lifofane, matla, lisebelisoa tsa elektroniki, likoloi le indasteri ea mabone, 'me ke e' ngoe ea lits'ebetso tsa bohlokoa tsa ho tjheseletsa.

Melemo ea tube ea HFW

Nakong ea ts'ebetso ea ho tjheseletsa, liphaephe tsa tšepe tsa HFW ha li hloke ho eketsoa ha tšepe e tlatsang. Ka hona, lebelo la ho tjheseletsa le potlakile 'me katleho ea tlhahiso e phahame. Liphaephe tsa HFW li sebelisoa haholo ho tsamaiseng oli le khase, liphaepheng tsa liliba tsa oli, meaho ea meaho le liphaepheng tse fapaneng tsa mechini. Leha ho le joalo, boleng ba liphaephe tsa tšepe tsa HFW bo angoa ke lintlha tse fapaneng tse kang thepa e tala le lits'ebetso. 'Me taolo ea boleng ba tlhahiso e se e le thata. Kahoo ts'ebetso ea tlhahiso le ho tjheseletsa e ntse e hloka ho ntlafatsoa khafetsa.

Phapang pakeng tsa ERW (ho welding e otlolohileng ya ho hanyetsa seam) le HFW (ho welding e phahameng) ke yona molao-motheo.

Ho tjheseletsa ka kganyetso, jwalo ka ha lebitso le bolela, ke mokgwa wa ho tjheseletsa ka ho sebedisa kgatello ka di-electrode kamora hore ho kopanngwa ha weldment, le ho sebedisa mocheso o hanyetsanang o hlahiswang ke motlakase o fetang hodima bokahodimo ba kgokelo le dibakeng tse haufi tsa lenonyello. Ho tjheseletsa ka kganyetso e phahameng: Ha motlakase o phallang ka kganyetso e phahameng o feta ka hara mokhanni wa tshepe, ho tla hlahiswa ditlamorao tse pedi tse ikgethang: phello ya letlalo le phello ya bohaufi. Ho tjheseletsa ka kganyetso e phahameng ho sebedisa ditlamorao tsena tse pedi ho tjheseletsa diphaephe tsa tshepe. Ditlamorao tsena tse pedi ke motheo wa ho phethahatsa ho tjheseletsa ka kganyetso e phahameng ya tshepe.

Ho tjheseletsa maqhubu a phahameng ho sebedisa phello ya letlalo ho tsepamisa matla a maqhubu a phahameng hodima karolo ya mosebetsi; mme ho sebedisa phello ya bohaufi ho laola boemo le mefuta ya tsela ya phallo ya maqhubu a phahameng. Lebelo la motlakase le potlakile haholo. E ka futhumatsa le ho qhibilihisa mathoko a dipoleiti tsa tshepe tse haufi ka nako e kgutshwane haholo, mme ya fihlella ho kenngwa ka ho ntsha motlakase. E nngwe le e nngwe e na le melemo le mathata a yona. Ka kakaretso, ho a hlokahala ho sekaseka le ho kgetha ho ya ka boemo bo itseng.

Nako ea poso: Pherekhong-06-2025