Ipayipi elingenamthungo lakhiwa ngokubhoboza induku yensimbi eqinile, ecishe incibilike, ebizwa ngokuthi i-billet, ene-mandrel ukuze kukhiqizwe ipayipi elingenazo izithungo noma amalunga.

Amapayipi angenamthungo akhiqizwa ngokubhoboza i-billet yensimbi eqinile bese uyibumba ibe yipayipi elingenalutho ngaphandle kokushisela. Le nqubo ivame ukuhilela ukushisa i-billet ibe yizinga lokushisa eliphezulu, ukuyibhoboza nge-mandrel ukuze idale isimo esingenalutho, bese uyibumba ngokwengeziwe ngokuyigoqa nokuyelula.

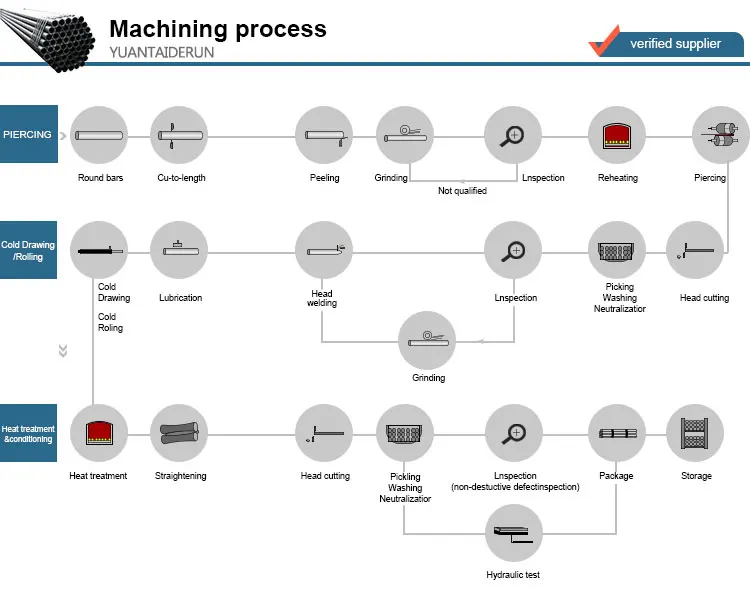

Ipayipi elingenamthungo lakhiwa ngebha eliyindilinga lensimbi eshisayo. Ibha liyashiswa lifike ezingeni lokushisa eliphezulu bese kufakwa i-probe ukuze kudalwe imbobo ngebhalindi. Ibhali libe selidluliselwa kuma-roller alinganisa isilinda nobubanzi obubekiwe kanye nobukhulu bodonga. Izigayo ezimbalwa zingakhiqiza ipayipi elingenamthungo elifinyelela ku-24-intshi ububanzi. Izindlela zokukhiqiza ezingenamthungo zisetshenziselwa ipayipi elincane elinobubanzi kodwa zinezindleko eziphezulu kanye nokutholakala okulinganiselwe, futhi njengoba ububanzi bukhuphuka, amapayipi ahlanganisiwe ayonga kakhulu.

Izakhiwo zezinto ezibonakalayo kanye nenqubo yokukhiqiza amaphuzu ayisihluthulelo amapayipi angenamthungo

Amapayipi angenamthungo ngokuvamile enziwa ngensimbi, kodwa ukusebenza kwawo kungathuthukiswa ngokumboza udonga lwangaphakathi ngepulasitiki. Lesi sakhiwo esihlanganisiwe sigcina amandla aphezulu amapayipi ensimbi futhi sinokumelana nokugqwala kwamapayipi epulasitiki. Kodwa-ke, uma ingubo yepulasitiki yonakele, ingxenye yensimbi eveziwe ingase ibangele izinkinga zokugqwala ngemva kokuthintana noketshezi.

Amaphuzu okulawula abalulekile enkambisweni yokukhiqiza

Ukugcoba nokuvimbela ukuqhekeka: Amapayipi angenamthungo adinga ukumelana nokucindezela okuphezulu kakhulu ngesikhathi senqubo yokwakha, ngakho-ke indawo engaphezulu idinga ukumbozwa ngamafutha okugcoba aphezulu ukuze kuvinjelwe ukuqhekeka. Kodwa-ke, amafutha okugcoba kumele asuswe ngokuphelele ngaphambi kokwelashwa kokushisa okulandelayo, ngaphandle kwalokho isinyibilikisi esisele esibolayo singase sibe khona epayipini isikhathi eside, ngaleyo ndlela sibangele izingozi zokugqwala - lokhu kubaluleke kakhulu kumapayipi angenamthungo anezindonga ezincane.

Ubukhulu bodonga kanye nobuqotho besakhiwo

Izakhiwo zemishini: Amandla okudonsa kanye namandla okukhiqiza kwepayipi kuncike ngqo ekujikeni kodonga. Noma yikuphi ukwehla kobukhulu bodonga okubangelwa ukugqwala kungabangela ukwehluleka kwesakhiwo.

Ukusebenza kokuphathwa kokushisa: Ubukhulu bodonga buthinta nokuzinza kokuqhuba kokushisa kwepayipi. Izinqubo zokukhiqiza ezingafanele zizokwandisa izingozi zokushintshashintsha kwezinga lokushisa noma izimo zokushisa eziphakeme, futhi zize ziholele ezingozini ezinkulu.

Amapayipi angenamthungo

Amapayipi angenamthungo atholakala ensimbini eqinile, okungukuthi, amapuleti noma imigoqo, eyakhiwa ibe yizimo eziqinile eziyindilinga (ezibizwa ngokuthi “ama-billet”), bese zishiswa bese ziphonswa kudayi njengenduku enezimbobo ukuze zakhe ithubhu noma igobolondo elingenalutho. Lolu hlobo lwepayipi lwaziwa ngokumelana kwalo nokucindezela okuphumelelayo, okusheshayo nokusebenza kahle kwezindleko uma kuqhathaniswa nezinye izinqubo zokukhiqiza amapayipi. Amapayipi angenamthungo avame ukusetshenziswa kumapayipi egesi yemvelo kanye nasemapayipini okuthutha uketshezi.

Njengoba amapayipi angenamthungo ekwazi ukumelana nokucindezeleka okuphezulu, asetshenziswa kabanzi nasezisetshenzisweni zokucindezela okuphezulu, okuhlanganisa izindawo zokuhluza, amasilinda e-hydraulic, izimboni ze-hydrocarbon, kanye nengqalasizinda kawoyela negesi.

Uma kuqhathaniswa nezinye izinhlobo zamapayipi, amapayipi angenamthungo awadingi ukushisela noma ukuhlangana futhi akhiwe ngama-billet aqinile ayindilinga, okuthuthukisa amandla awo nezinye izakhiwo, okuhlanganisa nokumelana nokugqwala. Ngokusho kwe-American Society of Mechanical Engineers (ASME), la mapayipi angamelana nokucindezeleka komshini ngempumelelo kakhulu kunamapayipi ahlanganisiwe (okungukuthi, amapayipi angenamthungo) futhi anezingcindezi zokusebenza eziphakeme.

Ngokuvamile, ukusetshenziswa kwamapayipi angenamthungo kuncike ekujiyeni kodonga. Amapayipi odonga amakhulu adinga amazinga okushisa aphezulu ukuze akhiqize, okunciphisa ukumelana nokuguquguquka, okuholela ekuphambukeni okukhulu.

Umncintiswano oyinhloko wepayipi elingenamthungo yipayipi le-ERW (HFI) ngenxa yezindleko zalo zokukhiqiza eziphansi. Izinzuzo eziyinhloko zepayipi elingenamthungo kunepayipi le-ERW yilezi: (a) akukho mthungo wokushisela, (b) ukusatshalaliswa okucishe kufane kwezakhiwo zezinto, kanye (c) ukucindezeleka okusele okuphansi kakhulu. Ngakolunye uhlangothi, ipayipi elingenamthungo libiza kakhulu kunepayipi le-ERW, ukujiya kwalo okuphambene kungase kungabi okufanayo, futhi ubuso balo bangaphakathi nangaphandle buvame ukuba buqinile kakhulu.

Kupayipi elihlanganisiwe, ukushisela kusetshenziselwa ukuvala umthungo wokushisela ngemva kokuba ipuleti lensimbi noma ikhoyili sekwenziwe ngesimo esiyindilinga. Ifektri isebenzisa izindlela zokuhlola ze-ultrasonic kanye/noma ze-x-ray ukuqinisekisa ikhwalithi yomthungo wokushisela, futhi ijoyinti ngalinye lepayipi lihlolwa ingcindezi edlula ingcindezi yokusebenza echaziwe. Ipayipi elihlanganisiwe lihlukaniswa ngokwendlela elakhiwe ngayo kanye nobuchwepheshe bokushisela obusetshenziswayo.

Ipayipi elihlanganisiwe le-arc welded (SAW) elicwiliswe emanzini lisebenzisa insimbi yokugcwalisa ngesikhathi senqubo yokushisela, kuyilapho ukushisela kokumelana kagesi/ukushisela kwe-electric fusion (ERW/EFW) kungadingi insimbi yokugcwalisa. I-SAW ihlukaniswe ngokwengeziwe ngokushisela okude (noma ukushisela okuqondile, i-L-SAW), kanti i-S-SAW ibhekisela kupayipi lokushisela elijikelezayo. Ngokuvamile, i-L-SAW enobubanzi obuphakathi iwumthungo owodwa kanti i-L-SAW enobubanzi obukhulu iwumthungo ophindwe kabili.

Ipayipi le-ERW likhiqizwa ngokusebenzisa ugesi ukuze kushiswe insimbi kuze kufike lapho imiphetho ihlangana khona. Le nqubo yokukhiqiza yaqalwa ngawo-1920, kusetshenziswa ugesi oshintshashintshayo onamaza aphansi ukuze kushiswe imiphetho, kodwa kamuva kwatholakala ukuthi ithambekele ekugqwaleni kokushiswa kanye nokushiswa okunganele. Namuhla, kusetshenziswa ugesi oshintshashintshayo onamaza aphezulu, owaziwa nangokuthi ukushiswa kokuxhumana. Ipayipi le-EFW libhekisela enqubweni esebenzisa imisebe yama-electron ukuqondisa amandla e-kinetic ukuze kuncibilikiswe izinto zokusebenza ukuze kwakheke i-weld.

Isikhathi sokuthunyelwe: Juni-19-2025