Yiziphi izindlela zokwelapha ukushisaipayipi lensimbi yomthungo oqondile?

Okokuqala, ukwakheka kwesakhiwo sezikhunta zobuchwepheshe kufanele kube okunengqondo, ukujiya akufanele kuhluke kakhulu, futhi ukuma kufanele kube okulinganayo. Kuzikhunta ezinokuguquguquka okukhulu, imithetho yokuguquguquka kufanele iqondwe, futhi isabelo somshini kufanele sigcinwe. Kuzikhunta ezinkulu, ezincane nezingasebenzi kahle, ukwakheka okuhlanganisiwe kungakhethwa. Kuzikhunta ezithile ezincane nezingasebenzi kahle, ukwelashwa kokushisa kwangaphambi kokushisa, ukwelashwa kokushisa okuguga kanye nokwelashwa kokushisa kwe-nitriding nokucima nokushisa kungakhethwa ukulawula ukunemba kwezikhunta. Lapho kulungiswa amaphutha afana nomgodi wesihlabathi, umgodi womoya kanye nokuguguleka kwesikhunta, imishini yokulungisa enethonya elincane lokushisa njengomshini wokushisela obandayo kufanele ikhethwe ukuze kugwenywe ukuguquguquka ngesikhathi sokulungisa.

Izikhunta ezincane nezingasebenzi kahle kufanele ziphathwe ngaphambi kokushisa ukuze kuqedwe ukucindezeleka okusele ngesikhathi somshini. Kuzikhunta ezincane nezingasebenzi kahle, ukucima ukushisa nge-vacuum kanye nokwelashwa kokupholisa okujulile ngemva kokucima kufanele kukhethwe ngangokunokwenzeka uma izimo zivuma. Ngesisekelo sokuqinisekisa ubulukhuni besikhunta, inqubo yokupholisa ngaphambi kokupholisa, ukucima ukupholisa okuhleliwe noma inqubo yokucima okufudumele kufanele ikhethwe ngangokunokwenzeka.

Khetha izinto zokwakha ngokufanele. Kuma-dies amahle nalawo angahlelekile, insimbi ye-die eguquguqukayo encane enezinto ezinhle zokusetshenziswa kufanele ikhethwe. Insimbi ye-die enokuhlukaniswa kwe-carbide enzima kufanele iphonswe kahle futhi iphathwe ngokushisa okucinyiwe nokushiswa. Kuma-die steel amakhulu nalawo angahlanganisiwe, ukwelashwa kokushisa okuphindwe kabili kwesixazululo esiqinile kungenziwa. Khetha izinga lokushisa lokushisa ngokufanele futhi ulawule ijubane lokushisa. Kuma-mold amahle nalawo angahlelekile, ukufudumala okuhamba kancane, ukufudumala kusengaphambili kanye nezinye izindlela zokushisa ezilinganiselayo zingasetshenziswa ukunciphisa ukuguquguquka kokwelashwa kokushisa kwesikhunta.

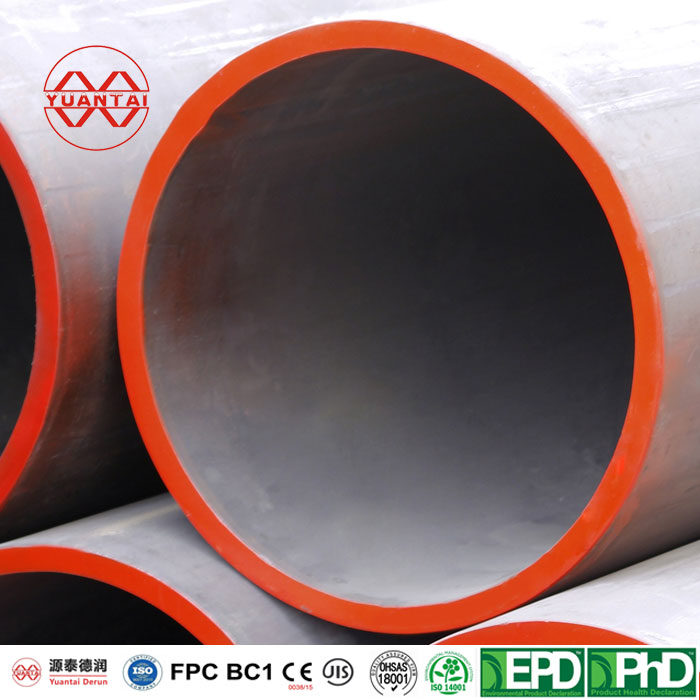

I-JCOE ubuchwepheshe bokwenza amapayipi bokukhiqiza amapayipi ensimbi odongeni amakhulu anobubanzi obukhulu. Isebenzisa kakhulu inqubo yokukhiqiza i-arc welding engaphansi kwezinhlangothi ezimbili. Imikhiqizo idlula ezinqubweni eziningi ezifana nokugaya, ukugoba ngaphambi, ukugoba, ukuvala umthungo, ukugoba kwangaphakathi, ukugoba kwangaphandle, ukuqondisa, kanye ne-flat end. Inqubo yokwakha ingahlukaniswa ngezinyathelo ze-N+1 (i-N iyinombolo ephelele). Ipuleti lensimbi liphakelwa ngokuzenzakalelayo eceleni futhi ligobe ngokwesayizi wesinyathelo esibekiwe ukuze kufezwe ukwakheka kwe-JCO yokulawula kwezinombolo okuqhubekayo. Ipuleti lensimbi lingena emshinini wokwakha ngokuvundlile, futhi ngaphansi kokucindezelwa kwetroli yokudla, isigaba sokuqala sokugoba ngezinyathelo eziningi ngezinyathelo ze-N/2 senziwa ukuze kufezwe ukwakheka kwengxenye engaphambili yepuleti lensimbi; Esigabeni sesibili, okokuqala, ipuleti lensimbi elenziwe yi-"J" kufanele lithunyelwe endaweni ecacisiwe ohlangothini oluphambene ngokushesha, bese ipuleti lensimbi elingakakhiwa kufanele ligobe ngezinyathelo eziningi ze-N/2 ukusuka kolunye uhlangothi ukuze kufezwe ukwakheka kwengxenye yesibili yepuleti lensimbi futhi kuqedwe ukwakheka kwe-"C"; Ekugcineni, ingxenye engezansi yepayipi lohlobo lwe-"C" igoba kanye ukuze kufezwe ukwakheka kwe-"O". Isimiso esiyisisekelo sesinyathelo ngasinye sokunyathela ukugoba okunamaphuzu amathathu.

Isikhathi sokuthunyelwe: Septhemba-30-2022