A seamless pipe is formed by piercing a solid, near-molten, steel rod, called a billet, with a mandrel to produce a pipe that has no seams or joints.

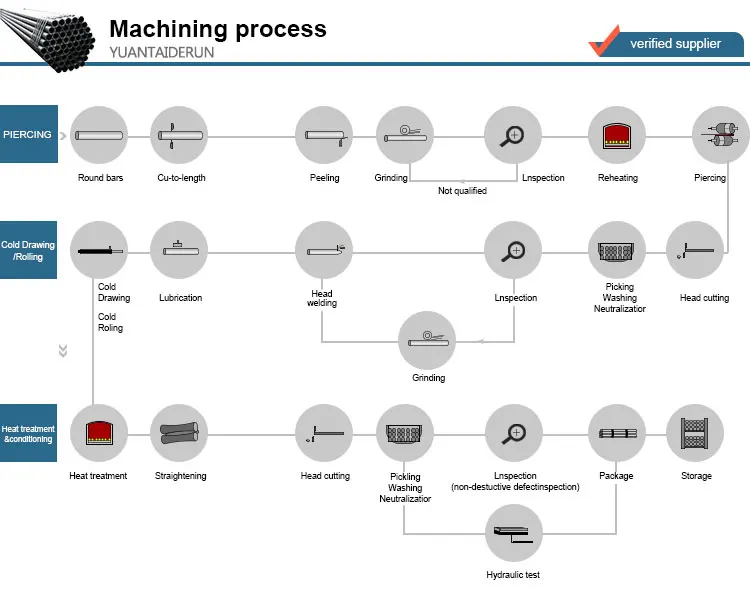

Seamless pipes are manufactured by piercing a solid steel billet and then shaping it into a hollow tube without any welding. This process typically involves heating the billet to a high temperature, piercing it with a mandrel to create a hollow shape, and then further shaping it through rolling and stretching.

Seamless pipe is formed from a cylindrical bar of hot steel . The bar is heated to a high temperature and then a probe is inserted to create a hole through the cylinder . The cylinder is then transferred to rollers which size the cylinder to the specified diameter and wall thickness . A few mills can produce seamless pipe up to 24-in in diameter. Seamless manufacturing methods are used for small diameter pipe but have higher cost and limited availability, and as diameter increases welded pipes are more economical.

Material properties and manufacturing process key points of seamless pipes

Seamless pipes are usually made of metal, but their performance can be improved by coating the inner wall with a plastic coating. This composite structure retains the high strength advantage of metal pipes and has the corrosion resistance of plastic pipes. However, if the plastic coating is damaged, the exposed metal part may still cause corrosion problems after contact with the fluid.

Key control points in the manufacturing process

Lubrication and crack prevention: Seamless pipes need to withstand extremely high pressure during the forming process, so the surface needs to be coated with high-pressure lubricants to prevent cracking. However, the lubricant must be completely removed before subsequent heat treatment, otherwise the residual corrosive solvent may exist in the pipe for a long time, thereby inducing corrosion risks - this is particularly significant for thin-walled seamless pipes.

Wall thickness and structural integrity

Mechanical properties: The tensile strength and yield strength of the pipe are directly dependent on the wall thickness. Any wall thickness reduction caused by corrosion may cause structural failure.

Thermal management performance: Wall thickness also affects the thermal conductivity stability of the pipe. Improper manufacturing processes will increase the risks of temperature fluctuations or high temperature conditions, and even lead to serious accidents.

Seamless pipes

Seamless pipes are derived from solid steel, i.e., plates or bars, which are formed into solid round shapes (called “billets”), which are then heated and cast onto a die such as a perforated rod to form a hollow tube or shell. This type of pipe is known for its more efficient pressure resistance, fast and cost-effectiveness compared to other pipe manufacturing processes. Seamless pipes are commonly used in natural gas pipelines as well as liquid transportation pipelines.

Since seamless pipes can withstand high pressures, they are also widely used in high-pressure applications, including refineries, hydraulic cylinders, hydrocarbon industries, and oil and gas infrastructure.

Compared to other types of pipes, seamless pipes do not require any welding or joints and are simply formed from solid round billets, which enhances their strength and other properties, including corrosion resistance. According to the American Society of Mechanical Engineers (ASME), these pipes can withstand mechanical stress more effectively than welded pipes (i.e., non-seamless pipes) and have higher working pressures.

Generally speaking, the application of seamless pipes depends on the wall thickness. Thicker wall pipes require higher temperatures to produce, which reduces deformation resistance, resulting in greater deflection.

The main competitor of seamless pipe is ERW (HFI) pipe because of its lower manufacturing cost. The main advantages of seamless pipe over ERW pipe are: (a) no weld seam, (b) nearly uniform distribution of material properties, and (c) very low residual stress. On the other hand, seamless pipe is more expensive than ERW pipe, their cross-sectional thickness may not be uniform, and their inner and outer surfaces are usually very rough.

In welded pipe, welding is used to close the weld seam after the steel plate or coil is formed into a cylindrical shape. The factory uses ultrasonic and/or radiographic inspection methods to ensure the quality of the weld seam, and each joint of the pipe is pressure tested to a pressure exceeding the specified working pressure. Welded pipe is classified according to how it is formed and the welding technology used.

Submerged arc welded (SAW) pipe uses a filler metal during the welding process, while electric resistance welding/electric fusion welding (ERW/EFW) does not require a filler metal. SAW is further divided into longitudinal welding (or straight welding, L-SAW), and S-SAW refers to spiral welding pipe. Typically, medium diameter straight-welded L-SAW is single-seam and large diameter L-SAW is double-seam.

ERW pipe is produced by using an electric current to heat the steel to the point where the edges fuse. This production process was introduced in the 1920s, using low-frequency alternating current to heat the edges, but was later found to be prone to weld corrosion and inadequate welds. Today, high-frequency alternating current is used, also known as contact welding. EFW pipe refers to a process that uses electron beams to guide kinetic energy to melt the workpieces to form the weld.

Post time: Jun-19-2025