Ndedzipi nzira dzekurapa kupisa kwesimbi yesimbi yakatwasuka?

Chekutanga, dhizaini yemamold ehunyanzvi inofanira kunge yakaringana, ukobvu hwayo haufanirwe kusiyana zvakanyanya, uye chimiro chayo chinofanira kunge chakaenzana. Kune mamold ane deformation yakakura, mitemo ye deformation inofanira kubatwa, uye muripo we machining unofanira kuchengetwa. Kune mamold makuru, akapfava uye asina kurongeka, marongerwo akabatanidzwa anogona kusarudzwa. Kune mamwe mamold akapfava uye asina kurongeka, pre heat treatment, older heat treatment uye quenching and tempering nitriding heat treatment inogona kusarudzwa kudzora kururama kwemamold. Pakugadzirisa zvikanganiso zvakaita sejecha gomba, mhepo gomba uye kupera kwemold, michina yekugadzirisa ine thermal impact diki senge cold welding muchina inofanira kusarudzwa kudzivirira deformation panguva yekugadzirisa.

Zviumbwa zvakapfava uye zvisina kurongeka zvinofanira kugadziriswa kuti zvisanyanya kushata panguva yekugadzirwa. Kune zviumbwa zvakapfava uye zvisina kurongeka, kudzima kupisa kwevacuum uye kutonhora kwakadzika mushure mekudzima zvinofanira kusarudzwa zvakanyanya kana mamiriro ezvinhu achibvumira. Pachinangwa chekuona kuoma kwechiumbwa, kutonhora kusati kwatotanga, kudzima kutonhora kwakatarwa kana kudzima kudziya kunofanira kusarudzwa zvakanyanya sezvinobvira.

Sarudza zvinhu zvine musoro. Kune madhiri akapfava uye asina kurongeka, simbi inochinja-chinja ine zvinhu zvakanaka inofanira kusarudzwa. Simbi inoparadzanisa makabhohaidhiretsi zvakanyanya inofanira kuumbwa zvakanaka uye kupiswa nekugadziriswa. Kune simbi huru neisina kurongeka, mushonga wakasimba wekugadzirisa kaviri unogona kuitwa. Sarudza tembiricha yekupisa uye dzora kumhanya kwekupisa. Kune madhiri akapfava uye asina kurongeka, kupisa kunononoka, kupisa kwekutanga uye dzimwe nzira dzekupisa dzakaringana dzinogona kushandiswa kuderedza kuchinja kwekupisa kwemold.

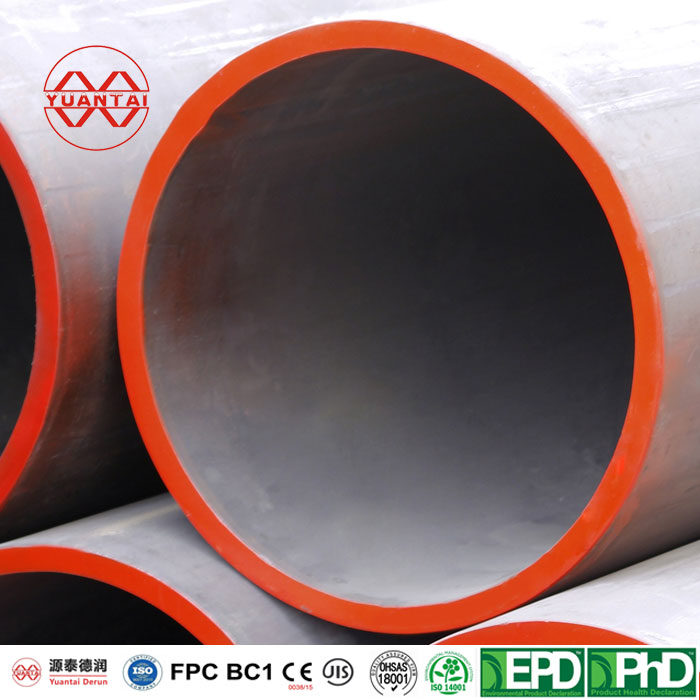

JCOE inyanzvi yekugadzira mapaipi ekugadzira mapaipi esimbi ane dhayamita hombe. Inonyanya kushandisa nzira yekugadzira arc welding ine mativi maviri. Zvigadzirwa zvinopinda mumatanho akasiyana-siyana akadai sekugaya, kukotama, kukotama, kuvhara seam, kukotama kwemukati, kukotama kwekunze, kutwasanudza, uye kupera kwakatwasuka. Maitiro ekugadzira anogona kukamurwa kuita matanho eN+1 (N inhamba yakanaka). Plate yesimbi inopihwa otomatiki mativi uye yakakotama zvichienderana nehukuru hwematanho akagadzwa kuti iite kuti JCO iite nhamba. Plate yesimbi inopinda mumuchina wekugadzira yakatambarara, uye pasi pekusundirwa kwetrolley yekudya, danho rekutanga rekukotama kwematanho akawanda neN/2 rinoitwa kuti "J" iite hafu yepamberi yeplate yesimbi iite; Mudanho rechipiri, chekutanga, plate yesimbi inoumbwa ne "J" inofanira kutumirwa kunzvimbo yakatarwa munzira inochinjika nekukurumidza, uye ipapo plate yesimbi isina kuumbwa inofanira kukotama mumatanho akawanda eN/2 kubva kune rimwe divi kuti iite hafu yechipiri yeplate yesimbi uye ipedzise kuumbwa kwe "C"; Pakupedzisira, chikamu chezasi chechubhu yerudzi rwe "C" chinokotamiswa kamwe chete kuti "O" iite. Nheyo huru yedanho rega rega rekutsika ndeyekukotamisa mativi matatu.

Nguva yekutumira: Gunyana-30-2022